Page is loading ...

READ ME NOW!!!

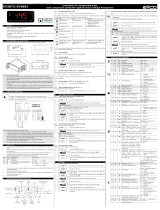

With reference to the label on the rear of the instrument and the required application

1. Check that power supply, probes and loads (compressor, heaters, etc.) are suitable for the

instrument.

2. Fasten the instrument to the panel as shown in the following fi gure.

3. Make all the required electrical connections.

4. Power up the unit.

5. After around 2 seconds, if the instrument displays the temperature read by the probes connected

to the device, go directly to point 7. If nothing is displayed or an alarm is signalled (alarm codes on

the display), power down, check the connections and the power supply and go to point 6.

6. Power the unit up again. If the instrument now correctly displays the temperature, go to point 7. If,

on the other hand, the problem described in point 5 is repeated, see the table “Alarms and signals:

display, buzzer and relay” to identify the cause of the problem.

7. ir33 smart is now ready to be confi gured. For correct confi guration based on the required

application, see the section “How to select and load a confi guration”.

+050001531 - rel. 1.1 del 09.03.2010

ir33 smart - IR33C7HB0E electronic controller for normal and low temperature ventilated refrigeration units

bn1: normal temperature (+2T10 °C) ventilated refrigeration units

with heater defrost (timed) - Temperature range: 2T10 °C

Temperature control Connection diagram

rd

Temp. °C

Set point

Compressor

DIRECT MODE

NTC/PTC 1

1

NTC/PTC 2

DI 1/NTC 3

DI 2/NTC 4

L

N

L

L

N

N

R3

R1

R4

R2

115/230 V~

50mA~ max

PROBE

POWER

SUPPLY

Inputs Room probe NTC 1

Outputs

Compressor

R1: 16 A relay

Defrost heater

R3: 8 A relay

Evaporator fan

R2: 8 A relay

Main parameters

(type F)

Name Type Description Default value

St

CtL

Set point

4 °C

rd Control differential (hysteresis)

2 °C

dl

dEF

Interval between defrosts

8 hours

dP1 Maximum evap. defrost duration

30 min

AL (*)

ALM

Minimum temperature alarm

-30 °C

AH (*) Maximum temperature alarm

30 °C

Ad

Temperature alarm delay

30 min

F0

FAn

Fan management

0

Fd Fans off after dripping

0 min

(*) alarm thresholds AL & AH absolute. Relay R4 is not used.

bn2: normal temperature (+2T10 °C) ventilated refrigeration units

with heater defrost (by temperature) and light control

Temperature range: 2T10 °C

Temperature control Connection diagram

rd

Temp. °C

Set point

Compressor

DIRECT MODE

NTC/PTC 1

NTC/PTC 2

DI 1/NTC 3

DI 2/NTC 4

L

L

N

N

R1 R2

115/230 V~

50mA~ max

DI

12

R3 R4

POWER

SUPPLY

PROBES

DOOR

SWITCH

OLJKW

*: short-circuit terminals 10 and 11 if the door switch is

not used

Inputs

Room probe NTC 1

Defrost probe NTC 2

Door switch Digital input DI1

Outputs

Compressor R1: 16 A relay

Defrost heater R3: 8 A relay

Evaporator fan R2: 8 A relay

Light R4: 8 A relay

Main parameters

(type F)

Name Type Description Default value

St

CtL

Set point

2 °C

rd Control differential (hysteresis)

2 °C

dl

dEF

Interval between defrosts

6 hours

dt1 Evaporator end defrost temperature

4 °C

dd Dripping time

2 min

d/1 Defrost probe 1 reading

-

AL (*)

ALM

Minimum temperature alarm

-30 °C

AH (*) Maximum temperature alarm

30 °C

Ad Temperature alarm delay

30 min

F0

FAn

Fan management

0

F1 Fan on temperature

5 °C

Fd Fans off after dripping

2 min

(*) absolute alarm thresholds

bn3: normal (+2T10 °C) or low temperature (-20T-14 °C) ventilated

refrigeration units with heater defrost (by temperature) and light control

Temperature range -20T-14 °C & +2T10 °C

Temperature control Connection diagram

rd

Temp. °C

Set point

Compressor

DIRECT MODE

NTC/PTC 1

NTC/PTC 2

DI 1/NTC 3

DI 2/NTC 4

L

L

N

N

R1 R2

115/230 V~

50mA~ max

DI

12

R3 R4

POWER

SUPPLY

PROBES

DOOR

SWITCH

OLJKW

*: short-circuit terminals 10 and 11 if the door switch is not used

Inputs

Room probe NTC 1

Defrost probe NTC 2

Door switch Digital input DI1

Outputs

Compressor R1: 16 A relay

Defrost heater R3: 8 A relay

Evaporator fan R2: 8 A relay

Light R4: 8 A relay

Main parameters

(type F)

Name Type Description Default value

St

CtL

Set point

-14 °C

rd Control differential (hysteresis)

2 °C

dl

dEF

Interval between defrosts

6 hours

dt1 Evaporator end defrost temperature

4 °C

dd Dripping time

2 min

d/1 Defrost probe 1 reading

-

AL (*)

ALM

Minimum temperature alarm

-50 °C

AH (*) Maximum temperature alarm

30 °C

Ad Temperature alarm delay

30 min

F0

FAn

Fan management

0

F1 Fan on temperature

5 °C

Fd Fans off after dripping

2 min

(*) absolute alarm thresholds

bn4: normal temperature ventilated refrigeration units (+2T10 °C)

with heater defrost (by temperature) and two evaporators

Temperature range +2T10 °C

Temperature control Connection diagram

rd

Temp. °C

Set point

Compressor

DIRECT MODE

NTC/PTC 1

NTC/PTC 2

DI 1/NTC 3

DI 2/NTC 4

L

L

N

N

R1 R2

115/230 V~

50mA~ max

12a 2b

R3 R4

POWER

SUPPLY

PROBES

Inputs

Room probe NTC 1

Defrost probe 2a NTC 2

Defrost probe 2b NTC 3

Outputs

Compressor R1: 2 HP relay

Defrost heater 1 R3: 8 A relay

Defrost heater 2 R4: 8 A relay

Evaporator fan R2: 8 A relay

Main parameters

(type F)

Name Type Description Default value

St

CtL

Set point

2 °C

rd Control delta

2 °C

dl

dEF

Interval between defrosts

6 hours

dt1 Evaporator end defrost temperature

4 °C

dt2 AUX evap. end defrost temperature

4 °C

dd Dripping time

2 min

d/1 Defrost probe 1 reading

-

d/2 Defrost probe 2 reading

-

AL (*)

ALM

Minimum temperature alarm

-30 °C

AH (*) Maximum temperature alarm

30 °C

Ad Temperature alarm delay

30 min

F0

FAn

Fan management

0

F1 Fan on temperature

5 °C

Fd Fans off after dripping

2 min

(*) absolute alarm thresholds

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

How to select and load a user confi guration

Step Action Effect Meaning

1

Switch the instrument on

while holding

After 2 seconds the

display shows the

message ‘bn0’

‘bn0’ is the current confi guration. (Standard CAREL

when fi rst switched on or other user confi guration,

if loaded)

2

Press

aux

or

def

The display shows the

messages ‘bn1’, ‘bn2’,

‘bn3’, ‘bn4’, ‘bn5’, ‘bn6’

Select the required confi guration

(refer to the following table)

3

Press

Set

The display shows “Std”

for 1 sec

The user confi guration selected in point 2 will be

loaded

This procedure can only be performed once: the most suitable confi guration for the application, once

loaded, will remain active the next time the instrument is started.

When switching on the fi rst time, bn0 corresponds to the Carel standard (default confi guration). The

procedure for loading one of the user confi gurations involves copying one of the sets of parameters

(bn1,...,bn6) to bn0. bn0 therefore always corresponds to the last confi guration loaded.

• Electronic controller for normal and low temperature ventilated refrigeration units

• 115/230 Vac switching power supply

• 16 A compressor relay

• Management of NTC (-50 to +90°C) and PTC (-50 to +150°C) sensors

• Simple and intuitive installation and confi guration

• 6 pre-loaded confi gurations for the most common refrigeration applications

• HACCP reports

• Real time clock

1

2

Wall mounting ir33

Wiring diagram

Wall mounting by two plastic brackets sliding in from side

1

2

IROPZDSP00

Display interface option

IROPZ48500

Serial board interface RS485

IROPZKEY**

Programming key

Optional connections

dima di foratura

drilling template

71x29 mm

34,4

70,5

79

76,2

80,6

38,6

56,5

65

Dimensions (mm)

Confi gurations

ir33 SMART is loaded with 6 default confi gurations (sets of parameters). Each confi guration identifi es

a specifi c refrigeration application, and can be identifi ed simply by the index (bn*) when switching the

instrument on.

Index Application Op. T. range Inputs Relay outputs

bn1

Normal temperature ventilated refrigeration

units with heater defrost (timed)

2T10°C NTC room

Compressor

Defrost

Fans

bn2

Normal temperature ventilated refrigeration

units with heater defrost (by temperature)

and light control

2T10°C

NTC room

NTC evaporator

DI door switch

Compressor

Defrost

Fans

Light

bn3

Normal or low temperature ventilated refrige-

ration units with heater defrost

(by temperature) and light control

-20T-14°C

2T10 °C

NTC room

NTC evaporator

DI door switch

Compressor

Defrost

Fans

Light

bn4

Normal temperature ventilated refrigeration

units with heater defrost (with two evapora-

tors, by temperature)

2T10°C

NTC room

NTC evaporator 1

NTC evaporator 2

Compressor

Defrost

Evap fans 1

Evap fans 2

bn5

Normal or low temperature ventilated

refrigeration units with heater defrost (with

two evaporators, by temperature)

-20T-14°C

2T10 °C

NTC room

NTC evaporator 1

NTC evaporator 2

Compressor

Defrost

Evap fans 1

Evap fans 2

bn6 Standard CAREL (default confi g.) -50T90 °C confi gurable confi gurable

NO POWER

& SIGNAL

CABLES

TOGETHER

READ CAREFULLY IN THE TEXT!

IMPORTANT: separate the probe and digital input cables from the

cables to inductive loads and power cables to avoid electromagnetic

disturbance. Never run power cables (including electrical panel

cables) and signal cables in the same conduits.

bn5: normal (+2T10 °C) or low temp. (-20T-14 °C) ventilated refrigera-

tion units with heater defrost (by temperature) & two evaporators

Temperature range -20T-14 °C & +2T10 °C

Temperature control Connection diagram

rd

Temp. °C

Set point

Compressor

DIRECT MODE

NTC/PTC 1

NTC/PTC 2

DI 1/NTC 3

DI 2/NTC 4

L

L

N

N

R1 R2

115/230 V~

50mA~ max

12a 2b

R3 R4

POWER

SUPPLY

PROBES

Inputs

Room probe NTC 1

Defrost probe 2a NTC 2

Defrost probe 2b NTC 3

Outputs

Compressor R1: 2 HP relay

Defrost heater 1 R3: 8 A relay

Defrost heater 2 R4: 8 A relay

Evaporator fan R2: 8 A relay

Main parameters

(type F)

Name Type Description Default value

St

CtL

Set point

-14 °C

rd Control delta

2 °C

dl

dEF

Interval between defrosts

6 hours

dt1 Evaporator end defrost temperature

4 °C

dt2 AUX evaporator end defrost temp.

4 °C

dd Dripping time

2 min

d/1 Defrost probe 1 reading

-

d/2 Defrost probe 2 reading

-

AL (*)

ALM

Minimum temperature alarm

-50 °C

AH (*) Maximum temperature alarm

30 °C

Ad Temperature alarm delay

30 min

F0

FAn

Fan management

0

F1 Fan on temperature

5 °C

Fd Fans off after dripping

2 min

(*) absolute alarm thresholds

bn6: standard CAREL (default confi guration)

Connection diagram

DI DI

L

N

L

L

N

N

$8;

12 12

R3

R1

R4

R2

115/230 V~

50mA~ max

NTC/PTC 1

NTC/PTC 2

DI 1/NTC 3

DI 2/NTC 4

PROBES

POWER

SUPPLY

Main parameters

(type F)

Name Type Description Default value

St

CtL

Set point

-14 °C

rd Control delta

2 °C

rt Temperature monitoring interval

-

rH Maximum temperature read

-

rL Minimum temperature read

-

dl

dEF

Interval between defrosts

8 hours

dt1 Evaporator end defrost temperature

4 °C

dt2 AUX evaporator end defrost temp.

4 °C

dP1 Maximum evaporator defrost duration

30 min

dP2 Maximum evaporator defrost duration

30 min

dd Dripping time

2 min

d8

Alarm bypass time after defrost and/or door

open

1 hour

d/1 Defrost probe 1 reading

-

d/2 Defrost probe 2 reading

-

AL

ALM

Minimum temperature alarm

0 °C

AH Maximum temperature alarm

0 °C

Ad Temperature alarm delay

120 min

F1

FAn

Fan on temperature

5 °C

Fd Fans off after dripping

1 min

Indications on the display

When fl ashing, the signals on the display indicate a request that cannot be implemented until the delay

timers have expired.

Icon Function

Normal operation

Startup

ON OFF Flashing

COMPRESS. compressor on compress. off compress. call

FAN fan on fan off fan call

DEFROST defrost in progress no defrost call defrost call

AUX

AUX auxiliary output

active

AUX auxiliary output not

active

anti-sweat heater

function active

ALARM

delayed external alarm

(before the time “A7“has

elapsed)

no alarm present

alarms in norm.

operation (e.g. high/low

temp.) or immediate or

delayed ext. alarm from

digital input

CLOCK

if at least one timed

defrost has been set

no timed defrost has

been set

clock alarm

ON if Real-

Time Clock

present

LIGHT

light auxiliary output

active

light auxiliary output not

active

anti-sweat heater

function active

SERVICE no malfunction

malfunction (e.g.

EEPROM error or faulty

probes)

HACCP

function enabled (HA

and/or HF)

function not enabled HACCP alarm saved

CONT. CYCLE function activated function not activated function called

Buttons on the keypad

But. Pressing the button alone Pressing together with other buttons

• if pressed for more than

5 s, accesses the menu

for setting the type F

parameters (frequent)

• in the event of alarms:

mutes the audible alarm

(buzzer) and deactivates

the alarm relay

• if pressed with SET for more

than 5s, accesses the menu

for setting type C parameters

(confi guration) or downloa-

ding the parameters

• if pressed together with UP/

AUX for more than 5s resets

any alarms with manual reset

Start-up: if pressed

for more than 5 s at

start-up activates the

RESET procedure

Automatic address as-

signment: if pressed

for more than 1 s

enters the automatic

serial address assign-

ment procedure

aux

if pressed for more than 1

s, activates /deactivates the

auxiliary output

• if pressed together with DOWN/DEF for more than 5s, activates/deactiva-

tes the continuous cycle

• if pressed with SET for more than 5s starts the report printing procedure

(function available but to be implemented)

• if pressed with PRG/MUTE for more than 5s, resets any alarms with

manual reset

def

if pressed for more than 5

s, activates /deactivates a

manual defrost

• if pressed together with UP/AUX for more than 5s activates/deactivates

the continuous cycle

• if pressed for more than 1 s with SEL, displays a submenu with the

HACCP alarm parameters (HA, HAn, HF, HFn)

Set

if pressed for more than 1

s, displays and/or sets the

set point

• if pressed with PRG/MUTE for more than 5s, accesses the menu for setting

type C parameters (confi guration) or downloading the parameters

• if pressed for more than 1 s with DOWN/DEF, displays a submenu with the

HACCP alarm parameters (HA, HAn, HF, HFn)

• if pressed with UP/AUX for more than 5s starts the report printing procedu-

re (function available but to be implemented)

How to set the set point

Step Action Effect Meaning

1

Press

Set

for 2 seconds

After 2 seconds the display will show

the current set point

This the currently active control

set point

2

Press

aux

or

def

The value on the display will increase

or decrease

Set the desired value

3

Press

Set

The controller will show the temp.read by

the probes again

The set point is modifi ed and

saved

Another way of changing the set point is to set parameter “St” (see the tables below)

8 (4) A

8A 2FLA

12LRA

8 (4) A

8A 2FLA

12LRA

8 (4) A

8A 2FLA

12LRA

DI DI

L

N

L

L

N

N

$8;

12 12

R3

R1

R4

R2

R1 R2 R3 R4

12 (2) A

12A 5FLA

30LRA

EN60730-1

UL 873

-10T60

tLAN interface

SERIAL BOARD & KEY

PROBES

POWER

SUPPLY

CAREL INDUSTRIES HQs

Via dell’Industria, 11 - 35020 Brugine - Padova (Italy)

Tel. (+39) 0499716611 – Fax (+39) 0499716600

http://www.carel.com – e-mail: [email protected]

CmF

H0 Serial address 0 to 207 1 11111

H1 Function of AUX output

0 = Norm. energised alarm output; 1 = Norm. de-

energised alarm output; 2 = Auxiliary output. Activate/

deactivates output by AUX button on keypad; 3 = Light

output; 4 = Auxiliary evap. defrost output; 5 = Pump

down valve output; 6 = Condenser fan output; 7 =

Delayed compressor output; 8 = Auxiliary output with

deactivation in OFF; 9 = Light output with deactivation

in OFF;

10 = No function associated with the output;

11 = Reverse output in control with dead band;

12 = Second comp. step output;

13 = Second comp. step output with rotation

1 33441

H2

Lock keypad and/or remote

control

0 = Set type F par. and set point disabled;

2 = Set type F parameters, settings from remote and set point

disabled; 3 = Settings from remote disabled;

4 = Cont. cycle, defrost, set type F par. and ON/OFF

disabled; 5 = Continuous cycle, defrost, set type F para-

meters, set point and ON/OFF disabled; 6 = Continuous

cycle, defrost, set type F par. and set point disabled

111111

H3 Remote control enable code 0 to 255 0 00000

H4 Terminal buzzer 0: enabled; 1: disabled 0 00000

H6 Lock terminal keypad

1 (0) = enable/disable print report; 2 (1) = enable/

disable defrost; 4 (2) = enable/disable continuous cycle;

8 (3) = enable/disable mute; 16 (4) = enable/disable

HACCP access; 32 (5) = enable/disable AUX output; 64

(6) = enable/disable ON/OFF

000000

H8

Select output activated by

time band

0: time band linked to light output

1: time band linked to AUX (see ‘H1’ or ‘H5’)

000000

H9

Enable set point variation with

time bands

0: set point variation with time band disabled

1: set point variation with time band enabled

000000

Hdh Anti-sweat heater offset

AUX output confi gured as light or AUX (‘H1’= 2, 3, 8

or 9) remains off until the control temp. is less than

‘St’+’Hd’ when fi rst switching on or when resetting

alarms. (-0T200 °C)

000000

HcP

HAn Number of HA alarm events

High temperature alarm (HA). The maximum number of

events counted is 15 (0 to 15)

000000

HA Date/time of the last HA alarm

This parameter accesses the submenu to display the day,

month, year, hours, minutes and duration of the last

alarm HA activated.

------

y_Year 0 to 99 000000

M_ Month 1 to 12 0 00000

d_Day 1 to 7 000000

h_ Hours 0 to 23 0 00000

m_ Minutes 0 to 59 0 00000

t_ Duration 0 to 99 hours 0 00000

HA1

Date/time of second-to-last

HA alarm

This parameter accesses the submenu to display the day,

month, year, hours, minutes and duration of the second-to-

last HA alarm activated.

------

HA2

Date/time of third-to-last

HA alarm

This parameter accesses the submenu to display the day,

month, year, hours, minutes and duration of the third-to-

last HA alarm activated.

------

HFn Number of HF alarm events

High temp. alarm for blackout (HF). The maximum

number of events counted is 15 (0 to 15)

000000

HF Date/time of the last HF alarm

This parameter accesses the submenu to display the day,

month, year, hours, minutes and duration of the last HF

alarm activated.

------

y_Year 0 to 99 000000

M_ Month 1 to 12 0 00000

d_Day 1 to 7 000000

h_ Hours 0 to 23 0 00000

m_ Minutes 0 to 59 0 00000

t_ Duration 0 to 99 hours 0 00000

HF1

Date/time of the second-to-last

HA alarm

This parameter accesses the submenu to display the day,

month, year, hours, minutes and duration of the second-to-

last HA alarm activated.

------

HF2

Date/time of the third-to-last

HA alarm

This parameter accesses the submenu to display the day,

month, year, hours, minutes and duration of the third-to-

last HA alarm activated.

------

Htd HACCP alarm delay Time delay for activation of HA and HF alarm 0 00000

rtc

td1 Defrost time band 1

Defrost setting with RTC for the fi rst time band.When

the display shows parameters td1 to td8, press SET to

set the day, hours and minutes of the defrost for the

selected time band

------

d_ Day

0 = Event disabled; 1,....7 = Monday,...,Sunday;

8 = Monday to Friday; 9 = Monday to Saturday;

10 = Saturday & Sunday; 11 = Every day

000000

h_ Hours 0 to 23

000000

m_ Minutes 0 to 59

000000

td2. ..

td8

Defrost time band 2 to 8

Defrost setting with RTC for the second to eighth time

bands

------

ton

Time band to switch light/

AUX on

Setting to switch light or AUX on with RTC (see par. H8)

When the display shows parameter ton, press SET to set

the ON day, hours and minutes

------

d_ Day

0 = Event disabled; 1,....7 = Monday,...,Sunday;

8 = Monday to Friday

000000

h_ Hours 0 to 23

000000

m_ Minutes 0 to 59 000000

toF

Time band to switch light/

AUX off

Setting to switch light or AUX off with RTC (see par. H8)

When the display shows parameter tof, press SET to set

the OFF day, hours and minutes

------

d_ Day

0 = Event disabled; 1,....7 = Monday,...,Sunday;

8 = Monday to Friday

000000

h_ Hours 0 to 23

000000

m_ Minutes 0 to 59 000000

tc RTC date/time setting

When the display shows parameter tc, press SET to set

the date and time of the RTC clock

------

y_ Year 0 to 99

000000

M_ Month 1 to 12 111111

d_ Day of the month 1 to 31 111111

u_ Day of the week 1 to 7 666666

h_ Hours 0 to 23

000000

m_ Minutes 0 to 59 000000

IMPORTANT WARNING: for the set times to become immediately operational, the instrument needs to be turned off and on

again. If this operation is not carried out, timing resumes operation the next time it is used, when the internal timers are reset.

Alarms and signals: display, buzzer and relay

Below is a table that describes the alarms and control signals, with the corresponding description, status

of the buzzer, alarm relay and type of reset.

Code Description Icon fl ashing

Alarm

relay

Buzzer Reset

rE Virtual control probe fault

ON ON AUTO

E0 Room probe S1 fault

OFF OFF AUTO

E1 Defrost probe S2 fault

OFF OFF AUTO

E2-3 Probe S3-4 fault

OFF OFF AUTO

“___” Probe not enabled - OFF OFF AUTO

LO low temperature alarm

ON ON AUTO

HI high temperature alarm

ON ON AUTO

AFr antifreeze alarm

ON ON MAN

IA immediate alarm from external contact

ON ON AUTO

dA delayed alarm from external contact

ON ON AUTO

dEF defrost running

always on

OFF OFF AUTO

Ed1 defrost on evaporator 1 ended by timeout - OFF OFF AUTO

Ed2 defrost on evaporator 2 ended by timeout - OFF OFF AUTO

Pd maximum pump down time alarm

O N O N AUTO/MAN

LP low pressure alarm

O N O N AUTO/MAN

AtS autostart in pump down

O N O N AUTO/MAN

cht high condenser temperature pre-alarm - OFF OFF AUTO/MAN

CHT high condenser temperature alarm

ON ON MAN

dor door open for too long alarm

ON ON AUTO

Etc real time clock fault

OFF OFF AUTO

EE Unit parameter EEPROM error

OFF OFF AUTO

EF Operating parameter EEPROM error

OFF OFF AUTO

HA HACCP alarm type HA

OFF OFF AUTO

HF HACCP alarm type HF

OFF OFF AUTO

rCt Connection with IR remote control active - - - -

Add Auto. address assignment procedure in progress - - - -

Prt Report printing in progress - - - -

LrH Low relative humidity procedure activation - - - -

HrH High relative humidity procedure activation - - - -

ccb Start continuous cycle call

ccE End continuous cycle call - - - -

dFb Start defrost call - - - -

dFE End defrost call - - - -

On Switched ON - - - -

OFF Switched OFF - - - -

rES Reset alarms with MAN reset, reset temp. monitor. - - - -

n1-n6 Alarm on unit 1-6 in the network

ON ON AUTO

dnL Download procedure in progress - -

d1-d6 Download procedure with errors on unit 1-6

OFF OFF -

Note: the buzzer is activated if enabled by parameter ‘H4’. The alarm relay is activated if auxiliary output 1 (H1) has been

assigned to the alarm relay function (normally closed or open). It can be disabled from the CAREL supervisory system.

Reset alarms with manual reset

All the alarms with man. reset can be reset by pressing “PRG/mute” and “UP/AUX” for more than 5 s.

Operating parameters

Complete list of parameters for each confi guration

frequent parameters ‘F’ psw protected parameters ‘P’ masked parameters (hidden)

Cd. Parameter Description

Confi guration

bn1 bn2 bn3 bn4 bn5 bn6

Pro

/2 Measurement stability 1 to 15 4 4 4 4 4 4

/3 Probe display response Temperature display refresh speed (0 to 15) 0 0 0 0 0 0

/4 Virtual probe Weight % of temp. control probe 2 (0 to 10%)

000000

/5 Select °C or °F 0: °C, 1: °F 0 0 0 0 0 0

/6 Decimal point 0: yes (-20 to 20 °C), 1: no 0 0 0 0 0 0

/tl Display on internal terminal

Probe reading displayed

1: virtual probe; 2: probe 1; 3: probe 2; 4: probe 3; 5:

probe 4; 6: probe 5; 7: set point

222221

/tE Display on external terminal

Probe displayed on remote term.

0: no remote term. ; 1: virtual probe; 2: probe 1; 3: probe 2;

4: probe 3; 5: probe 4; 6: probe 5

000000

/P Select type of probe 0: NTC –50T90 °C; 1: NTC –40T150 °C; 2: PTC –50T150 °C 0 0 0 0 0 0

/A2 Probe 2 confi guration

0: no probe; 1: product probe; 2: defrost probe; 3:

condenser probe; 4: antifreeze probe

022222

/A3 Probe 3 confi guration As for probe 2 (only if A4=0)

000220

/A4 Probe 4 confi guration As for probe 2 (only if A5=0)

000000

/c1 Probe 1 calibration or offset Corr. to probe 1 reading (-20T20 °C) 0 0 0 0 0 0

/c2 Probe 2 calibration or offset Corr. to probe 2 reading (-20T20 °C) 0 00000

/c3 Probe 3 calibration or offset Corr. to probe 3 reading (-20T20 °C)

000000

/c4 Probe 4 calibration or offset Corr. to probe 4 reading (-20T20 °C) 000000

ctl

St Set point r1Tr2 °C 4 2 -14 2 -14 0

rd Control delta Temp. control diff. or hysteresis (0.1T20 °C) 2 2 2 2 2 2

rn Dead zone 0.0T60 °C 444444

rr Reverse control differential +0.1T20 °C

2,0 2,0 2,0 2,0 2,0 2,0

r1 Minimum set point Min. value settable for the set point (-50Tr2 °C) -30 -30 -50 -30 -50 -50

r2 Maximum set point Max. value settable for the set point (r1T200 °C) 30 30 30 30 30 60

r3 Operating mode

0: direct thermostat with defrost control (cool)

1: direct therm. (cool); 2: reverse therm. (heat)

000000

r4

Automatic set point variation in

night-time

Value added to the set point in night-time operation (see

A4, A5 and A9) (-20T20 °C)

3,0 3,0 3,0 3,0 3,0 3,0

r5 Enable temp. monitoring 0: disabled; 1: enabled 0 0 0 0 0 0

rt Temp. monitoring interval temp. recording hours. (0 to 999) - -----

rH Maximum temperature read - -----

rL Minimum temperature read - -----

cmp

c0

Fan start delay (if relay fi tted)

on power-up

0 to 15 min 0 0 0 0 0 0

c1

Minimum time between consecutive

starts of compressor

0 to 15 min 0 0 0 0 0 0

c2 Min. compressor off time 0 to 15 min 0 0 0 0 0 0

c3 Min. compressor on time 0 to 15 min 0 0 0 0 0 0

c4 Duty setting or safety relay

Comp. operating time for control probe fault (Fixed off

time 15 min) (0 to 100 min)

15 15 15 15 15 0

cc Continuous cycle duration

Compressor operating time even when the temp. is

below the set point (0 to 15 hours)

000000

c6

Alarm bypass after continuous

cycle

0 to 250 hours 2 2 2 2 2 2

c7 Max pump down time 0 to 900 s

000000

c9

Enable autostart with pump

down operation

0 = Pump down cycle when closing the valve

1 = Pump down cycle whenever closing the valve and

on each following request from low pressure switch (no

cooling request)

000000

c10

Select pump down by time or

pressure

0 = End pump down by low press. switch activation; 1

= End when reaching low pressure or after maximum

time C7

000000

c11 Second compressor delay

Second compressor delay, after the fi rst, in start-up

(H1=7 or H5=7) (0 to 250 sec)

444444

dEF

d0 Type of defrost

0 = heater by temp. ; 1 = hot gas by temp.;

2 = heater by time; 3 = hot gas by time; 4 = heater by

time with temp. control

200000

dI Interval between defrosts 0 to 250 hours 8 6 6 6 6 8

dt1 Evaporator end defrost temp. -50T200 °C

4 44444

dt2 AUX evap. end defrost temp. -50T200 °C

444444

dP1

Maximum evaporator defrost

duration

1 to 250 min 30 30 30 30 30 30

dP2

Maximum AUX evaporator

defrost duration

1 to 250 min

30 30 30 30 30 30

d3 Defrost activation delay

Interval between defrost call and effective activation

of the relay

000000

d4 Defrost on start-up 0: disabled; 1: enabled 0 0 0 0 0 0

d5

Defrost delay on start-up or from

multifunction input

0 to 250 min 0 0 0 0 0 0

d6 Display during defrost

0 = During defrost the display shows “dEF” and the

actual temperature, alternating; 1 = During defrost the

display shows the last temperature displayed before

starting; 2 = During defrost the display shows “dEF”

on steady

111111

dd Dripping time after defrost

Waiting time before reactivating compressor and fans at

the end of a defrost (0 to 15 min)

022222

d8

Alarm bypass time after defrost

and/or door open

See a4, a5 and a9 (0 to 250 hours) 1 1 1 1 1 1

d8d Door open alarm delay See ‘a4’, ‘a5’ and ‘a9’ (0 to 250 hours)

000000

d9

Defrost priority over compressor

protectors

0 = protection times respected at start of defrost; 1 =

protection times not respected; the defrost has higher

priority

000000

d/1 Display defrost probe 1

- -----

d/2 Display defrost probe 2 °C/°F

------

dC Time base

0: ‘dI’ in hours, ‘dP1’ and ‘dP2’ in min.1: ‘dI’ in minutes

,‘dP1’and ‘dP2’ in seconds

000000

d10 Compressor running time

Compressor operating time with evaporator temp. less

than d11, after which a defrost is called (0 to 250 hours)

000000

d11 Temp. threshold in running time

Evaporation temp. below which the compressor must

continue operating for the time d10 to generate a defrost

call (-20 to 20 °C)

111111

d12 Advanced defrost

0 = Skip defrost and automatic variation in “dl” disabled;

1 = Skip defrost disabled, auto variation in “dl” enabled;

2 = Skip defrost enabled, auto variation in dl disabled; 3

= Skip defrost and automatic variation in “dl” enabled

000000

dn Nominal defrost duration 1 to 100%

65 65 65 65 65 65

dH Prop. factor for variation in “dl” 0 to 100% 50 50 50 50 50 50

ALM

A0 Alarm and fan differential 0.1T20 °C 2,0 2,0 2,0 2,0 2,0 2,0

A1 Type of threshold AL and AH 0: relative; 1: absolute 1 1 1 1 1 0

AL Min. temperature alarm -50T200 °C -30 -30 -50 -30 -50 0

AH Max. temperature alarm -50T200 °C +30 +30 +30 +30 +30 0

Ad Temperature alarm delay 0 to 250 min 30 30 30 30 30 120

ALM

A4 Digital 1 input confi guration

0 = input not active; 1 = Immediate ext. alarm;

2 = delayed external alarm (time A7); 3 = Enable defrost;

4 = Start defrost from ext. contact; 5 = Door switch with

comp. and fans OFF; 6 = remote ON/OFF; 7 = Curtain

switch; 8 = Low press. switch input for pump down; 9 =

Door switch with fans OFF; 10 = Direct / reverse opera-

tion; 11 = Light sensor; 12 = AUX output activation;

13 = Door switch with comp. and fans OFF (light not

managed); 14 = Door switch with fans OFF (light not

managed)

0 55000

A5 Digital 2 input confi guration as for A4

000000

A6

Stop compressor from external

alarm

Forced compressor operating time for external alarms

(0 to 100 min)

000000

A7 External alarm delay If A4= 2, A5= 2 or A9= 2 (0 to 250 min)

000000

A8 Enable alarms Ed1 and Ed2

0 = signal “Ed1” and “Ed2” on display (end defrost due

to maximum duration dP1/dP2) disabled1 = Sign. “Ed1”

and “Ed2” enabled

000000

Ac High condenser temp. alarm 0T200 °C

70 70 70 70 70 70

AE

High condenser temperature

alarm differential

Differential or hysteresis for activation/deactivation of

high cond. temp. pre-alarm (0.1T20 °C)

10 10 10 10 10 10

Acd

High condenser temp. alarm

delay.

0 to 250 min 000000

AF Off time with light sensor

Light sensor management

0 = sensor in the door jamb (the inside light is switched

on when the sensor detects light and off when it detects

darkness

> 0 = sensor inside cold room or cabinet; the inside light

is switched on when the sensor detects light. After the

time AF in seconds the light is switched off for 3 sec to

see if the door has been closed. In the event of darkness

the inside light remains off, the inside light it is switched

on again after a minimum time of 3 sec and the cycle

restarts (0 to 250)

000000

ALF Antifreeze alarm threshold Active if /A2, /A3, /A4 or /A5= 4 (-50T200 °C)

-5 -5 -5 -5 -5 -5

AdF Antifreeze alarm delay 0 to 15 min

111111

FAn

F0 Fan management

0 = Fans always on

1 = Fans on based on difference between control probe

and evaporator temp.

2 = Fans on based on evaporator temp.

000000

F1 Fan start temperature

F0 = 1 - F1 indicates the min. difference between room

and evap. temp. to activate the fans

F0 = 2 - F1 indicates the absolute fan activation temp.

-50T200 °C

5 55555

F2 Fan off with compressor off

0 = Fans always active (F0=0) or upon request (F0=1,2)

even when comp. off

1 = Fans off when compressor off

111111

F3 Fan in defrost

0 = Fans active during defrost

1 = Fans not active during defrost

001011

Fd Fans off after dripping Fan off time after defrost and after dd (0 to 15 min) 0 2 2 2 2 1

F4 Condenser fan stop temperature -50T200 °C

40 40 40 40 40 40

F5 Condenser fan start differential

Differential or hysteresis used for condenser fan control

(0.1T20 °C)

555555

+050001531 - rel. 1.1 del 09.03.2010

Technical specifi cations

Voltage Power

Power supply 115-230 V~, 50/60 Hz 6 VA, 50 mA ~ max.

Insulation guaranteed

by the power supply

insulation from very low

voltage parts

reinforced - 6 mm in air, 8 mm on surface, 3750 V insulation

insulation from relay outputs basic 3 - mm in air, 4 mm on surface, 1250 V insulation

Inputs S1 (probe 1) NTC & PTC

S2 (probe 2) NTC & PTC

DI1

S3 (probe 3)

voltage-free contact, contact resistance <10 , closing current 6 mA

NTC & PTC

DI1

S3 (probe 4)

voltage-free contact, contact resistance <10 , closing current 6 mA

NTC & PTC

Maximum distance of probes and digital inputs less than 10 m

Note: in the installation keep power supply and load connections separate from probe, digital input,

repeater display and supervisor cables.

Type of probe Std. CAREL NTC 10 k at 25 °C, range -50T90 °C

meas. error 1 °C in range -50T50 °C

3 °C in range 50T90 °C

High temperature NTC 50 k at 25 °C, range -40T150 °C

meas. error 1.5 °C in range -20T115 °C

4 °C in range outside of -20T115 °C

Std. CAREL PTC 985 at 25 °C, range -50T150 °C

meas. error 2 °C in range -50T50 °C

4 °C in range 50T150 °C

Relay outputs according to the model

EN60730-1 UL873

relay 250 V~ operating cycles 250 V~ operating cycles

R2, R3, R4 8 (4) A N.O. 100,000 8 A resistive 2 FLA

12 LRA C300

30,000

R1 12 (2) A

N.O./N.C.

100,000 12 A resistive 5 FLA

30 LRA C300

30,000

insulation from very low voltage parts reinforced: 6 mm in air, 8 mm on surface

3750 V insulation

insulation between independent relay outputs basic: 3 mm in air, 4 mm on surface

1250 V insulation

Connections screw terminals for cables from 0.5 to 2.5 mm

2

max current 12 A

The correct sizing of the power and connection cables between the instrument and the loads is the installer’s responsibility. In max.

load and max. operating temp. conditions, the cables used must be suitable for operation at least up to 105 °C.

Case plastic 34.4 x 76.2 x 79 mm (mounting depth 70,5 mm)

Assembly smooth, hard and indeformable panel using side fastening brackets to press in fully

drilling template 28.8 ±0.2 x 76.2 ±0.2 mm

Display digits 3 digit LED

display from -99 to 999

operating status indicated by graphic icons on the display

Keypad 4 silicone rubber buttons

Infrared receiver available

Clock with backup battery available

Auxiliary alarm relay available

Buzzer available

Clock error at 25°C ±10 ppm (±5.3 min/year)

error in the temperature range -50 ppm (-27 min/year)

ageing < ±5 ppm (±2.7 min/year)

discharge time typically 6 months (8 months max)

charge time typically 5 hours (<8 hours max)

Operating conditions -10T60 °C, <90% rH non-condensing

Storage conditions -20T70 °C, <90% rH non-condensing

Front panel index of protection assembly on smooth and indeformable panel with

IP65 gasket

Environmental pollution 2 (normal situation)

PTI of insulating materials printed circuits 250, plastic and insulating materials

17 5

Period of electrical stress across the insulating parts long

Category of resistance to heat and fi re category D and category B (UL 94-V0)

Class of protection against voltage surges category 1I

Type of action/disconnection 1B relay contacts (microswitching)

Construction of the control device built-in, electronic

Classifi cation according to protection against electric shock Class 2 when appropriately integrated

Device designed to he hand-held or integrated into equipment designed

to be hand-held

no

Software class and structure class A

Cleaning the front panel of the instrument only use neutral detergents and water

Serial interface for CAREL network external

Repeater display interface external

Maximum distance between interface and display 10 m

Programming key available

The IR33 range fi tted with the standard CAREL NTC sensor is compliant with standard EN 13485 on thermometers for

measuring the air and product temperature for the transport, storage and distribution of chilled, frozen, deep-frozen/

quick-frozen food and ice cream. Designation of the instrument: EN13485, air, S, A, 1, -50T90°C. The standard CAREL NTC

sensor is identifi able by the printed laser code on “WP” models, or the code “103AT-11” on “HP” models, both visible on

the sensor part.

Safety standards: compliant with the relevant European standards.

Installation warnings:

• the connection cables must guarantee insulation up to 90 °C; and, if necessary, up to 105 °C

• adequately secure the connection cables to the outputs so as to avoid contact with very low voltage components.

Manual defrost

As well as automatic defrost, a manual defrost can be activated, if the temperature conditions are right, by

pressing “DEF/DOWN” for 5 s.

HACCP functions

ir33 is compliant with the HACCP standards, as it monitors the temperature of the food stored. Alarm “HA”= max. th-

reshold exceeded: up to three HA events are saved (HA, HA1, HA2), from the most recent (HA) to the oldest (HA2),

with a signal HAn that displays the number of HA events saved. Alarm “HF”= power failure for more than 1 min.

and max. threshold AH exceeded: up to three HF events are saved (HF, HF1, HF2), from the most recent (HF) to the

oldest (HF2), with a signal HFn that displays the number of HF events saved. Setting the HA/HF alarm: parameter

AH (high temp. threshold); Ad and Htd (Ad + Htd = HACCP alarm delay). Displaying the details: press “SET” to

access parameters HA or HF and scroll using “UP/AUX“ or “DEF/DOWN“. Deleting the HACCP alarms: press “DEF/

DOWN” and “SET” for 5 sec. inside the menu, “res“ will be shown to indicate the alarm has been deleted. To

delete the saved alarms, press “DEF/DOWN“ + “SET” + “UP/AUX” together for 5 seconds.

Defrost event date and day (parameters td1 to td8)

0 = no event; 1 to 7 = Monday to Sunday; 8 = Monday to Friday; 9 = Monday to Saturday; 10 = Saturday

and Sunday; 11 = every day.

How to access and set type “F” parameters (FREQUENT, not protected by

password)

Step Action Effect Meaning

1

Press

for 5 seconds

After 5 seconds the display will show the 1st

parameter, “St” (set point)

Access to type “F” parameters is

direct

2

Press

aux

or

def

The display will scroll the list of type “F”

parameters (FREQUENT) (depends on the

confi guration loaded)

Select the desired parameter

3

Press

Set

The display will show the value of the

selected parameter

This is the current value of the

parameter

4

Press

aux

or

def

The value on the display will increase

or decrease

Set the desired value

5

Press

Set

The display will show the parameter

name again

IMPORTANT: parameters not yet

saved

6

Repeat steps 2, 3, 4 & 5 for all

parameters required

7

Press for 5 seconds

The controller will display the temperatu-

re read by the probes again

IMPORTANT: only now have all the

parameters been updated

How to access and set type “C” parameters (CONFIGURATION, password

protected)

Step Action Effect Meaning

1

Press &

Set

for 5 seconds

After 5 seconds the display shows “0”

Access to type “C” parameters

requires the password

2

Press

aux

or

def

The value on the display will increase

or decrease

Enter the password “22”

3

Press

Set

The display will show the fi rst

parameter in the list (depends on the

confi guration loaded)

The type “C” parameters also

include type “F”

4

Press

aux

or

def

The display will scroll the list of type

“C” parameters (CONFIGURATION)

Select the desired parameter

5

Press

Set

The display will show the value of the

selected parameter

This is the current value of the

parameter

6

Press

aux

or

def

The value on the display will increase

or decrease

Set the desired value

7

Press

Set

The display will show the parameter

name again

IMPORTANT: parameters not yet

saved

8

Repeat steps 4, 5, 6 & 7 for all

parameters required

9

Press

for 5 seconds

The controller will display the tempera-

ture read by the probes again

IMPORTANT: only now have all the

parameters been updated

For both types of access (type “F” and type “C”) there is a timeout (no button on the keypad pressed for

1 min), the procedure is ended without saving the parameter.

Accessing the parameters divided by functional blocks (allows the user

to scroll the list of parameters in blocks)

Once having accessed the type “F” or “C” parameters (see tables above)

Step Action Effect Meaning

1

Press

The display will show the name

of the functional block that the

parameter belongs to

Example ‘CMP’ for the compressor parame-

ters, ‘dEF’ for the defrost parameters

2

Press

aux

or

def

The display will show the name of the

other functional blocks

Example ‘Fan’ for the fan parameters

3

Press

The display will show the name of

the fi rst parameter in the functional

block selected

Example “F0” for ‘Fan’

Disposal of the product

The appliance (or the product) must be disposed of separately in compliance with the local standards in force on waste

disposal

IMPORTANT WARNINGS:The CAREL product is a state-of-the-art device, whose operation is specifi ed in the technical

documentation supplied with the product or can be downloaded, even prior to purchase, from the website www.carel.

com. The customer (manufacturer, developer or installer of the fi nal equipment) accepts all liability and risk relating to the

confi guration of the product in order to reach the expected results in relation to the specifi c fi nal installation and/or equip-

ment. The failure to complete such phase, which is required/indicated in the user manual, may cause the fi nal product to malfunction;

CAREL accepts no liability in such cases. The customer must use the product only in the manner described in the documentation

relating to the product.The liability of CAREL in relation to its products is specifi ed in the CAREL general contract conditions, available

on the website www.carel.com and/or by specifi c agreements with customers.

/