Page is loading ...

Keep this Product ID Number and use when contacting Customer Service:

OWNER’S MANUAL

MODEL N° 90231

OWNER’S MANUAL

COPY

2

Save this owner’s manual for future reference and in the event that

the manufacturer has to be contacted.

REGISTER YOUR PRODUCT ONLINE AT WWW.LIFETIME.COM

At Lifetime, we are committed to providing innovative and quality products. While registering, you will

have the opportunity to give us your feedback. Your input is valuable to us.

Lifetime’s Promise to You:

• You can also opt in to receive new product notifi cations or promotions.

• In the unlikely event of a product recall or safety modifi cation, your registration provides the

information we need to notify you directly.

• Registration is fast, easy, and completely voluntary.

Maintaining your privacy is our long-standing policy at Lifetime. And you can rest assured that

Lifetime will not sell or provide your personal data to other third parties, or allow them to use your

personal data for their own purposes.

REGISTER today!

We invite you to read our privacy policy at www.lifetime.com

**U.S. and Canada customers ONLY**

DO NOT CONTACT THE STORE!

CALL OUR CUSTOMER SERVICE DEPARTMENT at

1 (800) 225-3865

HOURS: 7:00 a.m. to 5:00 p.m. Monday through Friday (Mountain Standard Time)

**Call, or visit our Web site for Saturday hours**

Questions or Missing Parts?

ID:

TO SAVE TIME WHEN CONTACTING CUSTOMER SERVICE, PLEASE HAVE THE PRODUCT ID

AVAILABLE BEFORE YOU CALL; IT’S LOCATED AT THE BOTTOM-LEFT CORNER OF THE FRONT

PAGE OF THIS MANUAL.

**For Assistance in Europe,**

FOR CUSTOMERS OUTSIDE

THE U.S., CANADA, or EUROPE,

PLEASE CONTACT THE STORE

FOR ASSISTANCE.

Please contact:

LIFETIME EUROPE

After Sales, Euro Base

IDA Industrial Estate,

Cork Road Waterford, Ireland

Or call:

00 800 85561360

INSTRUCTION #1100048 N 9/06/2016

COPY

3

Most injuries are caused by misuse and/or not following instructions. Use caution when using this product.

To ensure safety, do not attempt to assemble this product without reading and

following all instructions carefully. Check the entire box and inside all packing

materials for parts and/or additional instruction material. Before beginning assembly,

identify and inventory all parts and hardware using the parts and hardware lists and

identifi ers in this document. Proper and complete assembly, use and supervision

are essential for proper orientation and to reduce the risk of accident or injury. A

high probability of serious injury exists if this product is not installed, maintained,

and/or operated properly. Failure to comply with any of the warnings in this

instruction manual may result in serious personal injuries such as cuts, broken

bones, nerve damage, paralysis, brain injury, or death. Failure to comply may also

result in property damage. Please heed all warnings and cautions.

FAILURE TO FOLLOW THESE WARNINGS MAY RESULT IN SERIOUS INJURY OR PROPERTY

DAMAGE AND WILL VOID WARRANTY.

• If using a ladder during assembly, use extreme caution.

• Two capable adults are recommended for this operation.

• Check base daily for leakage. Leaks may cause product to fall.

• Assemble the pole sections properly. Failure to do so could cause the pole

sections to separate during play or transport.

SAFETY INSTRUCTIONS

BEFORE BEGINNING ASSEMBLY

Keep the hardware bags and their contents separate. If any parts

are missing, call our Customer Service Department.

Identify and inventory all parts and hardware using the parts and

hardware lists and identifi ers in this document.

Test fi t all Bolts by inserting them into their respective holes. If

necessary, carefully scrape away any excess powder coating

buildup from inside the holes. Do not scrape away all of the

powder coating. Bare metal may rust. You may need to pound

some Bolts into place with a hammer or mallet.

COPY

4

TOOLS AND PARTS REQUIRED FOR THIS ASSEMBLY

*Two adults required to

complete assembly*

Only adults should set up the product. Do not allow children

in the setup area until assembly is complete.

Electric Drill

Phillips Screwdriver

(1)

7/16” Wrench

(2)

(1)

Pliers

Rubber Mallet

(1)

1/2” Wrench

(2)

(1)

9/16” Wrench

(2)

3/4” Wrench

(2)

3/16” Allen

Wrench

(2, included)

(1)

(not included)

1/2” x 3’ Rebar

(1)

Shovel

Tape Measure

Cement Mix

(1)

(1)

Wood Block

80 lb Bag(x7)

/60lb Bag(x9)

Requires at least 493 lb (224

kg) of cement mix to fill a

volume of 3.7 ft

3

(0.11 m

3

).

COPY

5

This area is located at the top,

left-hand corner of the page

and indicates which tools

and hardware are needed to

complete the assembly steps

on a page.

Note:

!

Refer to the following areas throughout the instructions

to assist in the assembly process:

This area is usually located in the

bottom, left-hand corner of a step

and indicates that special attention

is needed to perform a particular

part of a step.

These areas are usually located in

the bottom, right-hand corner of a

step and indicate that damage to

the product or serious injury may

occur if the caution or warning is

not heeded.

WARNING

ASSEMBLY GUIDES

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

CAUTION

6

PARTS LIST

HARDWARE LIST

ID Item Description Qty

BCO Pole Assembly Hardware

ADS 1/4” x 3/4” Screw 2

ABZ #14 x 1” Self-Tapping Screw 2

AAF 3/8” Washer 2

ABB 3/8” Centerlock Nut 2

ABE 3/8” x 4” Hex Bolt 2

ABR 1/2” x 3.41” Spacer 2

CIH Domed Countersink Washers 2

ID Item Description Qty

ALH Top Pole 1

ALF Middle Pole 1

ALE Bottom Pole 1

AMY Backboard Bracket 2

DFD U-Bolt Support Bracket 1

AJI Backboard 1

ALM Pole Cap 1

ALX Rim 1

AKZ Net 1

ALD Plastic Guard 1

AKF Gas Spring 1

AKG Gas Spring Cover 1

AKB Long Extension Arm 2

AJX Corner Frame Pad 2

AJQ Center Frame Pad 1

ALL Pole Bracket 1

AKI Handle 1

AMN Trigger 1

ALS Rear Lifter Arm 2

AKP Height Adjust Sticker 1

AMT Warning Sticker (Applied to Middle Pole) 1

7

HARDWARE LIST

ID Item Description Qty

BCS Backboard & Rim Assembly Hardware

AAM 5/16” x 1 1/2” Tap Bolt 2

DFE 3/8” x 3/4” Hex Bolt 4

ABK 5/16” Nylock Flange Nut 4

ABB 3/8” Centerlock Nut 4

ABD 5/16” Washer 2

ABF 7/16” Rubber Washer 2

AAJ 5/16” Hex T-Nut 2

AAV 5/16” Jam Nut 2

AOW Spring Retainer Plate 1

AJW Compression Spring 2

APZ 4” U-Bolt 1

BCR Backboard to Pole Assembly Hardware

DFB 1/2” x 7 1/2” Hex Bolt 2

AAD 1/2” x 7 1/16” Hex Bolt 2

DGA 3/4” x 3.61” Spacer 2

AAX 1/2” Centerlock Nut 4

ABN 1/2” x 1/8” Spacer 8

BCT Handle Assembly Hardware

BSG 5/16” Centerlock Nut 1

ACX 5/16” x 2 1/2” Hex Bolt 1

AAO 5/16” Nylock Nut 1

AAX 1/2” Centerlock Nut 2

ABM 3/8” x 1/2” Spacer 2

ABB 3/8” Centerlock Nut 2

AQE Release Pin 1

ABA 3/8” x 6 1/2” Hex Bolt 2

AAW 1/2” x 6 1/2” Hex Bolt 1

AKH Grease Packet 1

AAD 1/2” x 7 1/16” Hex Bolt 1

ABT .62” x 3.20” Spacer 1

BCU Frame Pad Assembly Hardware

ADP #10 x 7/8” Self-Drilling Flat Screw 10

8

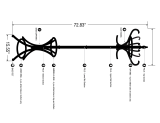

Parts shown at 10% of Actual Size

PARTS IDENTIFIER

ALH (x1)

Top Pole

ALF (x1)

Middle Pole

ALE (x1)

Bottom Pole

43 ”

3/8

43 ”

3/8

21 1/8”

AKC (x2)

Short Extension Arm

AKB (x2)

Long Extension Arm

AJX (x2)

Corner Frame Pad

AJQ (x1)

Center Frame Pad

ALS (x2)

Rear Lifter Arm

AKF (x1)

Gas Spring

AKI (x1)

Handle

AMN (x1)

Trigger

Warning Sticker

31”

43 ”

3/8

25 7/8”

9

AKZ (x1)

Net

ALX (x1)

Rim

AJI (x1)

Backboard

Parts shown at 5% of Actual Size

Parts shown at 10% of Actual Size

PARTS IDENTIFIER

AKG (x1)

Gas Spring Cover

10

Parts shown at 25% of Actual Size

PARTS IDENTIFIER

ALM (x1)

Pole Cap

ALD (x1)

Plastic Guard

ALL (x1)

Pole Bracket

AKP (x1)

Height Adjust Sticker

AMY (x2)

Backboard Bracket

DFD (x1)

U-Bolt Support

Bracket

1109 0 25

10’

9’6”

9’

8’6”

7’6”

8’

11

HARDWARE IDENTIFIER

ADS (x2)

1/4” x 3/4” Screw

ABZ (x2)

#14 x 1” Self-Tapping Screw

ABB (x2)

3/8” Centerlock Nut

AAF (x2)

3/8” Washer

ABE (x2)

3/8” x 4” Hex Bolt

ABR (x2)

1/2” x 3.41” Spacer

CIH (x2)

Domed Countersink Washer

ABD (x2)

5/16” Washer

ABF (x2)

7/16” Rubber Washer

AAM (x2)

5/16” x 1 1/2” Tap Bolt

AAV (x2)

5/16”Jam Nut

DFE (x4)

3/8” x 3/4” Bolt

ABB (x4)

3/8” Centerlock Nut

Hardware shown at Actual Size

Hardware shown at Actual Size

BCO

BCS

12

HARDWARE IDENTIFIER

Hardware shown at 25% of Actual Size

AJW (x2)

Compression Spring

APZ (x1)

4” U-Bolt

AOW (x1)

Spring Retainer Plate

ABK (x4)

5/16” Nylock Flange Nut

AAJ (x2)

5/16” Hex T-Nut

AAX (x4)

1/2” Centerlock Nut

DFB (x2)

1/2” x 7 1/2” Hex Bolt

ABN (x8)

1/2” x 1/8” Spacer

(Not actual length)

7 1/2”

(Not actual length)

AAD (x2)

1/2” x 7 1/16” Hex Bolt

DGA (x2)

3/4” x 3.61” Spacer

7 1/16”

Hardware shown at Actual Size

Hardware shown at Actual Size

BCS

BCR

13

HARDWARE IDENTIFIER

AAO* (x1)

5/16” Nylock

Nut

ABB (x2)

3/8” Centerlock Nut

ABA (x2)

3/8” x 6 1/2” Hex Bolt

(Not actual length)

AAX (x2)

1/2” Centerlock Nut

AAW (x1)

1/2” x 6 1/2” Hex Bolt

(Not actual length)

ADP (x10)

#10 x 7/8” Self-Drilling Flat Screw

Note: Only eight of the 10 Screws will be used.

ABM (x2)

3/8” x 1/2” Spacer

ABT (x1)

.62” x 3.20” Spacer

Note: The 5/16” Nylock Nut (AAO) will not be used in

this assembly.

ACX (x1)

5/16” x 2 1/2” Hex Bolt

AQE (x1)

Release Pin

(Not actual length)

AAD (x1)

1/2” x 7 1/16” Hex Bolt

7 1/16”

6 1/2”

6 1/2”

Hardware shown at Actual Size

BCT

Hardware shown at Actual Size

BCU

BSG (x1)

5/16” Centerlock Nut

14

GROUND PREPARATION

HARDWARE REQUIRED

SEC

1

PARTS REQUIRED

TOOLS REQUIRED

ALE (x1)

1/2” x 36” Rebar

Shovel

Tape Measure

Cement Mix

Level

NO HARDWARE REQUIRED FOR THIS SECTION

80 lb Bag(x7)

/60lb Bag(x9)

15

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Dig a round hole 24” deep and 18” in diameter. If you live in an area

where frost heaves may pose a problem, consult your local building

inspector to determine the proper hole depth. The edge of the hole

should be fl ush with the edge of the playing surface.

SEC

1.1

Note: A Ground Sleeve is available as an alternative to cementing

the Pole into the ground. Please contact Customer Service or visit

Lifetime.com online for more information.

!

NO HARDWARE REQUIRED FOR THIS PAGE

Mix 6 1/2 bags of concrete. Save 1/2 bag of concrete mix to use

later in the assembly. Pour the mixed concrete into the hole until it is

fi lled to the level of the playing surface.

24”

18”

16

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

ALE

14.5”

Make a mark 14.5 inches from the dimpled end of the Bottom Pole

(ALE) (do not scratch the powder coating).

SEC

1.2

Slide the dimpled end of the Bottom Pole (ALE) into the cement up

to the 14.5-inch mark. Position the pole four inches (4”) from the

playing surface.

SEC

1.3

NO TOOLS OR HARDWARE REQUIRED FOR THIS PAGE

17

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

The slots in the Bottom Pole (ALE) must be parallel to the playing surface.

If necessary, insert a straight object (a ruler, wire, etc.) through the

slots in the Bottom Pole. Rotate the pole until the straight object is

parallel to the playing surface.

SEC

1.4

Note: Use a Level to make sure the Bottom Pole is standing vertical. Form

the cement into a downward slope away from the pole to allow water runoff.

Failure to do so may result in premature rusting of the Pole.

!

Playing Surface

NO TOOLS OR HARDWARE REQUIRED FOR THIS PAGE

18

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Insert the 1/2” x 36” Rebar (not included) inside the Bottom Pole (ALE)

so it is about 15” from the top of the pole. Check the pole several

times within the fi rst hour to make sure that all sides are vertical and

that the 14.5-inch mark remains level with the surface.

SEC

1.5

Note: Allow 1-4 hours for the concrete to set before continuing.

!

1/2” x 36” Rebar

NO HARDWARE REQUIRED FOR THIS PAGE

Rebar

19

TOOLS AND HARDWARE REQUIRED FOR THIS PAGE

Mix the remaining 1/2 bag of concrete. Fill the Bottom Pole (ALE) with

concrete until it just below the slots near the top of the pole. Do not

overfi ll. Tamp the concrete down in the Bottom Pole with a broom

handle to remove air pockets. Clean all concrete off the outside of

the pole. Allow the concrete to set for at least 72 hours before installing the rest

of the system onto the Bottom Pole.

SEC

1.6

Cement Level

Inside Pole

Rebar

Note: STOP HERE! The concrete must cure for at least 72 hours (3 days) before

installing the rest of the system. In humid climates or wet weather, allow additional

time for the concrete to cure. Do not proceed until the curing process is complete.

!

NO HARDWARE REQUIRED FOR THIS PAGE

20

POLE ASSEMBLY

HARDWARE REQUIRED

SEC

2

ADS (x2)*

ABZ (x2)*

ABB (x2)

AAF (x2)

ABE (x2)

ABR (x2)

CIH (x2)*

*Note: Only one #14 x 1” Self-Tapping Screw (ABZ), one Domed Counter-

sink Washer (CIH) and one 1/4” x 3/4” Pan Head Screw (ADS) will be used

for this section. Save the remaining hardware for later in the assembly.

BCO

/