Page is loading ...

Notice d'instructions

Instruction manual

Bedienungsanleitung

Gebruiksaanwijzing

Manual de instrucciones

Istruzioni d'uso

Instrukcja obsługi

Instruçoes

Betjeningsvejledning

Bruksanvisning

NU-E.5000/0902

E.5000

10 -1100 N.m

■

■

■

■

■

■

■

■

■

■

Contrôleur de

couple

Torque tester

Drehmoment-

prüfgeräte

Momentsleuteltester

Medidor de par

Misuratore di

coppia

Controlador de

binario

Momentomierza

Momentmaler

Momenttestare

N

O

CARACTERISTIQUES

- PLAGE DE COUPLE : 10-1100 N.m

- PRECISION :

+

-

1% de la valeur lue

- UNITE : N.m, daN.m, cN.m, kgf.m, lbf.in, lbf.ft

- IMPERMEABILITE : IP5 (EN 60529)

- CONSOMMATION : utilisation 30-50 mA / 230 V - en veille 15 mA / 230 V

- COMPATIBILITÉ ÉLECTROMAGNÉTIQUE 89/336: CEI EN 50081-1 / CEI EN 50082-2

- TEMPERATURE : de stockage -20°C+70°C / en utilisation 0°-50°C

- TENSION D'ALIMENTATION : 115V - 60Hz / 230V - 50Hz

- DERIVE DE SENSIBILITE : 0,02% par °C

- LANGUES : FRANCAIS - ANGLAIS - ALLEMAND - NEERLANDAIS - ESPAGNOL - POLONAIS - PORTUGAIS - DANOIS - SUEDOIS - ITALIEN

LORSQUE LE ZERO CLIGNOTE EN CONTINU, VOUS DEVEZ FAIRE UNE

REMISE A ZERO EN APPUYANT SUR LA TOUCHE R.

LORS DU CHANGEMENT DE SENS DE CONTROLE, L ‘AFFICHEUR

VOUS DEMANDE ‘’RAZ ECRAN’’, C’EST A DIRE UNE REMISE A

ZERO EN APPUYANT SUR LA TOUCHE R.

LORSQUE LE ZERO CLIGNOTE NE PAS APPLIQUER DE COUPLE. ATTENDRE LE ZERO FIXE

OK

STOP NO

AFFICHEUR :

• AFFICHE LE COUPLE

• DE MESURE, LE ZERO FIXE,

• LES ERREURS….

ROUGE : HORS TOLERANCE

TEMOIN

SOUS TENSION

BARREGRAPH

VISUALISATION

ANALOGIQUE

DU COUPLE

INFORMATIONS SUR

LES MODES : TRAVAIL-SEUIL - UNITE - REGLAGE - Etc...

VALIDATION

DES CHOIX

DEFILEMENT

DES

FONCTIONS

REMISE A 0

OK

STOP NO

CHOIX DU MODE

D'UTILISATION

ROUGE : SANS REGLAGE

VERT : DANS TOLERANCE

FR

ATTENTION

- LORS DE LA PREMIERE MISE EN SERVICE, VOUS AVEZ LE CHOIX DE LA LANGUE AVEC LA POSSIBILITE DE LA CHANGER DANS LE MODE SEUIL

DECRIT CI-APRES.

- APRES 5 mn D’INACTIVITE, L’APPAREIL SE MET HORS SERVICE. IL SUFFIT D’APPUYER SUR UNE TOUCHE POUR L’ACTIVER.

CETTE MISE HORS SERVICE AUTOMATIQUE PERMET LA STABILITE THERMIQUE, SANS RISQUE POUR LE E.5000.

- TENIR CET APPAREIL PROPRE (Poussière, humidité, limaille ou tout autre agent corrosif)

- SEULS LES ADAPTATEURS FACOM DOIVENT ÊTRE UTILISES SUR L’APPAREIL TORKONTROL E.5000, A L’EXCLUSION DE TOUT AUTRE SYSTEME.

CES MEMES ADAPTATEURS NE SONT PAS UTILISABLES SUR UN AUTRE CONTROLEUR DE COUPLE.

- L'AJUSTEMENT PRÉCIS ADAPTATEURS/CAPTEUR INTERDIT TOUTES DÉFORMATION ET MARQUE. LA PROPRETÉ DU COUPLE ADAPTATEUR/

CAPTEUR EST GAGE D'UN SERVICE ÉFFICACE ET DURABLE.

- SI L'APPAREIL NE FONCTIONNE PAS DÈS LA MISE SOUS TENSION, VÉRIFIER L'ALIMENTATION SECTEUR, LE CÂBLE AINSI QUE LE FUSIBLE

AVANT LE RETOUR DU E.5000 AU SAV QU'IL SOIT SOUS OU HORS GARANTIE.

- LA BATTERIE EST EXCLUE DE LA GARANTIE.

------AUTOTEST OK------

MISE EN ROUTE DU E.5000

METHODES DU MODE TRAVAIL

MODE SEUIL MODE TRAVAIL

5 sec.

M

OK

MEMOISO SUIVEUR CRETE

M

MODE MEMOIRE

LANGUE

ANGLAIS

FRANCAIS

ALLEMAND

NEERLANDAIS

ESPAGNOL

POLONAIS

PORTUGAIS

DANOIS

SUEDOIS

ITALIEN

daN.m

Ibf.ft

Ibf.in

Kgf.m

cN.m

N.m

ACTIVÉ

DESACTIVÉ

BLOQUÉ

ACTIVÉ

DESACTIVÉ

DATE

HORLOGE

SIGNAL SONORE

PC/IMPRIMANTE

UNITÉ

SIGNAL

MÉMOIRE

REGLAGE

M

M

M

M

M

RAZ AUTO ? OUI

REGLER LE TEMPS D'AFFICHAGE

(REGLAGE DE 1 À 20 SECONDES)

ACTIVE

OK OK

ACTIVÉ

DESACTIVÉ

OK

BLOQUÉ

OK

SELECTION DE LA

VALEUR DU COUPLE

MODE

OPERATOIRE

OK

STANDARD

EXPERT

M

R

R

R

R

CONFIGURATION

R

OK

M

R

RAZ AUTO ? NON

OK

UTILISATION SUR TOUTE

LA PLAGE DU E.5000

SANS CONTROLE DE LA

TOLERANCE

SELECTION DE LA VALEUR

DU COUPLE ET DE LA

TOLERANCE DANS LE

MODE TRAVAIL

OK

OK

SELECTION DE LA

TOLERANCE

GB

N

O

CHARACTERISTICS

- TORQUE RANGE: 10-1100 N.m

- ACCURACY: ± 1% of the figure read

- UNIT: N.m, daN.m, cN.m, kgf.m, lbf.in, lbf.ft

- IMPERMEABILITY: IP5 (EN 60529)

- CONSUMPTION: use 30-50mA / 230V - on standby 15mA / 230V

- ELECTROMAGNETIC COMPATIBILITY 89/336: CEI EN 50081-1 / CEI EN 50082-2

- TEMPERATURE: storage - 20°C + 70°C / in use 0° to 50°C

- SUPPLY VOLTAGE: 115V - 60Hz / 230V - 50Hz

- SENSITIVITY DRIFT: 0.02% per °C

- LANGUAGES: FRENCH, ENGLISH, GERMAN, DUTCH, SPANISH, POLISH, PORTUGUESE, DANISH, SWEDISH, ITALIAN

WHEN ZERO FLASHES CONTINUOUSLY, A RESET MUST BE MADE BY

PRESSING THE R KEY.

WHEN CHANGING THE CONTROL DIRECTION, THE DISPLAY SCREEN

REQUESTS "SCREEN RESET", WHICH MEANS RESET TO ZERO BY

PRESSING THE R KEY.

WHILE THE ZERO IS FLASHING, DO NOT APPLY TORQUE. WAIT UNTIL THE ZERO STOPS FLASHING

OK

STOP NO

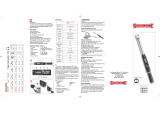

DISPLAY:

• DISPLAYS TORQUE

• MEASUREMENT, STEADY ZERO,

• ERRORS...

RED: OUT OF TOLERANCE

INDICATOR

ON

BAR GRAPH

ANALOG

VISUALIZATION

OF TORQUE

INFORMATION REGARDING

MODES: WORK - SETTING - UNIT - ADJUSTMENT - Etc.

VALIDATION

OF CHOICES

SCROLLING

OF

FUNCTIONS

RESET to 0

OK

STOP NO

CHOICE OF USE

MODE

RED: WITHOUT ADJUSTMENT

GREEN: IN TOLERANCE

WARNING

- AT THE TIME OF THE FIRST COMMISSIONING, YOU HAVE A CHOICE OF LANGUAGE WITH THE POSSIBILITY OF CHANGING IT IN THE

SETTING MODE DESCRIBED HEREAFTER.

- AFTER 5 MINUTES OF INACTIVITY, THE APPARATUS SWITCHES OFF. SIMPLY PRESS ANY KEY TO ENABLE IT. THIS AUTOMATIC CUT-OFF

FACILITATES THERMAL STABILITY, WITHOUT RISK FOR THE E.5000.

- KEEP THIS APPARATUS CLEAN (Dust, moisture, filings or any other corrosive agent)

- ONLY THE FACOM ADAPTERS MUST BE USED ON THE TORKONTROL E.5000 APPARATUS, EXCLUDING ANY OTHER SYSTEM. THESE SAME

ADAPTERS CANNOT BE USED ON ANOTHER TORQUE TESTER.

- THE PRECISE ADAPTERS / SENSOR ADJUSTMENTS PROHIBITS ANY DEFORMATION AND MAKE. THE CLEANLINESS OF THE ADAPTER/SENSOR

TORQUE IS PROOF OF EFFICIENT AND SUSTAINABLE SERVICE.

- IF THE APPARATUS DOES NOT WORK AS SOON AS IT IS SWITCHED ON, CHECK THE MAINS SUPPLY, THE CABLE AS WELL AS THE FUSE

BEFORE RETURNING THE E.5000 TO AFTER-SALES WHETHER IT BE UNDER GUARANTEE OR NOT.

- THE BATTERY IS NOT INCLUDED IN THE GUARANTEE.

Makes a change of mode by pressing on for 5 sec. and then on (work mode/setting mode)

Makes a change of menu

Makes a move in the menu, in order to choose the function to be used

Validates the function in progress

Makes the reset

Indicator for voltage supply

ISO MODE: in tolerance

HOLD MODE: in tolerance

PEAK MODE: in tolerance

ISO MODE: not applicable

HOLD MODE: acquisition value

PEAK MODE: acquisition value

ISO MODE: Out of tolerance

HOLD MODE: Out of tolerance

PEAK MODE: Out of tolerance

Progress of the torque

Displays the torque value

GENERAL DESCRIPTION

USE.

1• USE THE SETTING MODE TO MAKE THE FOLLOWING ADJUSTMENTS:

- LANGUAGE:

( ADJUST THE READING TO:

FRENCH - ENGLISH - GERMAN - DUTCH - SPANISH - POLISH - PORTUGUESE - DANISH - SWEDISH - ITALIAN ).

- UNIT:

( ADJUST THE UNIT DEPENDING ON THE WRENCH USED: (N.m, daN.m, cN .m, kgf.m, lbf.ft, lbf.in).

- SIGNAL:

( ADJUST THE TORQUE VALUE TO BE CHECKED AS WELL AS THE TOLERANCE FOR THE PEAK-HOLD METHODS ONLY

3 SIGNAL POSITIONS POSSIBLE: ENABLE, DISABLE or LOCKED (see following page).

- MEMORY:

( 1 ) ENABLE OR DISABLE MEMORIZATION OF TORQUE MEASUREMENTS DISPLAYED AS WELL AS ENABLE OR DISABLE THE

MEMORY MODE (see following page).

( 2 ) ADJUST DISPLAY WAITING TIME BETWEEN 1 AND 20 SECONDS IF THE MEMORIZATION IS ENABLED.

- ADJUSTMENT:

( CARRY OUT THE FOLLOWING ADJUSTMENTS:

DATE CLOCK SOUND SIGNAL PC/PRINTER CONFIGURATION

DATE: DAY CLOCK: HOURS LOW VOLUME PC OUTPUT EXPERT*

DATE: MONTH CLOCK: MINUTES HIGH VOLUME HP PRINTER STANDARD*

DATE: YEAR NO VOLUME CANON PRINTER

EPSON PRINTER

*EXPERT: This configuration is used with the E.5000 apparatus assembled on a control bench and mechanical application of the torque. In this case, sensitivity of the apparatus is

increased and it is possible to print out an information report on the E.5000.

*STANDARD: This configuration is used with the apparatus assembled on a workbench and manual application of the torque.

2•

SELECT THE CONTROL METHOD OF TORQUE WRENCHES IN WORK MODE:

ISO METHOD PEAK METHOD

The ISO and PEAK methods are exclusively reserved for automatic torque setting and resetting wrenches. HOLD METHOD

TRACKER METHOD

TRACKER METHOD: In the WORK mode, select TRACKER method, validate with OK, wait for steady zero, position the wrench and exert the torque.

ISO METHOD: (do not carry out control in ISO mode for a wrench whose maximum value is lower than 50 N.m)

The ISO method facilitates carrying out checks over the whole operating range of the wrench - these controls are carried out in 3 stages:

BEFORE CARRYING OUT THE 3 CONTROL STAGES, IT IS ESSENTIAL TO ADJUST THE MAXIMUM CAPACITY OF THE WRENCH IN ISO MODE AS WELL AS THE

WRENCH TOLERANCE.

• Carry out 5 torque settings of the wrench at maximum capacity.

• 1

st

stage is made at 20% capacity of the torque wrench followed by 5 successive tests.

• 2

nd

stage is made at 60% capacity of the torque wrench followed by 5 successive tests.

• 3

rd

stage is made at 100% capacity of the torque wrench followed by 5 successive tests.

In other words, a total of 15 checks with the possibility of printing out a test report immediately after the end of the test, or later in MEMORY MODE if the E.5000 is

connected to a printer.

• After each test, memorize the value by pressing OK or delete a figure following an operating error by pressing R.

USE: HOLD

AND PEAK METHODS. ( the display method is different from one mode to another )

• The PEAK, HOLD or TRACKER method facilitates making an accurate and rapid check of the torque wrench. Just display in the SETTING mode, the SIGNAL

menu and ENABLE it to enter the measured torque and the tolerance, in order to carry out the control.

To check the torque, return to WORK mode, display the PEAK, HOLD or TRACKER mode, validate with OK, wait for the steady zero on the display and position

the wrench in order to exert the torque.

DISPLAY METHOD: ISO, PEAK, HOLD OR TRACKER DEPENDS ON THE WRENCH USED. ( see equivalence chart ).

- the torque can be displayed positive or negative depending on direction (tightening or untightening).

OK

STOP NO

VERT

OK

ROUGE

NO

ROUGE

STOP

Reading of the Display Screen.

------AUTOTEST OK------

START-UP OF THE E.5000

METHOD : WORK MODE

SETTING MODE WORK MODE

5 sec.

M

OK

HOLDISO TRACKER PEAK

M

MEMORY MODE

LANGUAGE

ENGLISH

FRENCH

GERMAN

DUTCH

SPANISH

POLE

PORTUGUESE

DANISH

SWEDE

ITALIAN

daN.m

Ibf.ft

Ibf.in

Kgf.m

cN.m

N.m

ENABLED

DISABLED

LOCKED

ENABLED

DISABLED

DATE

CLOCK

SOUND

PC/PRINTER

USED UNIT

SIGNALING

MEMORY

BASIC

SETTING

M

M

M

M

M

AUT. RUECKS.? JA

ADJUST DISPLAY TIME

(ADJUSTMENT 1 to 20 SECONDS)

ENABLED

OK OK

ENABLED

DISABLE

OK

LOCKED

OK

SELECTION OF THE

TORQUE VALUE

OPERATIVE

MODE

OK

STANDARD

EXPERT

M

R

R

R

R

KONFIGURATION

R

OK

M

R

AUT. RUECKS.? NEIN

OK

USE OVER THE WHOLE

RANGE OF THE E.5000

WITHOUT CONTROL

OF THE TOLERANCE

SELECTION OF THE

TORQUE VALUE AND

TOLERANCE IN THE

WORK MODE

OK

OK

SELECTION OF

TOLERANCE

NL

N

O

TECHNISCHE EIGENSCHAPPEN

- BEREIK VAN DRAAIMOMENT: 10-1100 N.m

- PRECISIE: ± 1% van de afgelezen waarde

- EENHEID: N.m, daN.m, cNm, kgf.m, Ibf.in, Ibf.ft

- LUCHTDICHTHEID: IP5 (EN 60529)

- VERBRUIK: in bedrijf 30-50 mA / 230 V - in stand-by 15 mA / 230 V

- ELEKTROMAGNETISCH COMPATIBILITEIT 89/336: GOS EN 50081-1 / GOS EN 50082-2

- TEMPERATUUR: opslag -20°C+70°C / in bedrijf 0°-50°C

- VOEDINGSSPANNING: 115V - 60Hz / 230V - 50Hz

- GEVOELIGHEIDSAFWIJKING: 0,02% per °C

- TALEN: FRANS - ENGELS - DUITS - NEDERLANDS - SPAANS - POOLS - PORTUGEES - DEENS - ZWEEDS - ITALIAANS

ALS DE NUL CONTINU KNIPPERT, MOET U EEN RESET UITVOEREN

DOOR DE TOETS R IN TE DRUKKEN.

ALS U DE CONTROLERICHTING VERANDERT, VRAAG HET DISPLAY

OM EEN "DISPLAY RESET", D.W.Z EEN RESET DOOR TOETS R IN TE

DRUKKEN.

WACHT TOTDAT DE NUL NIET LANGER KNIPPERT. WACHT OP DE CONTINUE NUL

OK

STOP NO

DISPLAY:

• WEERGAVE VAN HET

• GEMETEN DRAAIMOMENT,

CONTINUE NUL,

• FOUTEN....

ROOD: BUITEN TOLERANTIE

CONTROLELAMPJE

AAN

STATUSBALK

ANALOGISCHE

WEERGAVE

DRAAIMOMENT

INFORMATIE OVER

DE METHODEN WERK - INSTELLINGEN - EENHEID - INSTELLEN - enz...

KEUZEBEVESTIGING

FUNCTIES

SCROLLEN

RESET

OK

STOP NO

DE WERKWIJZE

KIEZEN

ROOD: ZONDER AFSTELLING

GROEN: BINNEN TOLERANTIE

LET OP

- BIJ DE EERSTE INWERKINGSTELLING, KUNT U DE TAAL KIEZEN EN WIJZIGEN MET DE HIERONDER BESCHREVEN FUNCTIE INSTELLINGEN.

- NA EEN LEEGLOOP van 5 minuten WORDT HET APPARAAT UITGESCHAKELD. U HOEFT SLECHTS EEN WILLEKEURIGE TOETS IN TE DRUKKEN OM

HET TE ACTIVEREN. HET UITSCHAKELEN VAN HET APPARAAT IS VOOR DE THERMISCHE STABILITEIT, ZODAT ER GEEN GEVAAR IS VOOR DE E.5000.

- HET APPARAAT SCHOON HOUDEN (stof, vocht, vijlsel of ander corrosief materiaal)

- ER MOGEN ALLEEN FACOM ADAPTERS WORDEN GEBRUIKT VOOR DE TORKONTROL E.5000, MET UITSLUITING VAN ALLE ANDERE

SYSTEMEN. DEZE ADAPTERS ZIJN NIET BRUIKBAAR OP ANDERE MOMENTSLEUTELTESTERS.

- DE FIJNAFSTELLING VAN ADAPTERS/OPNEMER TOLEREERT GEEN VERVORMING EN ANDERE MERKEN. DE PROPERHEID VAN DE ADAPTER/

OPNEMER IS EEN GARANTIE VOOR EEN EFFICIËNTE DUURZAME WERKING.

- ALS HET APPARAAT NIET FUNCTIONEERT NA HET AANSCHAKELEN, CONTROLEERT U DE NETSPANNING, DE KABEL EN DE ZEKERING

VÓÓRDAT U DE .5000 AAN DE KLANTENSERVICE RETOURNEERT, ONGEACHT OF HET APPARAAT ONDER GARANTIE STAAT.

- ER STAAT GEEN GARANTIE OP DE ACCU.

------AUTOTEST OK------

INBEDRIJFNEMING VAN DE E.5000

METHODE : WERKFUNCTIE

INSTELFUNCTIE WERKFUNCTIE

5 sec.

M

OK

MEMOISO

VOLGER

PIEK

M

GEHEUGENFUNCTIE

TAAL

ITALIAANS

ENGELS

FRANS

DUITS

NEDERLANDS

SPAANS

POOLS

PORTUGEES

DEENS

ZWEEDS

daN.m

Ibf.ft

Ibf.in

Kgf.m

cN.m

N.m

ACTIEF

INACTIEF

BLOKKEREN

ACTIEF

INACTIEF

DATUM

KLOK

SGELUIDSSIGNAAL

PC / PRINTER

EENHEID

SIGNALERING

GEHEUGEN

BASISIN-

STELLING

M

M

M

M

M

AUTO RESET ? JA

DE WEERGAVETIJD INSTELLEN

(INSTELLEN VAN 1 TOT 20 SEC.)

ACTIEF

OK OK

ACTIEF

INACTIEF

OK

BLOKKEREN

OK

DE WAARDE VAN HET

DRAAIMOMENT

WERKWIJZE

OK

STANDAARD

EXPERT

M

R

R

R

R

CONFIGURAZIONE

R

OK

M

R

AUTO RESET ?NEE

OK

GEBRUIK OVER HET HELE

BEREIK VAN DE E.5000

ZONDER DE TOLERANTIE

TE CONTROLEREN

DE WAARDE VAN HET

DRAAIMOMENT EN DE

TOLERANTIE KIEZEN IN

DE FUNCTIE WERK

OK

OK

SDE WAARDE

DE TOLERANTIE

------AUTOTEST OK------

PUESTA EN MARCHA DEL E.5000

MODO : MODO TRABAJO

MODO AJUSTES MODO TRABAJO

5 sec.

M

OK

MEMOISO SEGUIM CRESTA

M

MODO MEMORIA

IDIOMA

ITALIANO

INGLES

FRANCES

ALEMAN

HOLANDES

ESPAÑOL

POLACO

PORTUGES

DANES

SUECO

daN.m

Ibf.ft

Ibf.in

Kgf.m

cN.m

N.m

ACTIVADAS

DESACTIVADAS

BLOQUEAR

ACTIVADAS

DESACTIVADAS

FECHA

RELOJ

SONIDO

PC / IMPRESOR

UNITÉ

SEÑALES

MEMORIA

REGLAJES

M

M

M

M

M

¿AJUSTE AUTO?SI

AJUSTAR EL TIEMPO DE

VISUALIZACIÓN (AJUSTE DE 1

A 20 SEGUNDOS)

ACTIVADAS

OK OK

ACTIVADAS

DESACTIVADAS

OK

BLOQUEAR

OK

SELECCIÓN DEL

VALOR DEL PAR

MODO

OPERATIVO

OK

ESTANDAR

AVANZADO

M

R

R

R

R

CONFIGURACION

R

OK

M

R

¿AJUSTE AUTO?NO

OK

USO EN TODA LA GAMA

DEL E.5000 SIN

CONTROLAR LA

TOLERANCIA

SELECCIÓN DEL VALOR

DEL PAR Y DE LA

TOLERANCIA EN EL

MODO DE TRABAJO

OK

OK

SELECCIÓN DE LA

TOLERANCIA

------AUTOTEST OK------

ATTIVAZIONE DELL’E.5000

METODO : MODO LAVORO

MODO SETTAGGI MODO LAVORO

5 sec.

M

OK

MEMOISO NORM PICCO

M

MODO MEMORIA

LINGUA

INGLESE

FRANCESE

TEDESCO

OLANDESE

SPAGNOLO

POLACCO

PORTOGHESE

DANESE

SVEDESE

ITALIANO

daN.m

Ibf.ft

Ibf.in

Kgf.m

cN.m

N.m

ATTIVATE

DISATTIVATE

BLOCCATE

ATTIVATE

DISATTIVATE

DATA

ORA

SUONO

PC/STAMPANTE

UNITA'

SEGNALAZIONI

MEMORIA

SETTAGGI

BASE

M

M

M

M

M

AUTOZERO ? SI

REGOLAZIONE DEL TEMPO

DI VISUALIZZAZIONE

(REGOLAZIONE DA 1 A 20 SEC.)

ATTIVATE

OK OK

ATTIVATE

DISATTIVATE

OK

BLOCCATE

OK

SELEZIONE DEL

VALORE DELLA COPPIA

MODO

OPERATIVO

OK

STANDARD

EXPERT

M

R

R

R

R

CONFIGURAZIONE

R

OK

M

R

AUTOZERO ? NO

OK

USO SU TUTTA

L’INTERVALLO

DELL’E.5000 SENZA

CONTROLLO DELLA

TOLLERANZA

SELEZIONE DEL VALORE

DELLA COPPIA E DELLA

TOLLERANZA NEL MODO

LAVORO

OK

OK

SELEZIONET

DELLA TOLLERANZA

PL

N

O

CECHY CHARAKTERYSTYCZNE

- ZAKRES MOMENTU: 10 - 1100 N.m

- DOK¸ADNOå:

±±

±±

±

1% odczytanej wartoÊci

- JEDNOSTKA: N.m, daN.m, cN.m, kgf.m, lbf.in, lbf.ft

- NIEPRZEPUSZCZALNOå: IPS (EN 60529)

- POBÓR MOCY: u˝ytkowanie 30-50 mA / 230 V – stan oczekiwania 15 mA / 230 V

- KOMPATYBILNOå ELEKTROMAGNETYCZNA 89 / 336: CEI EN 50081-1 / CEI EN 50082-2

- TEMPERATURA: przechowywania –20°C + 70°C / u˝ytkowania 0° - 50°C

- NAPI¢CIE ZASILAJÑCE: 115 V – 60 Hz / 230 V – 50 Hz

- ODCHYLENIE CZU¸OCI: 0,02% na °C

- J¢ZYKI: FRANCUSKI - ANGIELSKI - NIEMIECKI - HOLENDERSKI - HISZA¡SKI - POLSKI - POTUGALSKI - DU¡SKI - SZWEDZKI - W¸OSKI

JE˚ELI ZNAK ZERO MIGA W SPOSÓB CIÑG¸Y, NALE˚Y

WYKONAå ZEROWANIE NACISKAJÑC KLAWISZ R.

PRZY ZMIANIE KIERUNKU KONTROLI, NA WYWIETLACZU

ZOSTAJE WYWIETLONY KOMUNIKAT Z PROBÑ O

„ZEROWANIE EKRANU”, TZN. NALE˚Y WYKONAå

ZEROWANIE PRZEZ NACINI¢CIE KLAWISZA R.

NIE NALE˚Y PRZYK¸ADAå MOMENTU GDY ZNAK ZERO MIGA. CZEKAå GDY ZNAK ZERO B¢DZIE NIERUCHOMY

OK

STOP NO

WYWIETLACZ:

• WYWIETLANIE MOMENTU

• POMIAR, ZNAK ZERO

NIERUCHOM,

• B¸¢DY...

CZERWONY: BEZ REGULACJI

WSKAèNIK

W¸ÑCZENIA POD

NAPI¢CIE

WYKRES KRESKOWY

ANALOGOWEGO

WYWIETLANIA

MOMENTU

INFORMACJE O

TRYBACH: PRACA-PRÓG - JEDNOSTKA - REGULACJA - Itd...

POTWIERDZENIE

WYBORU

WYBIERANIE

FUNKCJI

ZEROWANIE

OK

STOP NO

WYBÓR TRYBU

U˚YTKOWANIA

CZERWONY: POZA TOLERANCJÑ

ZIELONY: W TOLERANCJI

UWAGA

- PODCZAS PIERWSZEGO URUCHOMIENIA, MO˚NA WYBRAå J¢ZYK W TRYBIE PRÓG OPISANYM PONI˚EJ.

- PO UP¸YWIE 5 min NIEU˚YTKOWANIA, URZÑDZENIE WY¸ÑCZA SI¢. ABY GO W¸ÑCZYå, WYSTARCZY NACISNÑå

DOWOLNY KLAWISZ. TEGO RODZAJU AUTOMATYCZNE WY¸ÑCZENIE POZWALA ZACHOWAå STABILNOå CIEPLNÑ

BEZ NIEBEZPIECZE¡STWA DLA E.5000.

- UTRZYMYWAå URZÑDZENIE W CZYSTOCI (Py∏, wilgotnoÊç, opi∏ki lub inny czynnik korozyjny).

- Z URZÑDZENIEM TORKONTROL E.5000, NALE˚Y U˚YWAå WY¸ÑCZNIE ¸ÑCZNIKI FACOM. ¸ÑCZNIKÓW

U˚YWANYCH Z TYM URZÑDZENIEM NIE NALE˚Y U˚YWAå Z INNYM PRZYRZÑDEM DO KONTROLI MOMENTU.

- DOK¸ADNE USTAWIENIE ¸ÑCZNIKÓW/CZUJNIKÓW ZAPOBIEGA DEFORMACJOM I ZNAKOWANIOM. UTRZYMANIE

¸ÑCZNIKA/CZUJNIKA W CZYSTOCI STANOWI GWARANCJ¢ TRWA¸EJ I SKUTECZNEJ PRACY.

- JE˚ELI URZÑDZENIE NIE DZIA¸A PO W¸ÑCZENIU NAPI¢CIA, SPRAWDZIå ZASILANIE SIECI, KABEL ORAZ

BEZPIECZNIK PRZED ODDANIEM E5000 DO SERWISU PO SPRZEDA˚Y NIEZALE˚NIE OD TEGO CZY URZÑDZENIE

POSIADA, LUB NIE POSIADA GWARANCJI.

- BATERIA NIE JEST OBJ¢TA GWARANCJÑ.

------AUTOTEST OK------

URUCHOMIENIE URZĄDZENIA E.5000

Metoda : TRYB PRACY

TRYB USTAWIANIA

TRYB PRACY

5 sek.

M

OK

PAMIĘCI

ISO

CIEŻKOWA SZCZYTU

M

TRYB PAMIĘCI

JĘZYK

STOSOWANY

WŁOSKI

ANGIELSKI

FRANCUSKI

NIEMIECKI

HOLENDERSKI

HISZPAŃSKI

POLSKI

PORTUGALSKI

DUŃSKI

SZWEDZKI

daN.m

Ibf.ft

Ibf.in

Kgf.m

cN.m

N.m

WŁĄ CZONE

WYŁĄCZONE

ZABLOKOWANE

WŁĄ CZONE

WYŁĄCZONE

DATA

GODZINA

DŹWIĘK

PC / DRUKARKA

JEDN.

SYGNALIZACJE

PAMIEĆ

USTAW.

BAZOWE

M

M

M

M

M

SAMOZER. ? TAK

REGULOWAĆ CZAS WYWIETLANIA

(REGULACJA OD 1 DO 20 SEK.)

WŁĄ CZONE

OK OK

WŁĄ CZONE

WYŁĄCZONE

OK

ZABLO-

KOWAN

E

OK

WYBÓR WARTOCI

MOMENTU

TRYB

OPERACYJNY

OK

STANDARDOWY

ZAAWANS.

M

R

R

R

R

KONFIGURACJA

R

OK

M

R

SAMOZER.? NIE

OK

UŻYTKOWANIE

URZĄDZENIA E.5000 W

PEŁNYM ZAKRESIE BEZ

KONTROLI TOLERANCJI

WYBÓR WARTOCI

MOMENTU I TOLERANCJI

W TRYBIE PRACY

OK

OK

WYBÓR

TOLERANCJI

------AUTOTEST OK------

INICIALIZAÇÃO DO E.5000 FACOM

MÉTODO : MODO TRABALHO

MODO AJUSTE MODO TRABALHO

5 sec.

M

OK

MEMOISO

SEGUIDOR

PICO

M

MODO MEMÓRIA

IDIOMA

ITALIANO

INGLÊS

FRANCÊS

ALEMÃO

HOLANDÊS

ESPANHOL

POLONÊS

PORTUGUÊS

DINAMARQUÊS

SUECO

daN.m

Ibf.ft

Ibf.in

Kgf.m

cN.m

N.m

ACTIVADA

DESACTIVADA

BLOQUEADA

ACTIVADA

DESACTIVADA

DATA

HORA

SOM

PC /IMPRESSORA

UNID.

SINAL

MEMÓRIA

AJUSTES

BÁSICOS

M

M

M

M

M

AUTO-AJUSTE ? SIM

AJUSTAR O TEMPO DE EXIBIÇÃO

(AJUSTE DE 1 A 20 SEGUNDOS)

ACTIVADA

OK OK

ACTIVADA

DESACTIVADA

OK

BLOQUEADA

OK

SELECÇÃO DO VALOR

DO BINÁRIO

MODO

OPERATIVO

OK

STANDARD

AVANÇADO

M

R

R

R

R

CONFIGURAÇÃO

R

OK

M

R

AUTO-AJUSTE ? NÂO

OK

UTILIZAÇÃO EM TODA A

FAIXA DO E.5000 SEM

CONTROLO DA

TOLERNCIA.

SELECÇÃO DO VALOR DO

BINÁRIO E DA TOLERNCIA

NO MODO TRABALHO.

OK

OK

SELECÇÃO

DA TOLERNCIA

------AUTOTEST OK------

START AF E.5000

METODE : ARBEJDSFUNKT .

INDST. FUNK . ARBEJDSFUNKT .

5 sek.

M

OK

MEMOISO SPOR PEAK

M

MEMORY FUNKT .

SPROG

ITALIENSK

ENGELSK

FRANSK

TYSK

HOLLANDSK

SPANSK

POLSK

PORTUGISISK

DANSK

SVENSK

daN.m

Ibf.ft

Ibf.in

Kgf.m

cN.m

N.m

AKTIVEREDE

FRAKOBLEDE

BLOKERE

AKTIVEREDE

FRAKOBLEDE

DATO

UR

LYDSIGNAL

PC / PRINTER

ENHED

SIGNALERINGER

HUKOMMELSE

BASISIND-

STILLING

M

M

M

M

M

AUT . NULST. ? JA

INDSTIL VISNINGSTIDEN

(INDSTILLING FRA 1 TIL 20 SEK.)

AKTIVEREDE

OK OK

AKTIVEREDE

FRAKOBLEDE

OK

BLOKERE

OK

VALG AF MOMENTETS

VÆRDI

DRIFTSFUNKTION

OK

STD

AVANCERET

M

R

R

R

R

KONFIGURATION

R

OK

M

R

AUT. NULST. ? NEJ

OK

BRUGEN AF HELE OMRÅ

DET FOR E.5000 UDEN

KONTROL AF TOLERANCE

VALG AF MOMENTETS

VÆRDI OG AF TOLERANCEN

I DRIFTSMÅDEN

ARBEJDSFUNKTION.

OK

OK

VALG AF

TOLERANCEN

SW

N

O

SÄRSKILDA EGENSKAPER

- MOMENTOMRÅDE: 10 - 1100 N.m

- NOGGRANNHET: ± 1% av avläst värde

- ENHET: Nm, daNm, cNm, kgf.m, lbf.in, lbf.ft

- OGENOMTRÄNGLIGHET: IP5 (EN 60529)

- EFFEKTBEHOV: användning 30-50 mA / 230 V – i beredskapsläge 15 mA / 230 V

- ELEKTROMAGNETISK KOMPATIBILITET 89/336: IEC EN 50081-1 / IEC EN 50082-2

- TEMPERATUR: vid förvaring -20 °C + 70 °C / vid användning 0° - 50 °C

- MATARSPÄNNING: 115V - 60Hz / 230V - 50Hz

- KÄNSLIGHETSDERIVAT: 0,02% per °C

- SPRÅK: FRANSKA - ENGELSKA - TYSKA - NEDERLÄNDSKA - SPANSKA - POLSKA - PORTUGISISKA - DANSKA - SVENSKA - ITALIENSKA

NÄR NOLLAN BLINKAR OAVBRUTET, MÅSTE APPARATEN

NOLLSTÄLLAS GENOM INTRYCKNING PÅ R TANGENTEN.

VID BYTE AV STYRRIKTNINGEN, FRÅGAR BILDENHETEN ‘’NOLLST.

DISPLAY’’, DVS. EN NOLLSTÄLLNING GENOM INTRYCKNING PÅ

R-TANGENTEN.

MEDAN NOLLAN BLINKAR ÄR DET INTE TILLÅTET ATT MOMENTDRA. VÄNTA TILLS EN FAST NOLLA TRÄDER FRAM PÅ DISPLAYEN

OK

STOP NO

DISPLAY:

• VISAR UPPMÄTT

• MOMENT, FAST NOLLA,

• FELEN ….

RÖD: UTANFÖR TOLERANS

INDIKERING AV

SPÄNNINGSSÄTTNING

STAPELDIAGRAM

ANALOG

MOMENTVISNING

UPPGIFTER OM

FUNKTIONERNA: ARBETE-INSTÄLLNINGAR - ENHET - REGLERING - osv.

VALIDERING

AV VALEN

BLÄDDRA I

FUNKTIONERNA

NOLLSTÄLLNING

OK

STOP NO

VAL AV

ANVÄNDNINGSLÄGE

RÖD: UTAN INSTÄLLNING

GRÖN: INOM TOLERANS

OBSERVERA

- VID FÖRSTA DRIFTSÄTTNING, KAN MAN VÄLJA SPRÅK MED MÖJLIGHETEN ATT BYTA NEDAN BESKRIVET INSTÄLLNINGSFUNKTION.

- NÄR APPARATEN VARIT OVERKSAM UNDER 5 min, BLIR DEN AUTOMATISKT AVSTÄNGD. DET RÄCKER MED ATT TRYCKA PÅ VALFRI TANGENT

FÖR ATT AKTIVERA DEN IGEN. DENNA AUTOMATISKA AVSTÄNGNING MÖJLIGGÖR VÄRMESTABILISERING UTAN RISK FÖR E.5000.

- HÅLL DENNA APPARAT REN (från damm, fuktighet, filspån och alla andra frätande medel)

- ENDAST FACOM-ADAPTRAR FÅR ANVÄNDAS TILL MOMENTTESTAREN E.5000, ALLA ANDRA SYSTEM ÄR FÖRBJUDNA.

DESSA ADAPTRAR FÅR INTE ANVÄNDAS TILL NÅGON ANNAN MOMENTTESTARE.

- ADAPTRARNAS/GIVARENS NOGGRANNA INSTÄLLNING GÖR ATT ALLA FORMFÖRÄNDRINGAR OCH SKADEMÄRKEN ÄR UTESLUTNA.

ADAPTERNS/GIVARENS RIKTIGA MOMENT BORGAR FÖR EFFEKTIV OCH HÅLLBAR SERVICE.

- OM APPARATEN VÄGRAR ATT FUNGERA DIREKT EFTER SPÄNNINGSSÄTTNING, KONTROLLERA NÄTSPÄNNINGEN, SLADDEN OCH

SÄKRINGEN INNAN E.5000 SKICKAS I RETUR TILL KUNDTJÄNSTEN OAVSETT OM DEN OMFATTAS AV GARANTIN ELLER INTE.

- BATTERIET OMFATTAS INTE AV GARANTIN.

------AUTOTEST OK------

IGÅNGSÄTTNING AV E.5000

METOD : ARBETSFUNKTION

INST . FUNKTION ARBETSFUNKTION

5 sek.

M

OK

MEMOISO SPÅR PEAK

M

MINNESFUNKTION

ANVÄNT

SPRAK

ITALIENSKA

ENGELSKA

FRANSKA

TYSKA

HOLLÄNDSKA

SPANSKA

POLSKA

PORTUGISISKA

DANSKA

SVENSKA

daN.m

Ibf.ft

Ibf.in

Kgf.m

cN.m

N.m

AKTIVERADE

DEAKTIVERADE

BLOCKERADE

AKTIVERADE

DEAKTIVERADE

DATUM

KLOCKSLAG

LJUDSIGNAL

PC / SKRIVARE

ENHET

SIGNALER

MINNE

BASIN

STÄLLNINGAR

M

M

M

M

M

AUT NOLLS . ? JA

INSTÄLLNING AV VISNINGSTID

(INSTÄLLNING FRÅN 1 TILL 20

SEKUNDER))

AKTIVERADE

OK OK

AKTIVERADE

DEAKTIVERADE

OK

BLOCKERADE

OK

VAL AV MOMENT

DRIFTFUNKTION

OK

STANDARD

AVANCERAD

M

R

R

R

R

KONFIGURATION

R

OK

M

R

AUT. NOLLS .? NEJ

OK

ANVÄNDNING AV E.5000

ÖVER HELA DESS MÄTOMRÅ

DE UTAN KONTROLL AV

TOLERANS

VAL AV MOMENT- OCH

TOLERANSVÄRDE I

ARBETSFUNKTIONEN

OK

OK

TOLERANSVÄRDE

Pièces détachées Onderdelen Części zamienne Lösa delar

Spare parts Despiece Peças sobressalentes

Ersatzteile Pezzi di ricambio Løsdele

E.5000RK

(1/4'' - 3/4'')

E.5000JS

(3/8'' - 1/2'')

E.5000M

E.5000FU

E.5000CO

E.5000BV

82.10

E.5000BV-02

Contenu du CDRom :

- Notice d'instructions NU-E.5000/0902

- Notice d'utilisation détaillée NU-E.5000CD/0902

- Procédure d'étalonnage avec certificat

- Procédure d' impression ou de transfert

Contents of the CDRom:

- Instructions NU-E.5000/0902

- Detailed instructions for use NU-E.5000CD/0902

- Calibration procedure with certificate

- Printing or transfer procedure

Inhalt der CD-ROM:

- Bedienungsanleitung NU-E.5000/0902

- Ausführliche Bedienungsanleitung NU-E.5000CD/0902

- Eichverfahren mit Bescheinigung

- Druck- oder Übertragungsverfahren

Inhoud van de CD-Rom:

- Instructiehandleiding van de NU-E.5000/0902

- Gedetailleerde instructiehandleiding van de NU-E.5000CD/0902

- IJkprocedure met ijkcertificaat

- Procedure voor afdrukken of datatransmissie

Contenido del CD-Rom:

- Manual de instrucciones NU-E.5000/0902

- Manual detallado del usuario NU-E.5000CD/0902

- Procedimiento de calibrado con certificado

- Procedimiento de impresión o de transferencia

Contenuto del CDRom:

Manuale d’istruzioni NU-E.5000/0902

Manuale d’istruzioni dettagliato NU-E.5000CD/0902

Procedura di taratura con certificato

Procedura di stampa o di trasferimento

Zawarto ç CD-ROM:

- Instrukcje dzia∏ania

NU-E.5000/0902

- Szczegó∏owa instrukcja u˝ytkowania

NU-E.5000CD/0902

- Procedura wzorcowania ze Êwiadectwem

- Procedura drukowania lub przesy∏ania danych

Conteúdo do CD-Rom:

- Manual de instruções NU-E.5000/0902

- Manual de utilização detalhada NU-E.5000CD/0902

- Procedimento de calibração com o respectivo certificado

- Procedimentode impressão ou transferência dos dados

Cd-rom'ens indhold:

- Betjeningsvejledning NU-E.5000/0902

- Detaljeret betjeningsvejledning NU-E.5000CD/0902

- Fremgangsmåde for kalibrering med certifikat

- Fremgangsmåde for udskrift eller overførsel

CD-Roms innehåll:

- Bruksanvisning till NU-E.5000/0902

- Detaljerad bruksanvisning till NU-E.5000CD/0902

- Kalibreringsförfarande med intyg

- Förfarande vid utskrift elleröverföring

FACOM Belgique S.A/NV

Weihoek 4

1930 Zaventem

BELGIQUE

✆ : (02) 714 09 00

Fax : (02) 721 24 11

FACOM NORDEN A/S

Navervej 16B

7451 SUNDS

DANMARK

✆ : (45) 971 444 55

Fax : (45) 971 444 66

FACOM GmbH

Postfach 13 22 06

42049 Wuppertal

Otto-Wells-Straße 9

42111 Wuppertal

DEUTSCHLAND

✆ : (0202) 270 63 0

Fax : (0202) 270 63 50

FACOM Herramientas SRL

Poligono industrial de Vallecas

C/.Luis 1°, s/n-Nave 95 - 2°Pl.

28031 Madrid

ESPAÑA

✆ : (0034) 91 778 21 13

Fax : (0034) 91 778 27 53

USAG Gruppo FACOM

Via Volta 3

21020 Monvalle (VA)

ITALIA

✆ : (0332) 790 111

Fax : (0332) 790 602

FACOM Oddzial w Warszawie

ul.Marconich 9 m.3

02-954 Warszawa

POLSKA

✆ : (0048 22) 642 71 14

Fax : (0048 22) 651 74 69

En France, pour tous renseignements techniques sur l'outillage à main, téléphonez au 01 64 54 45 14

BELGIQUE

LUXEMBOURG

DANMARK

FINLAND

ISLAND

NORGE

SVERIGE

DEUTSCHLAND

ESPAÑA

PORTUGAL

ITALIA

POLSKA

FACOM Gereedschappen BV

Kamerlingh Onnesweg 2

Postbus 134

4130 EC Vianen

NEDERLAND

✆ : (0347) 362 362

Fax : (0347) 376 020

FACOM Tools FAR EAST Pte Ltd

15 Scotts Road

Thong Teck Building #08.01.02

Singapore 228218

SINGAPORE

✆ : (65) 732 0552

Fax : (65) 732 5609

FACOM S.A./AG

12 route Henri-Stéphan

1762 Givisiez/Fribourg

SUISSE

✆ : (4126) 466 42 42

Fax : (4126) 466 38 54

FACOM-UK

Churchbridge Works - Walsall Road

CANNOCK - STAFFORDSHIRE

WS11 3JR

UNITED KINGDOM

✆ : (01922) 702 150

Fax : (01922) 702 152

FACOM TOOLS Inc.

3535 West 47th Street

Chicago Illinois 60632

U.S.A.

✆ : (773) 523 1307

Fax : (773) 523 2103

Société FACOM

6-8, rue Gustave Eiffel B.P.99

91423 Morangis cedex

FRANCE

✆ : 01 64 54 45 45

Fax : 01 69 09 60 93

http://www.facom.fr

NEDERLAND

SINGAPORE

FAR EAST

SUISSE

ÖSTERREICH

MAGYARORSZAG

CESKA REP.

UNITED

KINGDOM

EIRE

UNITED

STATES

FRANCE

&

INTERNATIONAL

/