Page is loading ...

FormNo.3383-938RevA

100inRearDischargeMower

Groundsmaster

®

360SeriesTractionUnit

ModelNo.31101—SerialNo.314000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)

*3383-938*A

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Introduction

Thisrotary-bladelawncuttingdeckismountedtoaride-on

machineandisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarilydesigned

forcuttinggrassonwell-maintainedlawnsinparks,sports

elds,andoncommercialgrounds.Itisnotdesignedfor

cuttingbrush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready.Themodelandserialnumbersare

stampedintoaplatethatismountedonthemowerhousing.

Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(

Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

ToroMowerSafety..................................................4

SafetyandInstructionalDecals.................................5

Setup............................................................................7

ProductOverview..........................................................7

Specications.........................................................7

Attachments/Accessories.........................................7

Operation.....................................................................8

AdjustingtheHeight-of-Cut.....................................8

AdjustingtheSkid(s)................................................9

AdjustingtheRollers................................................9

LevelingtheMower.................................................9

OperatingTips......................................................10

Maintenance.................................................................12

RecommendedMaintenanceSchedule(s)......................12

Lubrication............................................................14

ServicingtheMowerDeckGearBox

Lubricant...........................................................15

ServicingtheBushingsintheCastorArms.................15

ServicingtheCastorWheelsandBearings..................16

ServicingtheCuttingBlades.....................................16

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Safety

ThismachinemeetsorexceedsCENstandardEN836:1997,

ISOstandard5395:1990,andANSIB71.4-2012specications

ineffectatthetimeofproduction.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheCEN

standardEN836:1997,ISOstandard5395:1990,andANSI

B71.4-2012.

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.Iftheoperatoror

mechaniccannotreadthelanguageofthismanual,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandearprotection.Longhair,looseclothingor

jewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartenginefrom

theoperator'sposition.Alwaysusetheseatbeltwhenthe

ROPSisintheraisedposition.Donotusetheseatbelt

whentheROPSisintheloweredposition.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability.Usecaution

whileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•Neveroperatewithguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,and

functioningproperty.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowerthecuttingunits,disengage

drives,engageparkingbrake(ifprovided),shutoffengine

beforeleavingtheoperator'spositionforanyreason.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

3

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Theoperatorshallturnonashingwarninglights,if

provided,whenevertravelingonapublicroad,except

wheresuchuseisprohibitedbylaw .

MaintenanceandStorage

•Disengagedrives,lowerthecuttingunits,movetraction

pedaltoNeutral,setparkingbrake,stopengineand

removekey.Waitforallmovementtostopbefore

adjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drivesand

mufer.Letenginecoolbeforestoringanddonotstore

nearames,andenginetohelppreventres.Cleanupoil

orfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingblades.Wrapthebladesor

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.Wearprotectiveclothing

anduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Avoidsuddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Lowerthecuttingunitwhengoingdownslopes.

•Thegrassdeectormustalwaysbeinstalledandinthe

lowestpositiononthesidedischargecuttingunit.Never

operatethemowerwithoutthedeectororentiregrass

collector.

•Ifthecuttingunitdischargeareaeverplugs,shutthe

engineoffbeforeremovingtheobstruction.

•Cutgrassslopescarefully.Donotstart,stop,orturn

suddenly.

•Donottouchtheengineormuferwhiletheengineis

runningorsoonafterithasstoppedbecausetheseareas

couldbehotenoughtocauseburns.

MaintenanceandStorage

•Checktheblademountingboltsfrequentlytobesurethat

theyaretightenedtospecication.

4

•Makesurethatallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitstotheground.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Makesurethatthemowerfueltankisemptyifthe

machineistobestoredinexcessof30days.Donotstore

themowernearanyopenameorwheregasolinefumes

maybeignitedbyaspark.

•Performonlythosemaintenanceinstructionsdescribed

inthismanual.Ifmajorrepairsareeverneededor

ifassistanceisdesired,contactanAuthorizedToro

Distributor.

•Tomakesureofoptimumperformanceandcontinued

safetycerticationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

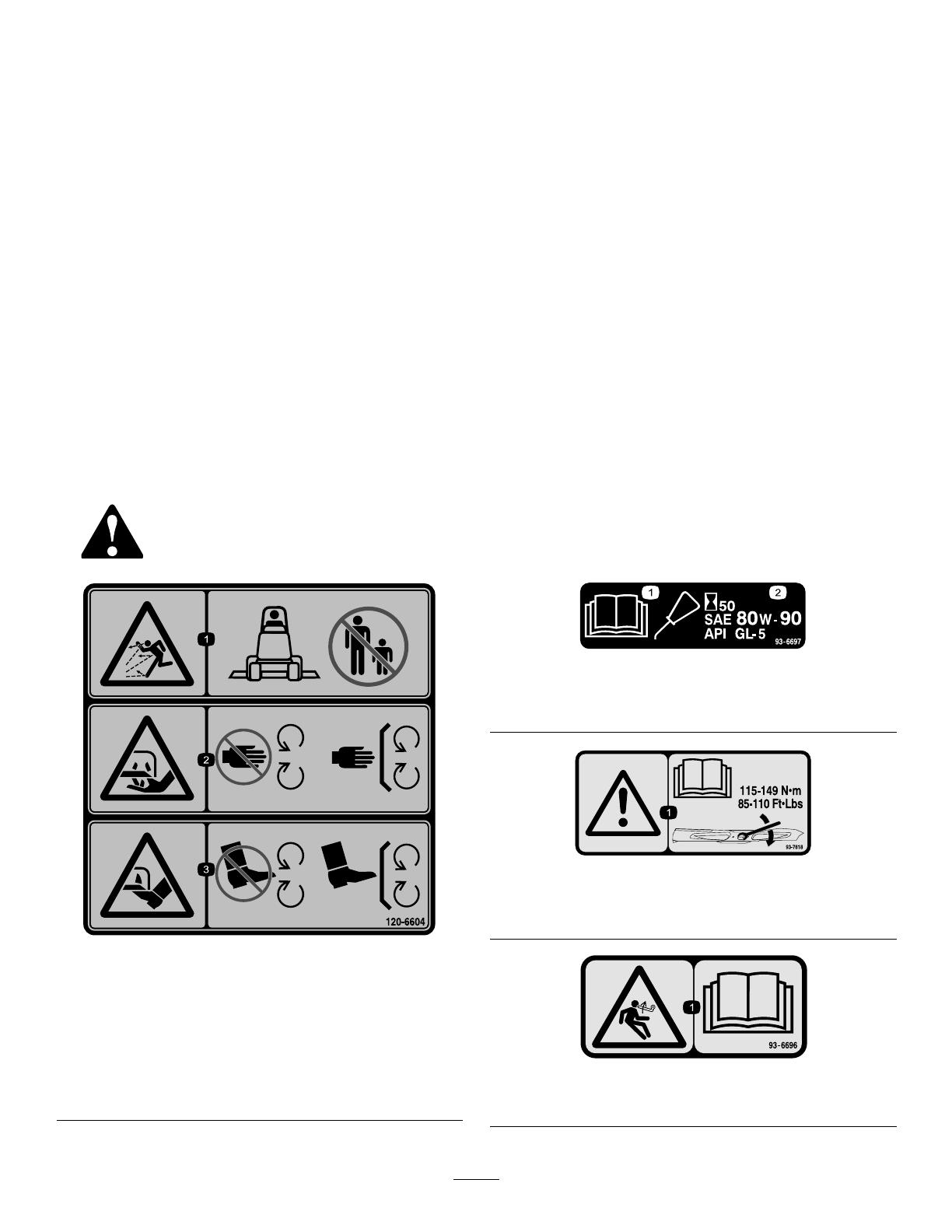

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts,keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts,keepallguardsandshieldsin

place.

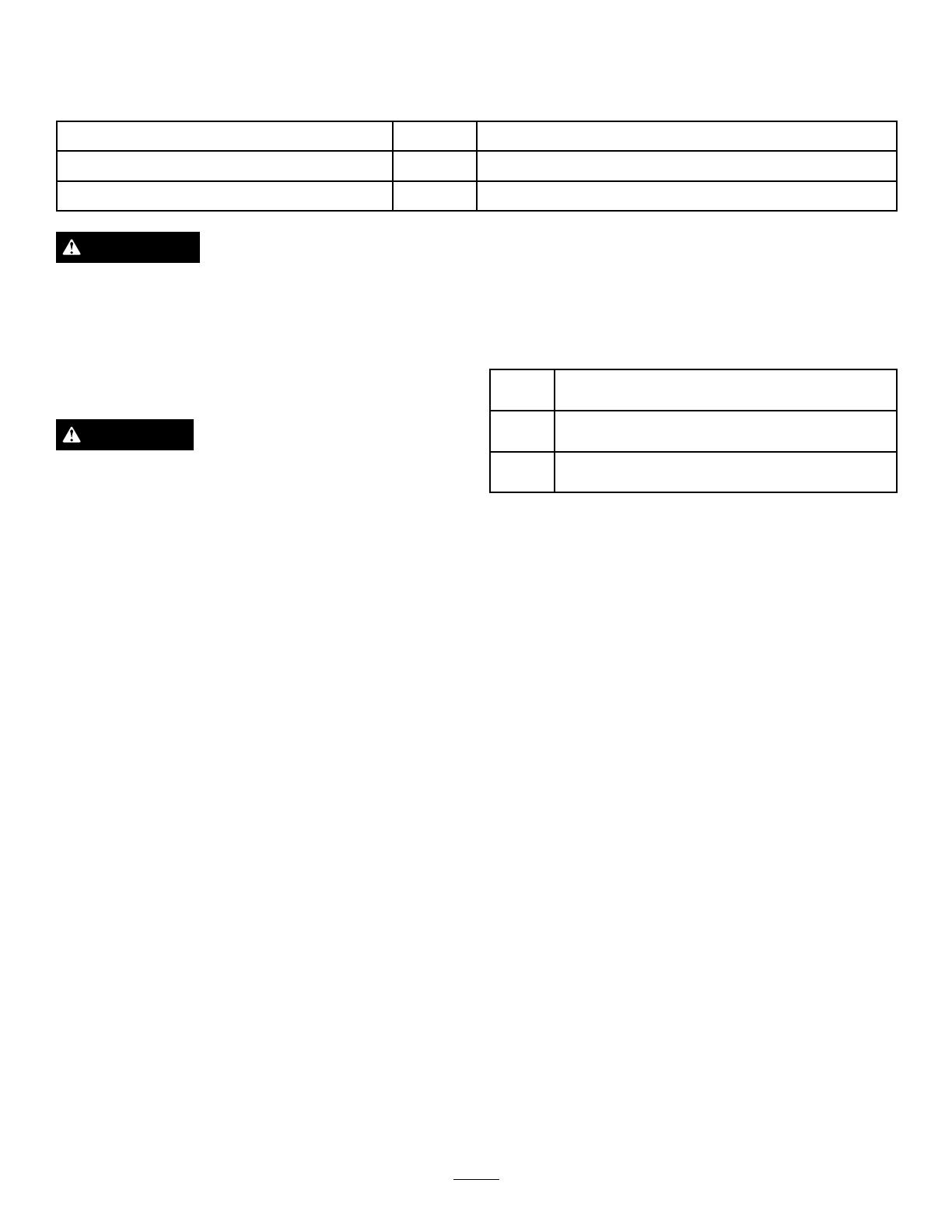

93-6697

1.ReadtheOperator's

Manual.

2.AddSAE80w-90(API

GL-5)oilevery50hours.

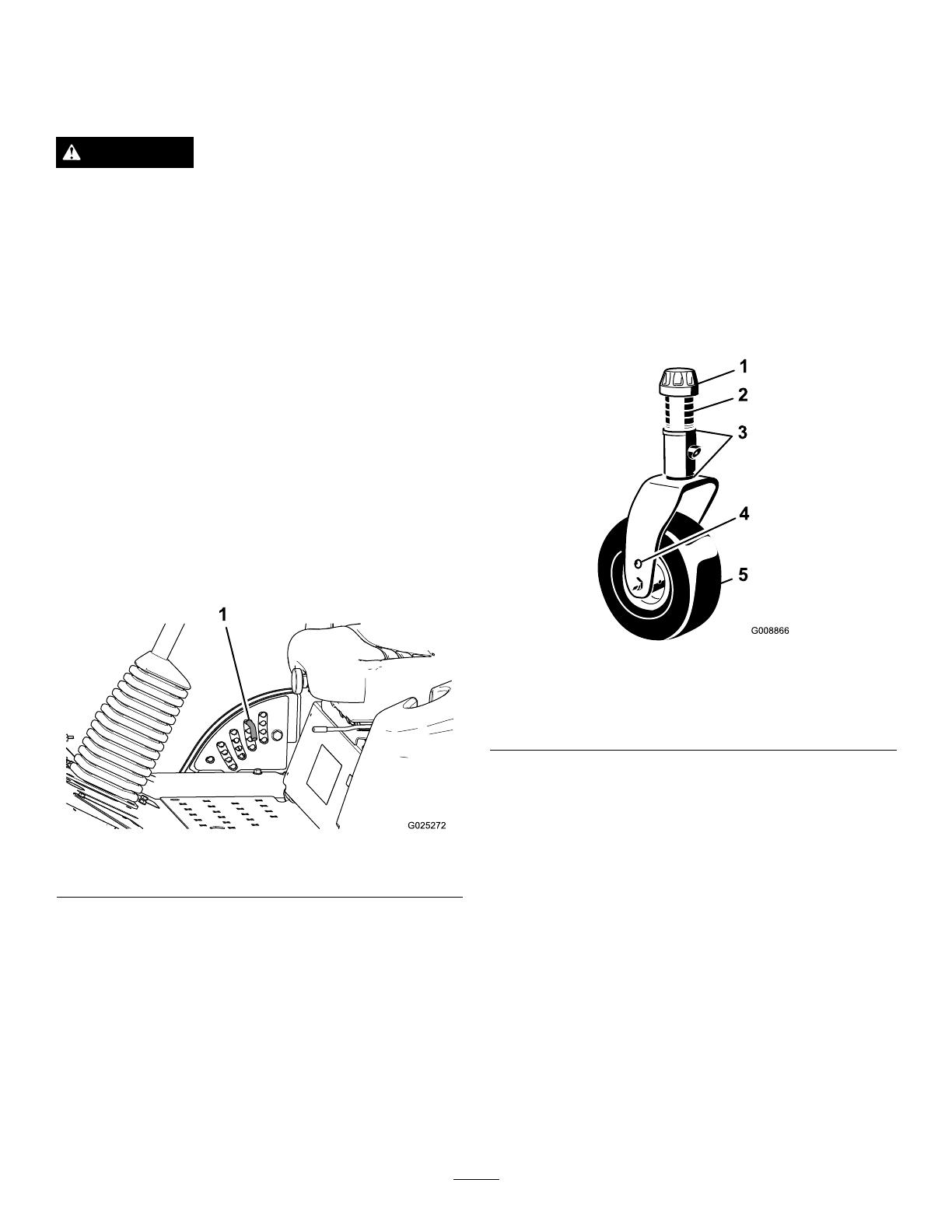

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N-m(85-110ft-lb).

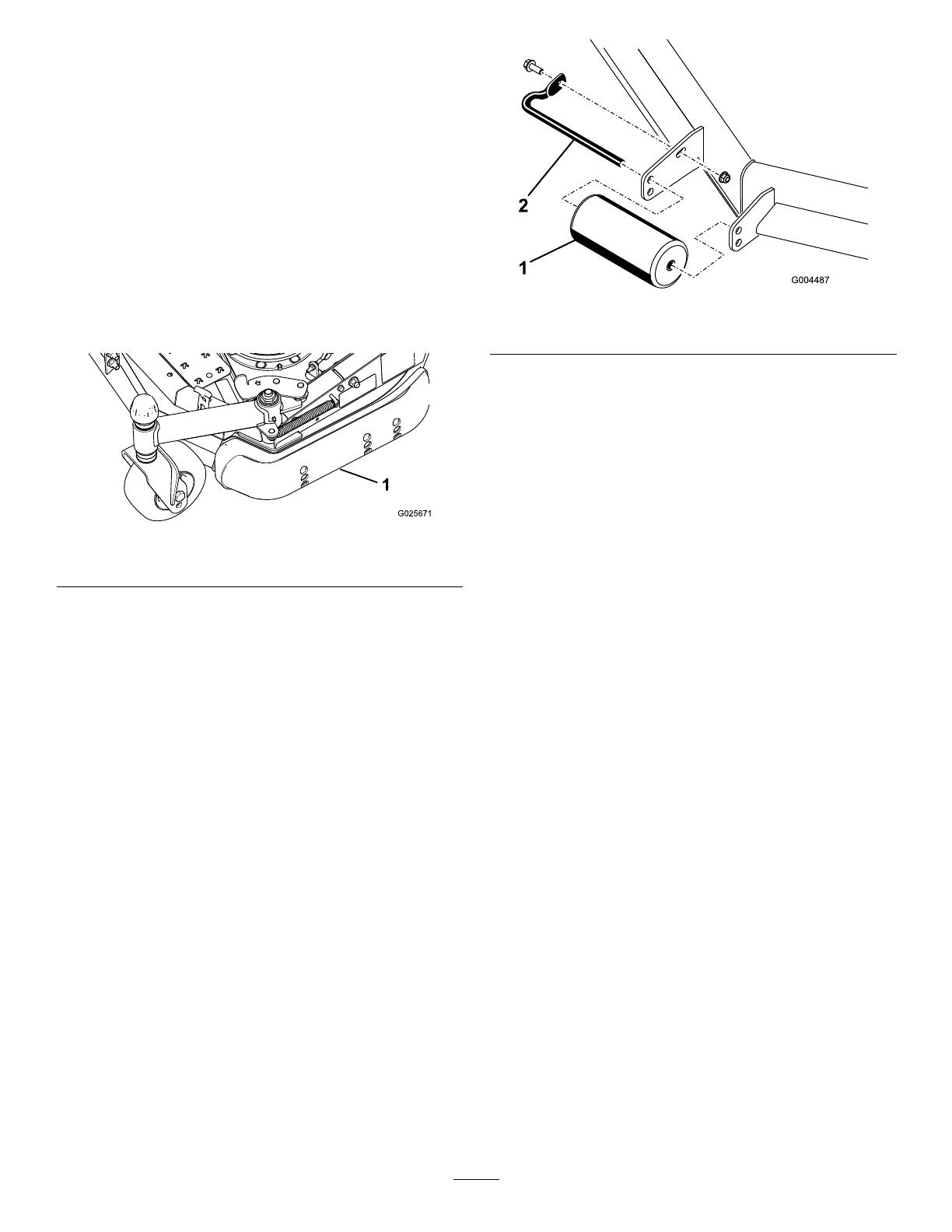

93-6696

1.Storedenergyhazard—readtheOperator'sManual.

5

119–6807

1.Warning—nostep

117–4979

1.Rotatingbelt—Keepguardinplace

125-9403

1.Height-of-cut

3.High

2.Low

6

Setup

MediaandAdditionalParts

Description

Qty.

Use

Operator'sManual

1Reviewthematerialandsaveinanappropriateplace

PartsCatalog

1

Usetoreferencepartnumbers

WARNING

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentallystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyou

doanymaintenance.

DANGER

IftheengineisstartedandthePTOshaftisallowed

torotate,seriousinjurycouldresult.

DonotstarttheengineandengagethePTOswitch

whenthePTOshaftisnotconnectedtothegear

boxonthecuttingunit.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Note:The100inRearDischargeMowermustbeusedin

conjunctionwithoneofthefollowingadapterkits:

•AdapterKit,Model31102isfornon-cabGroundsmaster

®360SeriesTractionUnitswithmodelandserial

numbersinthefollowingranges:

31223–314000101thru314000104

30536–314000101thru314000105

30539–314000101thru314000116

•AdapterKit,Model31103isforGroundsmaster®360

SeriesTractionUnitswithmodelandserialnumbersin

thefollowingranges:

31223–314000105andUp

30536–314000106andup

30539–314000117andup

ProductOverview

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Widthof

Cut

2.54m(100inches)

Height

ofCut

Adjustablefrom25to127mm(1to5inches)in6

mm(1/4inch)increments

Net

Weight

358kg(790lb.)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

7

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoany

maintenance.

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom25to127mm(1to5

inches)in6mm(1/4inch)increments.

CenterDeck

Theheight-of-cutonthecenterdeckisachievedbyrelocating

thestoppinintodifferentholelocations.

1.Withtheenginerunning,pushbackonthemowerlift

switchuntilthemowerisfullyraisedandreleasethe

switchimmediately.

2.Toadjust,rotatethestoppinuntilthenubonitlinesup

withtheslotsintheholesintheheight-of-cutbracket

andremoveit(

Figure2).

Figure2

1.Stoppin

3.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesired,insertthepin,androtateit

downtolockitinplace(Figure2).

Note:Therearefourrowsofholepositions(

Figure

2).Thetoprowgivesyoutheheightofcutlistedabove

thepin.Thesecondrowdowngivesyoutheheight

listedplus6mm(1/4inch).Thethirdrowdown

givesyoutheheightlistedplus12mm(1/2inch).The

bottomrowgivesyoutheheightlistedplus18mm

(3/4inch).Forthe127mm(5inch)positionthereis

onlyonehole,locatedinthesecondrow.Thisdoesnot

add6mm(1/4inch)tothe127mm(5inch)position.

4.Adjusttheanti-scalprollersandskidsasrequired.

WingDecks

Theheight-of-cutonthewingdecksisachievedby

positioningthecastorwheelaxlesintheupperorlowerholes

ofthecastorforks,addorremoveanequalnumberofspacers

fromthecastorforksandsecuretheheightofcutcollarto

thedesiredholesintheheightofcutrod.

1.Starttheengineandraisethecuttingunitofftheoor

sothattheheight-of-cutcanbechanged.Stopthe

engineandremovethekeyafterthecuttingunitis

raised.

2.Positionthecastorwheelaxlesinthesameholesin

bothcastorforks.Referto

Figure3todeterminethe

correctholesforthesetting.

Figure3

1.Tensioningcap4.Axlemountingholes

2.Spacers5.CastorWheel

3.Shims

Note:Whenoperatingin64mm(2–1/2inch)height

ofcutorhigher,theaxleboltmustbeinstalledinthe

lowercastorforkholetopreventgrassbuildupbetween

thewheelandthefork.Whenoperatinginheightof

cutslowerthan64mm(2–1/2inch)andgrassbuildup

isdetected,reversethemachinesdirectiontopullany

clippingsawayfromthewheel/forkarea.

3.Removethetensioningcapfromthespindleshaft

(Figure3)andslidethespindleoutofthecastorarm.

Putthe2shims(1/8inch)ontothespindleshaftas

theywereoriginallyinstalled.Theseshimsarerequired

toachievealevelacrosstheentirewidthofthecutting

units.Slidetheappropriatenumberof1/2inchspacers

ontothespindleshafttogetthedesiredheight-of-cut;

thenslidethewasherontotheshaft.

Note:Whenusing25mm(1inch),38mm(1-1/2

inch),oroccasionally51mm(2inch)height–of–cut,

movetheskidsandrollertothehighestholes.

4.Securetheadjustmentwiththetensioningcap.

8

AdjustingtheSkid(s)

Mounttheskidsinthelowerpositionwhenoperatingin

heightofcutshigherthan64mm(2-1/2inches)andinthe

higherpositionwhenoperatinginheightofcutslowerthan

64mm(2-1/2inches).

Note:Whentheskidsbecomeworn,youcanswitchtheskid

totheoppositesidesofthemower,ippingthemover.This

willallowyoutousetheskidslongerbeforereplacingthem.

1.DisengagethePTOandsettheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Loosenthescrewatthefrontofeachskid.(

Figure4).

Figure4

1.Skid

4.Removetheange-headboltsandnutsfromeachskid.

5.Moveeachskidtothedesiredpositionandsecurethem

withtheange-headboltsandnuts.

Note:Onlyusethetoporcentersetsofholesto

adjusttheskids.Thebottomholesareusedwhen

switchingsides,atwhichtimetheybecomethetop

holesontheothersideofthemower.

AdjustingtheRollers

Mounttherollersinthelowerpositionwhenoperatingin

heightofcutshigherthan64mm(2-1/2inches)andinthe

higherpositionwhenoperatinginheightofcutslowerthan

64mm(2-1/2inches).

1.DisengagethePTOandsettheparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Raisethefrontofthemachineandsupportitonjack

stands.

4.Removethefastenerssecuringeachrolleronyour

mowerandmovetherollersupordownasdesired

(

Figure5).

Figure5

1.Roller

2.Rollershaft

5.Installthefastenersasillustrated.

LevelingtheMower

LevelingFronttoBack

Cuttingunitpitchisthedifferenceinheight-of-cutfromthe

frontofthebladeplanetothebackofthebladeplane.Toro

recommendsabladepitchofapproximately8to11mm

(5/16to7/16inch).Thismeansthebackofthebladeplane

is8to11mm(5/16to7/16inch)higherthanthefront.

1.Positionthemachineonalevelsurfaceontheshop

oor.

2.Setthemowertothedesiredheight-of-cut,movethe

throttlelevertotheSlowposition,stoptheengine,set

theparkingbrake,andremovetheignitionkey.

3.Rotatethecenterbladesothatitpointsstraight

forward.

4.Usingashortruler,measurefromtheoortothefront

tipoftheblade.

5.Rotatethesamebladetiptotherearandmeasurefrom

theoortothetipofthebladeattherearofthemower.

6.Subtractthefrontdimensionfromthereardimension

tocalculatethebladepitch.

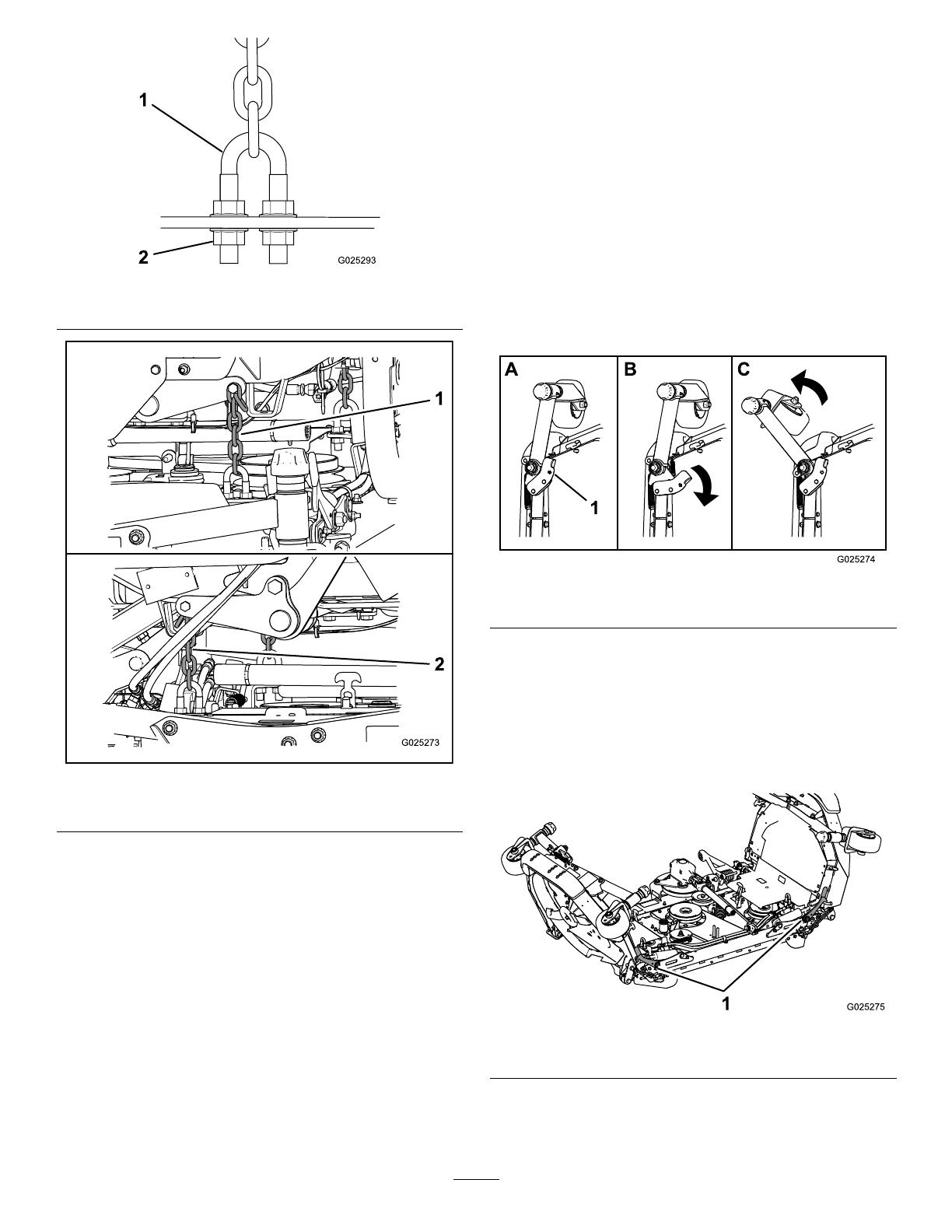

7.AdjusttheU-boltjamnuts(Figure6)securingtherear

deckchains(Figure7)tothemowerdecktoraisethe

rearofthemowersothatthebladepitchissetto8to

11mm(5/16to7/16inch).

9

Figure6

1.U-bolt2.Jamnut

Figure7

1.Leftrearliftchain2.Rightrearliftchain

LevelingSidetoSide

Ifthecutisunevenacrossthemowerswath,correctitas

follows:

1.Positionthemachineonalevelsurfaceontheshop

oor

2.Setthecuttingunittothedesiredheightofcut,move

thethrottlelevertotheSlowposition,stoptheengine,

settheparkingbrake,andremovetheignitionkey.

3.Checkandadjustfrontandreartractortirepressure;

refertoCheckingTirePressure.

4.Checkforbentblades.

5.Removethecoversfromthetopofthecuttingunits

6.Rotatethebladeoneachspindleuntiltheendsface

forwardandbackward.

7.Measurefromtheoortothefronttipofthecutting

edge

8.Adjustthejamnutssecuringthedeckchainstothe

mowerdeckuntilthemowerdeckislevel(

Figure7).

OperatingTips

FoldingCastorArm

Togainaccesstoorfromtheoperatorareawhenthewing

decksarefoldedup,releasethecastorarmlatch(Figure8)

androtatethecastorarmawayfromthetractionunit.

Figure8

1.Castorarmlatch

Important:Makesuretorotatethecastorarmbackto

thetractionunitbeforemowing.

TransportLatches

Beforetransportingthemachine,raisethecuttingunitsand

securethewingdecktransportlatches(Figure9).

Figure9

1.Wingdecktransportlatches

10

FastThrottleSetting/GroundSpeed

Tomaintainenoughpowerforthemachineanddeckwhile

mowing,operatetheengineatthefastthrottlepositionand

adjustyourgroundspeedforconditions.Agoodruleto

followis:decreasegroundspeedastheloadonthecutting

bladesincreases;andincreasegroundspeedasloadonthe

bladesdecreases.

MowingDirection

Alternatemowingdirectiontoavoidmakingrutsintheturf

overtime.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeed.

SelecttheProperHeight-of-CutSetting

toSuitConditions

Removeapproximately25mm(1inch)ornomorethan1/3

ofthegrassbladewhencutting.Inexceptionallylushand

densegrass,youmayhavetoslowdowntheforwardspeed

and/orraisetheheight-of-cuttothenexthighersetting.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

KeeptheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

Toreducetheriskofrehazard,keeptheengine,mufer,

batterycompartment,parkingbrake,cuttingunits,andfuel

storagecompartmentfreeofgrass,leaves,orexcessivegrease.

Cleanupanyspilledoilorfuel.

Usecompressedairoraleafblowertocleanthebeltdrive

area.Makesuretoinstallanyremovedguardsorcoverswhen

cleaninghasbeencompleted.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthebladesdailyforsharpness,andforany

wearordamage.Sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywithagenuineToro

replacementblade.RefertoServicingtheCuttingBlades.

11

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst2hours

•Tightenthecastorwheelnuts

Aftertherst10hours

•Tightenthecastorwheelnuts

Aftertherst50hours

•Changethemowerdeckgearboxlubricant

Beforeeachuseordaily

•Lubricatethecastorarmbushings

•Lubricatethecastorwheelbearings

•Checkthemowerblades.

Every50hours

•Lubricatethegreasettings

•Tightenthecastorwheelnuts

Every150hours

•Checkthelubricantinthemowerdeckgearbox.

Every400hours

•Changethemowerdeckgearboxlubricant

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentallystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionswitchbeforeyoudoanymaintenance.

WARNING

Ifyouraisethemachineusingonlyajacktosupportitwhileyouworkunderthemowerdeck,thejack

couldtip,causingthemowerdecktofall,crushingyouorbystanders.

Alwayssecurethemachinewithatleast2jackstandswhenyouhavethemowerdeckraised.

12

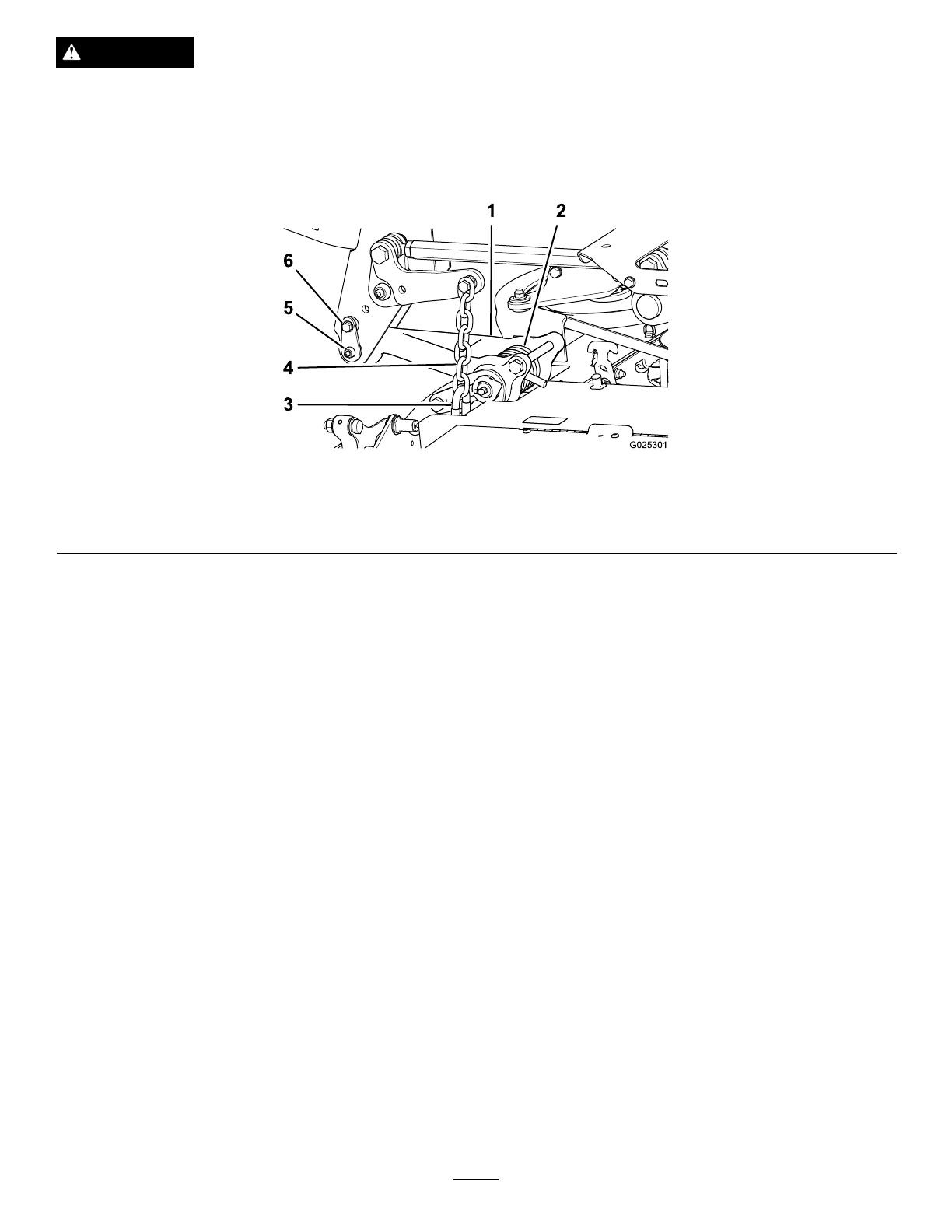

CAUTION

Onthetopofthemowerdeckaretwolinksthatconnectthemtotheframe.Connectedtotheselinksare

torsionspringsthatareundertension(

Figure10).Ifyoudisconnectthelinkthestoredenergyinthe

torsionspringwillbereleasedandcouldcausethelinkstomove,damagingyourhandsorngers.

Becarefulwhenremovingthemowerdeckfromtheframeandsecurethelinksbeforedisconnecting

themfromtheframe.

Figure10

1.Pulllink

4.Deckliftchain

2.Torsionspring5.Retainerpin

3.U-bolts

6.Shoulderscrew

13

Lubrication

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Ifthemachineisoperatedundernormalconditions,lubricate

allbearingsandbushingsafterevery50hoursofoperationor

immediatelyaftereverywashing.

Lubricatethefollowingareas:

•Castorforkshaftbushings(4)(

Figure11)

Figure11

•Decklinks(5)(Figure12)

Figure12

•Idlerarmpivots(4)(Figure13)

g025838

Figure13

•Wingdeckhinges(10)(Figure14)

Figure14

•Foldingcastorarmpivot(1)(Figure15)

Figure15

•PTODriveshaft(2)(Figure16)

Figure16

•Spindleshaftbearings(5)(Figure17)

G025837

Figure17

14

ServicingtheMowerDeck

GearBoxLubricant

ThegearboxisdesignedtooperatewithSAE80-90gear

lube.Althoughthegearboxisshippedwithlubricantfrom

thefactory,checkthelevelbeforeoperatingthecuttingunit

forthersttimeandevery150operatinghoursthereafter.

Changethelubricantinthegearboxevery400operating

hours.

CheckingtheMowerDeckGearBox

Lubricant

ServiceInterval:Every150hours

1.Positionthemachineandcuttingunitonalevelsurface.

2.Lowerthemowerdecktothe2.5cm(1inch)

height-of-cut.

3.DisengagethePTO,releasethetractionpedalandset

theparkingbrake.

4.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

5.Liftthefootrest,exposingthetopofthemowerdeck.

6.Removethedipstick/llplugfromthetopofthegear

box(Figure18)andmakesurethatthelubricantis

betweenthemarksonthedipstick.

Figure18

1.Fillpluganddipstick2.Drainlocation

7.Ifthelubricantlevelislow,addenoughlubricantuntil

thelevelisbetweenthemarksonthedipstick.

Note:Donotoverllorthegearboxmaybedamaged.

ChangingtheMowerDeckGearBox

Lubricant

ServiceInterval:Aftertherst50hours

Every400hours

1.Positionthemachineandcuttingunitonalevelsurface.

2.Lowerthemowerdecktothe2.5cm(1inch)

height-of-cut.

3.DisengagethePTO,releasethetractionpedalandset

theparkingbrake.

4.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

5.Liftthefootrest,exposingthetopofthemowerdeck.

6.Removethedipstick/llplugfromthetopofthegear

box(Figure18).

7.Placeadrainpanunderthedrainpluglocatedunder

thefrontofthegearboxandremovetheplug,draining

thelubricantintothepan.

8.Replacethedrainplug.

9.Addenoughlubricant,approximately414ml(14

ounces),untilthelevelisbetweenthemarksonthe

dipstick.

Note:Donotoverllorthegearboxmaybedamaged.

ServicingtheBushingsinthe

CastorArms

Thecastorarmshavebushingspressedintothetopand

bottomofthetubeandaftermanyhoursofoperation,the

bushingswillwear.Tocheckthebushings,movethecastor

forkbackandforthandfromsidetoside.Ifthecastor

spindleislooseinsidethebushings,thebushingsareworn

andmustbereplaced.

1.Raisethecuttingunitsothatthewheelsareoffof

theoor.Blockthecuttingunitsothatitcannot

accidentallyfall.

2.Removethetensioningcap,spacer(s),andthrust

washerfromthetopofthecastorspindle.

3.Pullthecastorspindleoutofthemountingtube.

Allowthethrustwasherandspacer(s)toremainon

thebottomofthespindle.

4.Insertapinpunchintothetoporbottomofthe

mountingtubeanddrivethebushingoutofthetube

(Figure19).Alsodrivetheotherbushingoutofthe

tube.Cleantheinsideofthetubestoremovedirt.

Figure19

1.Castorarmtube

2.Bushings

5.Applygreasetotheinsideandoutsideofthenew

bushings.Usingahammerandatplate,drivethe

bushingsintothemountingtube.

15

6.Inspectthecastorspindleforwearandreplaceitif

damaged.

7.Pushthecastorspindlethroughthebushingsand

mountingtube.Slidethethrustwasherandspacer(s)

ontothespindle.Installthetensioningcaponthe

castorspindletoretainallpartsinplace.

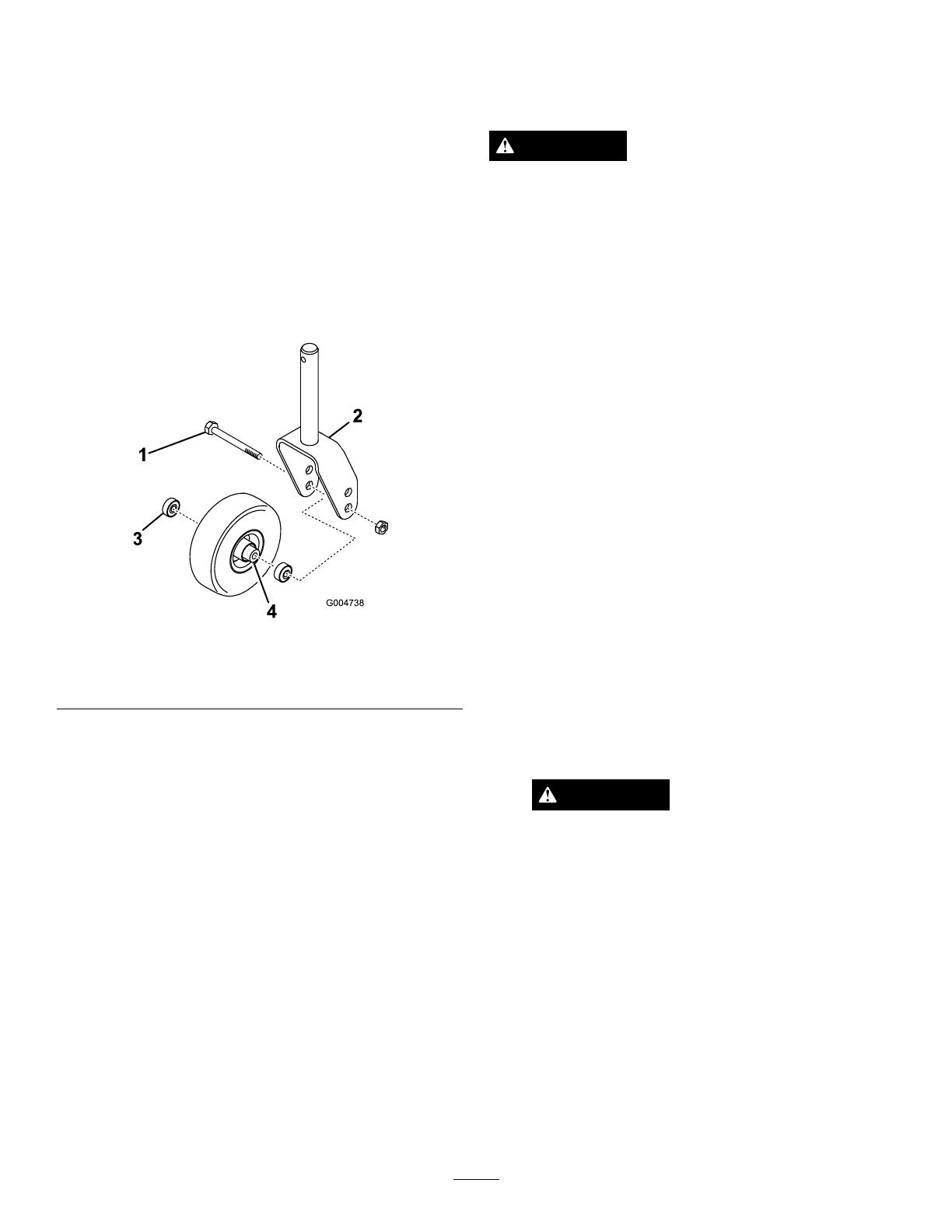

ServicingtheCastorWheels

andBearings

1.Removethelocknutfromtheboltholdingthecastor

wheelassemblybetweenthecastorfork(Figure20).

Graspthecastorwheelandslidetheboltoutofthe

forkorpivotarm.

Figure20

1.Castorwheel3.Bearing(2)

2.Castorfork

4.Bearingspacer

2.Removethebearingfromthewheelhubandallow

thebearingspacertofallout(

Figure20).Removethe

bearingfromtheoppositesideofthewheelhub.

3.Checkthebearings,spacer,andinsideofthewheelhub

forwear.Replaceanydamagedparts.

4.Toassemblethecastorwheel,pushthebearingintothe

wheelhub.Wheninstallingthebearings,pressonthe

outerraceofthebearing.

5.Slidethebearingspacerintothewheelhub.Pushthe

otherbearingintotheopenendofthewheelhubto

captivatethebearingspacerinsidethewheelhub.

6.Installthecastorwheelassemblybetweenthecastor

forkandsecureitinplacewiththeboltandlocknut.

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseasonbecause

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowthandincreasesthechanceofdisease.

Checkthebladesdailyforsharpness,andforanywear

ordamage.Sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywithagenuineToro

replacementblade.

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Inspectandcheckthebladesevery8hours.

BeforeInspectingorServicingthe

Blades

1.DisengagethePTO,releasethetractionpedalandset

theparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

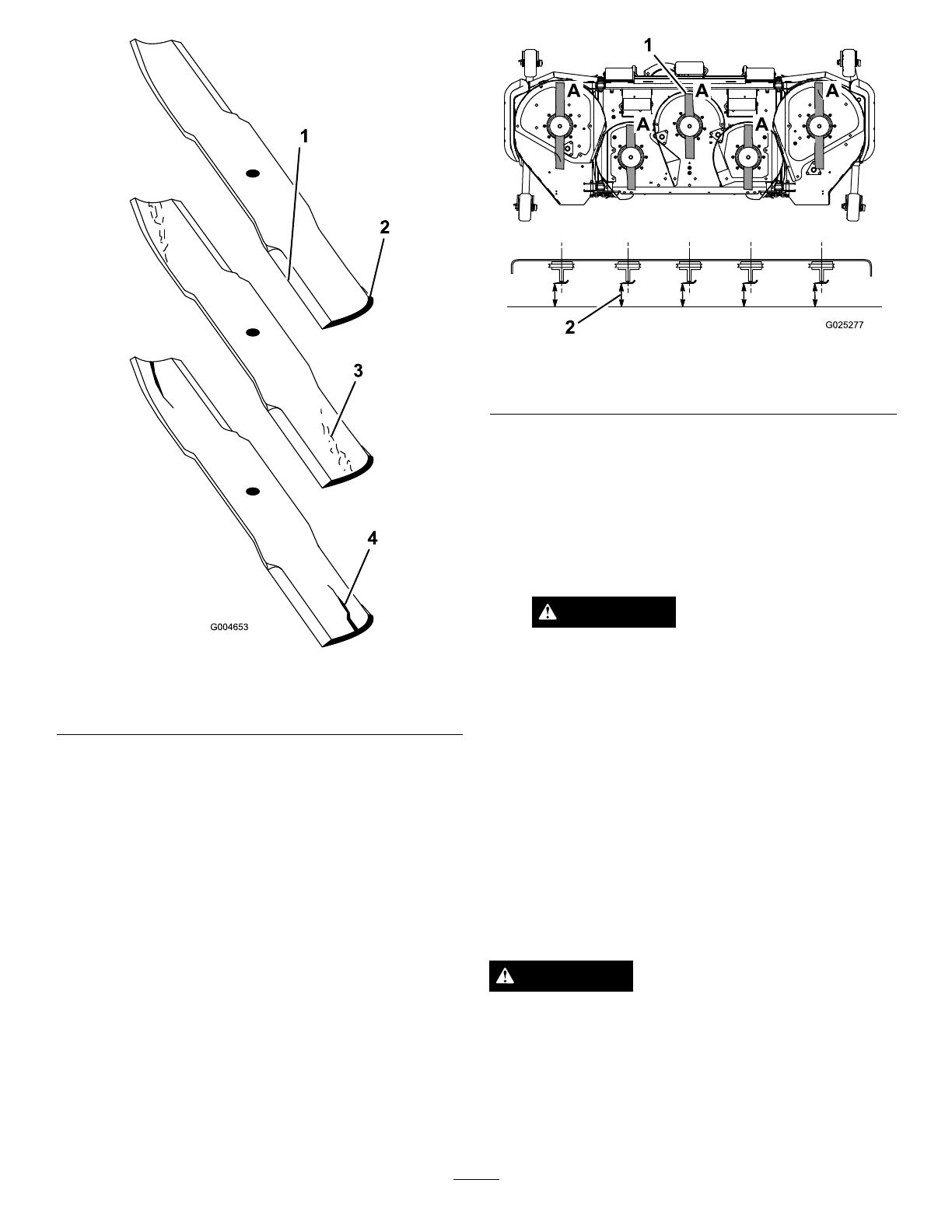

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(

Figure21).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades.RefertoSharpeningtheBlades.

2.Inspecttheblades,especiallythesailarea(Figure21).

Ifyounoticeanydamage,wear,oraslotformingin

thisarea(Figure21),immediatelyinstallanewblade.

DANGER

Ifyouallowthebladetowear,aslotwillform

betweenthesailandatpartoftheblade.

Eventuallyapieceoftheblademaybreak

offandbethrownfromunderthehousing,

possiblyresultinginseriousinjuryordeath

toyouorbystanders.

•Inspectthebladeperiodicallyforwearor

damage.

•Nevertrytostraightenabladethatisbent

orweldabrokenorcrackedblade.

•Replaceawornordamagedblade.

16

Figure21

1.CuttingEdge3.Wear/slotForming

2.SailArea4.Crack

CheckingforBentBlades

1.DisengagethePTO,releasethetractionpedalandset

theparkingbrake.

2.MovethethrottlelevertotheSlowposition,stopthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Rotatethebladesuntiltheendsfaceforwardand

backward(

Figure22).Measurefromalevelsurfaceto

thecuttingedge,positionA,oftheblades(Figure22).

Notethisdimension.

Figure22

1.PositionA

2.Measureherefromblade

tohardsurface

4.Rotatetheoppositeendsofthebladesforward.

5.Measurefromalevelsurfacetothecuttingedgeof

thebladesatthesamepositionasinstep3above.

Thedifferencebetweenthedimensionsobtainedin

steps3and4mustnotexceed3mm(1/8inch).Ifthis

dimensionexceeds3mm(1/8inch),thebladeisbent

andmustbereplaced;refertoRemovingtheBlades

andInstallingtheBlades.

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthebladeis

outofbalanceorisbent.Toensureoptimumperformance

andcontinuedsafetyconformanceofthemachine,use

genuineTororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

WARNING

Contactwithasharpbladecancauseseriousinjury.

Wearglovesorwrapsharpedgesofthebladewith

arag.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladebolt,anti-scalpplate,andbladefrom

thespindleshaft(

Figure25).

17

SharpeningtheBlades

WARNING

Whensharpeningblade,piecesofbladecouldbe

thrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpening

blades.

1.Sharpenthecuttingedgeatbothendsoftheblade

(Figure23).Maintaintheoriginalangle.Theblade

retainsitsbalanceifthesameamountofmaterialis

removedfrombothcuttingedges.

Figure23

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(

Figure24).Ifthebladestaysinahorizontal

position,thebladeisbalancedandcanbeused.Ifthe

bladeisnotbalanced,lesomemetalofftheendof

thesailareaonly(Figure25).Repeatthisprocedure

untilthebladeisbalanced.

Figure24

1.Blade2.Balancer

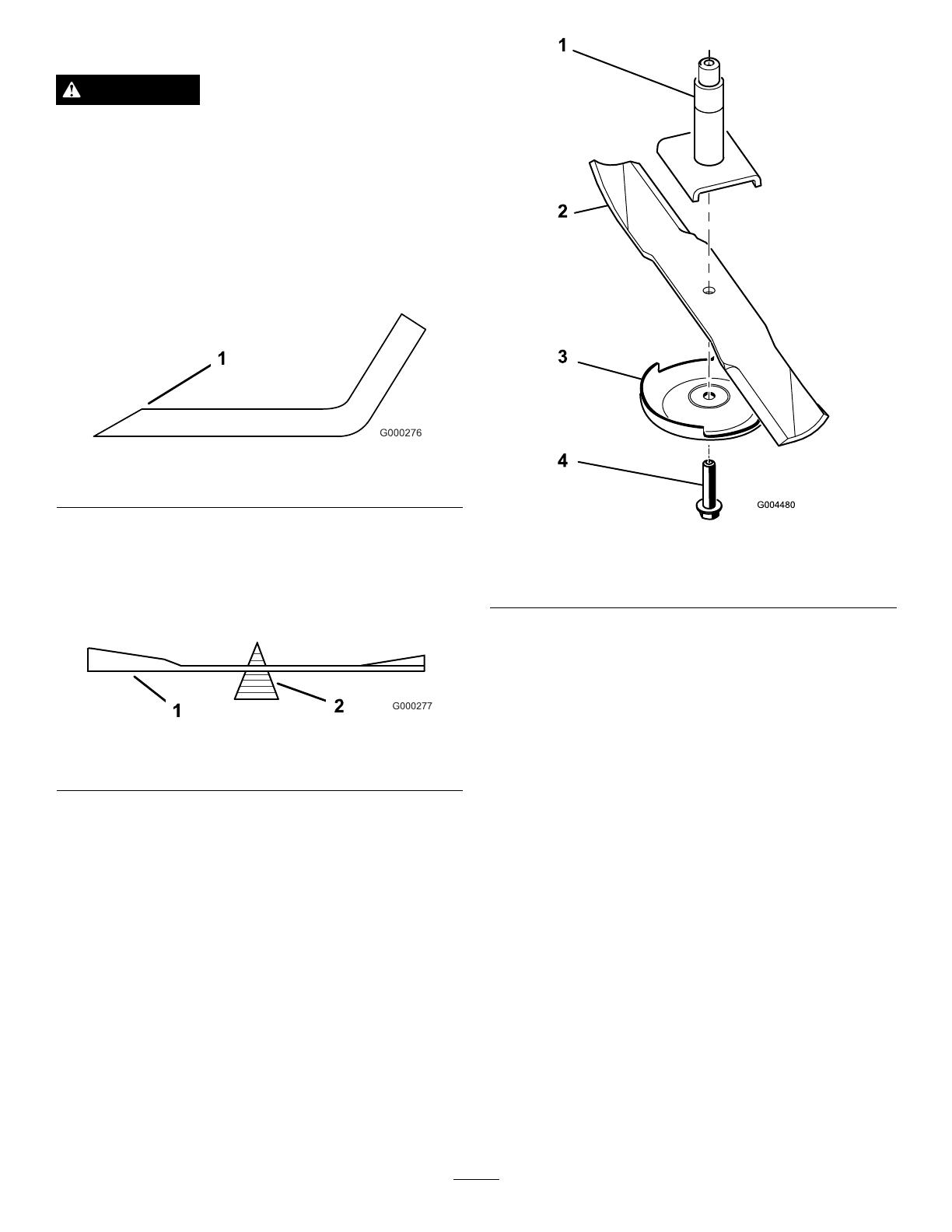

InstallingtheBlades

Note:The2wingdeckbladesarenotthesameasthe3

centerblades.

1.Installthebladeontothespindleshaft(Figure25).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installtheanti-scalpplateandbladebolt(Figure25).

Figure25

1.Spindle

3.Anti-scalpplate

2.SailAreaofBlade

4.BladeBolt

3.Torquethebladeboltto115-150N⋅m(85-110ft-lb).

18

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

SerialNo.

ProductDescriptionInvoiceDescription

GeneralDescription

Directive

31101314000001andUp100inRearDischargeMower

CUTTINGUNIT-100IN,

GM360

100inRearDischargeMower

2006/42/EC,

2000/14/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedT oromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUT echnicalContact:

PeterT etteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

Fax003214581911

8111LyndaleAve.South

Bloomington,MN55420,USA

September26,2013

19

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

8111LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:[email protected]

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator'sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,

duringnormalProductoperationinclude,butarenotlimitedto,brake

padsandlinings,clutchlinings,blades,reels,rollersandbearings

(sealedorgreasable),bedknives,sparkplugs,castorwheelsand

bearings,tires,lters,belts,andcertainsprayercomponentssuchas

diaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,

lubricants,additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesToroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforuseare

limitedtothedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sothe

aboveexclusionsandlimitationsmaynotapplytoyou.Thiswarranty

givesyouspeciclegalrights,andyoumayalsohaveotherrightswhich

varyfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementsuppliedwithyourproductor

containedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.

374-0253RevB

/