PRODUCT INFORMATION SHEET

Sept. 2007

50242ZP Epoxy Primer — Gray 1 Quart

50243ZP Epoxy Primer Catalyst 1 Quart

50244ZP Epoxy Primer — Gray 1 Gallon

50245ZP Epoxy Primer Catalyst 1 Gallon

Eastwood’s direct-to-metal Epoxy Primer suits a variety of needs, providing exceptional

resistance to corrosion, fast build, superb color holdout and unsurpassed adhesion to

bare metal substrates. This 2-part system is a must-have for any restoration project.

Features the superior durability of a catalyzed system, but without isocyanates, lead or

chromate. Thanks to excellent filling qualities, this epoxy is ideal for use after sand/

media blasting. This system is National Rule Compliant (Primer; Max VOC 4.8 lbs/Gal).

SAFETY

This product was designed for and is intended solely for use by trained professionals. Read all

warning statements and heed all recommended safety precautions before proceeding.

DO NOT USE THIS SYSTEM WITHOUT SUFFICIENT VENTILATION. Users must wear appropri-

ate, properly fitted NIOSH-approved activated charcoal cartridge respirator if a forced fresh-air

system is not available. Always wear eye and face protection, as well as gloves and protective

clothing. Do not use this product, or be exposed to spray mist / vapors if you have respiratory

problems. KEEP OUT OF REACH OF CHILDREN AND PETS.

This system comprises multiple components. Once mixed, this system will have hazards of all

components. Read warnings on all packages before opening.

SURFACE PREPARATIONS

For use over bare metal once previous finish has been blasted or stripped and all traces of sur-

face rust are removed. Clean surface with a Wax and Grease Remover such as Eastwood’s

11999ZP, a strong solvent blend designed to remove tar, wax, grease, road grime, silicone and

surface contaminants. If any new or smooth metal remains, be sure to abrade surface, then

re-clean with 11999ZP or other appropriate solvent product.

When applying Eastwood Epoxy Primer over existing finishes, use same steps starting with the

Wax and Grease Remover (11999ZP). Abrade the surface with 320 to 400 grit, then re-clean

with 11999ZP or other appropriate solvent product to remove any debris prior to application.

PAGE 1

part #50242ZP

PRODUCT INFORMATION SHEET

Sept. 2007

MIXING RATIOS

After shaking/stirring primer, thoroughly mix one part 50242ZP (primer, quart) with one

part 50243ZP (catalyst, quart), or 50244ZP (primer, gallon) with 502445ZP (catalyst, gal-

lon). No induction time is required with this epoxy system.

OPTION

To reduce film build, 1:1 mixture may be cut by up to 20% with a urethane-grade reducer

or other appropriate solvent product. Doing this may also improve the flow and leveling

of epoxy primer. Eastwood suggests using a Zero-VOC reducer to avoid potential compli-

ance issues.

Use caution in mixing materials as epoxy primer may begin to gel after approximately 90

minutes (at 70 °F).

SPRAY GUN SETUP

APPLICATION INSTRUCTIONS

Eastwood Epoxy Primer should be applied in medium wet coats, with a 30-minute flash

period between each (at 70 °F). Typically, one to two coats is enough to achieve the de-

sired 1 mil. dry film thickness, though more material may be applied as needed. Addi-

tional build requires longer flash periods between coats.

Epoxy primer may be topcoated after approximately 30 minutes (wait 45-60 minutes after

applying more than two coats), or up to about five days. After five days, primer MUST be

scuff sanded prior to topcoat application.

May be sanded (wet) the day after application. Wait two to three days before sanding

dry.

CLEANUP

Make sure all containers are sealed tightly immediately after each use. Gun and equip-

ment may be cleaned with a Gun Wash or other appropriate solvent.

MORE INFO

The Eastwood Company

263 Shoemaker Road

Pottstown, PA 19464

Toll free: (800) 343-1178

Fax: (610) 323-6269

www.eastwood.com

PAGE 2

B

+

A

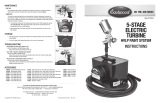

Type of gun: HVLP Conventional Gravity Conventional Siphon

Fluid tip: 1.4—1.8 mm 1.4—1.6 mm 1.6—1.8 mm

Spray pressure: 8-10 psi 45-55 psi 45-55 psi

For spills, leaks, fire or exposure

anytime Day or Night:

CHEMTREC 1-800-424-9300

(USA — Toll-Free) or (202) 483-7616

(International — Collect)

-

1

1

-

2

2

Eastwood Gray Epoxy Primer and Activator Quarts Operating instructions

- Type

- Operating instructions

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Eastwood MIG Welder 135 And Versa Cut Plasma Cutter 40 Operating instructions

Eastwood MIG Welder 135 And Versa Cut Plasma Cutter 40 Operating instructions

-

Eastwood Pinkalicious Intermix Paint Kit Operating instructions

-

Eastwood 4:1 High Solids Urethane Premium Show Clear Gallon Operating instructions

Eastwood 4:1 High Solids Urethane Premium Show Clear Gallon Operating instructions

-

Eastwood 4:1 GM Regal Red - Basecoat - Automotive Car Paint - Gallon Operating instructions

Eastwood 4:1 GM Regal Red - Basecoat - Automotive Car Paint - Gallon Operating instructions

-

Eastwood CONTOUR Polyester Primer Direct to Metal Surfacer Operating instructions

-

Eastwood Concours 2 Single HVLP Paint Gun Kit in Aluminum Case Operating instructions

Eastwood Concours 2 Single HVLP Paint Gun Kit in Aluminum Case Operating instructions

-

Eastwood Extreme Chassis Black Satin Finish Operating instructions

Eastwood Extreme Chassis Black Satin Finish Operating instructions

-

Eastwood Wheel Smoothing and Buffing Kit Operating instructions

Eastwood Wheel Smoothing and Buffing Kit Operating instructions

-

Eastwood Apollo 1000ml Aluminum Cup - feed tube and Check Valve Operating instructions

Eastwood Apollo 1000ml Aluminum Cup - feed tube and Check Valve Operating instructions

-

Eastwood Extreme Chassis Black Satin Finish Operating instructions

Eastwood Extreme Chassis Black Satin Finish Operating instructions

Other documents

-

Zinsser 256261 User manual

-

Rust-Oleum Marine 207002 User manual

Rust-Oleum Marine 207002 User manual

-

Giani FG-MB WHTEP KIT User manual

-

KILZ L211104 User manual

KILZ L211104 User manual

-

Rust-Oleum 206999 User manual

-

Seal-Krete 116001 User manual

Seal-Krete 116001 User manual

-

Rust-Oleum 306196 User manual

-

Seal-Krete 106001 User manual

Seal-Krete 106001 User manual

-

Dyco DYC9040/5 User manual

Dyco DYC9040/5 User manual

-

Columbia Coronado 25 User manual