PRESSUREWASHERMAINTENANCE

Clean Debris

Daily or before use, cleanaccumulated debris from cleaning

system. Keeplinkage, spring and controls clean. Keeparea

around and behind muffler free from any combustible debris.

Inspect cooling air slots and openings on the pressure

washer.These openings must be kept cleanand

unobstructed.

Cleaningsystem parts should be kept cleanto reducethe risk

of overheatingand ignition of accumulated debris.

• Usea damp cloth to wipe exterior surfaces clean.

NOTICE

Jlmproper treatment of pressurewasher can damageit and

_horten its life. _ ....

[, DONOTinsertanyobjectsthroughcoolingslots.

• Usea soft bristle brush to loosen cakedon dirt, oil, etc.

• Usea vacuum cleanerto pick up loose dirt and debris.

Check and Clean Inlet Screen

Examinegarden hose inlet screen.Cleanif it is clogged or

replaceif it is torn.

Check High Pressure Hose

High pressure hoses can developleaks from wear, kinking,

or abuse. Inspect hose beforeeach use. Checkfor cuts,

leaks,abrasions, bulging of cover, or damageor movement

of couplings. If any of these conditions exist, replacehose

immediately.

WARHIHG

The high pressure stream of water that this

_ quipment produces cancut through skin and its

underlyingtissues, leadingto serious injury and

)ossible amputation.

• NEVERrepairhighpressurehose.Replaceit.

, ReplacementhoseratingMUSTexceedmaximumpressure

ratingof unit.

Check Gun and Hozzle Extension

Examinehose connectionto spray gun and makesure it is

secure.Testtrigger by pressing it and making sure it springs

back into placewhenyou releaseit. Put safety latch in UP

position and test trigger. You should not beable to press

trigger. Replacespray gun immediately if it fails any of these

tests.

HozzJeMaintenance

A pulsing sensationfelt while squeezingthe spray gun trigger

may becaused by excessivepump pressure. Theprincipal

cause of excessivepump pressure is a spray tip clogged or

restricted with foreign materials, such asdirt, etc. Tocorrect

the problem, immediately cleanthe spray tip following these

instructions:

1. Shut off engine and turn off water supply.

2. ALWAYSpoint spray gun in a safe direction and squeeze

spray gun trigger to releaseretainedhigh water pressure.

WARNING

Thehigh pressure stream of water that this

equipment produces can cut through skin and its

_ nderlying tissues, leading to serious injury and

)ossible amputation.

Spraygun traps high water pressure, evenwhen

engine is stopped and water is disconnected,

which cancause injury.

• Keephighpressurehoseconnectedto pumpandspraygun

whilesystemispressurized.

, ALWAYSpointspraygunin safedirectionandsqueezespray

guntrigger,to releasehighpressure,everytimeyoustop

engine.Engagetriggerlockwhennotin use.

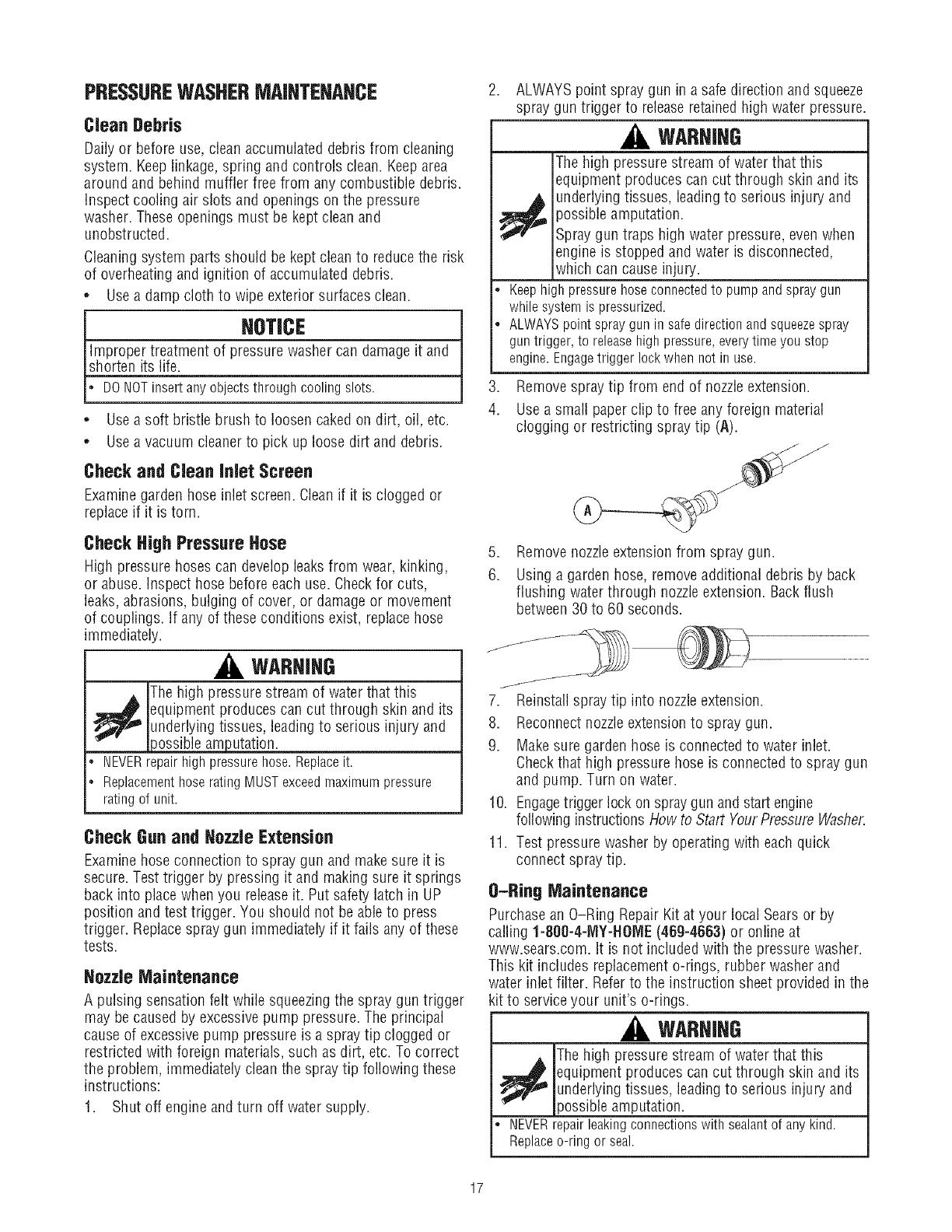

3. Removespray tip from end of nozzleextension.

4. Usea small paperclip to free any foreign material

clogging or restricting spray tip (A).

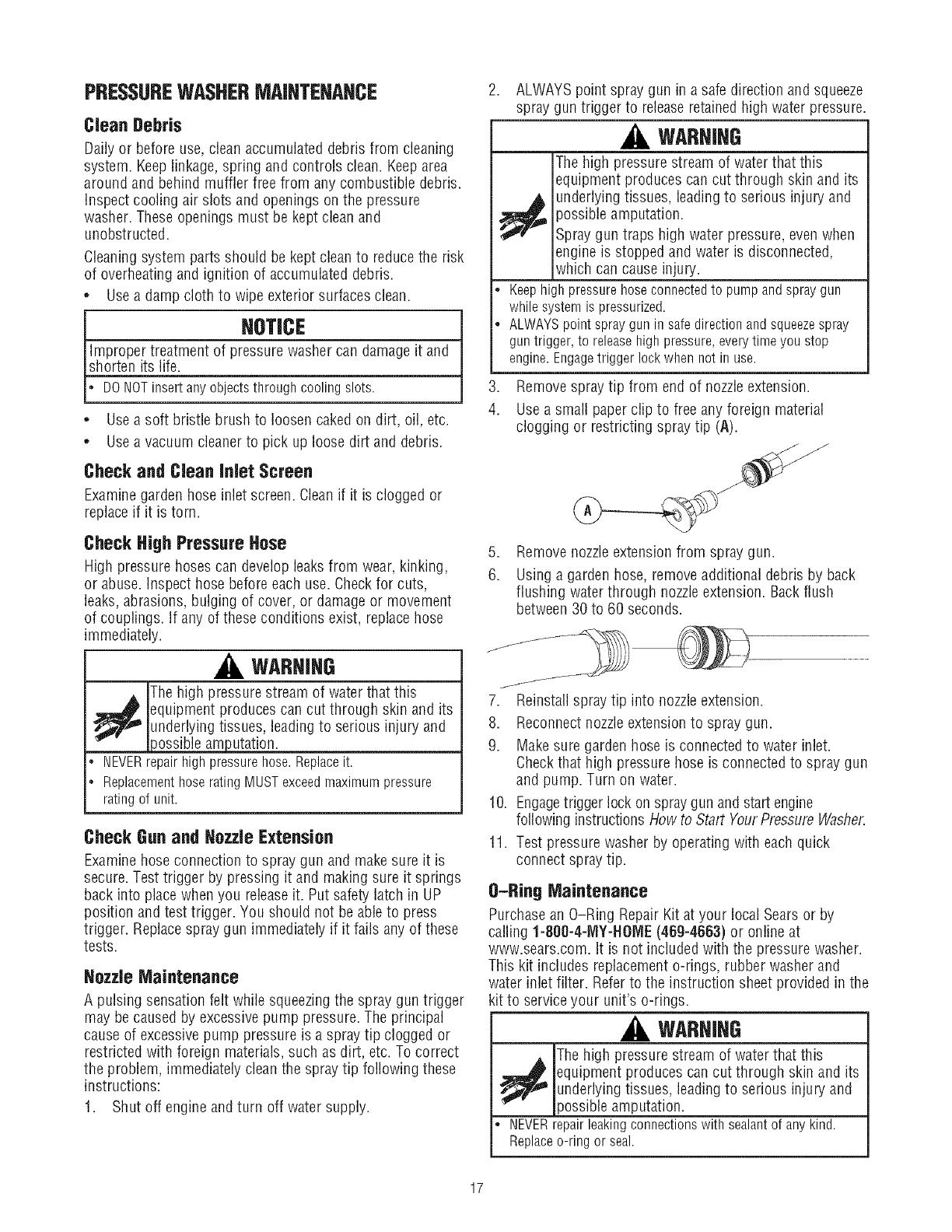

5. Removenozzleextension from spray gun.

6. Using a garden hose, remove additional debris by back

flushing water through nozzle extension. Back flush

between 30 to 60 seconds.

7. Reinstallspray tip into nozzleextension.

8. Reconnectnozzleextensionto spray gun.

9. Makesure garden hose is connectedto water inlet.

Checkthat high pressure hose is connectedto spray gun

and pump. Turn on water.

10. Engagetrigger lock on spraygun andstart engine

following instructions How to Start YourPressure Washer.

11. Test pressure washer by operating with eachquick

connect spray tip.

O-Ring Maintenance

Purchasean O-Ring RepairKit atyour local Searsor by

calling 1-800-4-NIY-HOME(46g-4663) or online at

www.sears.com. It is not included with the pressure washer.

This kit includes replacemento-rings, rubber washer and

water inlet filter. Referto the instruction sheet provided in the

kit to serviceyour unit's o-rings.

WARHIHG

Thehigh pressurestream of water that this

_ quipment produces cancut through skin and its

underlyingtissues, leadingto serious injury and

)ossible amputation.

, NEVERrepairleakingconnectionswith sealantof anykind.

Replaceo-ringor seal.

17