SERO DC AWA-SS-12 Specification

- Category

- Heat pumps

- Type

- Specification

This manual is also suitable for

Please read this operation manual before using the Heat Pump

INSTALLATION AND MAINTENANCE INSTRUCTIONS

AIR SOURCE HEAT PUMP

AWA-SS-10 AWA-SS-12 AWA-SS-16

( 3x400V / 3 / 50Hz )

( 230V / 50HZ )

MODEL :

AWA-SS-6 AWA-SS-8

( ALL IN ONE )

JULY 2009

Contents

1

System description

Principle of operation ............................................ 3

Control panel

Layout .................................................................. 5

Explanation .......................................................... 5

General information for the installer

Transport and storage ............................................ 7

Installation .............................................................. 7

Copper pipe connecting ........................................ 7

Inspection of the installation .................................. 7

Pipe connections

General .................................................................. 8

Copper Pipe connections ...................................... 8

Pipe connection (heating medium) ........................ 9

Pipe connections (water heater) ............................ 9

Pump capacity diagrams, heating medium side .. 12

Electrical connections

Wiring of the terminal (mode one)......................... 15

Connecting the room temperature sensor ........... 16

Layout of the PCB ............................................. 17

1.5mm2 terminal connection ............................. 17

Part of wiring diagram ........................................ 18

2.5mm2 terminal connection ............................... 18

Wiring diagram ( 230v / 50 Hz ) ............................ 19

Commissioning and adjusting

Preparations ........................................................ 21

Filling and venting the heating medium system ... 21

Readjusting, heat medium side ............................ 22

Emptying the water heater .................................. 22

Control

General Information ............................................. 23

Menus .................................................................. 24

Main Menu Information ........................................ 24

Sub-menu Operation............................................. 24

Sub-menu Heat Curve........................................... 25

Sub-menu Temperature ........................................ 26

Sub-menu Operating Time .................................... 29

Adjustments to be made regularly ........................ 30

Heat Generation-General....................................... 30

Adjustment of the CURVE valve ........................... 31

Adjustment of ROOM valve.................................... 33

Adjustment of Part of the Heat Curve .................... 34

Adjustment the MIN and MAX valve ..................... 35

Adjustment of the HEAT STOP valve......................35

Maximum Return Line Temperature ..................... 37

Warm water Production........................................... 37

Regular checks.......................................................38

Check of the Operating Mode............................... 38

Dealing with malfunctions

Draining, heat medium side ................................ 43

Component placement

Component positions 1 ........................................ 44

Component positions 2......................................... 45

Component positions 230 V / 50 HZ .................... 46

Component positions 3 x 400 V / 3 / 50 HZ ......... 46

List of components

List of components................................................ 47

Dimensions

Dimensions and setting-out coordinates .............. 48

Accessories

Accessories .......................................................... 51

Technical specifications

Technical specifications 230 V /3 X 400 V ........... 52

Unit Description .................................................... 3

Principle of heatpump ........................................... 4

Functions ............................................................. 6

Symbols ............................................................... 6

How to adjust the rate of flow .............................. 13

Connect the power cord ....................................... 14

Wiring of the terminal (mode two)......................... 15

Connecting the outside temperature sensor ........ 16

Wiring diagram ( 3X400v / 3 / 50 Hz ) ................... 20

Graph of recent change in TEMPERATURE............36

Checking the Water Level of the Heating system .38

Checking the safety valves.................................... 39

In the event of leakage.......................................... 39

Alarm Messages.................................................... 40

Terminology and Abbreviations............................. 41

Draining, water tank.............................................. 43

Draining, the chassis............................................. 43

Inspection ............................................................. 22

Adjust the heat medium pump .............................. 22

Enclosed kit .......................................................... 51

Sub-menu Integral ................................................. 26

Sub-menu Reset ................................................... 29

Sub-menu Man Test .............................................. 29

Dimensions of the AWA-SS-8 outdoor unit .......... 49

Dimensions of the AWA-SS-10 outdoor unit ........ 49

Dimensions of the AWA-SS-12 outdoor unit ........ 50

Dimensions of the AWA-SS-16 outdoor unit ........ 50

Description of the switch board............................. 42

How to connect the copper pipes ......................... 10

The step and diagram of collect refrigerant .......... 11

Sub-menu DEFROST ............................................ 30

Degree Minute's(DM) instruction............................ 27

Dimensions of the AWA-SS-6 outdoor unit .......... 49

AWA-SS series consists of a heat pump, water heater,

electrical module, circulation pumps and a control sys-

tem. AWA-SS series is connected to the Outdoor Unit

and heating medium circuits.

The heat source of the AWA-SS series is provided from

air. the Outdoor Unit of the system is a heat exchanger

for collecting the heat of air.

The air emits its heat to the refrigerant in the evapo-

rate of Outdoorunit. It then vaporises and is com-

pressed in the compressor. The refrigerant, the tem-

perature of which has now been raised, is passed to

the condenser where it gives off its energy to the heat-

ing medium circuit and, if necessary, to the water

heater. After the condenser there is a built-in electrical

module which cuts in if there is a high demand.

System description 2

Principle of operation

CW

HW

Expansion

vessel Heating

flow

Heating

return

The heating medium side and

the hot water side must be fit-

ted with the necessary safety

equipment in accordance with

the applicable regulations.

Condenser

Compressor Expansion

valve

Heating

medium

pump

Heating medium return

Heating medium flow

Three-way valve

Electrical

auxiliary heater

(VB),

(VB),

Compre

Gas valve

Liquid

valve

Outdoor unit

System description

3

Unit Description

In order to get the best results from the climate system AWA-SS series you should read through the

section For the System manager in these Installation and Maintenance instructions.

AWA-SS series

is

a

climate system

for

heating

houses

and

apartment

buildings

as

well

as

industrial

properties.

Air

is

used

as

the

heat

exchange

source.

AWA-SS series

is

a

complete

heating

installation

for

heating

and

hot

water

.

It

is

fitted

with

new design

on

the

market

to

be

developed

specifically

for

heat

pumps.

A

new

evaporator

enables

a

new

and

impr

oved

cir

culation

system

for

the

r

efrigerant.

The

heat

pump

has

an

integrated

150 or 200 litr

e

water

tank

and

an

immer

sion

heater

.

The

T

ap

W

ater

Stratification

system

impr

oves

the

ef

ficiency

of

heat

transfer

by

keeping

the

water

in

distinct

thermal

layers

in

the

water

tank.

The unit

is

fitted

with

a

r

egulating

computer

,

which

is

contr

olled

over

a

graphic

display

unit.

Heat

is

distributed

thr

oughout

the

house

over

a

hydr

onic

heating

system

r

eferr

ed

to

as

low temperatur

e

system

with

a

maximal

water

temperatur

e

to

radiators

(supply

line

temperatur

e)

of

65°C.

Most

of

the

heating

demand

is

taken

car

e

of

by

the

heat

pump

(compressor

unit),

the

auxiliary

heater

being

star

ted

only

when

demands

exceed

available

heat

pump

capacity

.

AWA-SS series

consists

of

five

main

components:

a.

Heat

Pump

Unit

Rotory or Scr

oll-compr

essor

Stainless

steel

heat

exchangers

Cir

culation

pumps

for

Brine

sytem

(brine)

and

heating

systems

V

alves

and

safety

equipment

for

r

efrigerant

system,

complete

with

necessary

electric

components

b.

W

ater

Heater

150 or 200

litr

e

Lined

with

copper

sheet

against

corr

osion

or

made

of

stainless

steel

Maintenance

fr

ee

as

no

anode

is

used

c.

Reversing

V

alve

Opening

or

closing

the

connection

to

water

heater

accor

ding

to

operating mode:

heating

or

warm

water

pr

oduction

d.

Auxiliary

Heater

3/6/9

kW

electric

heating

element

Three-step

capacity

contr

ol

Fitted

on

supply

line

Delivers

back-up

heat

in

case

of

gr

eat

heat

demand

that

exceeds

heat

pump

capacity

Star

ts

automatically

,

pr

ovided

operating

mode

“AUTO”

has

been

selected

e.

Regulating

Equipment

The

r

egulating

system

contr

ols

heat

pump

components

(compressor

,

cir

culation

pumps,

auxiliary

heater

and

r

eversing

valve).

Based

on

data

r

eceived

fr

om sensors,

it

star

ts

or

stops

heat

pump

operation

and

determines

whether

he

a

ting

or

warm

water

shall

be

pr

oduced.

The

system

consists

of:

Control

computer

with

graphic

display

unit

T

emperatur

e

sensors

(outside

air

,room,

supply

line,

r

eturn

line

system)

System description 4

Principle of heat pump

A

heat

pump

can

exploit

the

ener

gy

contained

in

natural

heat

sour

ces.

Or

,

to

put

it

dif

fer

ently

,

the

heat

pump

”collects”

heat

ener

gy

fr

om

the

heat

sour

ce.

This

makes

the

heat

pump

a

very

environmentally

friendly

and

economically

sound

alternative

for

space

heating.

a.

b

The

Outdoor unit is used as the

heat

pump’

s

evaporator

.

Here

the

heat

ener

gy

of

the

Outdoor Unit

causes

the

r

efrigerant,

cir

culating

thr

ough

the

evapo

rator

,

to

boil

and

turn

into

a

gas

–

it

evaporates.

c

The

r

efrigerant,

having

absorbed

heat

ener

gy

,

is

cir

culated

to

the

compr

essor

wher

e

pr

essur

e

and

temperatur

e

ar

e

raised.

d

The

r

efrigerant

continues

to

the

condenser

.

When

condensing,

it

r

eleases heat

ener

gy

to

the

heat

carrier

,

cir

culating

thr

ough

the

condenser

.

The

temperatur

e

of

the

r

efrigerant

sinks,

and

it

r

eturns

to

its

liquid

state.

e

The

heat

ener

gy

r

eleased

is

carried

by

the

heating

cir

cuit

to

water

heater

and

radiator

or

floor

heating

systems.

At

last

the

r

efrigerant

is

led

thr

ough

the

expansion

valve,

wher

e

its

pr

essur

e

is

r

educed,

and

then

con

tinues

to

the

evaporator

.

The

pr

ocess

is

r

estar

ted.

The

heat pump has two separate liquid circuits

Refrigerant circui

t

–

cir

culating

inside

the

heat

pump.

Thr

ough

evaporation,

compr

ession

and

condensation

it

absorbs

ener

gy

fr

om

the

outdoor unit

and

r

ele

ases

it

to

the

heat

carrier

.

The

r

efrigerant

is

chlorine-fr

ee.

Heating circuit

–

water

transporting

heat

ener

gy

to

the

heating

system

(radia

tors/floor

coils)

and

the

water

heater

.

Expantion valve/

pressure drop

Refrigerant

Condenser

Compressor/

pressure increase

Evaporator

Heating Circuit

Refrigerant Circuit

Fan

Control panel

5

Display

Left

button

Layout

C

D

button

Explanation

Power On/Off

A

Up

button

F

Down

button

Contr

ol

Panel

The

contr

ol

panel

of

AWA-SS

featur

es

a

graphic

display

contr

ol

buttons

.

Beside

the

contr

ol

panel

you

will

find

the

User’

s

Manual,

a

shor

t

description

of

how

to

incr

ease

and

r

educe

r

oom

temperature,

and

a

label

with

name

and

phone

number

of

dealer

.

Graphic

display

five

ROOM 20

o

C

Right

OPER. AUTO

ROOM 20

o

C

OPER. AUTO

Control panel 6

Functions

The control computer is operated with the help of a user friendly menu system that is displayed on the control

panel. There is a main menu and four sub-menus accessible from the main menu. The menus are described in detail

further down.

To be able to select the desired menu and increase or reduce preset values, you will use the five buttons.

• One button pointing upwards marked with a plus

• One button pointing downwards marked with a minus

• One button pointing to the right

• One button pointing to the left

•

One

button

pointing to the

Power ON/OFF

Symbols

For you to know at a glance the actual operating mode of the heat pump,

one of the following symbols will be shown in the lower part of the display

depending on which part of the unit is working:

8

The

heat

pump

is

running.

The

auxiliary

heater

is

activated.

The

figur

e

next

to

the

symbol indicates

capacity

step.

There

is

a room

heating

demand.

W

arm

water

is

being

pr

oduced.

Indicates

the

status

of

warm

water

pr

oduction.

If

the

symbol

is

empty

,

warm

water

temperatur

e

If

the

symbol

is

full,

warm

water

temperatur

is under

the setting temperature.

e reached to the setting

temperature

General information for the installer

7

Current regulations require the heating installation to

be inspected before it is commissioned. The inspec-

tion must be carried out by a suitably qualified person

and should be documented. The above applies to

closed heating systems. If the heat pump is replaced,

the installation must be inspected again.

AWA-SS series is placed on a firm base, preferably a

concrete floor or foundation. Install AWA-SS series

with its back to an outside wall, ideally in a room where

noise does not matter. If this is not possible, avoid

placing it against a wall behind a bedroom or other

room where noise may be a problem. Any wall that

backs on to a bedroom should be fitted with sound

insulation. Route pipes so they are not fixed to an inter-

nal wall that backs on to a bedroom or living room.

Installation

Copper pipe connecting

Inspection of the installation

1) The maximun length of the connecting copper pipe

between the mainframe and outdoor unit is 15 meters.

+2

0

-2

1

R

0

HM flow

49 (50) °C

Hot water

51 °C

+2

0

-2

1

R

0

HM flow

49 (50) °C

Hot water

51 °C

The AWA-SS series must be transported and stored

upright and dry. The AWA-SS series may however be

carefully laid on its back when being moved into

a building.

Transport and storage

2) There is no need to charge extra refrigerant into the

copper pipe while its length is less than 5 meters.

3) While the copper length is more than 5 meters,

copper pipe while its length is less than 5 meters.every

extra 10g refrigerant must be charged for per increased

1 meter length.

Pipe connections

8

Pipe installation must be carried out in accordance

with current norms and directives. The heat pump can

operate up to a return temperature of about 58* °C

and an outgoing temperature of about 70* °C from the

heat pump. The compressor produces up to 65* °C,

the rest is obtained using additional heating.

The other heat pumps has a max return temperature

of approximately 50 °C and an outgoing max tempera-

ture from the heat pump of approximately 60 °C.

Since the AWA,AWB series is not fitted with shut-off

valves, these must be fitted outside of the heat pump

to make future servicing easier.

During assembly the pipes for the heat medium

and water heater and possibly hot water circulation

are routed backwards. The distance between

AWA-SS series and the wall ought to be 50 mm.

General

NOTE!

The pipe system needs to be flushed

out before the heat pump is connected

so that debris cannot damage

component parts.

The size of the outlet for connecting copper pipe can be

adjusted by the fixing board.

Copper pipe connections

According to their practical situation,users can choose

the place on mainframe ( left or right ) for the out

of connecting copper pipe.

NOTE!

defrosting temperature sensor and outside

temperature sensor should be connected

outlet of mainframe and outdoor

Copper tuble size

to outdoor unit through the connecting

unit.

/

/

/

Modle

Size

AWA

-

SS

-

6

AWA

-

SS

-

8

AWA

-

SS

-

10

AWA

-

SS

-

12

AWA

-

SS

-

16

Gas

rör

1

/

2

"

5

/

8

"

5

/

8

"

3

/

4

"

3

/

4

"

Vätske

rör

1

/

4

"

3

/

8

"

3

/

8

"

1

/

2

"

1

/

2

"

Pipe connections

9

Pipe connections for the heat medium side are made

at the top. All required safety devices, shut-off valves

(as close to the heat pump as possible), and particle

filter (supplied) are fitted.

When connecting to a system with thermostats on all

radiators, a relief valve must be fitted, or some of the

thermostats must be removed to ensure sufficient

flow.

Pipe connections (heating

medium) The heat pump´s water heater must be fitted with the

necessary valve equipment.

Pipe connections (water heater)

The heat pump should be supplemented with an elec-

tric water heater if a bubble pool or other significant

consumer of hot water is installed. The valve coupling

in COMPACT (electrical water heater) can be divided.

The mixing valve stays in COMPACT and the remain-

ing valve coupling can be used for incoming cold

water in AWA-SS series.

P

EXP

HW CW SAV

SAV

VENTING VALVE

NOTE!

The venting valve should be set on

the top of the heating medium system.

SF

Pipe connections

10

How to connect the copper pipes

Piping Connecton

Attention :

When connectiong the pipe, a suitable pitching spanner must be used. If other spanner is used, it may

damage the joint due to inappropriate force.

4. Connect the electric cable as per circuit diagram, and bundle

it with the connecting pipe.

1. Open the cover of the outdoor unit.

2. Connect the pipe to the indoor unit and outdoor unit.

Align the centre of the pipe and fully screw in the angular nuts with Finger.

On connecting the pipe, one should ensure that the insulating material of the pipe be closely fitted to

the nuts at the joint.

On connecting to the external unit, the pipe should be wrapped with sponge padding to prevent

rain water from flowing in.

When bending the pipe, the radius cannot be too small and be about 150~160 mm.

connecting pipe

thick pipe

end nut

Connector

low pressure valve

high pressure valve

thin pipe

3. Use Vacuum pump to remove the air from indoor unit and

connection pipe.

Wipe the quick connectors with clean cloth to prohibit dust and impurity entering the pipes.

5. Take off the nuts in the mouths of high valve and low valve, turn

the valves core anticlockwise with hexagon panner till the valves

are opened completely. Recover and tighten the nuts.

6. Check leakage: check if there is leakage at each connection of the

pipes or nuts. If yes, remedial neasure must be taken, leakage is

not permitted in any case.

Pipe connections

11

4. Tighten the cap of two valves.

5. Disconnect the power cable from outdoor unit.

6. Loose the nut of the connect pipe to the outdoor unit valve with 2 spanner, disconnect the connect pipe

and the two valves.

1. Start the machine, operate heat pump on state.

2. Remove the cap of two valves with the spanner.

3. Tighten the core of the liquid valve (the smaller one) with valve key at first . After about 20 seconds, tighten

the core of the gas (the bigger one) with valve key. Turn off the machine at once and cut off the power supply.

If the outdoor unit needs to be disconnected and moved to another place, please recycle the

gas back into the compressor according to the following steps before doing the disconnecting:

The step and diagram of collect refrigerant

Liquid valve

Gas valve

Valve key

Liquid valve

Gas valve

Valve key

Liquid valve

Gas valve

20 seconds

Liquid valve

Gas valve

Pipe connections

12

Pump capacity diagrams, heating medium side

kPa

AWA-SS-8

AWA-SS-6

AWA-SS-10

Available

pressure

Flow

AWA-SS-12

l/s

1

2

3

0.22 0.44

0.66

0.88 1.10 1.32

80

70

60

50

40

30

20

10

0

1.54 1.76

0

AWA-SS-16

kPa

Tillgängligt tryck

Available

pressure

Flow

1

2

3

0.28 0.56

0.84

1.12 1.41.68

80

70

60

50

40

30

20

10

0

1.96 2.24

0

l/s

WILO RS-25/8

WILO RL-25/7.5

Pipe connections

13

The pump is

adjustable to adjust

the flow: 1, 2, or 3.

The pump is

adjustable to adjust

the flow: 1, 2, or 3.

WILO RS-25/8

WILO RL-25/7.5

How to adjust the rate of flow

Electrical connection 14

NOTE!

Electrical installation and service must

be carried out under the supervision of

a qualified electrician in accordance

with the stipulations in force.

Connect the power cord

( 230V / 50 HZ )

( 3X400V / 3 / 50 HZ )

R

S

L

N

N

N

T

Electrical connection15

Step1 Step3Step2

Step1 Step3Step2

Wiring of the terminal (mode one)

Wiring of the terminal (mode two)

Electrical connection 16

Connecting The Room Temperature Sensor

Connecting The Outside Temperature Sensor

OUTP=Defrost temperature sensor

Outdoor unit

OUTP

Outside air temperature sensor

RT

OCT

Outside air temperature sensor

OCT=Outside air temperature sensor

Room temperature sensor

RT

OCT

Room temperature sensor

RT=Room temperature sensor

Connecting The Defrost Temperature Sensor

OCT

OUTP

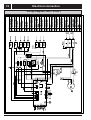

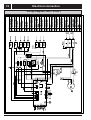

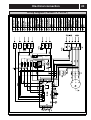

Electrical connection17

CWT WIT OUTP OCT RT WTT C0MP PA.OUT HP LP CSP

GND

EHI

N

3WV

4WV

N

GND

WCP

N

OFAN

N

GND

GND

WCP2

N

Layout of the PCB

From PCB / CON4 /11,12

From PCB / CON4 /9,10

From PCB / CON4 /7,8

From PCB / CON4 /5,6

From PCB / CON4 /3,4

From PCB / CON4 /1,2

From PCB / CON5 /1,2

From PCB / CON5 /3,4

From PCB / CON5 /5,6

From PCB / CON5 /7,8

From PCB / CON5 /9,10

From PCB / CON5 /11,12

3-Way Valve's Relay ( port 3)

From PCB/OUT6

From Fuse 2

From Fuse 3

From Fuse 2

From Water return Temperature Sensor

From Water feed Temperature Sensor

From Defrost Temperature Sensor

From Outside Air Temperature Sensor

From Room Temperature Sensor

From Water Tank Temperature Sensor

From Compressor Gas Outlet

Temperature Sensor

From Pressure Relief valve

From High Pressure Pressostat

From Low Pressure Pressostat

From

From

From

From

From Adjustable pressure switch

From Electrical auxiliary heater

Temperature Sensor

From Three-way valve forwaterflow

From Four_way Valve

From Water cycle pump

From Outdoor Unit FAN

From Water cycle pump2

From Neutral line

common terminal

From Neutral line

common terminal

From Neutral line

common terminal

From Neutral line

common terminal

From Neutral line

common terminal

1.5mm2 terminal connection

N

EH4

From Neutral line

common terminal

From Neutral line

common terminal

From Neutral line

common terminal

From Fuse 7

From Eletrical heater 4

NOTE!

The connecting wire of outdoor unit fan,

water cycle pump two and electrical heater four

should be connected to the 1.5mm

2

terminal

through the hole on the sound insulation board,

and connect to outside with the copper pipes.

3-Way Valve's Relay ( port 2)

L C DL C D

NO

COM

NO

COM

COM

NO

OUT3 OUT2 OUT1

RS NT

CON3

CON1

P C B

CON2

TRANSFORMER

CON4

OUT8 OUT7 OUT6 OUT5 OUT4OUT9

Outdoor Condition Temp

Room Temp

Water tank Temp

Defrost Temp

1 2 3 45678910 11 12

Water feed Temp

Water return Temp

OUTP

CON5

Ground Water Inlet Temp

Electric Heater interruptor/ Water Flow Switch

High Pressure

Low Pressure

Compressor interruptor

Compressor stoped protection

Compressor Gas Outlet Temp

12345678910111213141516

CON10

Electrical Expansion valve

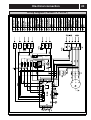

Electrical connection 18

Part of wiring diagram

2.5mm2 terminal connection

EH1

EH2

N

EH3

N

W

U

V

GND

T3

T2T1

L3

L2L1

C1

u

w

v

cm

RED

WHITE

BLACK

From AC contactor / L3

From AC contactor / L2

From AC contactor / L1

FromFrom Compressor

From Compressor / V

From Compressor / U

From Compressor / W

From Electrical heater 3

From Electrical heater 2

From Electrical heater 1 From Fuse 6

From Fuse 5

From Fuse 4

From 6mm2 terminal / N

From Neutral line

common terminal

4 way valve

Y/G

N

OFAN

WCP2

N

F3

3A

3A

2A

16A

16A

16A

F1

F4

F5

Heater 3

Heater 2

Heater 1

COMPRESSOR

CONTACTOR

BLUE

BLUE

BLUE

BLUE

F6

Water cycle

3 way valve

EH4

N

2A

F7

Y/G

WCP2

Y/G

F2 pump

C1

BLACK

BLUE

BLUE

BROWN

Relay of

3 way valve

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

SERO DC AWA-SS-12 Specification

- Category

- Heat pumps

- Type

- Specification

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Other documents

-

Jifon AquaHeat 13 User manual

Jifon AquaHeat 13 User manual

-

McQuay MDS030A Installation guide

-

CTC Union 406 Datasheet

-

Haier 1U24SU1ERE Installation guide

-

LG LRSPC2031T Owner's manual

-

Toolots DC-3006 User manual

-

LG LRSPC2331NI Owner's manual

-

MRCOOL A-18-HP-230A Installation guide

-

Nibe F1345 Series Installer Manual

-

CTC Union 406 Installation and Maintenance Manual