Page is loading ...

adjusted for the 10 unit grid

SIMPLESOFFIT® Soffit Framing System

Assembly and Installation Instructions

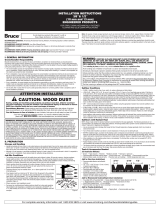

1. SYSTEM OVERVIEW

SimpleSoft® is a prefabricated grid framing system that

quickly and easily snaps together into an interior soft

allowing for a faster, more accurate framing installation.

This new framing system reduces time and labor associated

with cutting and measuring the framing members.

SimpleSoffit®

48" O.C

KAM12

KAM12

LAM12 or KAM12

LAM

Brace to Structure

every 96" O.C. min.

SimpleSoffit

SimpleSoffit

SimpleSoffit bending

with LAM12 or KAM12

Hanger Wire

to Structure

XL8945P

XL8945P

9/16"

1-1/4"

1-1/2"

2

1.1 Material Handling/Storage

Product requires proper handling. Please transport cartons supporting

the product so it doesn’t bend or twist. (Fig 1)

For storage, please store main beams in carton on a at rigid surface.

Opening the carton:

While the carton is on a at rigid surface, cut the long edge of the

carton to reveal the product inside (Fig 2). Once carton is opened

remove product from carton and take care that product stays straight

until clicking together. (Fig 3)

(Fig 2)

(Fig 3)

(Fig 1)

Envelope to

store six pieces

8"

8"

8"

26-3/8"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

3-5/8"

1-1/4"

Screw at corners

Protect with cap

3

1.2 Folding and Clicking SimpleSoft®

Keep the product at until ready to fold and click together. (Fig 4)

When folding the mains, ensure the proper alignment while clicking

together. Make sure each opposing Click Notch passing each other on the

right for proper locking with an audible click. (Fig 5)

The click conrms the Click Notch locked. Please note, a screw may be

needed in certain construction situations depending on the size, shape,

and condition of the soft (Fig 6). For assistance, contact your Armstrong®

Ceilings Installation Representative. Inquire with your Technical rep.

Install SimpleSoft frames in the space with Armstrong Drywall Grid

cross tees.

Standard SimpleSoft main spacing is 48" O.C. And maybe up to

72" O.C. depending on the loading condition. Please consider loading

when determining if 24", 36", 48", 60", or 72" cross tees should be used.

Product should be braced to structure as needed or 96" O.C.

1.3 Assembling with SimpleSoft® Screw Notch

When folding SimpleSoft main beams with bend dimensions tighter than

the minimum achievable with the Click Notch (see 1.8), assemble using the

SimpleSoft Screw Notch. (Fig 7A, 7B, 7C and 7D)

The Screw Notch allows tighter bend dimensions; HOWEVER, a screw

must be added once the main beam is folded.

Use snips to make two cuts as shown in (Fig 7B). Once cuts are made,

fold together with tabs passing to the right side of one another (Fig 7C).

Finally, use #8 panhead screw to secure Screw Notch assembly. (Fig 7D)

NOTE: For additional information on minimum bend dimensions, see

Section 1.8 Product Considerations and Capabilities, page 8.

(Fig 4)

(Fig 6)

(Fig 7B)

Envelope to

store six pieces

8"

8"

8"

26-3/8"

1-1/2"

1-1/2"

1-1/2"

1-1/2"

3-5/8"

1-1/4"

Screw at corners

Protect with cap

One screw at each

connection may be

necessary depending

on the installation

VIEW5

SCALE 1 / 2

A

DETAIL A

SCALE 1 : 1

B

DETAIL B

SCALE 2 : 1

SIMPLE SOFFIT FOLD 60° DETAILS

(Fig 5)

(Fig 7A)

(Fig 7C) (Fig 7D)

Click Notch

Click Notch

Tabs pass on right

side of each other

Screw Notch Cut here

Cut here

4

1.4 System Installation

Install SimpleSoft® frames in the space using Armstrong Drywall Grid

cross tees and KAM or LAM.

Connect SimpleSoft mains to the KAM

(Fig 8)

or LAM

(Fig 9)

as shown.

Standard SimpleSoft main spacing is 48" O.C. Product can be spaced

up to 72" O.C. depending on the loading condition. Please consider

loading when determining if 24", 36", 48", 60", or 72" cross tees should

be used.

(Fig 10)

Product should be braced to structure as needed or 96" O.C.

(Fig 8) (Fig 9)

(Fig 10)

SimpleSoffit with KAM SimpleSoffit with LAM

SimpleSoffit™

48" O.C

KAM12

KAM12

LAM12

or KAM12

LAM

Brace to

Structure Every

96" O.C. min.

SimpleSoffit

SimpleSoffit

SimpleSoffit bending

with LAM12 or KAM12

Hanger Wire

to Structure

XL8945P

XL8945P

48"

48"

SimpleSoft

48" O.C.

Spacing for SimpleSoft

Screw as

necessary

5

1.5 Product Attachment to structure

Product must be supported to structure via hanger wire or bracing

every 48" O.C. along the SimpleSoft® main beam.

There are many different conditions and applications for SimpleSoft.

Please use this as a guideline. Choose the best option for your

installation method.

For suspending soft framing to structure – installation of wire

should be on the vertical framing of the main runner where applicable.

(

Fig 11)

StrongBack can also be used. StrongBack™ screwed to SimpleSoft

framing every 48" is a solution for large plenum

drops.

(

Figs 12 and 13) (Fig 11)

(Fig 12)

SimpleSoft™

L-Upturn

Bracing as Required

Screw Attached to Cross Tee

KAM-151220E

SB12 StrongBack

Framing

Screws

Bracing as Required

Framing

Screws

SimpleSoft™

L-Upturn

SB12 StrongBack

KAM-151220E

(Fig 13)

Attach Hanger Wire

to the Vertical

Framing Member

6

1.6 Accessories attachments

Product can be adapted to work seamlessly with standard

Armstrong® Drywall Grid, transitions, light coves, and more.

For attachment to standard drywall grid, use the RC1. (Fig 14)

For additional attachment method splicing adjoining drywall main

beams, use framing scews attaching components together as shown

in (Fig 15).

For attachment to structure via black iron and Channel Beam Support

(CBS) hanger for SimpleSoft® grid.

(

Fig 16)

For attachment of Axiom® for light cove and perimeter integration.

(Fig 17)

(Fig 14)

(Fig 15)

(Fig 16)

(Fig 17)

5/8" Gypsum Board

2" one piece

Axiom® Classic

for Drywall

AXTBC

SimpleSoffit®

Hanger Wire

to Structure

SimpleSoft

Black Iron

#8 Sharp

Point Screws

CBS Hanger

for SimpleSoft™

SimpleSoft™

SimpleSoft

SimpleSoft™

HD8906

RC1

#8 Sharp Point Screws

12" Max 12" Max

SimpleSoft™

HD8906

HD8906

Framing

screws

SimpleSoft

Framing

Screws

7

1.7 Light Cove installation

Hanger wires must be installed at upper and lower corners.

SimpleSoft® main beam spacing may be no more than 48" O.C.

Consider 24" O.C. spacing as loading increases.

See (Fig 18) for SimpleSoft curved light cove detail and (Fig 19),

(Fig 20), and (Fig 21) for SimpleSoft straight light cove details.

Two (2) min no. 7" x 7/16" framing screws must be installed at corners,

(see Fig 9 on pg. 4). Limiting criteria will be deection at end of

cantilever (see Fig 17, where screw required is shown).

For cantilever distance, see Technical Guide for specic information.

(Fig 19)

(Fig 20)

(Fig 21)

(Fig 18)

SimpleSoft Curved Light Cove Detail

Hanger Wire to

Structure 48" O.C.

Armstrong

StrongBack™

SB12P

Armstrong®

Grid System

Screw

Required

Armstrong SimpleCurve®

SC-151220EQ

Armstrong

SimpleCurve

SC-151220EQ

Armstrong SimpleSoft®

Mains 16" or 24" O.C.

“X”

Armstrong

KAM-151220E

Armstrong

KAM-151220E

5/8" GYP Board

Light Fixture

Light Fixture

Axiom® One

Piece for

Drywall

Axiom AXTBC

ALTERNATIVE OPTION

Hanger Wire to

Structure 48" O.C.

Armstrong

StrongBack™

SB12P

Armstrong®

Grid System

Screw

Required

Armstrong SimpleCurve®

SC-151220EQ

Armstrong

SimpleCurve

SC-151220EQ

Armstrong SimpleSoft®

Mains 16" or 24" O.C.

“X”

Armstrong

KAM-151220E

Armstrong

KAM-151220E

5/8" GYP Board

Light Fixture

Light Fixture

Axiom® One

Piece for

Drywall

Axiom AXTBC

ALTERNATIVE OPTION

SimpleSoft Straight Light Cove Detail

Light Fixture

Axiom® One

Piece for

Drywall

Axiom AXTBC

ALTERNATIVE OPTION

Armstrong

SimpleSoft® Mains

A

rmstrong® Drywall

Cross Tee XL8945

Armstrong

Grid System

Screw

Required

Armstrong KAM-151220E

Armstrong

KAM-151220E

Armstrong

KAM-151220E

Armstrong

KAM-151220E

5/8" GYP Board

Light Fixture

“X”

Hanger Wire

to Structure

48" O.C.

SimpleSoft Straight Light Cove Detail

Hanger Wire

to Structure

48" O.C.

A

rmstrong® Drywall

Cross Tee XL8945

Armstrong Drywall Main Beam

HD8906 24" or 48" O.C.

Armstrong SimpleSoft®

Mains 24" or 48" O.C.

Armstrong

DW90C Armstrong

KAM-151220E

Armstrong

KAM-151220E

Armstrong

KAM-151220E

5/8" GYP Board

Light Fixture

“X”

Light Fixture

Axiom® One

Piece for

Drywall

Axiom AXTBC

ALTERNATIVE OPTION

Hanger Wire

to Structure

48" O.C.

A

rmstrong® Drywall

Cross Tee XL8945

Armstrong Drywall Main Beam

HD8906 24" or 48" O.C.

Armstrong SimpleSoft®

Mains 24" or 48" O.C.

Armstrong

DW90C Armstrong

KAM-151220E

Armstrong

KAM-151220E

Armstrong

KAM-151220E

5/8" GYP Board

Light Fixture

“X”

Light Fixture

Axiom® One

Piece for

Drywall

Axiom AXTBC

ALTERNATIVE OPTION

Light Fixture

Axiom® One

Piece for

Drywall

Axiom AXTBC

Hanger Wire to

Structure 48" O.C.

Armstrong SimpleSoft®

Mains 24" or 48" O.C.

Armstrong

KAM-151220E

Armstrong®

KAM-151220E

5/8" GYP Board

“X”

ALTERNATIVE OPTION

Armstrong

KAM-151220E

Light Fixture

SimpleSoft Straight Light Cove Detail

8

1.8 Product Considerations and Capabilities

Factory ends will be a minimum of 5-1/2" from rst notch. If

installation requires a dimension shorter than 5-1/2", it must be

trimmed in the eld.

Maximum 6 notches per main beam – combination of 3 bulb notches

and 3 face notches. (Fig 22)

See (Fig 23) for the minimum bend dimensions achievable with the

Click Notch. See (Fig 24) for the tighter bend dimensions achievable

with the Screw Notch.

Maximum 6 rout holes may be placed on a SimpleSoft® main beam –

location to be specied by customer.

Reference (Fig 23) and (Fig 24) for the shortest distance between notches.

5-1/2" is the minimum distance notches when face is oriented outward.

(Fig 23)

3-5/8" is the minimum distance that can be achieved with the

Screw Notch feature, but it must have #8 pan head screws at each

corner.

4-3/4" is the minimum distance between two notches with the bend

and click feature. 3" is the minimum distance that can be achieved with

the ScrewNotch feature, but it must have #8 pan head screws at each

corner.

NOTE: Cross tee height is slightly taller than SimpleSoft main beam

height. (Fig 25)

Armstrong AcoustiBuilt® Seamless Acoustical Ceiling System can

be installed on softs of any size or angle. For acoustical benet,

AcoustiBuilt is recommended on softs 36" or greater in height.

Standard Drywall is recommended for softs less than 36".

9/16"

1-1/4"

1-1/2"

Factory End

Bulb Side

Face Side

Click Notch

Double

Stitch

Face SideRout

Click Notch

Bulb

Face

9/16"

1-1/4"

1-1/2"

Factory End

Bulb Side

Face Side

Click Notch

Double

Stitch

Face SideRout

Click Notch

Bulb

Face

(Fig 22)

(Fig 25)

(Fig 24)

1-11/16"1-1/4"

(Fig 23)

MORE INFORMATION

BPLA-292252-223

For more information, or for an Armstrong Ceilings representative, call 1 877 276-7876.

For complete technical information, detail drawings, CAD design assistance, installation information, and

many other technical services, call TechLine customer support at 1 877 276-7876 or FAX 1 800 572-TECH.

All trademarks used herein are the property of AWI Licensing LLC and/or its afliates.

© 2023 AWI Licensing Company Printed in the United States of America

NOTE: This is the

folded result of 2 face

notches placed 5-1/2"

apart – minimum

spacing for the dies

Click Notch

SimpleSofts™ – Minimum

Folded Dimensions

3-1/2"

Face

Side

4-3/4"

NOT

E: 4-3/4" is the minimum

distance between Click Notches

SimpleSofts™ – Minimum

Folded Dimensions

Click Notch

Face Side

Click

Notch

4-3/4"

NOTE: 4-3/4" is the minimum

distance between Click Notches

SimpleSofts™ – Minimum

Folded Dimensions

Click Notch

Face Side

Click

Notch

NOTE: This is the

folded result of bulb

notches placed 5-1/2"

apart – minimum

spacing for the dies

SimpleSofts™ – Minimum

Folded Dimensions

5-1/2"

Bulb

Notch

Face Side

NOTE: This is the

folded result of bulb

notches placed 5-1/2"

apart – minimum

spacing for the dies

SimpleSofts™ – Minimum

Folded Dimensions

5-1/2"

Click

Notch

Face Side

3.258

3-5/8"

4.265

Bulb

Notch

Screw Notch

Screw Notch

Face Side

Click Notch

Face Side

3"

Simple

Notch

NOTE: 3-5/8" is the

minimum distance that

can be achieved with the

ScrewNotch feature, but

it must have #8 pan head

screws at each corner.

NOTE: 3" is the minimum

distance that can be achieved

with the ScrewNotch feature,

but it must have #8 pan head

screws at each corner.

/