Inst

Be

n

Wi

t

Natu

Mod

u

Mod

e

Other

d

OMM

OMM

OMM

TAG-

TAG-

TAG-

TAG-

Applie

s

G-19

-

N-19

-

OMM-13

6

allation

n

ch

m

t

h Ed

ral Gas,

u

lating

&

e

ls 750

t

d

ocuments f

o

-0137, GF-2

1

-0138, GF-2

1

-0139, GF-2

1

0019, GF-20

7

0022, GF-20

5

0047, GF-20

3

0048, GF-20

6

s

to serial n

u

-

0300 and ab

-

0100 and ab

o

6

_D • GF-210

and St

m

ark

®

ge C

o

Propan

e

&

Conde

n

t

hrough

6

o

r this prod

u

1

1 Operation

-

1

2 Reference

1

3 Edge Con

t

7

0 Boiler Ap

p

5

0 Vent-Co

m

3

0 Benchma

r

6

0 Benchma

r

u

mbers:

ove – BMK 7

o

ve – BMK 5

0

• 7/16/2019

artup

M

Plati

n

o

ntro

l

e

Gas a

n

n

sing B

o

6

000

u

ct include:

-

Service Man

Manual

t

roller Manua

p

lication Guid

e

bustion Air

G

r

k Gas Guide

r

k Power Gui

d

50 – 3000

0

00 & 6000

M

anual

n

um

B

l

ler

n

d Dual

o

ilers

ual

l

e

G

uide

d

e

B

oile

r

Fuel

r

s

Bench

m

CONTE

N

OMM-13

6

Tabl

e

FORE

W

SECTIO

N

1.1 WA

R

1.2 EME

1.3 PRO

1.4 IMP

O

SECTIO

N

2.1 INT

R

2.2 REC

2.3 UNP

A

2.4 SITE

2.4.1I

n

2.4.2S

e

2.5 LIFT

I

2.5.1B

M

2.5.2B

M

2.5.3B

M

2.6 SUP

P

2.6.1B

M

2.6.2B

M

2.6.3B

M

2.6.4D

2.7 PRE

S

2.8 CON

2.9 GAS

2.9.1G

a

2.9.2E

x

2.9.3

M

2.10 AC

2.10.1

E

2.10.2

P

2.10.3

E

2.11 FIE

2.11.1I

2.12 FL

U

2.12.1

M

2.13 CO

M

2.13.1

D

2.14 BS

T

SECTIO

N

3.1 INT

R

3.1.1C

o

3.1.2C

o

m

ark Plat

i

N

TS

6_

D • GF-210

e

ofC

o

W

ORD.....

N

1:

SA

F

R

NINGS &

C

RGENCY S

LONGED S

O

RTANT –

F

N

2:

INS

T

R

ODUCTIO

N

EIVING TH

E

A

CKING .....

PREPARA

T

n

stallationCl

e

e

ttingtheUn

i

I

NG PROVI

S

M

K750–10

0

M

K1500–3

0

M

K5000‐60

0

P

LY AND R

M

K750–10

0

M

K1500–3

0

M

K5000–6

0

u

alInletRet

u

S

SURE RE

L

DENSATE

D

SUPPLY P

I

a

sSupplySp

e

x

ternalGasS

u

M

anualGasS

h

ELECTRIC

A

E

lectricalPo

w

P

owerPanel

E

lectricalPo

w

LD CONTR

O

/OBoardCo

n

U

E GAS VE

N

M

ASSACHUS

E

M

BUSTION

D

UCTEDCO

M

T

SEQUEN

C

N

3:

ON

A

R

ODUCTIO

N

o

nnectingth

e

o

nfirmingth

e

i

num wit

h

• 7/16/2019

o

ntent

s

...............

.

F

ETYPREC

A

C

AUTIONS ..

HUTDOWN

HUTDOWN

F

OR MASS

A

T

ALLATIO

N

N

.................

E

UNIT ........

...................

T

ION ..........

e

arances.......

i

t..................

S

IONS ........

0

0LiftingPro

v

0

00LiftingPr

o

0

0LiftingPro

v

ETURN PI

P

0

0Supplyan

d

0

00Supplya

n

0

00Supplya

n

u

rnPiping.....

L

IEF VALV

E

D

RAIN

A

N

D

I

PING .........

e

cifications...

u

pplyRegula

t

h

utoffValve..

A

L POWER

w

erRequire

m

L

ocations.....

w

erPanelInt

e

O

L WIRING

n

nections.....

N

T INSTAL

L

E

TTSINSTALL

AIR ............

M

BUSTIONAI

R

C

ING ISOL

A

A

ERSETU

P

N

.................

e

EthernetC

a

e

EthernetCo

h

Edge C

o

Technical S

u

s

.

...............

A

UTIONS.

..................

.

..................

.

..................

.

A

CHUSETT

S

N

.............

..................

.

..................

.

..................

.

..................

.

....................

.

....................

.

..................

.

v

isions.........

.

o

visions.......

.

v

isions..........

.

P

ING ...........

.

d

ReturnPipi

n

n

dReturnPip

n

dReturnPip

....................

.

E

INSTALLA

D

PIPING ....

.

..................

.

....................

.

t

or...............

.

....................

.

WIRING ....

.

m

ents............

.

....................

.

e

rnalCompo

n

– I/O BOA

R

....................

.

L

ATION ......

.

ATIONS.......

.

..................

.

R

..................

.

A

TION VAL

V

P

..............

..................

.

a

ble..............

.

nnection.....

.

o

ntroller: I

u

pport • (800) 5

...............

.

...............

.

.

..................

.

..................

.

..................

S

INSTALL

A

...............

.

.

..................

.

..................

.

..................

.

..................

.

....................

.

.

....................

.

.

..................

.

....................

.

.

....................

.

.

....................

.

.

..................

n

g.................

.

ing...............

.

ing...............

.

.

....................

.

TION .........

.

..................

.

..................

.

....................

.

.

....................

.

.

....................

.

.

..................

.

....................

.

.

....................

.

n

ents............

.

R

D ..............

.

....................

.

.

..................

.

....................

.

.

..................

.

....................

.

V

E INST

A

LL

A

...............

.

.

..................

.

....................

.

.

....................

.

nstallatio

5

26-0288 • Mon

-

...............

.

...............

.

...................

...................

...................

A

TIONS ......

...............

.

...................

...................

...................

...................

.....................

.....................

...................

.....................

.....................

.....................

...................

.....................

.....................

.....................

.....................

...................

...................

...................

.....................

.....................

.....................

...................

.....................

.....................

.....................

...................

.....................

...................

.....................

...................

.....................

A

TION........

...............

.

...................

.....................

.....................

o

n Manual

-

Fri, 8 am - 5 pm

.

...............

.

...............

..................

.

..................

.

..................

.

..................

.

.

...............

..................

.

..................

.

..................

.

..................

.

....................

.

....................

.

..................

.

....................

.

....................

.

....................

.

..................

.

....................

.

....................

.

....................

.

....................

.

..................

.

..................

.

..................

.

....................

.

....................

.

....................

.

..................

.

....................

.

....................

.

....................

.

..................

.

....................

.

..................

.

....................

.

..................

.

....................

.

..................

.

.

...............

..................

.

....................

.

....................

.

EST Page

2

...............

...............

.

..................

.

..................

.

..................

.

..................

...............

.

..................

.

..................

.

..................

.

..................

.

....................

.

.

....................

.

.

..................

.

....................

.

.

....................

.

.

....................

.

.

..................

.

....................

.

.

....................

.

.

....................

.

.

....................

.

.

..................

.

..................

.

..................

.

....................

.

.

....................

.

.

....................

.

.

..................

.

....................

.

.

....................

.

.

....................

.

.

..................

.

....................

.

.

..................

.

....................

.

.

..................

.

....................

.

.

..................

...............

.

..................

.

....................

.

.

....................

.

2

of 54

.....5

.....9

...... 9

.... 10

.... 10

.... 11

...13

.... 13

.... 13

.... 13

.... 14

.....14

.....17

.... 19

.....19

.....20

.....20

.... 21

.....21

.....22

.....23

.....23

.... 24

.... 25

.... 27

.....27

.....27

.....30

.... 30

.....30

.....30

.....32

.... 33

.....34

.... 38

.....38

.... 39

.....39

.... 40

...43

.... 43

.....43

.....44

Bench

m

CONTE

N

OMM-13

6

3.1.3C

o

APPEN

D

m

ark Plat

i

N

TS

6_

D • GF-210

o

nfirmEther

n

D

IXA:

DI

M

i

num wit

h

• 7/16/2019

n

etDHCPCo

n

M

ENSION

A

h

Edge C

o

Technical S

u

n

figuration...

.

A

LANDCL

E

o

ntroller: I

u

pport • (800) 5

.

....................

.

E

ARANCE

D

nstallatio

5

26-0288 • Mon

-

.....................

D

RAWING

o

n Manual

-

Fri, 8 am - 5 pm

....................

.

S.............

EST Page

3

.

....................

.

...............

3

of 54

.....45

...47

Bench

m

CONTE

N

OMM-13

6

m

ark Plat

i

N

TS

6_

D • GF-210

i

num wit

h

• 7/16/2019

h

Edge C

o

Technical S

u

(This page

o

ntroller: I

u

pport • (800) 5

intentionall

y

nstallatio

5

26-0288 • Mon

-

y

blank)

o

n Manual

-

Fri, 8 am - 5 pm

EST Page

4

4

of 54

Bench

m

FORWA

R

OMM-13

6

FOR

The AE

R

modulati

of today

'

hydronic

fluctuati

n

are ideal

IMPO

R

Unless

o

Platinum

The Be

n

measur

e

Benc

h

MODE

L

BMK75

0

BMK10

0

BMK15

0

BMK20

0

BMK25

0

BMK30

0

BMK50

0

BMK60

0

The out

p

tempera

t

When in

s

and 500

0

Manage

m

the Bay

A

Whether

flexibility

positive

p

the follo

w

R

o

D

u

These b

o

addition,

(excludi

n

m

ark Plat

i

R

D

6_

D • GF-210

EWO

R

R

CO Bench

m

n

g and con

d

'

s energy a

system, t

h

n

g system l

o

ly suited for

R

TANT!

o

therwise s

p

Series of b

o

n

chmark

m

ments appl

y

markPlat

L

I

MIN

0

50,000(

1

0

0 50,000(

1

0

0 75,000(

2

0

0 100,000

0

0 167,000

0

0 200,000

0

0 400,000

0

0 400,000

p

ut of the b

o

t

ure.

s

talled and

0

& 6000 co

m

m

ent Distri

c

A

rea Air Q

u

used in sin

g

with minim

p

ressure ap

w

ing vent co

o

om Comb

u

o Vertic

a

o Horiz

o

u

cted Com

b

o Vertic

a

o Horiz

o

o

ilers are ca

the BMK

7

n

g the state

o

i

num wit

h

• 7/16/2019

R

D

m

ark (BMK

)

d

ensing unit

s

nd environ

m

h

e Bench

m

o

ads. Thes

e

modern lo

w

p

ecified all

d

o

iler.

m

odels ope

r

y

to both na

t

inumBoil

e

I

NPUTRAN

G

IMUM

1

4.6kW)

1

4.6kW)

2

2kW)

(29.3kW)

(48.9kW)

(58.6kW)

(117kW)

(117kW)

o

iler is a fu

n

operated in

m

ply with th

c

t (SCAQM

u

ality Mana

g

g

ular or mo

d

um installat

pliances. Si

nfigurations

u

stion Air:

a

l Discharg

e

o

ntal Discha

r

b

ustion Air:

a

l Discharg

e

o

ntal Discha

r

pable of bei

7

50 & 1000

o

f Massach

u

h

Edge C

o

Technical S

u

)

750 throu

g

s

. They rep

r

m

ental con

c

m

ark's mod

u

e

BMK mod

e

w

temperatu

r

d

escriptions

r

ate within

t

ural gas an

d

e

rIntake

a

G

E(BTU/HR

MAXI

M

750,000(22

0

1,000,000(2

9

1,500,000(4

4

2,000,000(5

8

2,500,000(7

3

3,000,000(8

7

5,000,000(1

4

6,000,000(1

7

n

ction of th

e

accordanc

e

e NO

x

emis

s

D), Rule 11

g

ement Di

s

d

ular arrang

i

on space r

e

ngle and/or

:

e

r

ge

e

r

ge

ng vented u

models ar

e

u

setts) .

o

ntroller: I

u

pport • (800) 5

g

h 6000 nat

u

r

esent a tru

e

c

erns. Desi

g

u

lating cap

a

e

ls provide

r

e, as well a

s

provided in

the input

d

propane

m

a

ndOutpu

.)

M

UM

0

kW)

4

9

3kW)

4

4

0kW)

6

8

6kW)

8

3

2kW)

1

7

9kW)

1

4

65kW)

3

7

58kW)

3

e

unit’s firin

e

with this I

n

s

ion standa

r

46.2. In ad

d

s

trict regul

a

e

ments, the

e

quirement

s

multiple br

e

tilizing Poly

p

e

also appr

o

nstallatio

5

26-0288 • Mon

-

u

ral gas an

d

e

industry a

d

g

ned for ap

p

a

bility relat

e

extremely

h

s

, conventio

this docu

m

and outpu

t

m

odels, unle

s

tRanges

OUTP

U

MINIMU

M

4

7,750(14.0

k

4

8,300(14.2

k

6

4,500(18.9

k

8

6,000(25.2

k

1

44,000(42.

2

1

74,000(51.

0

3

48,000(102

3

48,000(102

g rate (valv

n

struction

M

r

ds outlined

d

ition, the B

M

a

tion 9, Rul

e

e

BMK boile

r

s

. These bo

e

eched unit

s

p

ropylene a

n

o

ved for PV

o

n Manual

-

Fri, 8 am - 5 pm

d

propane f

u

d

vance that

p

lication in

e

s energy

h

igh efficien

c

nal heating

m

ent apply t

o

t ranges l

i

s

s otherwis

e

U

TRANGE(

M

k

W) 716,

2

k

W) 968,

0

k

W) 1,39

5

k

W) 1,86

0

2

kW) 2,39

5

0

kW) 2,87

4

kW) 4,75

0

kW) 5,70

0

v

e position)

M

anual, the

B

in: South

C

M

K 2500 –

6

e

7.

r

s offer the

m

ilers are C

a

s

are capab

n

d AL29-4C

C and CP

V

EST Page

5

u

eled boile

r

meets the

n

any closed

input direc

t

c

y operatio

n

systems.

o

the Benc

h

i

sted belo

w

e

specified.

BTU/HR.)

MAXIMUM

2

50(210kW)

0

00(284kW)

5

,000(409k

W

0

,000(545k

W

5

,000(702k

W

4

,000(842k

W

0

,000(1392k

0

,000(1670k

and return

w

B

MK 750 –

C

oast Air Q

u

6

000 compl

y

m

aximum v

e

a

tegory II a

n

le of operat

i

vent syste

m

V

C, vent sy

s

5

of 54

r

s are

n

eeds

loop

t

ly to

n

and

h

mark

w

. All

W

)

W

)

W

)

W

)

W)

W)

w

ater

2000

u

ality

y

with

e

nting

n

d IV,

i

on in

m

s. In

s

tems

Bench

m

FORWA

R

OMM-13

6

The Ben

offering

t

AERCO

T

TER

M

A (Amp)

ACS

ADDR

AGND

ALRM

ANSI

ASME

AUX

BAS

Baud R

a

BMK (B

e

BMS or

BLDG (

B

BST

BTU

BTU/HR

CCS

C-More

C

CFH

CO

COMM (

C

Cal.

CNTL

CPU

DBB

DIP

ECU

EMS

FM

GF-xxxx

m

ark Plat

i

R

D

6_

D • GF-210

chmark's a

d

t

he most effi

T

echnical

T

M

INOLOGY

te

e

nchmark)

BMS II

B

ldg)

C

ontrolle

r

C

omm)

i

num wit

h

• 7/16/2019

d

vanced ele

cient opera

t

T

erminolog

y

A

mper

A

ERC

O

A

ddre

s

A

nalo

g

Alarm

A

meri

c

A

meri

c

A

uxilia

Buildin

(see b

e

Symb

o

(signal

secon

d

A

ERC

O

A

ERC

O

Buildin

A

ERC

O

British

heat r

e

BTUs

p

Combi

n

A

con

t

Bench

m

Cubic

F

Carbo

n

Comm

Calibr

a

Contro

Centra

Doubl

e

Valves

Dual I

n

Electr

o

Energ

y

Factor

y

Gas Fi

h

Edge C

o

Technical S

u

ctronics ar

e

t

ing method

s

y

Meaning

s

e

O

Control S

y

s

s

g

Ground

c

an National

c

an Society

o

ry

g Automati

o

e

low)

o

l rate, or

s

ing events)

d

, unless ea

c

O

’s Benchm

O

Boiler Ma

n

g

O

on-board

Thermal U

n

e

quired to ra

p

er Hou

r

(1

n

ation Cont

r

t

rol system

m

ark, Innov

a

F

eet per Ho

u

n

Monoxide

unication

a

tion

l

l Processin

g

e

Block and

(SSOVs) a

n

n

-Line Pack

a

o

nic Control

y

Managem

e

y

Mutual. U

s

red (an AE

R

o

ntroller: I

u

pport • (800) 5

e

available i

n

s

and energ

y

s

M

y

stem, AER

C

Standards

o

f Mechani

c

o

n System,

o

s

imply the

transmitted

c

h symbol i

s

ark series b

n

agement

S

Boiler Sequ

e

n

it. A unit

o

ise 1 pound

BTU/hr = 0.

2

r

ol System

developed

a

tion and K

C

ur

(1 CFH =

g

Unit

Bleed, a g

n

d a soleno

i

a

ge, a type

o

Unit (O

2

se

n

e

nt System;

s

ed to defin

e

R

CO docum

e

nstallatio

5

26-0288 • Mon

-

n

several s

e

y

managem

e

M

EANING

C

O’s boiler

Institute,

c

al Engineer

s

often used

number of

per second

s

1 bit long.

b

oilers

S

ystems

e

ncing Tec

h

o

f energy a

(0.45 kg) o

f

2

9 W)

by AERCO

C

1000 Seri

e

0.028 m

3

/h

r

g

as trains c

o

i

d operated

v

o

f switch

n

sor)

often used

i

e

boiler gas

t

e

nt numberi

o

n Manual

-

Fri, 8 am - 5 pm

e

lectable m

o

e

nt system i

manageme

n

r

s

interchange

distinct sy

. It is not e

q

h

nology

pproximatel

y

f

water 1°F

(

and curre

n

e

s product li

n

r

)

o

ntaining 2

vent valve.

i

nterchange

a

trains.

ng system)

EST Page

6

o

des of ope

r

ntegration.

n

t systems

ably with E

M

mbol chan

g

q

ual to bits

p

y

equal to

t

(

0.55 °C)

n

tly used in

n

es.

Safety Shu

t

a

bly with B

A

6

of 54

r

ation

M

S

g

es

p

er

t

he

all

t

off

A

S

Bench

m

FORWA

R

OMM-13

6

AERCO

T

TER

M

GND

HDR

Hex

HP

HX

Hz

I.D.

IGN

IGST Bo

INTLK (I

N

I/O

I/O Box

IP

ISO

Lbs.

LED

LN

MA (mA

)

MAX (M

a

MBH

MIN (Mi

n

Modbus

®

NC (N.C

NO (N.O

NO

x

NPT

O

2

O.D.

OMM, O

&

onAER

PCB

PMC Bo

a

P/N

POC

PPM

PSI

m

ark Plat

i

R

D

6_

D • GF-210

T

echnical

T

M

INOLOGY

ard

N

TL’K)

)

a

x)

n

)

®

.)

.)

&

M

a

rd

i

num wit

h

• 7/16/2019

T

erminolog

y

Groun

d

Heade

Hexad

e

Horse

Heat

E

Hertz (

Inside

Ignitio

n

Ignitio

n

Interlo

c

Input/

O

Input/

O

Intern

e

Intern

a

Pound

s

Light

E

Low N

i

Millia

m

Maxim

1000

B

Minim

u

A

seri

a

Modic

o

Norma

Norma

Nitrog

e

Nation

a

Oxyge

n

Outsid

e

Opera

t

A

ERC

O

Printe

d

Primar

y

Contro

Part N

u

Proof

o

Parts

p

Pound

s

h

Edge C

o

Technical S

u

y

Meaning

s

d

r

e

cimal Num

Powe

r

E

xchange

r

Cycles Per

S

Diamete

r

n

n

/Stepper B

o

c

k

O

utput

O

utput (I/O)

B

e

t Protocol

a

tional Orga

n

s

(1 lb = 0.4

E

mitting Dio

d

i

trogen Oxid

m

pere (1 tho

u

um

B

TUs per H

o

u

m

a

l, hal

f

-dupl

e

o

n

lly Closed

lly Open

e

n Oxide

a

l Pipe Thr

e

n

e

Diamete

r

t

ion and Mai

O

’s on-line

r

d

Circuit Bo

a

y

Micro-Co

n

lle

r

u

mbe

r

o

f Closure

p

er Million

s

per Squar

e

o

ntroller: I

u

pport • (800) 5

s

M

ber (0 – 9,

A

S

econd)

o

ard, contai

n

B

ox currentl

n

ization for

S

5 kg)

d

e

e

u

sand

th

of a

n

o

u

r

e

x data tran

e

ad

ntenance M

r

emote moni

a

rd

n

troller (P

M

e

Inch (1 P

S

nstallatio

5

26-0288 • Mon

-

M

EANING

A

– F)

n

ed in the C

y used on

B

S

tandardiza

t

n

ampere)

n

smission p

r

M

anual

toring syste

M

C) board,

S

I = 6.89 kP

a

o

n Manual

-

Fri, 8 am - 5 pm

C

ontrolle

r

B

enchmark

b

tion

r

otocol dev

e

m

contained i

a

)

EST Page

7

b

oilers

e

loped by A

E

n the C-M

o

7

of 54

E

G

o

re

Bench

m

FORWA

R

OMM-13

6

AERCO

T

TER

M

PTP

P&T

ProtoNo

d

PVC

PWM

REF (R

e

RES.

RS232

(or EIA-

2

RS485

(or EIA-

4

RTN (Rt

n

SETPT (

SHLD (

S

SPDT

SSOV

TEMP (

T

Termina

t

Tip-N-T

e

UL

VAC

VDC

VFD

VPS

W

W.C.

µA

m

ark Plat

i

R

D

6_

D • GF-210

T

echnical

T

M

INOLOGY

d

e

f)

2

32)

4

85)

n

)

Setpt)

S

hld)

T

emp)

t

ing Resisto

r

e

ll

i

num wit

h

• 7/16/2019

T

erminolog

y

Point-t

o

Press

u

Hardw

a

Poly V

i

Pulse

W

Refere

Resisti

A

stan

on the

A

stan

d

on the

Return

Setpoi

n

Shield

Single

Safety

Temp

e

r

A

resi

s

in ord

e

comm

u

A

devi

c

A

busi

n

Volts,

A

Volts,

D

Variab

l

Valve

P

Watt

Water

Micro

a

h

Edge C

o

Technical S

u

y

Meaning

s

o

-Point (us

u

u

re and Tem

a

re interfac

e

i

nyl Chlorid

e

W

idth Modu

l

nce

ve

dard for se

r

RS232 Sta

n

d

ard for ser

RS485 Sta

n

n

t Tempera

t

Pole Doubl

e

Shut Off V

a

e

rature

s

tor placed

a

e

r to preve

n

u

nication

c

e that indic

a

n

ess that te

s

A

lternating

C

D

irect Curre

l

e Frequenc

P

roving Sys

t

Column, a

u

a

mp (1 milli

o

o

ntroller: I

u

pport • (800) 5

s

M

u

ally over R

S

perature

e

between

B

e

, a commo

n

l

ation

r

ial, full-dupl

n

dard

ial, hal

f

-dup

n

dard

t

ure

e

Throw, a t

y

a

lve

a

t each end

n

t reflection

s

a

tes if a pa

c

s

ts and vali

d

C

urrent

nt

y Drive

t

em

u

nit of press

u

o

n

th

of an a

m

nstallatio

5

26-0288 • Mon

-

M

EANING

S

232 netwo

r

B

AS and a b

o

n

synthetic

p

l

ex (FDX) t

r

lex (HDX) t

r

y

pe of switc

h

of a daisy-

c

s

that may

c

kage was ti

d

ates produ

c

u

re (1 W.C.

m

pere)

o

n Manual

-

Fri, 8 am - 5 pm

r

ks)

o

iler or wat

e

p

lastic

r

ansmission

r

ansmission

h

c

hain or mul

t

cause inva

pped durin

g

c

ts

= 249 Pa)

EST Page

8

e

r heate

r

of data ba

s

of data ba

s

t

i-drop netw

o

lid data in

t

g

shipping

8

of 54

s

ed

s

ed

o

rk

t

he

Bench

m

SECTIO

N

OMM-13

6

SEC

T

1.1

W

Installer

s

following

precauti

o

A

ERCO

in the a

b

for gas-

f

equipme

A

pplianc

which s

h

consulte

d

See se

c

Commo

n

IMPO

This In

s

conditi

o

referen

W

AR

N

Do

Flui

rel

e

de

c

Bef

o

inp

u

Th

e

mu

s

Ele

c

25

0

us

e

uni

t

A s

i

ins

t

acc

to

u

CAU

T

Ma

n

rin

s

DO

tec

h

m

ark Plat

i

N

1 – SAFE

T

6_

D • GF-210

T

ION

1

W

ARNI

N

s

and oper

a

warnings

a

o

ns include

d

Instruction

M

b

sence of lo

c

f

ired boiler

s

nt shall be

es and Eq

u

h

ould be c

a

d

before ins

t

c

tion 1.4

n

wealth of

M

RTANT!

s

truction M

a

o

n. It must

b

ce.

N

ING!

not use ma

t

ds under pr

e

e

ased. Be s

u

c

rease all tr

a

o

re attempti

u

ts to the u

n

e

exhaust v

e

s

t be compl

e

c

trical volta

g

0

0/3000) O

R

e

d in this eq

u

t

’s front pan

e

i

ngle-pole (

1

alled on the

essible posi

u

nit sheet m

e

T

ION!

n

y soaps u

s

s

ed thoroug

h

NOT use

h

nician to in

s

i

num wit

h

T

Y PRECA

U

• 7/16/2019

1

: SA

F

N

GS&C

A

a

ting perso

n

a

nd caution

s

d

in these i

n

M

anual, the

c

al codes,

A

s

and AN

S

installed in

u

ipment, C

S

a

refully

f

oll

o

t

allations ar

e

for import

a

M

assachuset

t

a

nual is an

i

b

e given to

t

ches, candl

e

e

ssure may

u

re to shut o

f

a

pped press

u

ng to perfor

m

n

it.

e

nt pipe of t

h

e

tely sealed

g

es up to 12

R

208, 460 o

r

u

ipment. Th

e

e

l) must be i

20 VAC uni

electrical s

u

tion to quic

k

e

tal enclosu

r

s

ed for gas

h

ly with clea

n

this boiler

s

pect and r

e

h

Edge C

o

U

TIONS

Technical S

u

F

ETYP

R

A

UTION

S

n

nel MUST,

s

are gener

a

n

structions.

installation

o

A

NSI Z223.1

S

I/NFPASB

accordance

S

A B149.1,

a

o

wed in all

e

made.

a

nt inform

a

t

s.

i

ntegral par

t

the user b

y

e

s, flames,

o

cause injur

y

f

f all incomi

n

u

res to zero

m

any main

t

h

e unit may

o

to prevent l

e

0 VAC (BM

K

r

575

V

AC (

e

refore the

c

nstalled at

a

ts) or three-

u

pply line of

k

ly and safel

r

es.

pipe leak t

e

n

water afte

r

if any part

e

place any

p

o

ntroller: I

u

pport • (800) 5

R

ECAU

T

S

at all tim

e

a

l and must

In addition

o

f units MU

S

(National F

u

for LP ga

with the c

u

a

nd applica

cases. A

u

a

tion regar

d

t

of the pro

d

y

the install

o

r other sou

r

y

to person

n

n

g and outg

o

before perf

o

t

enance on

t

o

perate und

e

e

akage of c

o

K

750 – 20

0

BMK 5000

&

c

over on the

a

ll times, ex

c

pole (220 V

A

the unit. Th

y disconne

c

e

sting are c

o

r

leak chec

k

has been

p

art that has

nstallatio

5

26-0288 • Mon

-

T

IONS

e

s, observe

be given th

to all the r

e

S

T conform

uel Gas Co

d

s-fired boil

e

u

rrent Instal

l

ble Provinc

i

u

thorities h

a

d

ing install

d

uct and m

u

er and kep

t

rces of ignit

i

n

el or dama

g

o

ing water

s

o

rming mai

n

t

he unit, sh

u

e

r a positiv

e

o

mbustion

p

0

0) AND 20

8

&

6000) AN

D

unit’s pow

e

c

ept during

m

A

C and hig

h

e switch m

u

c

t electrical

s

o

rrosive to

m

k

s have bee

n

under wat

e

been unde

r

o

n Manual

-

Fri, 8 am - 5 pm

all safety

e same att

e

equirement

s

with local b

u

d

e Publicati

o

e

rs. Where

l

ation Code

ial regulatio

a

ving jurisd

i

ation of

u

u

st be main

t

t

in a safe

p

i

on to chec

k

g

e to equip

m

s

hutoff valve

n

tenance.

u

t off all gas

e

pressure a

p

roducts int

o

8

OR 460

VA

D 24 VOLT

S

e

r panel (loc

a

m

aintenanc

e

h

er units) s

w

u

st be install

e

s

ervice. Do

n

m

etals. The

n

completed

e

r. Call a q

r

water.

EST Page

9

regulations.

e

ntion as s

p

s

included i

n

uilding cod

e

o

n No. NFP

A

applicable

for Gas B

u

ns for the

c

i

ction shoul

u

nits within

t

ained in le

g

p

lace for fu

t

k

for gas lea

k

m

ent when

s. Carefully

and electri

c

nd therefor

e

o

living spac

e

A

C (BMK

S

AC may b

a

ted behind

e

and servic

w

itch must b

e

e

d in an ea

s

n

ot affix swi

t

piping mus

t

.

ualified ser

v

9

of 54

The

p

ecific

n

this

e

s, or,

A

-54)

, the

u

rning

c

lass;

d be

the

g

ible

t

ure

k

s.

c

al

e

e

s.

e

the

ing.

e

s

ily

t

ch

t

be

v

ice

Bench

m

SECTIO

N

OMM-13

6

1.2

E

If overh

e

(Figure 1

NOTE

:

The In

s

valve t

o

In additi

o

points s

h

F

o

m

a

o

u

s

h

F

o

p

r

id

e

D

e

i

m

F

o

p

r

i

m

1.3

P

If there i

s

manual

g

shut-off

d

If the un

i

the instr

u

Platinu

m

When r

e

instructi

o

Benchm

a

perform

e

V

CL

O

m

ark Plat

i

N

1 – SAFE

T

6_

D • GF-210

E

MERGE

e

ating occu

r

-1) located

e

:

s

taller must i

o

operating

p

o

n, to ensur

e

h

ould be de

s

o

r automati

c

a

nually op

e

u

tside each

h

utdown swi

t

o

r automati

c

ovide a ma

n

e

ntification

a

e

sign the s

y

m

mediately s

o

r boilers

m

ovide an

e

m

mediately s

P

ROLON

G

s

an emerg

e

g

as valve l

o

d

evice.

i

t is being s

h

u

ctions in S

m

-Edge: OP

E

e

turning a

u

o

ns in Secti

o

a

rk Platin

u

e

d to verify t

h

V

ALVE

O

SED

i

num wit

h

T

Y PRECA

U

• 7/16/2019

NCYSH

U

r

s or the g

a

e

xternal to t

dentify and

p

ersonnel.

Figu

r

e

safety an

e

s

igned and i

m

c

ally opera

t

e

rated rem

o

boiler roo

m

t

ch or circui

t

c

ally operat

e

n

ually oper

a

a

t a location

y

stem so ac

t

hut off the f

u

m

onitored a

e

mergency

s

hut off the f

u

G

EDSH

U

e

ncy, turn o

f

o

cated upst

r

h

ut down fo

r

ection 8.11

:

E

RATIO

N

-S

E

u

nit to serv

i

o

n 4: Initial

S

u

m-Edge:

O

h

at all syste

m

h

Edge C

o

U

TIONS

Technical S

u

U

TDOW

a

s supply fa

he unit.

indicate the

r

e 1-1: Ma

n

e

mergency

s

m

plement a

t

t

ed unatten

o

te shutdow

m

door. D

e

t

breaker wil

e

d unatten

d

a

ted remote

readily acc

e

t

ivation of th

u

el.

nd/or oper

a

s

hutdown

s

u

el upon ac

t

U

TDO

W

f

f the electri

c

r

eam from

t

r

an extend

e

:

Shutting

B

E

RVICE Ma

n

i

ce after a

S

tartup Pro

c

O

PERATIO

N

m

-operating

o

ntroller: I

u

pport • (800) 5

2

N

ils to shut

o

location of

t

n

ual Gas

S

s

hutdown pr

o

t

the site:

ded boiler

s

n switch o

r

e

sign the s

y

l immediate

l

d

ed boilers

i

shutdown s

e

ssible in th

e

e emergen

c

a

ted from

a

s

witch in t

h

t

ivation.

W

N

c

al power s

u

t

he unit. Th

e

d period of

B

oiler Down

n

ual (OMM-

prolonged

s

c

edures and

N

-SERVICE

parameter

s

nstallatio

2

6-0288 • Mon-

F

o

ff, close t

h

t

he emerge

n

S

hutoff Va

l

r

ocedure th

a

s

located i

n

r

circuit br

e

y

stem so

a

l

y shut off t

h

in a locatio

s

witch or cir

c

e

event of b

o

c

y shutdown

a

continuou

h

e control

r

u

pply to the

e installer

m

f

time, such

For Extend

e

-

0137, GF-2

shutdown,

i

Section 5:

E

Manual

s

are correc

t

VALVE

OPEN

o

n Manual

F

ri, 8 am - 5 pm

E

h

e manual

g

n

cy shutdo

w

l

ve

a

t addresse

s

n

a boiler

r

e

aker locat

e

a

ctivation o

f

h

e fuel suppl

n other tha

c

uit breaker

o

iler mis-op

e

n

switch or c

u

sly occupi

e

r

oom that

AERCO bo

i

m

ust identif

y

as a year o

e

d Period i

n

11).

i

t is recom

m

Safety Dev

i

(OMM-013

7

t

.

E

ST Page 1

g

as shutoff

w

n manual g

a

s

the followi

n

r

oom, provi

e

d just insi

d

f

the emer

g

y to the uni

t

n a boiler

r

marked for

e

ration.

c

ircuit break

e

e

d control

r

is hard-wir

e

i

ler and clo

s

y

the emer

g

r more, co

m

n

the Benc

h

m

ended th

a

i

ce Testing

o

7

, GF-211

)

0 of 54

valve

a

s

n

g

de a

d

e or

g

ency

t

(s).

r

oom,

easy

e

r will

r

oom,

e

d to

s

e the

g

ency

m

plete

h

mark

a

t the

o

f the

)

be

Bench

m

SECTIO

N

OMM-13

6

1.4I

M

Requir

e

BoilerIn

s

followin

g

Boile

Com

m

Prior

teste

The

v

side‐

w

requ

i

(a)For

building

operate

d

seven(7

)

andpor

c

1. I

N

side

w

obse

r

insta

insta

mon

o

build

be t

h

prof

e

a.I

cra

w

bac

k

b.

co

m

the

bat

t

2. A

requ

i

ANSI

/

3.S

I

exte

r

with

equi

p

VEN

T

m

ark Plat

i

N

1 – SAFE

T

6_

D • GF-210

M

PORT

A

e

ments f

o

s

tallations

w

g

requireme

r must be i

n

m

onwealth

o

tounit op

e

dusingan

o

v

enttermin

a

w

all ventin

i

rementsex

t

all side w

a

orstructure

d

bytheCo

m

)

feetabove

c

hes,thefoll

N

STALLATIO

N

w

all horizo

n

r

vethatah

lled on the

lling plumb

e

o

xide detec

ingorstruc

t

h

e responsi

b

e

ssionalsfor

ntheevent

w

lspaceor

a

k

‐upmayb

e

In the even

t

m

pletionofi

n

above req

u

t

eryoperat

e

PPROVED

C

i

red in acc

o

/

UL2034lis

t

I

GNAGE: A

r

ior of the

b

theexhaus

t

p

ment. The

T

DIRECTLY

B

i

num wit

h

T

Y PRECA

U

• 7/16/2019

A

NT–F

O

o

r Massa

c

w

ithintheC

o

nts:

n

stalled by

o

fMassach

u

e

ration, the

o

n‐corrosive

a

tionmust

b

g is used,

t

ractedfro

m

a

ll horizont

a

usedinwh

o

m

monwealt

h

finishedgr

a

owingrequ

i

N

OF CARB

O

n

tal vented

ardwiredc

a

floor level

e

r or gasfitt

e

tor with a

n

t

ureserved

b

ility of th

e

theinstalla

t

thatthesid

a

nattic,th

e

e

installedo

n

t

that the r

e

n

stallation,

t

u

irements;

p

e

dcarbonm

o

C

ARBON

M

o

rdance wit

h

t

edandIAS

metal or pl

a

b

uilding at a

t

venttermi

sign shall r

e

B

ELOW.KE

E

h

Edge C

o

U

TIONS

Technical S

u

O

RMA

S

c

husetts I

n

o

mmonweal

a plumber

o

u

setts.

completeg

a

soap.

b

elocated

a

the instal

l

m

248CMR

5

a

lly vented

o

leorinpa

r

h

andwher

e

a

deinthea

r

i

rementssh

a

O

N MONO

X

gas fueled

e

a

rbonmon

o

where the

e

r shall obs

n

alarm is i

bytheside

w

e

property

o

t

ionofhard

ewallhoriz

o

e

hardwire

d

n

thenexta

d

e

quirement

s

t

heowners

p

rovided, h

o

o

noxidedet

M

ONOXIDE

D

h

the abov

e

certified.

a

stic identif

i

minimum

h

nalforthe

e

ad, in prin

t

E

PCLEARO

F

o

ntroller: I

u

pport • (800) 5

2

S

SACHU

S

n

stallatio

n

thofMassa

o

r a gas fitt

a

s trainand

a

minimum

o

l

ation mus

t

5

.08(2):

gas fueled

r

tforreside

n

e

theside w

r

eaofthev

e

a

llbesatisfi

e

X

IDE DETEC

T

e

quipment,

o

xidedetect

gas equip

m

erve that a

nstalled on

w

allhorizon

o

wner to s

e

wiredcarb

o

o

ntallyvent

d

carbonm

o

d

jacentfloo

r

s

of this su

b

hallhavea

p

o

wever, th

a

ectorwith

a

D

ETECTORS

e

provision

s

i

cation plat

e

h

eight of ei

g

h

orizontally

t

size no le

s

F

ALLOBSTR

nstallatio

2

6-0288 • Mon-

F

S

ETTSI

N

n

s

chusettsm

u

t

er who is li

all connec

t

o

f4feet ab

t

conform

equipment

n

tialpurpos

e

allexhaust

v

e

nting,inclu

d

e

d:

T

ORS: At th

e

the installi

n

orwithan

a

m

ent is to

b

battery op

e

each addi

t

talvented

g

e

cure the s

e

o

nmonoxid

e

edgasfuel

e

o

noxidedet

e

rlevel.

b

division ca

n

p

eriodofth

a

t during s

a

a

nalarmsha

S

: Each car

b

s

shall com

e

shall be p

g

ht (8) feet

ventedgas

s

s than one

‐

UCTIONS".

o

n Manual

F

ri, 8 am - 5 pm

E

N

STALL

A

u

stconform

censed wit

h

t

ions must

b

b

ovegradel

e

to the fol

installed i

n

es,includin

g

v

enttermin

dingbutno

t

e time of i

n

n

g plumber

a

larmandb

b

e installed.

e

rated or h

a

t

ional level

g

asfuelede

q

e

rvices of

q

e

detectors.

e

dequipme

n

e

ctorwitha

n

not be m

e

irty(30)da

y

a

id thirty (3

a

llbeinstall

e

r

bon mono

x

ply with N

F

ermanently

above gra

d

fueledhea

t

‐

half (1/2) i

n

(Continued

E

ST Page 1

A

TIONS

tothe

h

in the

b

e leak

e

vel.If

lowing

n

every dw

e

g

thoseown

ationisless

t

limitedto

d

n

stallation

o

or gasfitter

atteryback

‐

In additio

n

a

rd wired c

a

of the dw

e

q

uipment.I

t

q

ualified lic

e

n

tisinstalle

d

larmandb

a

e

t at the ti

m

y

stocompl

y

0) day peri

o

e

d.

x

ide detect

o

F

PA 720 a

n

mounted t

o

d

e directly i

n

t

ingapplian

n

ch in size,

)

1 of 54

e

lling,

edor

than

d

ecks

o

f the

shall

‐

upis

n

, the

a

rbon

e

lling,

t

shall

e

nsed

d

ina

a

ttery

m

e of

y

with

o

d, a

o

r as

n

d be

o

the

n

line

ceor

"GAS

Bench

m

SECTIO

N

OMM-13

6

Requir

e

4.I

N

fuele

obse

r

provi

(b)EXE

M

1.

T

the

2.

roo

m

par

t

(c)MA

N

theman

u

venting

s

provide

d

include:

1.

D

syste

2.A

(d)MA

N

When t

h

equipm

e

systems

"

1.T

h

ore

q

2.

T

instr

u

(e)Aco

gasfuel

e

venting

d

theinsta

m

ark Plat

i

N

1 – SAFE

T

6_

D • GF-210

e

ments f

o

N

SPECTION

:

d equipme

n

r

ves carbo

n

sionsof24

8

M

PTIONS:T

h

T

heequipm

e

mostcurre

n

Product Ap

m

or struct

u

t

forresiden

N

UFACTURE

R

u

facturero

f

s

ystem des

i

d

by the ma

D

etailed inst

mcompon

e

completep

a

N

UFACTUR

E

h

e manufa

c

e

ntdoesnot

"

,thefollow

h

ereferenc

e

q

uipmentin

s

T

he "specia

u

ctionsfort

p

yofall ins

t

e

dequipme

n

d

esigninstr

u

llation.

……………….

[

i

num wit

h

T

Y PRECA

U

• 7/16/2019

o

r Massa

c

The state

o

n

t shall not

n

monoxid

e

8

CMR5.08(

2

h

efollowin

g

e

ntlistedin

n

teditionof

proved sid

e

u

re separat

e

tialpurpos

e

R

REQUIRE

M

f

ProductA

p

i

gn or venti

nufacturer

f

ructions fo

r

e

nts;and

a

rtslistfort

E

R REQUIRE

M

c

turer of a

provideth

e

ingrequire

m

e

d"specialv

s

tallationin

s

l venting s

y

hatsystem

s

t

allationins

t

n

t,allventi

n

u

ctionsshal

l

[

EndofExtr

a

h

Edge C

o

U

TIONS

Technical S

u

c

husetts I

n

o

r local gas

approve th

e

e

detectors

2

)(a)1throu

g

g

equipment

Section10

e

NFPA54as

e

wall horiz

o

e

from the

e

s.

M

ENTS‐GA

p

provedsid

e

ng system

f

or installat

i

r

the install

a

heventing

s

M

ENTS‐G

A

Product A

p

e

partsforv

m

entsshall

b

entingsyst

e

s

tructions;a

y

stems" sh

a

s

hallinclud

e

t

ructionsfo

r

n

ginstructi

o

l

remainwi

t

a

ctedInfor

m

o

ntroller: I

u

pport • (800) 5

2

n

stallatio

n

inspector

o

e

installatio

n

and sign

a

g

h4.

isexemptf

e

ntitled"Eq

adoptedby

o

ntally vent

dwelling, b

u

S EQUIPME

e

wallhoriz

o

component

s

on of the

e

a

tion of th

e

s

ystemdesi

g

A

S EQUIPM

E

p

proved sid

entingthef

b

esatisfied

b

e

m"instruct

i

nd

a

ll be Prod

e

apartslist

r

allProduc

t

o

ns,allpart

s

t

htheappli

a

m

ationFro

m

nstallatio

2

6-0288 • Mon-

F

n

s

o

f the side

w

n

unless, up

a

ge installe

rom248C

M

uipmentN

o

y

theBoard;

ed gas fuel

e

u

ilding or s

t

NT VENTIN

G

o

ntallyvent

e

s

with the

e

quipment

a

e

venting s

y

g

norventin

g

ENT VENTI

N

d

e wall hor

i

f

luegases,b

b

ytheman

u

i

onsshallb

e

d

uct Appro

v

anddetaile

d

t

Approved

s

s

lists forve

n

a

nceorequ

m

248CMR

5

o

n Manual

F

ri, 8 am - 5 pm

E

w

all horizo

n

p

on inspecti

o

d in accor

M

R5.08(2)(a

)

o

tRequired

T

and

ed equipm

e

t

ructure us

e

G

SYSTEM

P

e

dgasequi

p

equipment,

a

nd the ven

t

y

stem desig

g

system.

N

G SYSTEM

izontally v

e

utidentifie

s

u

facturer:

e

included

w

v

ed by the

d

installatio

n

s

idewallh

o

ntinginstru

c

ipmentatt

h

5

.08(2)]……

…

E

ST Page 1

n

tally vente

d

o

n, the insp

dance wit

h

)

1through

4

T

oBeVent

e

e

nt installe

d

e

d in whole

P

ROVIDED.

W

p

mentprovi

the instru

c

t

ing system

n or the v

e

NOT PROV

e

nted gas f

u

s

"specialv

e

w

iththeappl

Board, an

d

n

instructio

n

o

rizontallyv

e

c

tions,and

/

h

ecomple ti

…

…………

2 of 54

d

gas

ector

h

the

4

:

e

d"in

d

in a

or in

W

hen

desa

c

tions

shall

e

nting

IDED.

u

eled

e

nting

iance

d

the

n

s.

e

nted

/

orall

onof

Bench

m

SECTIO

N

OMM-13

6

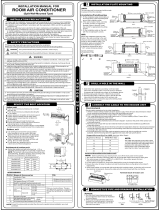

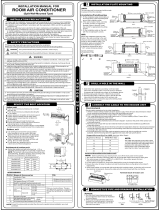

SEC

T

2.1I

N

This sec

t

A

ERCO

2.2

R

Each Be

BMK mo

B

B

B

B

B

The unit

damage.

shipmen

t

signed.

CAU

T

While

p

from th

e

NOTE

:

indicat

o

during

s

inform

a

adjust

e

be ma

d

2.3

U

Carefull

y

packagi

n

A

fter un

p

damage

immedia

t

The follo

the unit’

s

P

r

A

S

C

o

A

o

n

m

ark Plat

i

N

2 – INST

A

6_

D • GF-210

T

ION

2

N

TROD

U

t

ion provide

s

Benchmark

R

ECEIVI

N

nchmark B

o

dels is appr

o

B

MK 750:

B

MK 1000:

B

MK 1500/2

0

B

MK 2500/3

0

B

MK 5000/6

0

must be m

o

The unit

t

completen

T

ION!

p

ackaged in

e

front onl

y

:

A

ERCO is

o

r on the ou

t

s

hipment. If

a

tion on the

c

r before pro

d

e clear to t

h

U

NPACK

y

unpack th

e

n

g materials

p

acking, m

a

not indica

t

t

ely if any d

a

wing acces

s

s

shipping c

o

r

essure/Te

m

S

ME Press

u

o

ndensate

D

1”, 1-1/2”

o

n

Propane

a

i

num wit

h

A

LLATION

• 7/16/2019

2

: INST

A

U

CTION

s

the descri

Platinum B

o

N

GTHE

U

o

iler System

o

ximately a

s

1100

1200

0

00: 1800

0

00: 2200

0

00: 3,53

0

o

ved with t

h

s

hould be

ess at the

t

the shippin

g

y

.

not respon

s

t

side of the

c

the Tip-N-T

e

c

arrier’s pa

p

ceeding. A

n

h

e deliverin

g

ING

e

unit takin

a

ke a close

t

ed by the

a

mage is de

s

ories come

o

ntainer or

a

m

perature

G

u

re Relief

V

D

rain Trap

o

r 2” Natu

r

a

nd Dual F

u

h

Edge C

o

Technical S

u

A

LLATI

ptions and

p

o

ile

r

s.

U

NIT

is shipped

a

s

follows:

lbs. (499 k

g

lbs. (544 k

g

lbs. (817 k

g

lbs. (1000

k

0

lbs. (1601

k

h

e proper ri

g

completely

t

ime of rec

e

g

container,

s

ible for lost

c

rate, which

e

ll indicator

p

erwork and

y other visu

carrier.

g care not

inspection

Tip-N-Tell

tected.

standard w

i

a

re factory i

n

G

auge

V

alve

(P/N 24441

)

r

al Gas Su

p

u

el units

o

ntroller: I

u

pport • (800) 5

2

ON

p

rocedures

n

a

s a single

c

g

)

g

)

g

).

k

g)

k

g)

g

ging equip

inspected

f

e

ipt from th

e

the unit mu

s

or damage

d

indicates if

is tripped, d

request a f

r

al damage t

to damage

of the unit

indicator.

T

i

th each uni

t

n

stalled on t

h

)

p

ply Shuto

ff

nstallatio

2

6-0288 • Mon-

F

necessary t

o

c

rated unit.

T

ment for sa

f

or evidenc

e

e

carrier an

d

s

t be moved

d

freight. Ea

c

the unit has

d

o not sign f

o

r

eight claim

a

t

o the packa

the unit e

n

to ensure

t

T

he freight

t

and are ei

t

h

e unit:

f

f Valve, an

d

o

n Manual

F

ri, 8 am - 5 pm

E

o

unpack, i

n

T

he shippin

g

fety and to

e

of shippi

d

before th

e

by pallet ja

c

c

h unit has

A

been turne

d

o

r the ship

m

and inspect

i

ging materi

a

n

closure w

h

t

hat there i

s

carrier sh

t

her packed

d a Propa

n

E

ST Page 1

n

spect and i

g

weight for

t

avoid equi

p

ng damag

e

e

bill of lad

i

c

k or forklift

A

Tip-N-Tell

d

on its sid

e

m

ent. Note t

h

i

on by a clai

a

ls should a

l

h

en cutting

s

no eviden

ould be n

o

separately

w

n

e Shutoff

V

3 of 54

nstall

t

hese

p

ment

e

and

i

ng is

e

h

e

ms

l

so

away

ce of

o

tified

w

ithin

V

alve

Bench

m

SECTIO

N

OMM-13

6

When o

containe

standard

until rea

d

2.4

S

Ensure t

h

A

s

A

G

A

Bench

m

concrete

inch (10

In additi

o

such tha

t

Figures

2

2.4.1

I

All Ben

c

installed

minimu

m

if Local

B

require

m

The min

i

F

S

R

T

A

ll gas

p

interfere

In multip

space fo

into con

s

NOTE

:

Bench

m

cleara

n

If installi

n

combina

t

have a

p

Boilers i

n

Section

SERVIC

E

m

ark Plat

i

N

2 – INST

A

6_

D • GF-210

ptional acc

e

r

, factory in

or optional

d

y for install

a

S

ITEPRE

h

at the site

s

A

ccess to

a

s

pecified in

t

A

ccess to A

C

G

uide (TAG

-

A

level conc

r

m

ark 750/10

0

“housekee

p

.2 to 20.3 c

m

o

n, to ensur

e

t

the conde

n

2

-1a – 2-1d.

I

nstallati

o

c

hmark mod

with the pr

e

m

clearance

B

uilding Co

d

m

ents.

i

mum acce

p

BMK 75

0

F

ront: 24 in

c

S

ides: 24 in

c

R

ear: 24 in

c

T

op: 18 in

c

p

iping, wate

r

with the re

m

le unit instal

r piping co

n

s

ideration.

A

:

m

ark units

m

n

ces still ap

p

n

g a Combi

t

ion mode,

b

p

anel want

n

advance

a

6.6: Combi

n

E

Manual (

G

i

num wit

h

A

LLATION

• 7/16/2019

e

ssories a

r

stalled on

t

accessorie

s

a

tion or use

.

PARATI

O

s

elected for

a

natural ga

t

he Benchm

a

C

input po

w

-

0048, GF-2

r

ete housek

e

0

0 units mu

s

p

ing” pad.

B

m

) concrete

e

proper co

n

n

sate asse

m

o

nClear

a

els are the

e

scribed cle

a

dimensions

,

d

es require

p

table clea

r

0

- 3000

c

hes (61 cm

)

c

hes (61 cm

)

c

hes (61 cm

)

c

hes (45.7 c

m

piping and

m

oval of any

lations, it is

n

nections a

n

A

ll piping m

u

m

ay be instal

p

ly. See dra

w

nation Cont

b

ut can still

to continue

nd place th

e

n

ation Con

t

G

F-211).

h

Edge C

o

Technical S

u

e ordered,

t

he unit, or

s

shipped l

o

.

O

N

installation

o

s and/or p

r

a

rk Pre-Inst

a

w

e