Page is loading ...

Table of Contents

1. Introduction ........................................................................................................................... 1

1.1. What is the Cerbo GX? ..................................................................................................... 1

1.2. What's in the box? ........................................................................................................... 1

2. Installation ............................................................................................................................. 2

2.1. Cerbo GX Overview of connections ....................................................................................... 2

2.2. Power ......................................................................................................................... 2

2.3. Mounting options and accessories ........................................................................................ 3

2.4. Connecting Victron products ............................................................................................... 3

2.4.1. Multis/Quattros/Inverters (VE.Bus products) ................................................................... 3

2.4.2. Battery Monitor SmartShunt, BMV-700 series; and MPPTs with a VE.Direct port ......................... 4

2.4.3. VE.Can Devices ................................................................................................... 5

2.4.4. VE.Can and BMS-Can Interfaces ............................................................................... 5

2.4.5. Inverter RS, Multi RS and MPPT RS ............................................................................ 6

2.4.6. BMV-600 series .................................................................................................... 6

2.4.7. DC Link box ........................................................................................................ 6

2.4.8. VE.Can Resistive Tank Sender Adapter ........................................................................ 6

2.5. Connecting a PV Inverter ................................................................................................... 6

2.6. Connecting a USB GPS .................................................................................................... 7

2.7. Connecting a NMEA 2000 GPS ........................................................................................... 7

2.8. Connecting a Fischer Panda Generator .................................................................................. 7

2.9. Connecting a GX Tank 140 ................................................................................................. 8

2.10. Connecting Tank Level Sensors .......................................................................................... 8

2.11. Connecting third-party NMEA 2000 tank senders ...................................................................... 9

2.12. Connecting Temperature Sensors ....................................................................................... 9

2.12.1. Hardwired sensors ............................................................................................... 9

2.12.2. Wireless Bluetooth Ruuvi sensors ........................................................................... 11

2.13. Connecting IMT Solar Irradiance, Temperature and Wind Speed Sensors ....................................... 12

2.13.1. Data Visualisation - VRM ..................................................................................... 15

2.14. Relay connections ....................................................................................................... 16

2.15. AC load monitoring ...................................................................................................... 17

3. Internet connectivity ............................................................................................................... 18

3.1. Ethernet LAN port ......................................................................................................... 18

3.2. Wi-Fi ........................................................................................................................ 18

3.3. GX GSM .................................................................................................................... 19

3.4. Mobile (cellular) network using a 3G or 4G router ..................................................................... 19

3.5. USB tethering using a mobile phone .................................................................................... 19

3.6. IP Configuration ........................................................................................................... 19

3.7. Connecting both Ethernet and Wi-Fi (failover) ......................................................................... 20

3.8. Minimize internet traffic ................................................................................................... 20

3.9. More information about setting up an internet connection and VRM ................................................ 20

4. Accessing the GX device ......................................................................................................... 21

4.1. Using VictronConnect via Bluetooth ..................................................................................... 21

4.2. Accessing via the built-in WiFi Access Point ........................................................................... 22

4.3. Accessing Remote Console via the local LAN/WiFi Network ........................................................ 23

4.3.1. Alternative methods to find the IP Address for Remote Console .......................................... 23

4.4. Accessing via VRM ........................................................................................................ 24

5. Configuration ....................................................................................................................... 26

5.1. Menu structure and configurable parameters .......................................................................... 26

5.2. Battery state of charge (SoC) ............................................................................................ 33

5.2.1. Which device should I use for SoC calculation? ............................................................. 33

5.2.2. The different solutions explained in detail .................................................................... 33

5.2.3. Notes on SoC .................................................................................................... 34

5.2.4. Selecting SoC source ........................................................................................... 35

5.2.5. Details on VE.Bus SOC ........................................................................................ 35

5.2.6. The System Status menu ...................................................................................... 35

5.3. Customize the logo on the Boat & Motorhome page .................................................................. 36

5.4. Temperature relay ......................................................................................................... 37

Cerbo GX Manual

6. Firmware updates .................................................................................................................. 39

6.1. Changelog .................................................................................................................. 39

6.2. Via internet or with microSD-card/USB-stick ........................................................................... 39

6.2.1. Direct download from the internet ............................................................................. 39

6.2.2. MicroSD-card or USB-stick .................................................................................... 39

6.3. Revert to a previous firmware version .................................................................................. 40

6.3.1. Stored firmware backup feature ............................................................................... 40

6.3.2. Install a specific firmware version from SD/USB ............................................................ 40

6.4. Venus OS Large image ................................................................................................... 41

7. VE.Bus Inverter/charger monitoring ............................................................................................ 42

7.1. Input current-limiter setting ............................................................................................... 42

7.2. Phase rotation warning ................................................................................................... 42

7.3. Grid failure monitoring .................................................................................................... 43

7.4. Advanced menu ........................................................................................................... 44

8. DVCC - Distributed Voltage and Current Control ............................................................................. 45

8.1. Introduction and features ................................................................................................. 45

8.2. DVCC Requirements ...................................................................................................... 46

8.3. DVCC effects on the charge algorithm .................................................................................. 47

8.4. DVCC features for all systems ........................................................................................... 47

8.4.1. Limit charge current ............................................................................................. 47

8.4.2. Limit managed battery charge voltage ........................................................................ 48

8.4.3. Shared Voltage Sense (SVS) .................................................................................. 48

8.4.4. Shared Temperature Sense (STS) ............................................................................ 49

8.4.5. Shared Current Sense (SCS) .................................................................................. 49

8.5. DVCC features when using CAN-bus BMS battery ................................................................... 50

8.6. DVCC for systems with the ESS Assistant ............................................................................. 51

9. VRM Portal ........................................................................................................................... 52

9.1. VRM Portal Introduction .................................................................................................. 52

9.2. Registering on VRM ....................................................................................................... 52

9.3. Datalogging to VRM ....................................................................................................... 52

9.4. Troubleshooting data logging ............................................................................................ 53

9.5. Analysing data offline, without VRM ..................................................................................... 56

9.6. Remote Console on VRM - Troubleshooting ........................................................................... 56

10. Marine MFD integration by App ................................................................................................ 58

10.1. Introduction & requirements ............................................................................................ 58

10.2. Compatible MFDs and instructions .................................................................................... 58

11. Marine MFD integration by NMEA2000 ....................................................................................... 60

11.1. NMEA2000 Introduction ................................................................................................. 60

11.2. Supported Devices / PGNs ............................................................................................. 60

11.3. NMEA2000 Configuration ............................................................................................... 61

11.4. NMEA2000 Configuring device instances ............................................................................. 62

11.5. NMEA2000-out technical details ....................................................................................... 62

11.5.1. NMEA2000 Glossary .......................................................................................... 62

11.5.2. NMEA2000 Virtual-devices ................................................................................... 63

11.5.3. NMEA2000 Classes and functions ........................................................................... 63

11.5.4. NMEA 2000 Instances ......................................................................................... 63

11.5.5. NMEA2000 Changing Instances ............................................................................. 64

11.5.6. PGN 60928 NAME Unique Identity Numbers ............................................................... 65

12. RV-C Support ...................................................................................................................... 66

12.1. RV-C Introduction ........................................................................................................ 66

12.2. Limitations ................................................................................................................ 66

12.3. Supported Devices ....................................................................................................... 67

12.4. RV-C Configuration ...................................................................................................... 67

12.5. Garnet SeeLevel II 709-RVC & Victron GX device support ......................................................... 67

12.5.1. Wiring the Garnet SeeLevel II 709-RVC tank level sensor to a GX device ............................. 68

12.5.2. Installation and configuration ................................................................................. 68

Cerbo GX Manual

13. Wakespeed WS500 support ..................................................................................................... 69

13.1. Introduction ............................................................................................................... 69

13.2. Requirements ............................................................................................................ 69

13.3. Wiring the WS500 to VE.Can ........................................................................................... 69

13.4. Wiring Example .......................................................................................................... 69

13.5. GX device user interface for WS500 ................................................................................... 70

13.6. VRM Portal ............................................................................................................... 71

13.7. Troubleshooting .......................................................................................................... 71

13.7.1. Error code #91 and #92 ....................................................................................... 71

13.7.2. Current field contains two dashes ........................................................................... 71

14. Mopeka Pro sensor support .................................................................................................... 73

14.1. Introduction ............................................................................................................... 73

14.2. Installation ................................................................................................................ 73

14.3. Configuration ............................................................................................................. 74

14.4. Tank level monitoring .................................................................................................... 75

15. Digital Inputs ...................................................................................................................... 76

15.1. Configuration ............................................................................................................. 76

15.2. Read-out of digital inputs via Modbus-TCP ........................................................................... 77

16. GX - Generator auto start/stop ................................................................................................. 78

16.1. GX - Generator auto start/stop ......................................................................................... 78

16.2. Wiring ...................................................................................................................... 78

16.3. Enabling the start/stop function ........................................................................................ 78

16.4. General start/stop - Main Page ......................................................................................... 79

16.5. Settings ................................................................................................................... 79

16.6. Conditions: User-definable parameters which trigger a generator auto-start. .................................... 80

16.7. Troubleshooting .......................................................................................................... 84

17. Reset to factory defaults procedure .......................................................................................... 85

18. Error Codes ........................................................................................................................ 86

19. More information .................................................................................................................. 87

20. FAQ .................................................................................................................................. 88

20.1. Q1: I cannot switch my Multi/Quattro system on or off .............................................................. 88

20.2. Q2: Do I need a BMV to see proper battery state of charge? ....................................................... 88

20.3. Q3: I have no internet, where can I insert a sim-card? .............................................................. 88

20.4. Q4: Can I connect both a GX Device and a VGR2/VER to a Multi/Inverter/Quattro? ............................ 88

20.5. Q5: Can I connect multiple Cerbo GX to a Multi/Inverter/Quattro? ................................................. 88

20.6. Q6: I see incorrect current (amps) or power readings on my Cerbo GX ........................................... 89

20.7. Q7: There is a menu entry named "Multi" instead of the VE.Bus product name .................................. 89

20.8. Q8: There is a menu entry named "Multi", while there is no Inverter, Multi or Quattro connected .............. 89

20.9. Q9: When I type the ip-address of the Cerbo GX into my browser, I see a web page mentioning

Hiawatha? ....................................................................................................................... 90

20.10. Q10: I have multiple Solar chargers MPPT 150/70 running in parallel. From which one will I see the

relay status in the Cerbo GX menu? ......................................................................................... 90

20.11. Q11: How long should an automatic update take? .................................................................. 90

20.12. Q12: I have a VGR with IO Extender, how can I replace this with a Cerbo GX? ................................ 90

20.13. Q13: Can I use Remote VEConfigure, as I was doing with the VGR2? .......................................... 90

20.14. Q14: The Blue Power Panel could be powered through the VE.Net network, can I also do that with a

Cerbo GX? ...................................................................................................................... 90

20.15. Q15: What type of networking is used by the Cerbo GX (TCP and UDP ports)? ............................... 90

20.16. Q16: What is the functionality behind the menu item Remote support (SSH), in the Ethernet menu? ....... 91

20.17. Q17: I don’t see support for VE.Net products in the list, is that still coming? .................................... 91

20.18. Q18: What is the data usage of the Cerbo GX? .................................................................... 91

20.19. Q19: How many AC Current Sensors can I connect in one VE.Bus system? ................................... 91

20.20. Q20: Issues with Multi not starting when Cerbo GX is connected / Caution when powering the Cerbo

GX from the AC-out terminal of a VE.Bus Inverter, Multi or Quattro ...................................................... 91

20.21. Q21: I love Linux, programming, Victron and the Cerbo GX. Can I do more? ................................... 92

20.22. Q22: How do I change the logo ....................................................................................... 93

20.23. Q23: Multi restarts all the time (after every 10sec) ................................................................. 93

Cerbo GX Manual

20.24. Q24: What is Error #42? ............................................................................................... 93

20.25. Q25: My GX device reboots itself. What is causing this behavior? ............................................... 93

20.26. GPL Note ............................................................................................................... 94

21. Appendix ........................................................................................................................... 95

21.1. RV-C ....................................................................................................................... 95

21.1.1. Supported DGNs ............................................................................................... 95

21.1.2. RV-C out ........................................................................................................ 95

21.1.3. DGN 60928 Unique Identity Numbers ....................................................................... 98

21.1.4. RV-C in .......................................................................................................... 98

21.1.5. Device Classes ................................................................................................ 98

21.1.6. Instance Translation ........................................................................................... 99

21.1.7. RV-C Fault and Error Handling ............................................................................... 99

21.1.8. RV-C Device Priority .......................................................................................... 100

Cerbo GX Manual

1. Introduction

1.1. What is the Cerbo GX?

The Cerbo GX sits at the heart of your energy installation. All the other system-components - such as inverter/chargers, solar

chargers, and batteries - are connected to it. The Cerbo GX ensures that they all work in harmony.

There is an optional touch screen accessory for the Cerbo GX called the GX Touch.

Monitoring of the system can be done either with the Cerbo GX in front of you - or from anywhere in the world using an internet

connection and the VRM Portal.

The Cerbo GX also provides Remote firmware updates and allows settings to be changed Remotely.

The Cerbo GX is part of the GX product family. GX products are Victron's state-of-the-art monitoring solution that run our

Venus OS operating system.

All the information in this manual refers to the latest software. You can check your device has the latest version in the Firmware

menu when the GX device is connected to the internet. For installations without internet, you can find the latest version in Victron

Professional.

1.2. What's in the box?

• Cerbo GX

• Power cable with inline fuse and M8 terminal eyes for battery or DC busbar-attachment.

• VE.Can terminators (2 pcs)

• Terminal Blocks for all the connectors on each side.

•Watch this Video for an unboxing and overview of the interfaces.

https://www.youtube.com/embed/3wheKaU2_qw

Cerbo GX Manual

Page 1 Introduction

2. Installation

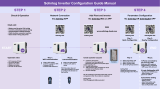

2.1. Cerbo GX Overview of connections

CANCANCANCAN

2 x Potential Free Relays

Generator start/stop, alarm signaling, remote control switch

Ekrano GX power

from battery

VE.Bus RJ45

Digital Multi Control GX

Multi

MultiPlus

MultiPlus-II

Quattro

Quattro-II

VE.Bus Phoenix Inverter

Networking

Modbus TCP,

Internet connectivity,

Node-RED

Ethernet

3 x VE.Direct

ports

BMV & SmartShunt

SmartSolar & BlueSolar MPPT

VE.Direct inverter, Phoenix Smart IP43

charger, Peak Power Pack

RS485 Energy meter

3 x USB ports (one

power only)

GX LTE 4G

RS485 to USB interface

USB hubs

WiFi dongles

Keyboard

USB GPS modules

USB memory

VE.Can RJ45

VE.Can to CAN-bus BMS

cable Type A or B

Victron Compatible Battery Management Systems

Built-in Bluetooth & WiFi

Connection to

VictronConnect app

with Remote Console,

Bluetooth smart sensors

SmartSolar MPPT VE.Can

VE.Can RJ45

Lynx Smart BMS

1 x VE.Can, 1 x BMS-can

Inverter RS Smart Solar,

MPPT RS Solar, Multi RS,

SmartSolar VE.Can, Lynx

Shunt VE.Can, Lynx Smart

BMS, Skylla-i, Skylla-IP65

Internet router

500 kbps

Managed Battery BMS

VRM &

Remote

Support

Compatible

AC PV inverter

To Marine NMEA 2000

Network

VE.Can to NMEA 2000

micro-C male cable

Zigbee wireless to USB

Compatible

Marine MFD

Zigbee wireless to RS485

adapter

EM24 Ethernet

Energy meter

MicroSD card

firmware updates

data logging

- Aux

Error

- Vbatt +

-

- Aux

Error

- Vbatt +

-

- Aux

Error

- Vbatt +

-

- Aux

Error

- Vbatt +

-

VE.Bus RJ45

MPPT RS

230W

67

814W

240W

230W

67

814W

240W

230W

67

814W

240W

VE.Can RJ45

VE.Can RJ45

GX LTE 4G

EV Charging Station

WiFi, Bluetooth,

Modbus TCP

Skylla-i

4 x Digital inputs

Door Alarm

Bilge pump

Bilge alarm

Burglar alarm

Smoke alarm

Fire alarm

CO2 alarm

Generator running

5V max – not isolated

4 x Temperature

inputs

4 x Resistive tank level inputs4 x Resistive tank level inputs

Cerbo GX power

from battery

GX Touch 50/70 touchscreen display

230 W

67

814 W

240 W

230 W

67

814 W

240 W

230 W

67

814 W

240 W

2.2. Power

The device is powered by using the Power in V+ connector. It accepts 8 to 70 V DC. The device will not power itself from any of

the other connections (eg network). The supplied DC power cable includes an inline 3.15 A slow blow fuse.

If the DC voltage exceeds 60V, the Cerbo GX is classified as a “built-in product”. Installation should be in such a way the user

cannot touch the terminals.

When the Cerbo GX is used in an installation with a VE.Bus BMS, connect the Power in V+ on the Cerbo GX to the terminal

labelled 'Load disconnect' on the VE.Bus BMS. Connect both negative leads to the negative stub of a common Battery.

A Cautionary word about Powering from the AC-out terminal of a VE.Bus Inverter, Multi or Quattro:

If you power the Cerbo GX from an AC adaptor connected to the AC-out port of any VE.Bus product (Inverter, Multi or Quattro),

then a deadlock will occur after the VE.Bus products are powered-down for any reason (after any operational fault or during

a black start). The VE.Bus devices will not boot-up until the Cerbo GX has power …but the Cerbo GX will not boot-up until it

has power. This deadlock can be rectified by briefly unplugging the Cerbo GX VE.Bus cable at which point you will observe the

VE.Bus products will immediately begin to boot-up.

Or a modification can be done to the RJ45 cabling. See FAQ Q20 [91]for more information about this.

Note that both with or without above modification, powering the monitoring equipment with the AC-out of an inverter/charger

(ofcourse) has the disadvantage that all monitoring is shut down when there is a problem that causes the inverter/charger to shut

Cerbo GX Manual

Page 2 Installation

down. Examples are Inverter overload, high temperature or low battery voltage. It is therefore recommended to power the GX

device from the battery.

Isolation

Because the Cerbo GX is connected to many different products, please ensure that proper care is taken with isolation to prevent

ground loops. In 99% of installations this will not be a problem.

• The VE.Bus ports are isolated

• The VE.Direct ports are isolated

• The VE.Can ports are not isolated.

• The USB ports are not isolated. Connecting a Wi-Fi Dongle or GPS Dongle will not create a problem as it is not connected

to another power supply. Even though there will be ground loop when you mount a separately-powered USB hub, during

extensive testing we have not found that it caused any issues.

• The Ethernet port is isolated, except for the shield: use unshielded UTP cables for the Ethernet network

Extending USB ports by use of a self-powered USB hub

Although the number of USB ports can be extended by using a hub, there is a limit to the amount of power that the onboard USB

port can provide. When extending the number of USB ports, we recommend you always use powered USB hubs. And to minimize

the chance of issues, be sure to use good-quality USB hubs. As Victron also offers a VE.Direct to USB adapter, you can use this

arrangement to increase the number of VE.Direct devices you can connect to your system, please see this document for the limit

of how many devices can be attached to various different GX devices.

2.3. Mounting options and accessories

https://player.vimeo.com/video/706533134#t=5m47s

2.4. Connecting Victron products

2.4.1. Multis/Quattros/Inverters (VE.Bus products)

In order to keep this document short we are going to refer to all Multis, Quattros and Inverters as VE.Bus products.

The earliest version of the VE.Bus devices which can be connected to the Cerbo GX is 19xx111 or 20xx111, which were released

in 2007. VE.Bus firmware 26xxxxx and 27xxxxx are also supported …but 18xxxxx is not.

Note that for Multis, Quattros and EasySolars, it is not possible to use the Remote On/Off (header on the VE.Bus control PCB) in

combination with a Cerbo GX. There should be wire between the left and middle terminal, as it is when shipped from the factory.

In case a wired switch that disables the system is required, use the Safety Switch Assistant instead.

This limitation does not apply to the next generation of VE.Bus inverter/chargers: when using a MultiPlus-II, Quattro-II or

EasySolar-II, the Remote on/off terminal header *can* be used in combination with Cerbo GX.

Single VE.Bus products

To connect a single VE.Bus product, connect it to one of the VE.Bus sockets on the back of the Cerbo GX. Both sockets are

identical, use either one. Use a standard RJ45 UTP cable, see our pricelist.

Parallel, split- and three-phase VE.Bus systems

To connect multiple VE.Bus products, configured as a parallel, split-phase or three phase VE.Bus system, connect either the first

or the last VE.Bus product in the chain to either one of the VE.Bus sockets on the back of the Cerbo GX. Use a standard RJ45

UTP cable, see our pricelist.

VE.Bus systems with Lithium batteries and a VE.Bus BMS

• Connect the Cerbo GX to the socket labelled ‘MultiPlus/Quattro’, or to one of the Multis/Quattros in the system. Do not connect

it to the Remote panel socket on the VE.Bus BMS.

• Note that it will not be possible to control the On/Off/Charger Only switch. This option is automatically disabled in the Cerbo GX

menu when a VE.Bus BMS is used. The only way to control a Multi or Quattro when used with a VE.Bus BMS is to add a Digital

Multi Control to the system. Setting the input current limit is possible in systems with a VE.Bus BMS.

• Combining MultiPlus/Quattro with a VE.Bus BMS and a Digital Multi Control is possible. Simply connect the Digital Multi Control

to the RJ-45 socket on the VE.Bus BMS labelled Remote panel.

• To allow auto-power-down in the Cerbo GX in case of a low battery, make sure the Cerbo GX is powered via the VE.Bus

BMS: connect Power in V+ on the Cerbo GX to Load disconnect on the VE.Bus BMS. And connect both negative leads to the

negative stub of a common Battery.

Cerbo GX Manual

Page 3 Installation

Combining the Cerbo GX with a Digital Multi Control

It is possible to connect both a Cerbo GX and a Digital Multi control to a VE.Bus system. The ability to switch the product On, Off

or set it to Charger Only via the Cerbo GX will be disabled. The same applies to the input current limit: when there is a Digital

Multi Control in the system, the input current limit which is set at that control panel will be the master-setting, and changing it on

the Cerbo GX will not be possible.

Connecting multiple VE.Bus systems to a single Cerbo GX

Only one VE.Bus system can be connected to the VE.Bus ports on the back of the Cerbo GX. The professional way to to monitor

more systems is to add a second Cerbo GX

If you do require to connect more than one system to the same Cerbo GX, use an MK3-USB. Functionality will be limited:

• Only the system connected to the built-in VE.Bus ports is used to generate the data on the Overview pages.

• All connected systems will be visible on the Device-list

• All connected systems will be taken into account for Energy consumption and distribution calculations (kWh graphs on VRM)

• Only the system connected to the built-in VE.Bus ports is used for the Generator start/stop logic

• In case of an ESS system, only the system connected to the built-in VE.Bus ports is used in the ESS mechanisms. The other

one is displayed in the device list only.

Alternatively the VE.Bus to VE.Can interface (ASS030520105) can be used. Add one for each additional system. Note that we

advise against it; this interface is a deprecated product. Make sure that the VE.Can network is terminated and powered. For

powering the VE.Can network, see Q17 in our data communication whitepaper.

Additional features provided by a GX device to VE.Bus products

An internet connected GX device allows for remote configuration via the VRM Portal. Please read the Remote VE.Configure

manual for more information, system requirements and specific steps to access this feature.

2.4.2. Battery Monitor SmartShunt, BMV-700 series; and MPPTs with a VE.Direct port

Direct connection via a VE.Direct cable is limited to the number of VE.Direct ports on the device (see Overview of Connections).

There are two types of VE.Direct cable available:

1. Straight VE.Direct cables, ASS030530xxx

2. VE.Direct cables with an angled connector on one end. These are designed to minimize the required depth behind a panel,

ASS030531xxx

VE.Direct cables have a maximum length of 10 metres. It is not possible to extend them. If longer lengths are required, use a

VE.Direct to USB adapter with an active USB extension cable.

It is also possible to use the VE.Direct to VE.Can interface, but note that this only works for BMV-700 and BMV-702. Not for the

BMV-712, MPPT solar chargers and Inverters with a VE.Direct port. See next paragraph for more information on that VE.Can

interface.

Connecting more VE.Direct devices to your Cerbo GX than number of VE.Direct Ports

First of all, note that the maximum of VE.Direct devices that can be connected is GX device specific, and constrained by the CPU

power. It may also be reduced for very complex systems, such as many AC PV inverters or synchronised inverter chargers, etc.

So always allow some additional headroom in the design. How they are connected, so direct, via USB or hub does not change

this maximum. See here for the maximum limit on all GX devices Devices.

For the Cerbo GX, this limit 15.

Then, these are the options on how to connect more VE.Direct products than available VE.Direct ports:

• Option 1: Use the VE.Direct to USB interface. The Cerbo GX has built-in USB ports (see Overview of Connections). Use a

USB-hub when additional USB ports are required.

• Option 2: (Only!) the BMV-700 and BMV-702 can also be connected using the VE.Direct to VE.Can interface. Note that the

BMV-712, MPPTs and VE.Direct Inverters cannot be connected using this CAN-bus interface as it does not translate their data

into CAN-bus messages. When using the VE.Direct to VE.Can interface, make sure that the VE.Can network is terminated,

and also powered. For powering the VE.Can network, see Q17 in our data communication whitepaper. Lastly, note that this

CAN-bus interface is deprecated.

DC Load Monitor Mode

If you wish to use a SmartShunt or BMV-712 to monitor individual DC circuits, rather than as a whole-of-system battery monitor

you can change the Monitor mode setting from Battery Monitor to DC Energy Meter in VictronConnect.

If DC meter is selected, you can the select the following types (also in VictronConnect);

Cerbo GX Manual

Page 4 Installation

Solar charger, Wind charger, Shaft generator, Alternator, Fuel cell, Water generator, DC/DC charger, AC charger, Generic source,

Generic load, Electric drive, Fridge, Water pump, Bilge pump, DC system, Inverter, Water heater

Once connected to a GX device, the type, and the amps and power of the DC load is shown in the user interfaces and available

on the VRM Portal.

When configured as type “DC System”, the GX does more than just recording and visualisation:

1. the power shown in the DC system box is the sum of power reported by all SmartShunts configured as such. Allowing

multiple meters is done to accommodate for example a catamaran, so you can measure the DC Systems on Port hull and on

Starboard hull.

2. the DC System Current is being compensated for when setting DVCC charge current limits to Multis, Quattros and Solar

Chargers. For example when a load of 50A is being measured, and CCL by the battery is 25A, the limit given to the Multis

& Solar Chargers is 75A. An improvement for systems with significant DC loads such as Yachts, Coaches and RVs.

Notes and limitations: (A) this feature is available for SmartShunts and BMV-712. Not for BMV-700 or BMV-702.

(B) Setting the meter mode is done with VictronConnect, in the BMV/SmartShunt itself.

(C) The NMEA2000-out feature does not support these new types, for example when using a SmartShunt to measure output of

an alternator, that data is not made available on NMEA2000.

Notes about older VE.Direct MPPTs

• An MPPT 70/15 needs to be from year/week 1308 or later. Earlier 70/15s are not compatible with the Cerbo GX , and

unfortunately upgrading the MPPT firmware will not help. To find the year/week number of your model, look for the serial

number which is printed on a label on its back. For example number HQ1309DER4F means 2013, week 09.

2.4.3. VE.Can Devices

To connect a product with a VE.Can port, use a standard RJ45 UTP cable (available with straight and elbow connectors).

Don't forget to terminate the VE.Can network at both ends using a VE.Can terminator. A bag with two terminators is supplied with

each VE.Can product. They are also available separately.

Other notes:

1. In order to work with the Cerbo GX, an MPPT 150/70 must be running firmware v2.00 or newer.

2. You can combine a Skylla-i control panel with a Cerbo GX.

3. You can combine a Ion Control panel with a Cerbo GX.

4. All VE.Can devices power the VE.Can network, so it won't be necessary to power the VE.Can network separately in these

circumstances. All the protocol converters, for example the VE.Bus to VE.Can interface; and the BMV to VE.Can interface, do

not power the VE.Can network.

The following products also support VictronConnect-Remote monitoring and configuration:

• Lynx Shunt VE.Can and Lynx Smart BMS

• Multi RS, Inverter RS and MPPT RS

• Skylla-i and Skylla-IP44/-IP65 (requires firmware v1.11)

• all VE.Can solar chargers except the very old (big rectangular case with display) BlueSolar MPPT VE.Can 150/70 and 150/85

2.4.4. VE.Can and BMS-Can Interfaces

The Cerbo GX has two CANbus interfaces. They are independent from a data and connected device perspective. They are not

electrically isolated. One is labelled VE.Can, the other is labeled BMS-Can, with a screen print on the top side of the unit when

it is facing towards you. These each correspond to the 'VE.Can port' and BMS-Can port' listed in the services menu of the GX

software.

By default; VE.Can is set to 250 kbit/s & BMS-Can (if present) is set to 500 kbit/s

VE.Can is intended to be used for the Victron (and Victron compatible) VE.Can products, such as the VE.Can MPPTs, and

VE.Can Lynx Shunt. You can string these VE.Can 250 kbit/s devices together along this bus. It must be terminated at both ends

with the included VE.Can terminators.

BMS-Can is intended to be used with compatible managed battery systems, such as Pylontech, BYD, Freedomwon and many

more. These must be terminated at the Victron end (on the Cerbo GX) with the included terminator (same one as used with

VE.Can). It may or may not be necessary to terminate at the managed battery, BMS or BMU - this will be documented in the

specific Victron Compatible managed battery instructions for that battery. Some batteries automatically terminate.

You can't mix VE.Can and BMS-Can on the same bus. If you wish to use both, they require a GX device with two separate buses,

each with 2 RJ45 ports - 4 CANbus ports in total.

Cerbo GX Manual

Page 5 Installation

You cannot set BMS-Can ports to anything other than 500 kbit/s, and disabled.

You CAN set the VE.Can port from 250 kbit/s to be 500 kbit/s (or one of several other CANbus speeds for other CANbus

applications).

Other types of Batteries and BMS may claim compatibility with BMS-Can, or VE.Can, but if they are not on the battery

compatibility list then they have not been tested and confirmed to work by Victron.

One extra element of possible confusion is that there ARE some BMS products on the market that use a CANbus BMS profile at

250 kbit/s.

These can only be connected to the VE.Can port, and it must also be set to match this (VE.Can & CAN-bus BMS (250 kbit/s)) in

the services menu for the VE.Can port.

These BMS can be used in the same cable daisy chain as other Victron VE.Can devices.

2.4.5. Inverter RS, Multi RS and MPPT RS

The Inverter RS, Inverter RS Solar and Multi RS have both VE.Direct and VE.Can interfaces. For these specific products, it is

only possible to connect a GX device via the VE.Can interface, and it is not possible to connect a GX device via the VE.direct

interface.

The VE.Direct interface on these specific products is only used for connection of a VE.Direct to USB adapter for programming.

This restriction does not apply to the MPPT RS, which can be connected to a GX device via either VE.Direct or VE.Can.

2.4.6. BMV-600 series

Connect the BMV-600 using the VE.Direct to BMV-60xS cable. (ASS0305322xx)

2.4.7. DC Link box

Connect the DC Link box, using the RJ-12 cable supplied. Then connect the BMV-700 to the Cerbo GX - see connecting

BMV-700 for more instructions.

2.4.8. VE.Can Resistive Tank Sender Adapter

See its page and manual on our website for details about the Adapter.

To connect a product with a VE.Can port, use a standard RJ45 UTP cable.

Don't forget to terminate the VE.Can network on both ends using a VE.Can terminator. A bag with two terminators is supplied with

each VE.Can product. They are also available separately (ASS030700000). (Available with straight or elbow connectors.)

Make sure that the CAN-bus is powered, see the Power chapter in the Tank Sender Adapter manual for details.

2.5. Connecting a PV Inverter

Measuring the output of a PV Inverter will provide the user with an overview of both actual power balance and the energy

distribution. Note that these measurements are only used to display information. They are not needed, nor used, by the

installation for its performance. Besides monitoring, the GX device can also curtail some types and brands of PV Inverters,

ie. reduce their output power. This is used, and required, for the ESS Zero or limited feed-in feature.

Direct connections

Type Zero feed-in Details

Fronius Yes LAN Connection, see GX - GX - Fronius manual

SMA No LAN Connection, see GX - GX - SMA manual

SolarEdge No LAN Connection, see GX - SolarEdge manual

ABB Yes LAN Connection, see GX - ABB manual

Using a meter For PV Inverters that cannot be interfaced digitally, a meter can be used:

Type Zero

feed-in

Details

AC Current Sensor No Connected to inverter/charger analog input. Lowest cost - least accurate. Energy

Meter

Energy Meter No Wired to the Cerbo GX, or connected wirelessly using our Zigbee to USB/RS485

interfaces. See the Energy Meters start page

Cerbo GX Manual

Page 6 Installation

Type Zero

feed-in

Details

Wireless AC sensors No See the Wireless AC Sensor manual - Discontinued

2.6. Connecting a USB GPS

Use a GPS to remotely, on the VRM Portal, track vehicles or boats. Also its possible to configure a Geofence, which will

automatically send an alarm when the system leaves a designated area. And gps-tracks.kml files can be downloaded, to for

example open in Navlink and Google Earth.

Victron does not sell USB-GPS, but the Cerbo GX will support third-party GPS modules which use the NMEA0183 command-set

- almost all do. It can communicate at both 4800 and 38400 baud rates. Plug the unit into either of the two USB sockets …

connection may take a few minutes, but the Cerbo GX will automatically recognize the GPS. The unit's location will automatically

be sent to the VRM online portal and its position shown on the map.

The Cerbo GX has been tested for compatibility with:

• Globalsat BU353-W SiRF STAR III 4800 baud

• Globalsat ND100 SiRF STAR III 38400 baud

• Globalsat BU353S4 SiRF STAR IV 4800 baud

• Globalsat MR350 + BR305US SiRF STAR III 4800 baud

2.7. Connecting a NMEA 2000 GPS

Use a GPS to remotely, on the VRM Portal, track vehicles or boats. Also its possible to configure a Geofence, which will

automatically send an alarm when the system leaves a designated area. And gps-tracks.kml files can be downloaded, to for

example open in Navlink and Google Earth.

The third party NMEA 2000 GPS sender must meet the following requirements:

• The NMEA 2000 device class must be 60, Navigation.

• The NMEA 2000 device function must be 145, Ownship Position (GNSS).

• Position (latitude, longtitude) must be transmitted in either PGN 129.025.

• Height, which is optional, must be transmitted in PGN 129.029.

• Course and speed (both optional), must be transmitted in PGN 129.026

Most NMEA 2000 GPS-es are expected to work. Compatibility has been tested with:

• Garmin GPS 19X NMEA 2000

To connect a NMEA 2000 network to the VE.Can port on the GX device, which both have a different style connector, there are two

solutions:

1. The VE.Can to NMEA2000 cable. Which by either inserting or leaving out the fuse allows to either power the NMEA2000

network with Victron equipment, or not. Take note of below warning.

2. The 3802 VE.Can Adapter by OSUKL. Its advantage is that it lends itself well to connecting a single NMEA-2000 device such

as a tank sender into a VE.Can network. It's also able to power a lower voltage NMEA-2000 network directly from a 48V

Victron system.

Warning and solution for 24V and 48V systems

Whilst all Victron components accept up to 70V input on their CAN-bus connections, some NMEA 2000 equipment does not. They

require a 12V powered NMEA 2000 connection, and sometimes work up to 30 or 36V. Make sure to check the datasheet of all

used NMEA 2000 equipment. In case the system contains NMEA 2000 that requires a network voltage below the battery voltage,

then either see above 3802 VE.Can Adapter by OSUKL. Or alternatively install the VE.Can to NMEA 2000 cable without it’s fuse,

and provide suitable power to the NMEA 2000 network using for example a NMEA 2000 power adapter cable – which is not

supplied by Victron. The VE.Can port on the GX Device does not need external power to operate.

2.8. Connecting a Fischer Panda Generator

See GX - Fischer Panda generators.

Cerbo GX Manual

Page 7 Installation

2.9. Connecting a GX Tank 140

The GX Tank 140 is an accessory for our range of GX system monitoring products.

It takes readings from up to four tank level sensors.

Tank levels can be read-out locally in the system, as well remotely through our VRM Portal.

The GX Tank 140 is compatible with current senders (4 to 20 mA) as well as voltage senders (0 to 10 V). The connection to the

GX Device is via USB, which is also how the GX Tank is powered: no additional power wires required.

To make wiring the tank sender as simple as possible, two of the four inputs provide a 24 V power supply, to power the sender.

Using the other two channels requires an external power supply, and there is a power in terminal together with fused outputs to

facilitate that.

Upper and lower limits are configurable, to allow using senders that provide only part of the scale, for example 0 to 5 V.

For marine applications, the GX Device can transmit these tank levels on the NMEA 2000 network to be picked up by other

displays such as an MFD.

The GX Tank 140 product page links to the complete documentation of this product.

2.10. Connecting Tank Level Sensors

See the Connection Overview for the location and number of tank level sensor inputs.

The tank level inputs are resistive and should be connected to a resistive tank sender. Victron does not supply tank senders.

The built-in tank sensor connections do not support mA or 0-5V type sensors, this type will require additional accessories or

replacement with a resistive type sensor.

Sensors are enabled (and disabled) in the I/O menu of the GX device settings. Once enabled, the tank will appear in the GX

menu with options to customise the setup to suit your specific installation.

Set the tank volume unit (Cubic meter, litre, imperial or U.S gallon), and capacity. It is also possible to configure custom shapes

for non-linear tanks, with up to 10 variations e.g 50% of sensor is equal to 25% of volume & 75% of sensor is equal to 90% of

volume.

The tank level ports can each be configured to work with either European (0 - 180 Ohm); or US tank senders (240 - 30 Ohm)

standards; or to configure a custom Ohm resistance range between 0 Ohm and 300 Ohm (requires firmware v2.80 or higher).

You can set tank fluid type to Fuel, fresh water, waste water, live well, oil, blackwater (sewage) and also set a custom name.

Tank level data is sent to VRM, shown on the boat and motorhome overview displays (if connected and enabled), and can be

used as a trigger for the relay when it is set to 'tank pump'.

Cerbo GX Manual

Page 8 Installation

To physically attach the tank probes requires a ferrule or exposed copper end of at least 10 mm+ to be inserted into the

removable terminal block connector. Once correctly attached, you must use the orange tab if you wish to remove the secured

wire.

2.11. Connecting third-party NMEA 2000 tank senders

A third party NMEA 2000 tank sender must meet the following requirements to be visible on the GX Device:

• Transmit the NMEA 2000 Fluid Level PGN, 127505

• The NMEA 2000 device class needs to either General (80) in combination with function code Transducer (190), or Sensor

(170). Or, the NMEA 2000 device class needs to be Sensors (75), in combination with function Fluid Level (150).

A single function reporting multiple Fluid Levels is currently not supported.

For some tank senders it is also possible to configure the capacity and the fluid type on the GX Device menus - for example the

Maretron TLA100. This facility may be available with other senders made by other manufacturers - it's well-worth trying.

Tested compatible NMEA2000 tank senders:

• Maretron TLA100

• Maretron TLM100

• Navico Fluid Level Sensor Fuel-0 PK, partno. 000-11518-001. Note that you need a Navico display to configure the Capacity,

Fluid type, and other parameters of the sensor. See voltage warning below.

• Oceanic Systems (UK) Ltd (OSUKL) - 3271 Volumetric Tank Sender. In case it doesn’t work, it needs a firmware update.

Contact OSUKL for that. See voltage warning below.

• Oceanic Systems UK Ltd (OSUKL) - 3281 Water Level Sender. See voltage warning below

Most likely others work as well. If you know of one working well, please edit this page -or- get in touch with us on Community ->

Modifications.

To connect an NMEA2000 network to the VE.Can port on the GX device, which both have different type connectors, there are two

solutions:

1. The VE.Can to NMEA2000 cable. Which by either inserting or leaving out the fuse allows to either power the NMEA2000

network with Victron equipment, or not. Take note of below warning.

2. The 3802 VE.Can Adapter by OSUKL. Its advantage is that it lends itself well to connecting a single NMEA-2000 device such

as a tank sender into a VE.Can network. It's also able to power a lower voltage NMEA-2000 network directly from a 48V

Victron system.

Warning and solution for 24V and 48V systems

Whilst all Victron components accept up to 70V input on their CAN-bus connections, some NMEA2000 equipment does not. They

require a 12V powered NMEA2000 connection, and sometimes work up to 30 or 36V. Make sure to check the datasheet of all

used NMEA2000 equipment. In case the system contains NMEA2000 that requires a network voltage below the battery voltage,

then either see above 3802 VE.Can Adapter by OSUKL. Or alternatively install the VE.Can to NMEA2000 cable without it’s fuse,

and provide suitable power to the NMEA2000 network using for example a NMEA-2000 power adapter cable – which is not

supplied by Victron. The VE.Can port on the GX Device does not need external power to operate.

2.12. Connecting Temperature Sensors

2.12.1. Hardwired sensors

See the Connection Overview for the location and number of temperature sensors.

They can be used to measure & monitor all kinds of temperature-inputs.

Cerbo GX Manual

Page 9 Installation

Temperature senders are not included. The required sensor is ASS000001000 - Temperature sensor Quattro, MultiPlus and GX

Device. Note that this is different to the BMV temperature accessory.

They are not required to be connected to the battery (though they appear like a battery lug).

To physically attach the temperature probes requires a ferrule or exposed copper end of at least 10 mm+ to be inserted into the

removable 4-pin terminal block connector. Once correctly attached, you must push in the orange tab if you wish to remove the

secured wire. Sensors are connected with the red wire to the top of the connector, and the black wire to the bottom.

Sensors are enabled (and disabled) in the Settings → I/O → Analog inputs menu of the GX device settings.

Once enabled, temperature sensor data is visible in the device list, and also logged to VRM.

Selecting the temperature sensor from the device list menu then allows you to set the temperature type setting to either Battery,

Fridge or Generic. It is also possible to set a custom name in the Device menu.

It is possible to adjust the temperature offset and scale, however for now this feature is limited to users with 'superuser'

permission level.

Cerbo GX Manual

Page 10 Installation

2.12.2. Wireless Bluetooth Ruuvi sensors

The Ruuvi sensor features temperature, humidity and atmospheric pressure streamed wirelessly to the GX device.

The Cerbo GX built-in bluetooth connection is disabled when the internal CPU temperature exceeds 53 degrees C (influenced by

load and/or ambient temperature). For reliable operation it is necessary to use a USB Bluetooth adapter.

USB Bluetooth adapters that have been tested and known to work:

USB Bluetooth adapter

Insignia (NS-

PCY5BMA2) Logilink BT0037 TP-Link UB400(UN) TP-Link UB400(UN) Ideapro USB bluetooth

adapter 4.0

Ewent EW1085R4 Laird BT820 Laird BT851 Kinivo BTD-400 -

A list of additional adapters that are also being tested, as well as adapters that have been tested and are known not to work, is

available here: https://community.victronenergy.com/questions/112834/connect-ruuvi-to-ccgx.html

Installation procedure

Make sure that Bluetooth is enabled in the Bluetooth menu (enabled by default)

Go to Settings → I/O → Bluetooth sensors menu, then Enable to enable Bluetooth temperature sensors.

The Ruuvi sensors come supplied with a removable plastic pull tab. This prevents it from discharging while on the shelf. Pull out

the plastic tab and the unit will start transmitting its temperature information.

The sensor should appear in the menu, "Ruuvi ####" - with a 4 hexidecimal device ID, enable the specific Ruuvi sensor.

The Bluetooth adapters submenu displays a list of available Bluetooth adapters. The menu option Continuous scanning

permanently scans for new Bluetooth sensors.

If you have multiple sensors, you may wish to physically write this device ID on the sensor case itself to help keep track.

The sensor should now be visible in the main menu - by default is labelled 'Generic temperature sensor (##)'

Cerbo GX Manual

Page 11 Installation

It is possible inside the temperature sensor menu to adjust the type, and also to set a custom name.

The Ruuvi sensors are estimated to last more than 12 months on a single replaceable CR2477 3V Li coin battery. Both the

internal battery voltage and the battery status are displayed in the menu of the respective sensor. Status 'Ok' = battery voltage

≤2.50V. Status 'Sensor battery low' = battery voltage ≥2.50V.

It is possible to update the firmware for the Ruuvi with Ruuvi's own separate phone app, though this is not necessary unless you

are experiencing issues.

2.13. Connecting IMT Solar Irradiance, Temperature and Wind Speed Sensors

Compatibility

Ingenieurbüro Mencke & Tegtmeyer GmbH (IMT) offer a range of digital silicon irradiance sensor models within the Si-RS485

series that are all compatible with a Victron GX device.

The optional/additional external module temperature, ambient temperature and wind speed sensors are also supported.

Optional/additional external sensors are either connected to the solar irradiance sensor with pre-installed plugs or pre-wired

to the solar irradiance sensor (external module and ambient temperature only). When external sensors are connected via an

appropriate solar irradiance sensor, all measurement data is transmitted to the Victron GX device with the single interface cable.

Each model solar irradiance sensor within Si-RS485 series has a different capability with regards to external sensors (or comes

with an external sensor pre-wired), so carefully consider any future desires/requirements before initial purchase.

It is also possible to connect an independent IMT Tm-RS485-MB module temperature sensor (visible as ‘cell temperature’) or IMT

Ta-ext-RS485-MB ambient temperature sensor (visible as ‘external temperature’) directly to the Victron GX device, without a solar

irradiance sensor or in addition to one.

Operation

The IMT Si-RS485 series solar irradiance sensors operate using RS485 electrical interface and Modbus RTU communication

protocol.

The Victron GX device must be running version 2.40 or later.

The IMT sensor needs to be firmware version 1.52 minimum - for more information about this please contact IMT.

Physical connection to the Victron GX device is via USB port and requires a Victron RS485 to USB interface cable.

A suitable external DC power source (12 to 28 VDC) is also required - the sensor is NOT powered via USB.

Wiring Connections

The schematic in the installation guide below depicts the wiring configuration in a typical installation.

Cerbo GX Manual

Page 12 Installation

Wire connections

Si-Sensor Victron RS485 to USB interface Signal

Brown Orange RS485 Data A +

Orange Yellow RS485 Data B -

Red - Power Pos - 12 to 28 VDC

Black Power Neg/Gnd - 0 VDC

Black (thick) - Ground / Cable Shield / PE

- Red Power Pos - 5 VDC (not used)

- Black Power Neg/Gnd - 0 VDC (not used)

Brown Terminator 1 - 120R (not used)

Green Terminator 2 - 120R (not used)

Installation Notes

The maximum DC power supply voltage permitted for the IMT Si-RS485 series solar irradiance sensor range is 28.0 VDC -

accordingly for 24 V and 48 V battery banks/systems an appropriate Victron DC-DC converter (24/12, 24/24, 48/12 or 48/24) or

AC-DC adaptor must be utilised in the installation.

For 12 V battery banks/systems the IMT Si-RS485 series solar irradiance sensor range may be powered directly from the battery

bank and will continue to operate down to minimum voltage of 10.5 V (as measured at the sensor, account for voltage drop in the

cable).

For detailed wiring/installation notes and specifications refer to the IMT Si-RS485 series solar irradiance sensor 'Quick Reference

Guide' and Victron RS485 to USB interface cable ‘Datasheet’.

To ensure signal integrity and robust operation, particularly ensure that;

• Extension cabling complies with the minimum cross-sectional area specifications in the related table - dependent on DC supply

voltage and cable length

• Extension cabling has appropriate shielding and twisted pair cores

Cerbo GX Manual

Page 13 Installation

• The original cable attached to the Victron RS485 to USB interface is reduced to a maximum length of 20cm in installations

where the total cable length is over 10m or there are installation/site specific interference issues – in this case appropriate/high

quality cabling should be used for the entire cable length, rather than only for the extension length

• Cabling is installed separated/away from the main DC or AC power cabling

• All wiring is properly terminated (including unused wires) and properly isolated from weather/water ingress

• The sensor housing is not opened or tampered with during installation - as sealing integrity will be compromised (and warranty

void)

The IMT Si-RS485TC series solar irradiance sensor includes internal Galvanic Isolation (up to 1000V) between power supply and

RS485 Modbus circuits, accordingly the non-isolated Victron RS485 to USB interface is suitable for most installations.

However, if an isolated RS485 to USB interface is preferred the only compatible device is Hjelmslund Electronics USB485-

STIXL (any others type will not be recognised by the GX device).

Multiple Sensors

It is possible to connect multiple IMT Si-RS485 series solar irradiance sensors to a common Victron GX device, however a

dedicated Victron RS485 to USB interface is required for each individual unit.

Multiple units cannot be combined on a single interface (as this is not supported by the related Venus OS software).

Configuration

There is normally no need for any special/additional configuration – the default ‘as shipped’ configuration is compatible for

communication with a Victron GX device.

However, in cases where the IMT Si-RS485 series solar irradiance sensor has been previously used in another system and/or the

settings changed for any reason, it is necessary to restore the default configuration before further use.

To revise the configuration, download the IMT 'Si-MODBUS-Configuration software tool'. Follow the instructions in the IMT ‘Si

Modbus Configurator Documentation’. and check/update the following settings:

• MODBUS Address: 1

• Baud Rate: 9600

• Data Format: 8N1 (10 Bit)

For further support related to configuration of the IMT Si-RS485 Series irradiance sensors please contact IMT Solar directly.

User Interface - GX Device

Upon connection to the Victron GX device and power up the IMT Si-RS485 Series irradiance sensor will be automatically

detected within a few minutes and appear in the 'Device List' menu.

Within the ‘IMT Si-RS485 Series Solar Irradiance Sensor’ menu all available parameters will be automatically displayed

(dependent on the sensors connected) and update in real time.

Within the ‘Settings’ sub-menu it is possible to manually enable and disable any optional/additional external sensors that are

connected to the IMT Si-RS485 Series irradiance sensor.

Cerbo GX Manual

Page 14 Installation

2.13.1. Data Visualisation - VRM

To review logged historical data on the VRM portal, expand the ‘Meteorological Sensor’ widget list and select the ‘Meteorological

Sensor’ widget.

Data from all available sensor types will be automatically displayed in the graph. Individual sensors/parameters can also be

disabled/enabled by clicking on the sensor name/legend.

Cerbo GX Manual

Page 15 Installation

/