Page is loading ...

Instruction

Manual

Surface Strain

Transmitter

Type 9238B...

9238B_002-542e-02.23

Foreword

9238B_002-542e-02.23 Page 1

Foreword

Thank you for choosing a Kistler quality product character-

ized by technical innovation, precision and long life.

Information in this document is subject to change without

notice. Kistler reserves the right to change or improve its

products and make changes in the content without obliga-

tion to notify any person or organization of such changes

or improvements.

© 2011 … 2023 Kistler Group. Kistler Group products are

protected by various intellectual property rights. For more

details visit www.kistler.com. The Kistler Group includes

Kistler Holding AG and all its subsidiaries in Europe, Asia,

the Americas and Australia.

Kistler Group

Eulachstrasse 22

8408 Winterthur

Switzerland

Tel. +41 52 224 11 11

www.kistler.com

Surface Strain Transmitter, Type 9238B...

Page 2 9238B_002-542e-02.23

Content

1.Introduction ................................................................................................................................... 4

2.Important notes .............................................................................................................................. 5

2.1For your safety ..................................................................................................................... 5

2.2Unpacking ..................................................................................................................... ....... 6

2.3Notes on using the transmitter ............................................................................................. 6

2.4Hints on using this instruction manual .................................................................................. 6

3.General description ........................................................................................................................ 7

3.1What is strain? ..................................................................................................................... 7

3.1.1NormalsStrain – shear strain .................................................................................... 7

3.2What is the purpose of a strain transmitter? ......................................................................... 8

3.3Design and principle of operation of strain transmitter Type 9238B... .................................. 9

3.3.1Design ..................................................................................................................... 9

3.3.2Measurement principle .......................................................................................... 10

3.3.3Integral fully-digital charge amplifier ..................................................................... 10

3.4Factory calibration of transmitter ........................................................................................ 11

4.Installation and commissioning ................................................................................................... 13

4.1Important instructions ........................................................................................................ 13

4.2Choosing measuring point .................................................................................................. 13

4.2.1Surface materials ................................................................................................... 14

4.3Allowing for thermal effects ............................................................................................... 15

4.3.1Self-heating ........................................................................................................... 16

4.4Machining mounting surface .............................................................................................. 16

4.5Mounting ........................................................................................................................... 18

4.5.1Mounting strain transmitter ................................................................................... 18

4.6Connecting strain transmitter Type 9238B... ...................................................................... 19

4.6.1Notes on cable laying ............................................................................................ 19

4.6.2Connecting strain transmitter Type 9238B............................................................. 20

4.6.3Cable concept ....................................................................................................... 22

4.7Commissioning ................................................................................................................... 23

4.7.1Simplest form of measurement – relative ............................................................... 23

4.7.2Simplest form of measurement – strain .................................................................. 24

4.7.3Range switching .................................................................................................... 25

4.7.4Indirect force measurement ................................................................................... 26

5.Calibration and maintenance ....................................................................................................... 27

5.1In-Situ calibration of surface strain transmitter Type 9238B... ............................................. 27

5.1.1Working point calibration by peak value comparison ............................................ 27

5.1.1.1Test system requirements ....................................................................... 28

5.1.1.2Reference sensor installation .................................................................. 28

5.1.1.3Load application ..................................................................................... 29

5.1.1.4Calibration process worksheet ................................................................ 30

Introduction

9238B_002-542e-02.23 Page 3

5.2Kistler calibration service ..................................................................................................... 31

6.Operation ..................................................................................................................................... 32

6.1Setting up strain transmitter Type 9238B... with ManuWare ............................................... 32

6.1.1Configuration examples ......................................................................................... 36

6.2Resolution of measurement signal ....................................................................................... 38

6.3Quasistatic measurements .................................................................................................. 38

6.4Tips for good measurements ............................................................................................... 38

7.Maintenance ................................................................................................................................. 39

7.1Overload protection ............................................................................................................ 39

7.2Maintenance ....................................................................................................................... 39

8.Remedying faults .......................................................................................................................... 40

8.1Troubleshooting and remedying faults ................................................................................ 40

8.2Repairing strain transmitter ................................................................................................. 40

8.3Technical data ..................................................................................................................... 41

8.4Dimensions of Type 9238B… .............................................................................................. 43

8.5Pin allocation ...................................................................................................................... 43

8.6Ordering key ....................................................................................................................... 44

8.7Included accessories ............................................................................................................ 44

8.8Optional accessories ............................................................................................................ 44

9.Annex ........................................................................................................................................... 45

9.1Glossary .............................................................................................................................. 45

9.2Measurement uncertainty ................................................................................................... 48

9.3Linearity .............................................................................................................................. 49

9.4Frequency range ................................................................................................................. 51

9.5Influence of temperature .................................................................................................... 52

10.Index ............................................................................................................................................. 54

Total Pages 55

Surface Strain Transmitter, Type 9238B...

Page 4 9238B_002-542e-02.23

1. Introduction

Please take the time to thoroughly read this instruction

manual. It will help you with the installation, maintenance,

and use of this product.

To the extent permitted by law Kistler does not accept any

liability if this instruction manual is not followed or prod-

ucts other than those listed under Accessories are used.

Kistler offers a wide range of products for use in measuring

technology:

Piezoelectric sensors for measuring force, torque, strain,

pressure, acceleration, shock, vibration and acoustic

emission

Strain gage sensor systems for measuring force and

moments

Piezoresistive pressure sensors and transmitters

Signal conditioners, indicators and calibrators

Electronic control and monitoring systems as well as

software for specific measurement applications

Wireless data transmission modules

Kistler also develops and produces measuring solutions for

the application fields of engines, vehicles, manufacturing,

plastics and biomechanics sectors.

Our product and application brochures will provide you

with an overview of our product range. Detailed data

sheets are available for almost all products.

If you need additional help beyond what can be found

either on-line or in this manual, please contact Kistler's

extensive support organization.

Important notes

9238B_002-542e-02.23 Page 5

2. Important notes

It is essential for you to study the following notes, which

are for your personal safety during work, and to ensure

long term, fault-free operation of this product.

2.1 For your safety

This product has been thoroughly tested and has left

the factory in a perfectly safe condition. In order to

maintain this condition and ensure safe operation, com-

pliance is required with the instructions and warning

notes in this instruction manual.

The press force sensor must be installed, operated and

maintained only by persons who are familiar with this

product and who are adequately qualified for the work

involved.

If it is to be assumed that safe operation is no longer

possible, the equipment must be shut down and made

safe against being accidentally started up.

Safe operation must be assumed to be no longer possible

when the product

shows visible signs of damage,

has been overloaded,

is no longer operating,

has been in lengthy storage under unsuitable conditions

and,

has been subjected to rough transport conditions.

Install the surface strain transmit

t

e

r

in

p

osition as

pr

e-

scribed. Details can be found in section 4.2.

Surface Strain Transmitter, Type 9238B...

Page 6 9238B_002-542e-02.23

2.2 Unpacking

Check all packaging for transport damage. Report any such

damage to the transporters and to the authorized Kistler

distributor.

Check accessories delivered (see section 8.7), before first

use of the equipment. Report any missing parts to the au-

thorized Kistler distributor.

2.3 Notes on using the transmitter

The surface strain transmitter must be used only under

the environmental and operating conditions specified.

Protect the connector of the surface strain transmitter

sensor against contamination and on no account touch

it with your fingers (connector front). Fit the cover sup-

plied over the connector when it is not in use.

Use only specified connecting cables.

Protect the surface strain transmitter when it is not in

use by storing it in its original packaging.

2.4 Hints on using this instruction manual

We recommend that you read the entire instruction manu-

al carefully. However, if you are in a hurry and already

have experience with Kistler surface strain transmitter, read

the specific information needed.

We have attempted to give these instructions a clear

presentation to make it easier for you to gain direct access

to the information you need.

Please keep this instruction manual in a safe place where

you can retrieve it at any time.

If you lose this instruction manual, please contact your

Kistler distributor and ask them for an immediate replace-

ment.

General description

9238B_002-542e-02.23 Page 7

3. General description

3.1 What is strain?

The physical measurand that is measured is the relative

measure of strain and is defined as the change in length

of a part of a machine under load divided by the original

length l0.

If the dimension of the body increases, one talks in terms

of a positive strain (or tensile strain), otherwise of a nega-

tive strain (or compressive strain).

The measurand is dimensionless. The SI unit of strain as

a relative measure is [m/m].

Kistler uses as the unit for relative strain

1 = 1 microstrain = 10–6 m/m = m/m

3.1.1 NormalsStrain – shear strain

Any component stretched or compressed longitudinally ex-

periences a shear strain in the transverse direction. The

shear strain is usually approximately 30 % of the normal

strain in the opposite direction. If the component is, for ex-

ample, compressed in the longitudinal direction, it stretches

in the transverse direction. Depending on the application,

this effect can be exploited and accordingly the shear strain

measured instead of the normal strain.

Fig. 1: Any body stretched or compressed in one direc-

tion experiences the opposite strain in the trans-

verse direction.

m

m

l

l

l

ll

00

01

Surface Strain Transmitter, Type 9238B...

Page 8 9238B_002-542e-02.23

3.2 What is the purpose of a strain transmitter?

A strain transmitter is primarily used to measure the surface

strain of a structure. However, as in all processes in which

forces are applied, the load-bearing structure of the ma-

chine undergoes a greater or lesser tensile or compressive

strain, a strain transmitter can be used equally effectively

for indirect measurement of dynamic and quasistatic forc-

es (see Figure 2). The sensitivity of the indirect force meas-

urement has to be determined by means of in-situ calibra-

tion.

Fig. 2: Indirect force measurement using strain forms

one extreme of the above spectrum. Despite

lower sensitivity, the relationship between force

and strain is in most cases linear enough to allow

sufficiently accurate measurement and monitor-

ing.

The key areas of application of the strain transmitter Type

9238B... are:

Process monitoring of medium forces

(press-fitting, crimping, bonding, punching, fine blank-

ing, deep drawing and embossing)

Process monitoring in presses exerting large forces

(for forging and production of car bodies, etc.)

Machine tool monitoring

<10 %

10 ... 99 %

>> 99 %

Force shunt measurement

Sensitivity

Fp

Fn

Fs

Fp

Indirect force measuremen

t

Force Shunt

Direct force measuremen

t

Range of

indirect force

measurement

using strain

General description

9238B_002-542e-02.23 Page 9

1

The strain transmitter Type 9238B... has the following ex-

cellent features:

Simple mounting with just a single M6 hexagon socket

head cap screw

Integral charge amplifier makes it particularly good val-

ue for money

Flexible adjustment of the output signal thanks to fully-

digital amplifier

Absolute protection against overload

The Kistler strain transmitter Type 9238B... is supplied cali-

brated and is ready for immediate use.

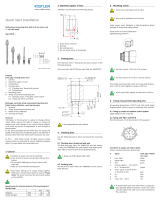

3.3 Design and principle of operation of strain transmitter Type 9238B...

3.3.1 Design

Fig. 3: Schematic section through strain transmitter Type

9238B…

The strain transmitter 9238B... basically consists of five vital

elements.

1 Machine structure that is being stretched or compressed

cyclically.

2 Two contact feet of the strain transmitter transfer the

strain of the structure by friction to the body of the sen-

sor and to the piezoelectric element for measuring shear

force.

3 Piezoelectric measuring element, which generates a

charge proportional to the applied shear force.

4 Sensor case or body, which acts as a spring converting

the strain into a proportional force.

5 Amplifier case containing the fully digital charge ampli-

fier, which converts the charge generated by the meas-

uring element into a standard 0 ... 10 V voltage signal.

2

3

4 5

1

2

3

4 5

Surface Strain Transmitter, Type 9238B...

Page 10 9238B_002-542e-02.23

3.3.2 Measurement principle

To enable the strain of the structure of the machine to be

transferred by friction to the strain sensor, the contact feet

(2) have to be pressed onto the surface of the structure

with a preloading force acting perpendicular to the bear-

ing surface.

The design of the strain transmitter Type 9238B... allows

the bearing surfaces (or contact feet (2)) to be preloaded

through the case with a single M6 screw.

The strain of the material forming the structure (of the ma-

chine) acts on the surface of the structure as a change in

length. As the strain transmitter is firmly connected to the

surface, the distance between the two contact feet chang-

es with the strain. This change in distance is picked up by

the body of the sensor (Figure 3, (4)) and converted into a

strain-proportional shear force, which acts on the piezoe-

lectric measuring element (Figure 3, (3)).

The transmitter is designed so that a strain generates a

negative charge. The integral charge amplifier standardly

converts this into a positive output signal according to a

Kistler convention. The signs change accordingly for com-

pressive strain.

3.3.3 Integral fully-digital charge amplifier

The strain transmitter Type 9238B... is equipped with a mi-

croprocessor-controlled, highly-integrated charge amplifier.

This offers the user very considerable flexibility. Via the se-

rial interface (RS-232C):

all parameters can be set

the measuring cycle can be controlled

(MEASURE/RESET).

the measuring range can be switched

measurement data can be transmitted (20 Hz).

General description

9238B_002-542e-02.23 Page 11

Fig. 4: Block circuit diagram of strain transmitter Type

9238B...

The charge amplifier with preamplifier is designed using

proven high-insulation technology. After this stage the

output signal of the preamplifier is digitized at 1 kHz and

processed in the microcontroller. Full scale voltage, offset

and signal inversion are calculated digitally in real time. The

calculated output value is converted into the analog output

signal in a digital-to-analog converter. As usual the two

process control signals /Range II and /Measure can also

control the transmitter from the process controller by

means of hardware.

3.4 Factory calibration of transmitter

The strain transmitter Type 9238B... is calibrated by the

factory. This involves determining the actual sensitivity and

the maximum linearity error using the method of 'continu-

ous calibration'. Calibration is performed for the range

0 ... –500 ; with the transmitter programmed to

500 /10 V and 50/10 V (mechanical measuring range

/ full scale output) respectively. The calibration is recorded

on the included calibration certificate.

Surface Strain Transmitter, Type 9238B...

Page 12 9238B_002-542e-02.23

Fig. 5: Example of an included calibration certificate

The results of factory calibration can be used for direct

measurement of strain. The shown sensitivity can be used

by the postprocessing system (e.g. data acquisition) to cor-

rectly interpret the output signal (e.g. 200,8 mV corre-

sponds to 1 with the nominal setting of 50 /10 V).

If the strain transmitter Type 9238B... is to be used for indi-

rect force measurement, in-situ calibration has to be carried

out in any case.

Installation and commissioning

9238B_002-542e-02.23 Page 13

4. Installation and commissioning

4.1 Important instructions

The strain transmitter Type 9238B... is a precision instru-

ment whose specifications can only be fully exploited with

correct use and only retained with careful handling. Please

observe the following instructions:

The strain transmitter may only be installed by persons

adequately qualified for this work.

Do not drop the strain transmitter or hit it hard! The

peak of such a shock force can cause permanent dam-

age.

Do not use a hammer to position the workpieces, as

such blows can also lead to damage!

Please see the following sections for instructions for in-

stalling the strain transmitter and setting up the measuring

chain.

4.2 Choosing measuring point

To enable successful indirect measurement, particular at-

tention must be paid to the choice of measuring point.

Measuring chain requirements:

The strain at the measuring point must be as propor-

tional as possible to the force to be measured.

A machine that does not allow exact location of the

point of application of the force must be fitted with

several strain sensors or transmitters if measurement

always has to be correspond accurately to the operating

force (for instance in a 4-column press, 2 or 4 sensors

are required) irrespective of the force application point.

On the one hand the strains at the measuring point

have to lie within the measuring range of the sensor.

On the other hand, to get a signal-to-noise ratio as

large as possible in operation it must be ensured that

the measuring range of the strain sensor is optimally

exploited.

The measuring point should not be subjected to any

high thermal loads (heat radiation and air currents).

Ideally, the material and ambient temperature at the

measuring point are equal and constant during the

measuring cycle.

The material of the surface must have sufficient wall

thickness at the measuring point.

Surface Strain Transmitter, Type 9238B...

Page 14 9238B_002-542e-02.23

It is scarcely possible to find measuring points on machines

whose strains are the result of pure tensile and compressive

stresses. At practically every measuring point the strain is a

combination of tensile or compressive and bending stress-

es. The percentage of the strain due to bending is often

considerably higher than that due to pure tension or com-

pression. More accurate investigation of the relationship

between strain due to bending and working force fre-

quently reveals nonlinear characteristics, whose cause is to

be found in the spring effects of gaps between bearing and

flange surfaces, or in effects related to the sliding of the

faces of joints. Such nonlinearities become apparent during

working force calibration, when the relationship between

reference force and strain signal is being measured.

4.2.1 Surface materials

The transmitter is basically intended for use on steel struc-

tures, which do not present any problems. Measurement of

strain on other materials, such as cast iron, aluminum or

other metals, must be approached with caution. Known

problems include reduced surface pressure and hence re-

duced preloading, hysteresis effects, material fatigue in the

contact area and insufficient mounting thread strength.

Although we do not advise here against trials on alterna-

tive materials, it is necessary to clarify the prospects of suc-

cess on a case by case basis, possibly with the aid of tests.

Installation and commissioning

9238B_002-542e-02.23 Page 15

4.3 Allowing for thermal effects

Any setup used to measure strains arising in mechanical

engineering applications is susceptible to two types of

thermal effects:

Effect 1

Error signals due to temperature differences between strain

sensor and structure to be measured (even if the coeffi-

cients of thermal expansion of structure and sensor are

equal).

Effect 2

Error signals in the event of temperature changes of strain

sensor and structure to be measured with different coeffi-

cients of thermal expansion (even if sensor and structure

undergo absolutely identical temperature changes).

Consequences of effect 1:

The measuring point must not be subjected to any ex-

ternal thermal loads (heat radiation, strong air currents).

The material at the measuring point must not be sub-

jected to any rapid temperature changes.

Consequences of effect 2:

The strain transmitter Type 9238B... is temperature

compensated for use on steels. This means it stretches

like the steel surface on which it is mounted when

heated equally. Even use on gray cast iron may give rise

to small measuring errors caused by temperature, if ei-

ther the useful signals are very small or the change in

temperature during a measurement is relatively large. A

parallel change in temperature of 1 °C of a gray cast

iron structure and the strain sensor during a measuring

cycle results in an error signal of approximately 2 . In

a large useful signal of, for example, 600 this error is

negligible, in a useful signal of 60 the error is, how-

ever, already 3,3 %.

The error signals produced by temperature changes by us-

ing the strain sensor on aluminum or other materials with

coefficients of thermal expansion differing greatly from

steel reach different orders of magnitude. Changes in tem-

perature over longer measuring cycles, i.e. in the quasistat-

ic range, have a particularly detrimental effect in these cas-

es, in which scarcely tolerable errors are to be expected.

The longest cycle time that can still be accepted is about

10 s.

Surface Strain Transmitter, Type 9238B...

Page 16 9238B_002-542e-02.23

4.3.1 Self-heating

The charge amplifier with controller incorporated in the

strain transmitter Type 9238B... itself generates heat. This

self-heating can be more or less depending on the mode of

operation. As a guide it may be assumed that, with an am-

bient temperature of 20 °, the drift due to self-heating

with a cycle time of <20 s will never exceed 0,8 µ (1 % of

800 µ FS).

If more stringent demands are made on the thermal stabil-

ity, it is advisable to leave the transmitter switched on for

half an hour before the first measurement. If it is neverthe-

less required to be ready for measurement quickly, the

transmitter can also remain on permanently.

4.4 Machining mounting surface

The strain transmitter Type 9238B... is designed for mount-

ing on flat metal surfaces. The higher the required quality

of the measurement results the more stringent the de-

mands placed on the quality of the bearing surfaces.

The minimum bearing surface quality requirements for en-

suring the specified data are to be found in Figure 6.

If possible, manufacturers who offer their machines for op-

tional fitting or retrofitting with the strain sensor are ad-

vised to prepare two suitable measuring points on the ma-

chines to facilitate subsequent fitting.

Installation and commissioning

9238B_002-542e-02.23 Page 17

Fig. 6: Preparation of bearing surface of strain transmit-

ter Type 9238B...

The machined surface can be either rectangular or concen-

tric. To ensure the transmitter Type 9238B... with the am-

plifier case does not lie on the surface, it must not be re-

cessed deeper than 0,2 mm into the surrounding surface.

The M6 threaded bore as shown in Figure 6 must be in the

middle of the machined surface.

After machining, the mounting surface must be thoroughly

cleaned with a degreasing agent.

The better the quality of the mounting surface and position

of the threaded bore, the higher the quality of the meas-

ured signals.

Surface Strain Transmitter, Type 9238B...

Page 18 9238B_002-542e-02.23

4.5 Mounting

4.5.1 Mounting strain transmitter

Perfect mounting is important in achieving quality and par-

ticularly reproducibility.

Clean bearing surface and threaded bore of the mount-

ing carefully with a degreasing cleaning agent (such as

ethanol, acetone, carbon tetrachloride or petrol).

For a controlled tightening torque the thread and the

screw head bearing surfaces must be greased (for ex-

ample using Kistler special grease Type 1063).

IMPORTANT: Make sure no grease gets on the bearing

surfaces between strain transmitter and structure surface.

To ensure the necessary friction these bearing surfaces

must be absolutely dry and free from grease.

Align the transmitter in the direction of the greatest an-

ticipated strain.

Preload the screw with 14 N·m using a torque wrench.

Fig. 7: Mounting Strain Transmitter Type 9238B...

Without grease the preload with the nominal tightening

torque can be significantly less. However, a reduction in

preload results in limiting of the measuring range. A reduc-

tion in preload is only useful with very soft materials (such

as aluminum) in order to reduce the pressure on the bear-

ing surfaces.

Prior to measurement or calibration the machine with

mounted and preloaded strain sensors must be loaded at

least ten times with the maximum working force arising.

Screw M6x30 (65012719)

Tightening torque: 14 N·m

/