IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

, and NOTE have special meanings. Pay special attention to the messages high-

lighted by these signal words.

The circle with a slash in this manual means “Don’t do this” or “Don’t let this happen”.

WARNING

!

CAUTION

!

Indicates a potential hazard that could result in death or injury.

WARNING

!

Indicates a potential hazard that could result in vehicle damage.

CAUTION

!

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

This service manual is intended for authorized Suzuki dealers and qualified service technicians only.

Inexperienced technicians or technicians without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the technician and may render the vehicle unsafe for the driver

and passengers.

WARNING

!

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

• If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

• Do not modify the steering wheel, instrument panel or any other air bag system component on or

around air bag system components or wiring. Modifications can adversely affect air bag system

performance and lead to injury.

• If the vehicle will be exposed to temperatures over 93 °C (200 °F), for example, during a paint baking

process, remove the air bag system components, that is air bag (inflator) modules, SDM and/or seat

belt with pretensioner, beforehand to avoid component damage or unintended activation.

WARNING

!

FOREWORD

This SUPPLEMENTARY SERVICE MANUAL is a supplement to GRAND VITARA (JB416/JB420) SERVICE

MANUAL.

It has been prepared exclusively for the following applicable model.

Applicable model:

GRAND VITARA (JB416/JB420) vehicles

This supplementary service manual describes only different service information of the above applicable model

as compared with GRAND VITARA (JB416/JB420) SERVICE MANUAL. Therefore, whenever servicing the

above applicable models, consult this supplement first. And for any section, item or description not found in this

supplement, refer to the related manual below.

When replacing parts or servicing by disassembling, it is recommended to use SUZUKI genuine parts, tools and

service materials as specified in each description.

All information, illustrations and specifications contained in this literature are based on the latest product infor-

mation available at the time of publication approval. And used as the main subject of description is the vehicle of

standard specifications among others.

Therefore, note that illustrations may differ from the vehicle being actually serviced.

The right is reserved to make changes at any time without notice.

Related Manuals:

© COPYRIGHT SUZUKI MOTOR CORPORATION 2005

Manual Name Manual No.

GRAND VITARA (JB416/JB420) SERVICE MANUAL 99500-64J00-01E

RECOMMENDATON OF GENUINE SUZUKI PARTS AND ACCESSORIES USE

SUZUKI strongly recommends the use of genuine SUZUKI parts* and accessories. Genuine SUZUKI parts and

accessories are built to the highest standards of quality and performance, and are designed to fit the vehicle's

exact specifications.

A wide variety of non-genuine replacement parts and accessories for SUZUKI vehicles are currently available in

the market. Using these parts and accessories can affect the vehicle performance and shorten its useful life.

Therefore, installation of non-genuine SUZUKI parts and accessories is not covered under warranty.

Non-Genuine SUZUKI Parts and Accessories

Some parts and accessories may be approved by certain authorities in your country.

Some parts and accessories are sold as SUZUKI authorized replacement parts and accessories. Some genu-

ine SUZUKI parts and accessories are sold as re-use parts and accessories. These parts and accessories are

non-genuine Suzuki parts and accessories and use of these parts are not covered under warranty.

Re-use of Genuine SUZUKI Parts and Accessories

The resale or re-use of the following items which could give rise to safety hazards for users is expressly forbid-

den:

1) Air bag components and all other pyrotechnic items, including their components (e.g. cushion, control

devices and sensors)

2) Seatbelt system, including their components (e.g. webbing, buckles, and retractors)

The air bag and seat belt pretensioner components contain explosive chemicals. These components should be

removed and disposed of properly by SUZUKI authorized service shop or scrap yard to avoid unintended explo-

sion before scrapping.

*The parts remanufactured under SUZUKI's approval can be used as genuine SUZUKI parts in Europe.

00

0

1

2

3

4

5

6

7

8

9

10

11

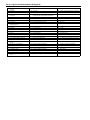

Precautions............................................................... 00-i

Precautions............................................................ 00-1

General Information................................................... 0-i

General Information ...............................................0A-1

Maintenance and Lubrication..................................0B-*

Engine ......................................................................... 1-i

Precautions...............................................................1-*

Engine General Information and Diagnosis ...........1A-1

Aux. Emission Control Devices...............................1B-*

Engine Electrical Devices....................................... 1C-*

Engine Mechanical................................................. 1D-*

Engine Lubrication System .....................................1E-*

Engine Cooling System...........................................1F-*

Fuel System...........................................................1G-*

Ignition System....................................................... 1H-*

Starting System........................................................1I-*

Charging System.....................................................1J-*

Exhaust System......................................................1K-*

Suspension................................................................. 2-i

Precautions...............................................................2-*

Suspension General Diagnosis...............................2A-*

Front Suspension...................................................2B-1

Rear Suspension.................................................... 2C-*

Wheels and Tires................................................... 2D-*

Driveline / Axle ........................................................... 3-i

Precautions...............................................................3-*

Drive Shaft / Axle ....................................................3A-*

Differential...............................................................3B-*

Transfer..................................................................3C-1

Propeller Shafts...................................................... 3D-*

Brakes ......................................................................... 4-i

Precautions.............................................................. 4-1

Brake Control System and Diagnosis ....................4A-1

Front Brakes...........................................................4B-1

Rear Brakes........................................................... 4C-*

Parking Brake......................................................... 4D-*

ABS........................................................................4E-1

Electronic Stability Program...................................4F-1

Transmission / Transaxle..........................................5-i

Precautions...............................................................5-*

Automatic Transmission/Transaxle........................5A-1

Manual Transmission/Transaxle ............................ 5B-*

Clutch.....................................................................5C-*

Steering....................................................................... 6-i

Precautions...............................................................6-*

Steering General Diagnosis ................................... 6A-*

Steering Wheel and Column ..................................6B-1

Power Assisted Steering System...........................6C-*

HVAC...........................................................................7-i

Precautions...............................................................7-*

Heater and Ventilation............................................7A-1

Air Conditioning System.........................................7B-1

Restraint......................................................................8-*

Precautions...............................................................8-*

Seat Belts............................................................... 8A-*

Air Bag System ...................................................... 8B-*

Body, Cab and Accessories......................................9-i

Precautions.............................................................. 9-1

Wiring Systems ...................................................... 9A-*

Lighting Systems....................................................9B-1

Instrumentation / Driver Info. / Horn.......................9C-1

Wipers / Washers...................................................9D-1

Glass / Windows / Mirrors ...................................... 9E-*

Security and Locks..................................................9F-*

Seats......................................................................9G-*

Interior Trim............................................................ 9H-*

Sun Roof / T-Top / Convertible Top.........................9I-*

Hood / Fenders / Doors...........................................9J-*

Body Structure ....................................................... 9K-*

Paint / Coatings.......................................................9L-*

Exterior Trim...........................................................9M-*

Control systems....................................................... 10-i

Precautions.............................................................10-*

Cruise Control System .........................................10A-1

Body Electrical Control System............................10B-1

Immobilizer Control System .................................10C-1

Keyless Start System...........................................10E-1

TABLE OF CONTENTS

NOTE

For the screen toned sections with asterisk (*) in the “TABLE OF CONTENTS” below, refer to the same

sections of the service manual mentioned in the “FOREWORD” of this manual.

Table of Contents 00- i

00

Section 00

CONTENTS

Precautions

Precautions...............................................00-1

Precautions........................................................... 00-1

Precautions for Vehicles Equipped with

a Supplemental Restraint (Air Bag) System ......00-*

General Precautions ............................................00-*

Precaution in Servicing Full-Time 4WD

Vehicle ...............................................................00-*

Precaution for Vehicle Equipped with ESP®

System............................................................. 00-1

Precautions for Catalytic Converter .....................00-*

Precaution for CAN Communication System.......00-*

Precautions for Electrical Circuit Service.............00-*

Precautions for Installing Mobile

Communication Equipment................................00-*

Air Bag Warning...................................................00-*

Discharge Headlight Warning ..............................00-*

A/C System Caution.............................................00-*

Fastener Caution..................................................00-*

Suspension Caution.............................................00-*

Wheels and Tires Caution....................................00-*

Brakes Caution and Note....................................00-1

Differential Gear Oil Note.....................................00-*

Repair Instructions ...............................................00-*

Electrical Circuit Inspection Procedure ................00-*

Intermittent and Poor Connection Inspection.......00-*

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

00-1 Precautions:

Precautions

Precautions

Precaution for Vehicle Equipped with ESP®

System

S5JB0E0000020

• When testing with any of the following equipments

(when vehicle is tested by rotating wheels (tires)

under vehicle stop), be sure to deactivate ESP®

system referring to “Precautions in Speedometer Test

or Other Tests: in Section 4F” to obtain correct data.

When vehicle acceleration is not sensed and wheels

are rotating, ESP® control module judges that wheels

are in slip condition and controls engine torque to

reduce by TCS control.

– 2 or 4-wheel chassis dynamometer

– Speedometer tester

– Brake tester

–Etc.

ESP® control module

• When ESP® control module is removed / installed, do

not use impact wrenches which generate shock or

impact to avoid damaging sensors in ESP® control

module.

• When any of the following operation is done, calibrate

steering angle sensor, G sensor and master cylinder

pressure sensor (in ESP® control module) referring to

“Sensor Calibration: in Section 4F”.

– When battery or dome fuse is removed.

– When steering angle sensor is replaced.

– When ESP® control module is removed.

– When yaw rate / G sensor assembly is removed.

Brakes Caution and Note

S5JB0E0000014

CAUTION

!

All brake fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of same part

number or with an equivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts. There is

to be no welding as it may result in extensive

damage and weakening of the metal.

NOTE

Before inspecting and servicing brakes for

vehicle equipped with ABS (ESP®), make

sure that ABS (ESP®) is in good condition.

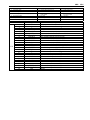

Table of Contents 0- i

0

Section 0

CONTENTS

General Information

General Information ................................0A-1

General Description.............................................0A-1

Abbreviations ......................................................0A-1

Symbols ...............................................................0A-*

Wire Color Symbols .............................................0A-*

Fastener Information............................................0A-*

Vehicle Lifting Points............................................0A-*

Engine Supporting Points ....................................0A-*

Vehicle Identification Number ..............................0A-*

Engine Identification Number...............................0A-*

Transmission Identification Number.....................0A-*

Component Location........................................... 0A-*

Warning, Caution and Information Label

Location .............................................................0A-*

Maintenance and Lubrication..................0B-*

Precautions........................................................... 0B-*

Precautions for Maintenance and

Lubrication .........................................................0B-*

Scheduled Maintenance...................................... 0B-*

Maintenance Schedule under Normal

Driving Conditions..............................................0B-*

Maintenance Recommended under Severe

Driving Conditions..............................................0B-*

Repair Instructions .............................................. 0B-*

Engine Accessory Drive Belt Inspection ..............0B-*

Engine Accessory Drive Belt Replacement..........0B-*

Valve Lash (Clearance) Inspection......................0B-*

Engine Oil and Filter Change...............................0B-*

Engine Coolant Change.......................................0B-*

Exhaust system Inspection ..................................0B-*

Spark Plugs Replacement ...................................0B-*

Air Cleaner Filter Inspection.................................0B-*

Air Cleaner Filter Replacement............................0B-*

Fuel Lines and Connections Inspection...............0B-*

Fuel Filter Replacement.......................................0B-*

Fuel Tank Inspection............................................0B-*

Crankcase Ventilation Hoses and

Connections Inspection (Vehicle without

A/F Sensor)....................................................... 0B-*

PCV Valve Inspection ......................................... 0B-*

Fuel Evaporative Emission Control System

Inspection.......................................................... 0B-*

Brake Discs and Pads Inspection ....................... 0B-*

Brake Drums and Shoes Inspection.................... 0B-*

Brake Hoses and Pipes Inspection ..................... 0B-*

Brake Fluid Change ............................................ 0B-*

Parking Brake Lever and Cable Inspection......... 0B-*

Clutch Fluid Inspection........................................ 0B-*

Tire / Wheel Inspection and Rotation.................. 0B-*

Wheel Discs Inspection....................................... 0B-*

Wheel Bearing Inspection................................... 0B-*

Suspension System Inspection........................... 0B-*

Steering System Inspection ................................ 0B-*

Propeller Shafts and Drive Shafts

Inspection.......................................................... 0B-*

Manual Transmission Oil Inspection................... 0B-*

Manual Transmission Oil Change....................... 0B-*

Automatic Transmission Fluid Inspection............ 0B-*

Automatic Transmission Fluid Change ............... 0B-*

Automatic Transmission Fluid Cooler Hose

Inspection.......................................................... 0B-*

Transfer Oil Inspection (If Equipped) .................. 0B-*

Differential Oil Inspection .................................... 0B-*

Transfer (If Equipped) and Differential Oil

Change.............................................................. 0B-*

Power Steering (P/S) System Inspection............ 0B-*

All Hinges, Latches and Locks Inspection........... 0B-*

HVAC Air Filter Inspection (If Equipped)............. 0B-*

HVAC Air Filter Replacement (If Equipped)........ 0B-*

Final Inspection for Maintenance Service ........... 0B-*

Specifications.......................................................0B-*

Tightening Torque Specifications........................ 0B-*

Special Tools and Equipment............................. 0B-*

Recommended Fluids and Lubricants................. 0B-*

Special Tool ........................................................ 0B-*

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

0A-1 General Information:

General Information

General Description

Abbreviations

S5JB0E0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

ATDC: After Top Dead Center

ATF: Automatic Transmission Fluid

A/T: Automatic Transmission

AWD: All Wheel Drive

B:

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BTDC: Before Top Dead Center

B+: Battery Positive Voltage

C:

CAN: Controller Area Network

CKP Sensor: Crankshaft Position Sensor

CKT: Circuit

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Control Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor

(Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

ELR: Emergency Locking Retractor

EPS: Electronic Power Steering

ESP®: Electronic Stability Program

EVAP: Evaporative Emission

EVAP Canister: Evaporative Emission Canister

(Charcoal Canister)

F:

FWD: Front Wheel Drive

4WD: 4 Wheel Drive

G:

GEN: Generator

GND: Ground

H:

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

HVAC: Heating, Ventilating and Air Conditioning

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

IMT: Intake Manifold Tuning

ISC Actuator: Idle Speed Control Actuator (Motor)

L:

LH: Left Hand

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor,

AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Multipoint Fuel Injection)

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

Min: Minimum

M/T: Manual Transmission

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

OCM: Occupant Classification module

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

P/S: Power Steering

R:

RH: Right Hand

S:

SAE: Society of Automotive Engineers

SDM: Sensing and Diagnostic Module (Air Bag

Controller, Air bag Control Module)

General Information: 0A-2

SFI: Sequential Multiport Fuel Injection

SOHC: Single Over Head Camshaft

T:

TBI: Throttle Body Fuel Injection (Single-Point Fuel

Injection, SPI)

TCC: Torque Converter Clutch

TCM: Transmission Control Module (A/T Controller, A/T

Control Module)

TPMS: Tire Pressure Monitoring System

TP Sensor: Throttle Position Sensor

TVV: Thermal Vacuum Valve (Thermal Vacuum

Switching Valve, TVSV, Bimetal Vacuum Switching

Valve, BVSV)

TWC: Three Way Catalytic Converter (Three Way

Catalyst)

2WD: 2 Wheel Drive

V:

VIN: Vehicle Identification Number

VSS: Vehicle Speed Sensor

VVT: Variable Valve Timing (Camshaft Position Control)

W:

WU-OC: Warm Up Oxidation Catalytic Converter

WU-TWC: Warm Up Three Way Catalytic Converter

0A-3 General Information:

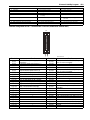

Table of Contents 1- i

1

Section 1

CONTENTS

Engine

Precautions................................................. 1-*

Precautions..............................................................1-*

Precautions for Engine...........................................1-*

Engine General Information and

Diagnosis .................................................1A-1

Precautions...........................................................1A-1

Precautions on Engine Service............................1A-*

Precautions in Diagnosing Trouble.....................1A-1

Precautions For DTC Troubleshooting.................1A-*

Precautions of ECM Circuit Inspection.................1A-*

Precautions of Electric Throttle Body

System Calibration.............................................1A-*

General Description.............................................1A-2

Statement on Cleanliness and Care ....................1A-*

Engine Diagnosis General Description ................1A-*

On-Board Diagnostic System Description...........1A-2

Engine and Emission Control System

Description........................................................1A-5

CAN Communication System Description...........1A-5

Air Intake System Description..............................1A-*

Description of Electric Throttle Body System.......1A-*

Description of Electric Throttle Body

System Calibration.............................................1A-*

Generator Control System Description ................1A-*

A/F Sensor Description........................................1A-*

Electronic Control System Description................1A-7

Engine and Emission Control Input / Output

Table...............................................................1A-15

Schematic and Routing Diagram......................1A-16

Engine and Emission Control System

Diagram ..........................................................1A-16

Component Location.........................................1A-17

Electronic Control System Components

Location ..........................................................1A-17

Diagnostic Information and Procedures..........1A-19

Engine and Emission Control System

Check.................................................................1A-*

Malfunction Indicator Lamp (MIL) Check .............1A-*

DTC Check ..........................................................1A-*

DTC Clearance ....................................................1A-*

DTC Table.........................................................1A-19

Fail-Safe Table.....................................................1A-*

Scan Tool Data ....................................................1A-*

Visual Inspection................................................. 1A-*

Engine Basic Inspection...................................... 1A-*

Engine Symptom Diagnosis................................ 1A-*

Malfunction Indicator Lamp Does Not Come

ON with Ignition Switch ON and Engine

Stop (but Engine Can Be Started)...................1A-25

Malfunction Indicator Lamp Remains ON

after Engine Starts ..........................................1A-27

DTC P0010: Camshaft Position Actuator

Circuit (For M16 Engine)................................... 1A-*

DTC P0011 / P0012: Camshaft Position -

Timing Over-Advanced or System Performance

/ -Retarded (For M16 Engine)........................... 1A-*

DTC P0030: HO2S Heater Control Circuit

(Sensor-1)......................................................... 1A-*

DTC P0031 / P0032: HO2S Heater Control

Circuit Low / High (Sensor-1)............................ 1A-*

DTC P0037 / P0038: HO2S Heater Control

Circuit Low / High (Sensor-2)............................ 1A-*

DTC P0101: Mass Air Flow Circuit Range

/ Performance.................................................... 1A-*

DTC P0102: Mass Air Flow Circuit Low

Input.................................................................. 1A-*

DTC P0103: Mass Air Flow Circuit High

Input.................................................................. 1A-*

DTC P0106: Manifold Absolute Pressure

Range / Performance........................................ 1A-*

DTC P0107: Manifold Absolute Pressure

Circuit Low Input ............................................... 1A-*

DTC P0108: Manifold Absolute Pressure

Circuit High Input............................................... 1A-*

DTC P0111: Intake Air Temperature Circuit

Range / Performance........................................ 1A-*

DTC P0112: Intake Air Temperature

Sensor Circuit Low............................................ 1A-*

DTC P0113: Intake Air Temperature

Sensor Circuit High........................................... 1A-*

DTC P0116: Engine Coolant Temperature

Circuit Range / Performance............................. 1A-*

DTC P0117: Engine Coolant Temperature

Circuit Low ........................................................ 1A-*

DTC P0118: Engine Coolant Temperature

Circuit High........................................................ 1A-*

DTC P0122: Throttle Position Sensor

(Main) Circuit Low............................................. 1A-*

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

1-ii Table of Contents

DTC P0123: Throttle Position Sensor

(Main) Circuit High ............................................ 1A-*

DTC P0131 / P0132 / P0134: O2 Sensor

(HO2S) Circuit Low Voltage / High Voltage

/ No Activity Detected (Sensor-1)...................... 1A-*

DTC P0133: O2 Sensor (HO2S) Circuit

Slow Response (Sensor-1)............................... 1A-*

DTC P0137 / P0138: O2 Sensor (HO2S)

Circuit Low Voltage / High Voltage

(Sensor-2)......................................................... 1A-*

DTC P0140: O2 Sensor (HO2S) Circuit No

Activity Detected (Sensor-2) ............................. 1A-*

DTC P0171 / P0172 / P2195 / P2196: Fuel

System Too Lean / Rich / Stuck Lean /

Stuck Rich......................................................... 1A-*

DTC P0222: Throttle Position Sensor (Sub)

Circuit Low ........................................................ 1A-*

DTC P0223: Throttle Position Sensor (Sub)

Circuit High ....................................................... 1A-*

DTC P0300 / P0301 / P0302 / P0303 /

P0304: Random Misfire Detected / Cylinder

1 / Cylinder 2 / Cylinder 3 / Cylinder 4

Misfire Detected................................................ 1A-*

DTC P0327 / P0328: Knock Sensor Circuit Low

/ High................................................................. 1A-*

DTC P0335: Crankshaft Position (CKP)

Sensor Circuit (For J20 Engine)........................ 1A-*

DTC P0335: Crankshaft Position (CKP)

Sensor Circuit (For M16 Engine)....................... 1A-*

DTC P0340: Camshaft Position (CMP)

Sensor Circuit ................................................... 1A-*

DTC P0401 / P0402: Exhaust Gas

Recirculation Flow Insufficient Detected /

Excessive Detected .......................................... 1A-*

DTC P0403: Exhaust Gas Recirculation

Control Circuit ................................................... 1A-*

DTC P0420: Catalyst System Efficiency

below Threshold................................................ 1A-*

DTC P0443: Evaporative Emission System

Purge Control Valve Circuit............................... 1A-*

DTC P0462: Fuel Level Sensor Circuit Low........ 1A-*

DTC P0463: Fuel Level Sensor Circuit High....... 1A-*

DTC P0480: Fan 1 (Radiator Cooling Fan)

Control Circuit ................................................... 1A-*

DTC P0500: Vehicle Speed Sensor

(VSS) Malfunction...........................................1A-28

DTC P0504: Brake Switch “A”/“B” Correlation

(For J20 Engine) ............................................... 1A-*

DTC P0532: A/C Refrigerant Pressure

Sensor Circuit Low............................................ 1A-*

DTC P0533: A/C Refrigerant Pressure

Sensor Circuit High........................................... 1A-*

DTC P0601 / P0602 / P0607: Internal

Control Module Memory Check Sum Error

/ Control Module Programming Error /

Control Module Performance............................ 1A-*

DTC P0616: Starter Relay Circuit Low................ 1A-*

DTC P0617: Starter Relay Circuit High............... 1A-*

DTC P0620: Generator Control Circuit ............... 1A-*

DTC P0625 / P0626: Generator Field

Terminal Circuit Low / High............................... 1A-*

DTC P0660: Intake Manifold Tuning Valve

Control Circuit / Open (For J20 Engine)............ 1A-*

DTC P1501 / P1502: Electric Load Current

Sensor Circuit Low / High.................................. 1A-*

DTC P1510: ECM Back-Up Power Supply

Malfunction........................................................ 1A-*

DTC P1603: TCM Trouble Code Detected

(For J20 Engine) .............................................1A-29

DTC P1674: CAN Communication (Bus Off

Error)...............................................................1A-31

DTC P1676: CAN Communication

(Reception Error for TCM (for A/T model))......1A-35

DTC P1678: CAN Communication

(Reception Error for BCM) ..............................1A-38

DTC P1685: CAN Communication

(Reception Error for ABS or ESP® Control

Module)..........................................................1A-42

DTC P2101: Throttle Actuator Control

Motor Circuit Range / Performance................... 1A-*

DTC P2102: Throttle Actuator Control

Motor Circuit Low.............................................. 1A-*

DTC P2103: Throttle Actuator Control

Motor Circuit High ............................................. 1A-*

DTC P2111: Throttle Actuator Control System

- Stuck Open..................................................... 1A-*

DTC P2119: Throttle Actuator Control

Throttle Body Range / Performance.................. 1A-*

DTC P2122: Pedal Position Sensor (Main)

Circuit Low Input ............................................... 1A-*

DTC P2123: Pedal Position Sensor (Main)

Circuit High Input............................................... 1A-*

DTC P2127: Pedal Position Sensor (Sub)

Circuit Low Input ............................................... 1A-*

DTC P2128: Pedal Position Sensor (Sub)

Circuit High Input............................................... 1A-*

DTC P2135: Throttle Position Sensor (Main

/ Sub) Voltage Correlation................................. 1A-*

DTC P2138: Pedal Position Sensor (Main /

Sub) Voltage Correlation................................... 1A-*

DTC P2227 / P2228 / P2229: Barometric

Pressure Circuit Malfunction ............................. 1A-*

Inspection of ECM and Its Circuits....................1A-46

ECM Power and Ground Circuit Check............... 1A-*

Fuel Injector Circuit Check.................................. 1A-*

Fuel Pump and Its Circuit Check......................... 1A-*

Fuel Pressure Check........................................... 1A-*

A/C System Circuits Check...............................1A-68

Electric Load Signal Circuit Check....................1A-71

Radiator Cooling Fan Low Speed Control

System Check................................................... 1A-*

Radiator Cooling Fan High Speed Control

System Check................................................... 1A-*

Repair Instructions .............................................. 1A-*

Idle Speed and IAC Throttle Valve Opening

Inspection.......................................................... 1A-*

Special Tools and Equipment...........................1A-72

Special Tool ......................................................1A-72

Table of Contents 1-iii

Aux. Emission Control Devices ..............1B-*

Diagnostic Information and Procedures............ 1B-*

EGR System Inspection.......................................1B-*

Repair Instructions .............................................. 1B-*

EVAP Canister Purge Inspection.........................1B-*

EVAP Canister Purge Valve and Its Circuit

Inspection...........................................................1B-*

Vacuum Passage Inspection ...............................1B-*

Vacuum Hose and Purge Valve Chamber

Inspection...........................................................1B-*

EVAP Canister Purge Valve Inspection...............1B-*

EVAP Canister Inspection....................................1B-*

EGR Valve Removal and Installation...................1B-*

EGR Valve Inspection..........................................1B-*

PCV Hose Inspection...........................................1B-*

PCV Valve Removal and Installation ...................1B-*

PCV Valve Inspection ..........................................1B-*

Specifications....................................................... 1B-*

Tightening Torque Specifications.........................1B-*

Special Tools and Equipment............................. 1B-*

Recommended Service Material..........................1B-*

Special Tool .........................................................1B-*

Engine Electrical Devices........................1C-*

Repair Instructions .............................................. 1C-*

Engine Control Module (ECM) Removal

and Installation.................................................. 1C-*

Manifold Absolute Pressure (MAP) Sensor

Inspection.......................................................... 1C-*

Electric Throttle Body Assembly

On-Vehicle Inspection....................................... 1C-*

Electric Throttle Body System Calibration........... 1C-*

Accelerator Pedal Position (APP) Sensor

Assembly On-Vehicle Inspection ...................... 1C-*

Accelerator Pedal Position (APP) Sensor

Assembly Removal and Installation.................. 1C-*

Accelerator Pedal Position (APP) Sensor

Assembly Inspection......................................... 1C-*

Engine Coolant Temperature (ECT) Sensor

Removal and Installation................................... 1C-*

Engine Coolant Temperature (ECT)

Sensor Inspection ............................................. 1C-*

Air Fuel Ratio (A/F) Sensor On-Vehicle

Inspection.......................................................... 1C-*

Heated Oxygen Sensor (HO2S-2) Heater

On-Vehicle Inspection....................................... 1C-*

Air Fuel Ratio (A/F) Sensor, Heated Oxygen

Sensor (HO2S-2) Removal and Installation...... 1C-*

Camshaft Position (CMP) Sensor Removal

and Installation.................................................. 1C-*

Camshaft Position (CMP) Sensor

Inspection.......................................................... 1C-*

Crankshaft Position (CKP) Sensor

Removal and Installation................................... 1C-*

Crankshaft Position (CKP) Sensor

Inspection.......................................................... 1C-*

Knock Sensor Removal and Installation ............. 1C-*

Control Relay Inspection..................................... 1C-*

Mass Air Flow (MAF) and Intake Air

Temperature (IAT) Sensor On-Vehicle

Inspection.......................................................... 1C-*

Mass Air Flow (MAF) and Intake Air

Temperature (IAT) Sensor Removal and

Installation.........................................................1C-*

Mass Air Flow (MAF) and Intake Air

Temperature (IAT) Sensor Inspection............... 1C-*

Vacuum Tank Assembly Inspection (For

J20 Engine).......................................................1C-*

Electric Load Current Sensor On-Vehicle

Inspection (For J20 Engine)..............................1C-*

Electric Load Current Sensor Removal

and Installation (For J20 Engine)......................1C-*

Specifications.......................................................1C-*

Tightening Torque Specifications........................1C-*

Engine Mechanical ...................................1D-*

For M16A Engine with VVT..................................... 1D-*

General Description............................................. 1D-*

Engine Construction Description......................... 1D-*

Camshaft Position Control (VVT Variable

Valve Timing) System Description....................1D-*

Diagnostic Information and Procedures............ 1D-*

Compression Check............................................ 1D-*

Engine Vacuum Check........................................1D-*

Valve Lash (Clearance) Inspection ..................... 1D-*

Repair Instructions .............................................. 1D-*

Air Cleaner Filter Removal and Installation.........1D-*

Air Cleaner Filter Inspection and Cleaning.......... 1D-*

Cylinder Head Cover Removal and

Installation.........................................................1D-*

Throttle Body and Intake Manifold

Components......................................................1D-*

Throttle Body On-Vehicle Inspection................... 1D-*

Electric Throttle Body Assembly Removal

and Installation.................................................. 1D-*

Throttle Body Cleaning........................................ 1D-*

Intake Manifold Removal and Installation ...........1D-*

Engine Mountings Components..........................1D-*

Engine Assembly Removal and Installation........ 1D-*

Timing Chain Cover Components.......................1D-*

Timing Chain Cover Removal and

Installation.........................................................1D-*

Timing Chain Cover Inspection...........................1D-*

Oil Control Valve Removal and Installation......... 1D-*

Oil Control Valve Inspection................................1D-*

Timing Chain and Chain Tensioner

Components......................................................1D-*

Timing Chain and Chain Tensioner

Removal and Installation...................................1D-*

Timing Chain and Chain Tensioner

Inspection.......................................................... 1D-*

Camshaft, Tappet and Shim Components.......... 1D-*

Camshaft, Tappet and Shim Removal and

Installation.........................................................1D-*

Camshaft, Tappet and Shim Inspection..............1D-*

Valves and Cylinder Head Components .............1D-*

1-iv Table of Contents

Valves and Cylinder Head Removal and

Installation......................................................... 1D-*

Valves and Cylinder Head Disassembly

and Assembly ................................................... 1D-*

Valves and Valve Guides Inspection................... 1D-*

Cylinder Head Inspection.................................... 1D-*

Valve Spring Inspection ......................................1D-*

Pistons, Piston Rings, Connecting Rods

and Cylinders Components............................... 1D-*

Pistons, Piston Rings, Connecting Rods

and Cylinders Removal and Installation............ 1D-*

Pistons, Piston Rings, Connecting Rods

and Cylinders Disassembly and Assembly.......1D-*

Cylinders, Pistons and Piston Rings

Inspection.......................................................... 1D-*

Piston Pins and Connecting Rods

Inspection.......................................................... 1D-*

Crank Pin and Connecting Rod Bearings

Inspection.......................................................... 1D-*

Main Bearings, Crankshaft and Cylinder

Block Components............................................ 1D-*

Main Bearings, Crankshaft and Cylinder

Block Removal and Installation......................... 1D-*

Crankshaft Inspection ......................................... 1D-*

Main Bearings Inspection.................................... 1D-*

Sensor Plate Inspection...................................... 1D-*

Rear Oil Seal Inspection .....................................1D-*

Flywheel Inspection............................................. 1D-*

Cylinder Block Inspection....................................1D-*

Specifications....................................................... 1D-*

Tightening Torque Specifications........................ 1D-*

Special Tools and Equipment............................. 1D-*

Recommended Service Material......................... 1D-*

Special Tool ........................................................ 1D-*

For J20 Engine ........................................................ 1D-*

General Description............................................. 1D-*

Engine Construction Description......................... 1D-*

Air Cleaner Element Introduction........................ 1D-*

IMT (Intake Manifold Tuning) System................. 1D-*

Diagnostic Information and Procedures............ 1D-*

Compression Check............................................ 1D-*

Engine Vacuum Check........................................ 1D-*

Valve Lash (Clearance) Inspection.....................1D-*

Repair Instructions .............................................. 1D-*

Air Cleaner Assembly Removal and

Installation......................................................... 1D-*

Air Cleaner Filter Removal and Installation......... 1D-*

Air Cleaner Filter Inspection and Cleaning..........1D-*

Throttle Body and Intake Manifold

Components...................................................... 1D-*

Throttle Body On-Vehicle Inspection................... 1D-*

Electric Throttle Body Assembly Removal

and Installation..................................................1D-*

Throttle Body Cleaning........................................1D-*

Intake Manifold Removal and Installation ...........1D-*

Cylinder Head Cover Removal and

Installation......................................................... 1D-*

Engine Mountings Components.......................... 1D-*

Engine Assembly Removal and Installation........1D-*

Timing Chain Cover Components.......................1D-*

Timing Chain Cover Removal and

Installation.........................................................1D-*

Timing Chain Cover Cleaning and

Inspection..........................................................1D-*

2nd Timing Chain and Chain Tensioner

Components......................................................1D-*

2nd Timing Chain and Chain Tensioner

Removal and Installation...................................1D-*

2nd Timing Chain and Chain Tensioner

Inspection..........................................................1D-*

1st Timing Chain and Chain Tensioner

Components......................................................1D-*

1st Timing Chain and Chain Tensioner

Removal and Installation...................................1D-*

1st Timing Chain and Chain Tensioner

Inspection..........................................................1D-*

Camshafts, Tappet and Shim Components........1D-*

Camshafts, Tappet and Shim Removal

and Installation..................................................1D-*

Camshaft, Tappet and Shim Inspection..............1D-*

Valves and Cylinder Head Components .............1D-*

Valves and Cylinder Head Removal and

Installation.........................................................1D-*

Valves and Cylinder Head Disassembly

and Assembly....................................................1D-*

Valves and Valve Guides Inspection...................1D-*

Cylinder Head Inspection....................................1D-*

Valve Spring Inspection ......................................1D-*

Pistons, Piston Rings, Connecting Rods

and Cylinders Components...............................1D-*

Pistons, Piston Rings, Connecting Rods

and Cylinders Removal and Installation............1D-*

Pistons, Piston Rings, Connecting Rods

and Cylinders Disassembly and Assembly .......1D-*

Pistons, Piston Rings, Connecting Rods

and Cylinders Inspection and Cleaning.............1D-*

Main Bearings, Crankshaft and Cylinder

Block Components............................................ 1D-*

Main Bearings, Crankshaft and Cylinder

Block Removal and Installation.........................1D-*

Main Bearings, Crankshaft and Cylinder

Block Inspection................................................1D-*

Specifications.......................................................1D-*

Tightening Torque Specifications........................1D-*

Special Tools and Equipment.............................1D-*

Recommended Service Material.........................1D-*

Special Tool ........................................................1D-*

Engine Lubrication System.....................1E-*

For M16A Engine with VVT..................................... 1E-*

General Description............................................. 1E-*

Engine Lubrication Description ........................... 1E-*

Diagnostic Information and Procedures............ 1E-*

Oil Pressure Check ............................................. 1E-*

Repair Instructions .............................................. 1E-*

Oil Pan and Oil Pump Strainer Components....... 1E-*

Oil Pan and Oil Pump Strainer Removal

and Installation.................................................. 1E-*

Table of Contents 1-v

Oil Pan and Oil Pump Strainer Cleaning..............1E-*

Oil Pump Components.........................................1E-*

Oil Pump Removal and Installation......................1E-*

Oil Pump Disassembly and Reassembly.............1E-*

Oil Pump Inspection.............................................1E-*

Specifications........................................................1E-*

Tightening Torque Specifications.........................1E-*

Special Tools and Equipment..............................1E-*

Recommended Service Material..........................1E-*

Special Tool .........................................................1E-*

For J20 Engine .........................................................1E-*

General Description..............................................1E-*

Engine Lubrication Description ............................1E-*

Diagnostic Information and Procedures.............1E-*

Oil Pressure Check..............................................1E-*

Repair Instructions ...............................................1E-*

Oil Pan and Oil Pump Strainer Components........1E-*

Oil Pan and Oil Pump Strainer Removal

and Installation...................................................1E-*

Oil Pan and Oil Pump Strainer Cleaning..............1E-*

Oil Pump Components.........................................1E-*

Oil Pump Removal and Installation......................1E-*

Oil Pump Disassembly and Assembly .................1E-*

Oil Pump Inspection.............................................1E-*

Specifications........................................................1E-*

Tightening Torque Specifications.........................1E-*

Special Tools and Equipment..............................1E-*

Recommended Service Material..........................1E-*

Special Tool .........................................................1E-*

Engine Cooling System ...........................1F-*

General Description..............................................1F-*

Cooling System Description.................................1F-*

Coolant Description..............................................1F-*

Schematic and Routing Diagram.........................1F-*

Coolant Circulation...............................................1F-*

Diagnostic Information and Procedures.............1F-*

Engine Cooling Symptom Diagnosis....................1F-*

Repair Instructions ...............................................1F-*

Cooling System Components ..............................1F-*

Coolant Level Check............................................1F-*

Engine Cooling System Inspection and

Cleaning.............................................................1F-*

Cooling System Draining .....................................1F-*

Cooling System Flush and Refill..........................1F-*

Cooling Water Pipes or Hoses Removal

and Installation...................................................1F-*

Thermostat Removal and Installation (For

M16 Engine Model)............................................1F-*

Thermostat Removal and Installation (For

J20 Engine Model).............................................1F-*

Thermostat Inspection .........................................1F-*

Radiator Cooling Fan Motor On-Vehicle

Inspection...........................................................1F-*

Radiator Cooling Fan Relay Inspection................1F-*

Radiator Cooling Fan Assembly Removal

and Installation...................................................1F-*

Radiator On-Vehicle Inspection and

Cleaning.............................................................1F-*

Radiator Removal and Installation.......................1F-*

Water Pump Removal and Installation (For

M16 Engine Model)............................................1F-*

Water Pump Removal and Installation (For

J20 Engine Model).............................................1F-*

Water Pump Inspection........................................1F-*

Specifications........................................................1F-*

Tightening Torque Specifications.........................1F-*

Special Tools and Equipment..............................1F-*

Recommended Service Material..........................1F-*

Fuel System ..............................................1G-*

Precautions...........................................................1G-*

Precautions on Fuel System Service ..................1G-*

General Description.............................................1G-*

Fuel System Description .....................................1G-*

Fuel Delivery System Description .......................1G-*

Fuel Pump Description........................................1G-*

Schematic and Routing Diagram........................1G-*

Fuel Delivery System Diagram............................1G-*

Diagnostic Information and Procedures............1G-*

Fuel Pressure Inspection ....................................1G-*

Fuel Cut Operation Inspection ............................1G-*

Repair Instructions ..............................................1G-*

Fuel System Components...................................1G-*

Fuel Hose Disconnecting and Reconnecting ......1G-*

Fuel Pressure Relief Procedure..........................1G-*

Fuel Leakage Check Procedure..........................1G-*

Fuel Lines On-Vehicle Inspection .......................1G-*

Fuel Pipe Removal and Installation.....................1G-*

Fuel Injector On-Vehicle Inspection....................1G-*

Fuel Injector Removal and Installation................1G-*

Fuel Injector Inspection.......................................1G-*

Fuel Pressure Regulator Removal and

Installation.........................................................1G-*

Fuel Pressure Regulator Inspection....................1G-*

Fuel Filler Cap Inspection ...................................1G-*

Fuel Tank Inlet Valve Removal and

Installation.........................................................1G-*

Fuel Tank Inlet Valve Inspection.........................1G-*

Fuel Tank Removal and Installation....................1G-*

Fuel Tank Inspection...........................................1G-*

Fuel Tank Purging Procedure.............................1G-*

Fuel Pump On-Vehicle Inspection.......................1G-*

Fuel Pump Assembly Removal and

Installation.........................................................1G-*

Main Fuel Level Sensor Removal and

Installation.........................................................1G-*

Fuel Pump Inspection .........................................1G-*

Sub Fuel Level Sensor Removal and

Installation.........................................................1G-*

Sub Fuel Level Sensor Inspection ......................1G-*

Specifications.......................................................1G-*

Tightening Torque Specifications........................1G-*

Special Tools and Equipment.............................1G-*

Recommended Service Material.........................1G-*

Special Tool ........................................................1G-*

Ignition System.........................................1H-*

1-vi Table of Contents

General Description............................................. 1H-*

Ignition System Construction ..............................1H-*

Schematic and Routing Diagram........................ 1H-*

Ignition System Wiring Circuit Diagram............... 1H-*

Component Location ........................................... 1H-*

Ignition System Components Location................ 1H-*

Diagnostic Information and Procedures............ 1H-*

Ignition System Symptom Diagnosis................... 1H-*

Reference Waveform of Ignition System.............1H-*

Ignition System Check ........................................ 1H-*

Ignition Spark Test..............................................1H-*

Repair Instructions .............................................. 1H-*

High-Tension Cord Removal and Installation

(For M16 Engine).............................................. 1H-*

High-Tension Cord Inspection (For M16

Engine).............................................................. 1H-*

Spark Plug Removal and Installation.................. 1H-*

Spark Plug Inspection.........................................1H-*

Ignition Coil Assembly (Including ignitor)

Removal and Installation................................... 1H-*

Ignition Coil Assembly (Including ignitor)

Inspection.......................................................... 1H-*

Ignition Timing Inspection ................................... 1H-*

Specifications....................................................... 1H-*

Tightening Torque Specifications........................ 1H-*

Special Tools and Equipment............................. 1H-*

Starting System..........................................1I-*

Precautions.............................................................1I-*

Cranking System Note..........................................1I-*

General Description...............................................1I-*

Cranking Circuit Introduction.................................1I-*

Starting Motor Circuit Description .........................1I-*

Diagnostic Information and Procedures..............1I-*

Cranking System Symptom Diagnosis..................1I-*

Starting Motor Performance Test..........................1I-*

Repair Instructions ................................................1I-*

Starting Motor Dismounting and

Remounting.........................................................1I-*

Starting Motor Components..................................1I-*

Starting Motor Inspection......................................1I-*

Specifications.........................................................1I-*

Starting Motor Specifications ................................1I-*

Tightening Torque Specifications..........................1I-*

Special Tools and Equipment...............................1I-*

Recommended Service Material...........................1I-*

Charging System...................................... 1J-*

General Description..............................................1J-*

Battery Description...............................................1J-*

Generator Description..........................................1J-*

Diagnostic Information and Procedures.............1J-*

Battery Inspection ................................................1J-*

Generator Symptom Diagnosis............................1J-*

Generator Test (Undercharged Battery

Check)................................................................1J-*

Generator Test (Overcharged Battery

Check)................................................................1J-*

Repair Instructions ...............................................1J-*

Jump Starting in Case of Emergency...................1J-*

Battery Dismounting and Remounting .................1J-*

Water Pump and Generator Drive Belt

Removal and Installation (For M16 Engine).......1J-*

Water Pump and Generator Drive Belt

Tension Inspection and Adjustment (For

M16 Engine).......................................................1J-*

Water Pump and Generator Drive Belt

On-Vehicle Inspection (For J20 Engine)............1J-*

Water Pump and Generator Drive Belt

Removal and Installation (For J20 Engine)........1J-*

Generator Dismounting and Remounting.............1J-*

Generator Components........................................1J-*

Generator Inspection............................................1J-*

Specifications........................................................1J-*

Charging System Specifications ..........................1J-*

Tightening Torque Specifications.........................1J-*

Exhaust System........................................1K-*

General Description............................................. 1K-*

Exhaust System Description ............................... 1K-*

Diagnostic Information and Procedures............ 1K-*

Exhaust System Check....................................... 1K-*

Repair Instructions .............................................. 1K-*

Exhaust System Components............................. 1K-*

Exhaust Manifold Removal and Installation

(For M16 Engine Model) ................................... 1K-*

Exhaust Manifold Removal and Installation

(For J20 Engine Model)..................................... 1K-*

Exhaust Pipe and Muffler Removal and

Installation......................................................... 1K-*

Specifications.......................................................1K-*

Tightening Torque Specifications........................ 1K-*

Special Tool ........................................................1H-*

Engine General Information and Diagnosis: 1A-1

Engine General Information and Diagnosis

Precautions

Precautions in Diagnosing Trouble

S5JB0E1100002

• Don’t disconnect couplers from ECM, battery cable

from battery, ECM ground wire harness from engine

or main fuse before confirming diagnostic information

(DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information

in ECM memory.

• Diagnostic information stored in ECM memory can be

cleared as well as checked by using SUZUKI scan

tool or OBD generic scan tool (Vehicle without

diagnosis connector). Before using scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

It is indistinguishable which module turns on MIL

because not only ECM but also TCM (for A/T model)

turns on MIL (For details of on-board diagnostic

system for A/T model, refer to “On-Board Diagnostic

System Description: in Section 5A in related manual”.

Therefore, check both ECM and TCM (for A/T model)

for DTC when MIL lights on.

When checking ECM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by ECM.

– OBD generic scan tool displays DTC detected by

each of ECM and TCM (for A/T model)

simultaneously.

• Priorities for diagnosing troubles

If two or more DTCs are stored, proceed to the DTC

flow which has been detected earliest in the order and

follow the instruction in that flow.

If no instructions are given, troubleshoot DTCs

according to the following priorities.

a. DTCs other than DTC P0171 / P0172 (Fuel

system too lean / too rich), DTC P0300 / P0301 /

P0302 / P0303 / P0304 (Misfire detected) and

DTC P0401 / P0402 (EGR flow malfunction)

b. DTC P0171 / P0172 (Fuel system too lean / too

rich) and DTC P0401 / P0402 (EGR flow

malfunction)

c. DTC P0300 / P0301 / P0302 / P0303 / P0304

(Misfire detected)

• Be sure to read “Precautions for Electrical Circuit

Service: in Section 00 in related manual” before

inspection and observe what is written there.

• ECM replacement:

When substituting a known-good ECM, check for the

following conditions. Neglecting this check may cause

damage to a known-good ECM.

– Resistance value of all relays and actuators is as

specified respectively.

– MAP sensor, electric load current sensor (for J20

engine), A/C refrigerant pressure sensor (if

equipped with A/C), accelerator pedal position

(APP) sensor, TP sensor and CO adjust resistor (if

not equipped with A/F sensor) are in good condition

and none of power circuits of these sensors is

shorted to ground.

• Communication of ECM, BCM, combination meter,

keyless start control module (if equipped), ABS /

ESP® control module, 4WD control module (if

equipped), steering angle sensor (if equipped) and

TCM (for A/T model) is established by CAN

(Controller Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description: ”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System: in

Section 00 in related manual”.

• Immobilizer transponder code registration after

replacing ECM:

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code with ECM correctly according to “Procedure after

ECM Replacement: in Section 10C in related

manual”.

1A-2 Engine General Information and Diagnosis:

General Description

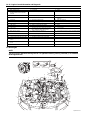

On-Board Diagnostic System Description

S5JB0E1101003

Vehicle not Equipped with Diagnosis Connector

ECM in this vehicle has the following functions.

• When the ignition switch is turned ON with the engine

at a stop, malfunction indicator lamp (MIL) (1) turns

ON to check the circuit of the malfunction indicator

lamp (1).

• When ECM detects a malfunction which gives an

adverse effect to vehicle emission while the engine is

running, it makes the malfunction indicator lamp (1) in

the meter cluster of the instrument panel turn ON or

flash (flashing only when detecting a misfire which

can cause damage to the catalyst) and stores the

malfunction area in its memory.

(If it detects that continuously 3 driving cycles are

normal after detecting a malfunction, however, it

makes MIL (1) turn OFF although DTC stored in its

memory will remain.)

• As a condition for detecting a malfunction in some

areas in the system being monitored by ECM and

turning ON the malfunction indicator lamp (1) due to

that malfunction, 2 driving cycle detection logic is

adopted to prevent erroneous detection.

• When a malfunction is detected, engine and driving

conditions then are stored in ECM memory as freeze

frame data. (For the details, refer to description on

“Freeze Frame Data (Vehicle Not Equipped with

Diagnosis Connector): ”.)

• It is possible to communicate by using not only

SUZUKI scan tool (2) but also OBD generic scan tool.

(Diagnostic information can be accessed by using a

scan tool.)

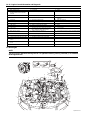

Vehicle Equipped with Diagnosis Connector

ECM diagnosis troubles which may occur in the area

including the following parts when the ignition switch is

ON and the engine is running, and indicates the result by

turning on or flashing malfunction indicator lamp (1).

• A/F sensor (if equipped)

• Heated oxygen sensor (if equipped)

• ECT sensor

• TP sensor

• MAF sensor

• IAT sensor

• MAP sensor

• CMP sensor

• CKP sensor

• Knock sensor

• Wheel speed sensor

• CPU (Central Processing Unit) of ECM

• APP sensor

• Oil control valve (for M16 engine)

• Radiator cooling fan relay

3. DLC

1

2

3

I5JB0A110002-01

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...