Page is loading ...

SEARS

OWNERS

MANUAL

MODEL NO.

919.154020

919.154120

919.154320

919.154420

Listed

Air

compressor

IMPORTANT.,

Read the Safety Guidelines

and All lnstruott0ns

Carefully Before Operating

CRAFTSMAN

PERMANENTLY LUBRICATED

AIR COMPRESSOR

ASSEMBLY

OPERATION

MAINTENANCE

REPAIR PARTS

B

i

Record in the spaces provldc_L

(1) The model number whl<;h _un be

found on the laber on the ba¢_ of the

Shroud.

(2)

(3)

The code number which oan be

fourKJon the fob label on the baok of

the air tank.

The Manufacturers Number (ASME

Code Compre880r_ Only) Is locatsd

on the motel data plate whl©h is

v_ded onto the I_ck _fde of the air

tzn_, (Thia ¢eta plzrbpi= painted the

iseme_elOr aS the tank.)

Pvatafnthese numbers for future

refePen_,

Model No.

Code No.

a_. No.

S)-30-_..4,.B lotae

Sears, Roebuck and Co,, Chicago, IL 60684 U,S,A,

TABLE OF CONTENTS

Page

WARRANTY ......................................................... 3

SAFETY GUIDELINES ................................................ 3

WARNING CHART ....................................................... 3

SPECiRCATION CHART ................................................ 5

GLOSSARY ................................................................... 5

ACCESSORIES FOR USE W!TH SEARS AIR COMPRESSORS ,, 6

GENERAL INFORMATION ............................................. 6

DESCRIPTION OF OPERATION .................................. 6

ASSEMBLY INSTRUCTIONS ............................................ 7

ToolsN_¢C!edforAss_mbty.............................................. 7

Installing Wheels, Handle, Rubber foot strip............................... 7

Installing Regulator .................................................... 7

INSTALLATION AND BREAK-IN PROCEDURES .......................... 7

location ofAir Compressor............................................. 7

Lubric,_ttonand 0it ..................................................... 7

_._t_'_fon Cord_ ....................................................... 7

GroundingInst_'uctions.................................................8

greak-lnProcedures....................................................8

OPERATING PROCEDURES ........................................ 8

MAINTENANCE .........................................................g

Air _Iter ..............................................................9

Check V_tve- Repl_ceme_ ........................................... 9

Safety _aJve - Inspection ........................................... 8

Motor...................................................................9

STORAGE ..............................................................lo

TROUBLESHOOTING GUIDE ........................................ 1o

AIR COMPRESSOR DIAGRAM ...................................... t:2

Part,=,List .................................................................... 13

COMPRESSOR PUMP DIAGRAM .......................................14

ParlSList........................................................15

HOW TO ORDER REPAIR PARTS ........................................ 16

FULL ONE YEAR WARRANTY

AIR COMPRESSORS

Ifthisair compressorfailsdue toa defectInmaterialor workmanshipwithinone yearfromthe

date ofpurchases.RETURN IT TOTHE NEAREST SEARS SERVICE GENTERtOEPARTMET,_r

THROUGHOUT THE UNITED STATESAND SEARS WILL REPAIR IT,FREE OF CHARGE,

ifthisair compressorisused for commercial or rentalpurposes,the warrantywillapptyfor nlnety

days from the date of purchase.

Thiswarrantygives you specificlega{ rightsand you may have othernghtswhich varyfrom state

tostate..

Sears, Roebuck and Co. Sears Tower, Dept. 6_1/731A, Chicago, 1L60684

SAFETY GUIDELINES

Thtsmanualcontainsinformation thatis importantfor youto knowand understand,ThisInforma-

tionrelatesto protectingYOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS To help

you recognize this information, we use the followingsymbols°Pleaseread the manual and pay

attentionto these sectlort._.

URGENT SAFETY INFORMATION ,- A

HAZARD THAT WILL CAUSE SERIOUS

INJURY OR LOS_; OF LIFE,

IMPORTANT SAFETY INFORMATION - A

HAZARD THAT MIGHT CAUSE SERIOUS

INJURY OR LOSS OF LIFE.

information for preventing damage to

equipment,

NOTE

informationthat you shouldpay specialat_en-

lion to.

HAZARDS CAN OCCUR IF EQUIPMENT tS NOT USED PROPERLY,

PLEASE READ THE FOLLOWtNQ CHART,

WHAT TO

LOOK FOR

Hot Parts

Flammable

vapors

WHAT COULD HAPPEN

HOW TO PREVENT IT

The compressor heed gets hot when the air

compressor Is running. Ifyou touchit, you may

be seriously bumecL

Itisnormalforthe motor and pressure switchto

spo.rt_when operating, if the v_pors from

gasoline or other solventscome into¢onte=¢t

w!ththesparks,theymayignite and c&usea fire

or explosion

Never touchthe air compressorhead during or

immediatelyafter opert_tion_

,,H,,,I,,, ,,i,, i, ,,/ ..... :

Always operale the air compressor in well-

ventit=_d 8r€1_5:free ot ga3o_Jrt_or artier_oJv_t

vapors, Do not operate the coml:_essornear the

spray area

W.ATT0

LOOK FOR

Nr Tank

WHAT COULD HAPPEN

Modifications to the air compressorcan cause

the air tanktorupture orexplode,

HOW TO PREVENT IT

Do not adjust, remove or tamper with the safety

valve orpressureswitch. Ifsafety valveorpressure

switch r_e=emen_ ;s necessary,a part with the

same ratingmust be used

Never useamot0r withahlgher horsepower rating

thanthe one supplied.

Never replacetheair lan_ witha differentmo0el or

a large_tank,

Changingthe air tank willcause It to weaken.

The tank may rupture or exp!ode_

Compassed Air' Cornpr_'_ed sir can propeldust,dirt. or loose

partio[esit comes in contactwith,

N_er ddlt{n_o,weld, or inany way modily the air

tank,

N_werpolntany nozzfeorsprayertoward aperson

or anypart of thebody,,

Always wearsafety gogglesOrglasseswhenusing

the air compressor,

AF,,_ys turn the air compressoroff beforeattach-.

ingorremovingaccessories,

Eie ty

Too much air pressure appliedto air toolsor

accessories cart cause damage or risk Of

bursting.

Yourair compressorIs poweredby electricity.

LikeanyothereleGtdcaJlypDwereddevice,ifitis

notusedproperlyItmaycauseelectdeaJshock

Che_kthe m.anufactuter'sm_(mum pressurerat-

ingfor air tools9.ndaccessories.Rsguta_r outlet

pressure must never exceed the maximum_¢es-

sure rating.

Always unplug t!le air compressor prior1omalrtte-

nonce ot repair,

Never use the air compressoroutdoors when it is

r_ning.

ToxicVapors

I!iS_rmal for€ompressedalr_containtoxicor

irritating vapors.8uoh vapor's are harmful if

inhaled.

Always I_Ugthe cordintoan ale€tricotcutter with

the specified voltage and adequate fuse

p_teetfon,

Neverdlrect|yInhale_hecompressedair produced

by thisunit.

Certain materials you are spraying(like pairrl,

weedkiUe(sandor insecticide)may beharmful

If you Inhalethem,

UnsuJtat_fe

Solvent=

and

The solvents!,t,1 - Trich!omethane M'elhy-

lena ChlorideCanchemlc_.tly reactwith alumi-

numu_edin paintspray g_Jr_,paintpumps,etc..,

and cause an explosion These solventscan

also react with galvani=od components and

cause corrosionand weakeningof paris. This

does _lotaffect youraircompressor_but it may

affect the equipmentbeing u_d,

Read and follow the safety Instructions provided

on the i_bel or safety data sheetfor the matetla[

you arespraying.Usea respiratorma_kilthere tsa

chance of tnh_tlng anything you are spraying,

Read =t instructions.., be ¢un_that ther_l_iral_r

maskis sultabte foryour application.

Ifthe material youintend 1ospraycontainsthe sol-

ventsltSledat l_ft [read thelabel ordale sheet},do

not u_ accessoriesthatcontain aluminum or g_u-

vanlze_ part=.Youmusl eitherchang_ themateria_

you intend to spray, or use only stafnle=s _teel

spray equipment,

4

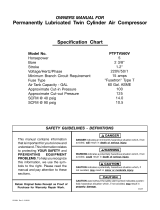

SPECIFICATION CHART

Mo_I No.

Horsepower

DisplacementCFM

Bore

Stroke

Voltage.SinglePhase

MinimumBranch CircuitRequirement

"'Fuse Type

Air TankCapaclty

Approximate Cut-inPressure

ApproximateCut-outPressure

SCFM C_40 psig

SGFM ('.490 psfg

919.154020 919.1_20 919J54120 919.1_4420

2 2 2 2

I0,0 100 t0,0 10,0

2%" _1/t" _=_" _'_"

1,13'° 1.13" 1,,13" 1.13'

t?.0 120 12.0 t213

"15amp_ "15arnps "15amps ÷15amps

"Fusetron" "Fusetron" "Fusetron" "Fusetmn•

•"TypeT "Type T "Type T **Type T

t2 g_L 20 gel, 12gel ASME 20 gal.ASME

80 80 80 80

100 100 _00 I00

70 7O 7,0 70

5,6 5.8 5.6 5.6

These compre_ors can be operated on a 15amp Glrcutt if:

1.Voltage supply to clr=uit is normal.

2, CirouttIs not used to supply any otl_r electrical needs (lights, appliances, etc.)

3. Extension r._rds comply with specifications in owners manual.

4. Clrouit ts equipped with 15amp otrcuit breaker or 15 amp Fuset_ronType "T" time delay tuse_

If any of the above conditlorm cannot be met, or if operation of the compressor repeatedly causes

Interruption of the power It may be necessary to operate it from a 20 amp €ircuit. It is not necessary to

changethe cord set.

"'A circuit breaker iepreferred. Use only a f,._seor circuitbreaker thatis the same ratingas the branch circuitthe air

compressortsoperatedon. II theair compressorIs conr_oled toa circuitprotectedbyfuses, usedueJelementtime

delay fuses(Buss FuestronType"T" onty)

GLOSSARY

CFM: Cubicfeet per minute.

SCFM: Standardcubicfeetperminute:aunitof meas-

ure of_Jrdelivery.

PSlG: Poundsper squareinch gauge;a unitofmeas-

ure of pressure,

ASME: American Societyof Mechanist Engineers;

made, tested, inspected and registeredtomeet the

stanches oftheASME,

U.L LISTED: S_mplesol compressor outfits, taken

from production,w_resubmitted to U.L and found to

comply with their requirements for design and

performance.

Cut-In Pressure: While themotor isoff, airtankpres-

sure dropsas you continue to use yourae,ces_ory.

Whenthe_ankpressure drops toa certainlowlevellh_

motor wltlm-s_rt autorr=atioaJly.The low preesureet

which themotorautomatically re-startsiscalled'cuF]n

pre_ure".

Cut-Out Pressures: Whenyou turnonyaur aircorm

pressorand it beginstorun, eirpressureIn theeir tank

begins to build, tt buildsto a certain high pressure

beforethe motor automaticallyshulsoff - protecting

your air tank from pressurehigherthan its¢_paclty.

The highpressureat whichthemotor shutsOffiScalled

"cut-out preesure'L

ACCESSORIES FOR USE WITH SEARS AIR COMPRESSORS

The followingaccessoriesare availablethroughtl_ecurrcnt general sales catalogor at full-line8cars stor_,

. SPRAYGUNS

• BLOWGUNS

• AIRCAULKINGGUNS

• AIR POWERED WASHER GUNS

"SANDBLASTERS

•AIR BRUSHES

- AIR LINEFILTERS

, TiRE AIR CHUCKS

" PAINTTANK,._

, AIR TANKS

• INFLATER KIT_i

• QUICK CONNECTOR SETS

(various sizes)

•VISCOSIMETER

, AIR PRESSURE REQULATORS

•OIL FOG LUBRICATORS

. AIR TOOLS:

Sanders

Dfifis

tmpact wrenches

Hammers

• AIR HOSE;

W', %e"or% '_I.D.

in variOuSlengths

GENERAL

Youhavepurchasedanaircompressorunitoonsisilngof

a 1 _'lir',der, sing_staga air compressorpump, an air

tank,air hose,wheels,handle,and associatedcontrols

Youwillalso lindan air chuck.

T'-_sair compressor requiresno oil, Now you can enjoy

all the benefffsofhaving an air compressorwltl_outever

havingtopurchase,add or changeoil

INFORMATION

Your air compressorcan be used for operating paint

sprayguns, air loois, caul_ng guns, grease guns,air

bruohes, sandbtaBtens,or inflatingtiresand plasticto_p_,

sprayingweedklllers, insecticides,etc.

_p_ra_e air tran:dormerswhichcombine the functions

ofair regulptionand/ofmoistureanddirtremovalshould

beusedwhereapplicable.

DESCRIPTION OF OPERATION

5

Air Compressor Pump: To compressair, the piston

moves upand downInthecyllt_te_oOnthe downstroke,

aimsdrawninthroughtheair intakevalves,The exhaust

valvererr_lnsctose_t.Ontheupstrokeofthepiston,a{ris

compressed. The intakevalves €_o=e_nd compressed

air isfor_edout throughthe e_haus!valve, throughthe

outlet tube,lhmugh thecheckvalveand intotheair tank,

Workingair is not _vallable untl_the compressorhas

raisedthe airtankp_essureabovethatrequired at theair

_utlet.

Check Valve;Wh_ file aircompressorIsoperating, I._e

chock v_Jvo(s"open",allowing compressed airto enter

theaft tank.Whenthe aircompressorreaches"cut-,out"

pre_eure,the checkvalve "=loses", allowing airpressure

tOn_m=tnInsidethe air tank,

Preaaure Releue Valve; The pressurereleasevalve

located on thesideofthepressureswitch, is designedto

automatically release compr_8Od air from the com-

_essor ha_d and theoutlet;tube whenthe _ir compres-

sot reaches"cut-out" pm_;_ or is _hutoff, If theair Is

notreleased, themotorwilltryto=t¢,rt,but wigbe unable

t_.Thepressurerel_=sevalveallows the motortor_._r t

freely.Whenthem_tor stops running,air willbe heard

escapingfrom thevalveforafew seconds.Noair should

be heardleaking whenthe motor is running,

Pressure Switch: The presSureswirchautomatically

start_themotorwhenthesir tl_,rtkpressuredropsbeiOW

D_JU_C_K

the f_otoryeel "¢ut,-in"pressure,tt _ops the motorwhen

the air tank pressurereaches thefactory set =cut-out"

pmssL_e.

Safety Valve: Ifthepressure=witchdoes notshutoffthe

air compressor at itscut-outpressuresel_[ng,thesafety

valvewillprotectagainsthighpressureby'"poppingout_'

at iLspre-set p_ss_re.

Regulator: The air pressure comingfromtheair tan_ is

controlled by the regulator knob, Turn the knob

clcckwlseto incn_e pressureand counter.clockwise

todecreasepressure.To_rvoldminorre_djuslmentafter

ma_ng a change in pressures_tttng,alwaysapproach

the desired pressure from a i_wer pressure. When

reducing1tOma h_gherto a lowersetting,flintred_ce lo

some pressuretessth_n that desired,then bringup to

the desired pressure,.Dependingontheair requirements

of e_,ch particular accessory, the out(at regulatedair

pressUr_may h_v_ to be adjustedwillie oper_ting

_ccessory,

Outlet Prauurl Gauge: The outlet pressuregauge

indicates theair pressurea'_aJlab_e_t theou_letsideof

the taguiatOr,ThL_pressureis controlledbytheregulator

and is atways less or eq_Jalto the tank pressure.See

"Operating Procedures,,"

l_nk Pmuure Gauge: The tank pressureg_ugeindi-

o_tes the refer'tinairpressure inthet=nk,

ASSEMBLY INSTRUCTIONS

Tools Needed for Assembly

*pipethreadsealant(not incJuded)

, an a,clJustable wrench for attaching the pressure

regulator

"a _t_0,socket or open end wrench for attaching the

wheelsand hose adaptan

"a 7/1_openand wrenchfor attaching theair pressure

gauges

, a _e °'he,v.Re'i"for Installing the pluginthe regulal_

, a %" open end wrenchtotightenhandlescrews

"s #2 philtipe screwdriver for attaching the control

cover

installing Wheels, Handle, Rubber Foot Strip

i WARNIN_ !

THE WHEELS AND HANDLE OO NOT PRO-

VIDE ADEQUATE CLEARANCE, $TABJLITY

OR SUPPORT FOR PULLING THE UNIT UP

AND DOWN STAIRS OR STEPS, THE UN[T

MUST I_ELtFT]_D,ORPUSHED UPA RAMP.

1. Dipthe handlegrip Insoapywaterand sttdeintoposi-

tionas shownon photoon page 6 orpage 12.

2, Attachthe handleto the insideofthecompressorsad-

diebyp_jshtngthehandleIn,unllitheslotinthehandle

engageswith the labs in the saddle,Pufithe handle

bsckar<linstallthe twos<z_ws,one oneach sideof

the_e_ldte.Tightensecurely,

ittory be necemury to brace or support one

enU of theoutfit when attaching thewheels

end the r_Jbber foot _trlp,because the air

compressor will have a tenden=y to tip.

3- Rsmove theprotectivepaperstrip frOmth_adhesive

backed rubber footstrip,Attachtherubberfootstrip to

thebottom of 1heairtitnkleg. Press firmlyintoplace°

4. Attachone wheelto each sideof theair ¢omp_ssor.

Use one shoulder bott and one nut for each wheel,

Tightensecurely.

Installing Regulator

Use a small amountof,pipethreadsealant on aJipipe

threadjoints.

Installthe regulatoron 1heendof lhe manifold using the

short pipe nipple. The arrow on the bottom ol the

regulatOrmustpoi_ away from the manifold in order fo_

theregulatortofunctionproperly,

_nstalithe adapterand plugIn the regulator,,The plugis

supplied withtheregulator,Installthe rearcoverandthe

gaugesat thesame time,See diagrambelow,

R_ULATED

PRESSURE GAUG_

TANK

PRESSURE GAUGP-

tnstallthecontrol_over. FastenIt to the manifoldusing

thephillipsscrew.Installthe plasticmounting ringtothe

regulatortofastenthetopofthecontmtcover,See photo

on page 6.

INSTALLATION AND BREAK-IN PROCEDURES

Locationofthe Air Compressor

Loca4ethe air compressorina ctean,dry endwelJventi-

lateclarea. The air filler mustbe kept clearo'l obstruc.

tlons which could reduce air delivery of the air

compressor.The air compressorshould be locatedat

least12' away'fromthe wail or other obstructionsthat

wl!linterfere withtheftow ofair.Theaircompressorhead

and shroudare designed to al!ow forpropercooling.,If

humidity Is high a _ears air filter can be installed iD

remove excessive moisture. Follow the instructions

packaged withthe air filterfor proper installation,

LubricationandOil

Thtsunit n_eas no adcllttonallubrication or otling

Extension Cords

Useextre,air hose insteaxJOf_nextensioncordtoavoid

voltagedrop and power loss to the motor,

tf an axlet_sloncordmustt_ us'_, be sum itis:

. a 3-wire ext_._ion cordthath_ a _-,bladegrounding

pll_, end !_3-_lotreceptacletigatwl!laccepttheplugon

the product,

. t_ good condition_

• no longerthan _50f_t.

.12 gtlUge (AWG) or larger. (Wire size increases as

gaugenumber _lecreaseso10 AWG and 8 AWG may

atsol_eused,OO NOT USt_t4 or 16AWG_)

Grounding Instr,JcUons

L_ i

IMPROPER GROUNDING CAN RESULT iN

ELECTRICAl. SHOCK. IN THE EVENT OF A

SHORT CIRCUIT, GROUNDING REDUCES

IHE RISK OF SHOCK BY PROVIDING AN

ESCAPE WIRE FOR THE ELECTRIC CUR-

RENT. THIS AIR COMPRESSOR MUST BE

PROPERLYGROUNDED.

1.The air compressortsequippedwltha cord havinga

groundingwire with an _ppr_priate groundingplug.

The plugmust be usedwith an outletthat has been

installedand groundedin accordance wi_hall IocaI

codes and ordinances, The out_etmust have the

_aJ'_econfigurationas the plug. DO NOT USE AN

ADAPTER,

2, Do notmodify the plug1hathas been provided.!! it

does not tit the available outlet, the correct outlet

shoutdbe installedby a qualifiederectrician

3 inspecttheplugandcordbeforeeachuse_Donotuse

ifthereare signsof damage,

RISK OF ELECTRICAL SHOCK, IF REPAIR-

ING OR REPLACING CORD OR PLUG, THE

GROUNDING WIRE MUST BE KEPT SEPA-

RATE FROM THE CURRENT.CARRYING

WIRES, NEVER CONNECT THE GROUND,

tNG WIRE TO A FLAT BLADE PLUG TER-

MINAL (THE GROUNDING WIRE HAS

INSULATION WITH AN OUTER SURFACE

THAT IS GREEN - WiTH OR WITHOUT YEL-

LOW STRIPES.)

if these grounding ine_ru_Uonsare not completely

unclerstood0orif Indoubtas towhether[hecompressor

is properlygrounO_d,havetheinstall=ioncheckedbya

qualifiedelectrlclan_

Ground

" Wire ""

GROUNDING ,,2" L..------J

PIN

120 vOltS,i5 amps

Break-In PrOc_ums

Serious damage moy _glt If_I'KIfoll_ing

break-in tnatructrono =r==not closely

followed.

Thisprocedureisonly _quir-ud the firstlime the=Jrcom-

preSSOriSputintoserwce,

1.Set the swlt_ OFFtAUTOlevertothe'OFF'

poetriespressure

2 Plug the.power c_ordinto the (;orrectbranc;h cimUit

receptacJe,

3 Turnthe regulatorc!oc.kw'L_,e,,openingit fulIy,topre.

ventmr pressureI:_uz=o-up=nthetanK,

4_Move *,heOFF!AUTO leverto"AUTO'. Th_ compres-

sorwltIstarL

5, Run _he compressorfor 10 minutes, Make surethe

rupegulatorIsopenand themisno tankpressure build- ,_

6 After 10 rnin.utes,_ose t,heregultttorby lurningit

counter-c_oc:Kwise,fne_urtankv_lIfill_ OJt-,outpres-

sure andlhanthe rno_r Will510p

OPERATING PROCEDURES

1,Beforeattaching aJrhose or accessories, make sure

the OFFtAUTO lever is set to "OFF" and the air

regulatorIs closed (Close it by turningit counter-

ClOCkWiSe)

2_At_chhOSe _ndaocessorfes.

WARNING

1"OOMUCH AIR PREgSURE CREATES A

HAZARDOUS RISK OF BURSTING, CARE-

FULLYFOLLOWSTEPS 3 AND 5 EACHTIME

THE COMPRF-_SOR IS USED.

.

COMPRESSED AIR FROMTHE OUTFIT MAY

CONTAIN WATER CONDENSATION. DO

NOT SPRAY UNRLTERED AIR AT AN ITEM

Tl1AT GOULD B_ DAMAGED. SOMF AIR

OPERATED TOOLS OR DEVICES MAY

REQUIRE FILTERED AIR. READ THE

INSTRUCTIONS FOR THE AIR TOOL OR

DEVICE,

Checkthemanufacturer'sm_lmum preserve_ating

for air tools and accessories, "Theregulatoroutlet

pressuremustnever exceed themaximurnprB_$ure

_at]ng.

4. TurntheOFF!AUTO le._r to "AUTO"andallow Tank

pressureto_,Jlld,Motorwill6toowhentankpresmure

reaches"Cut-out"pressure.

S Open theregulatorbyturningitclockwise Adjustthe

regulatortothecorrectpressuresettJng,Your com-

pressor{=readyfor use.

6. AlwaysoperaletheaircompressorInwell-ventilated

areas;freeof gasoline or other solventvapors Do

notoperatethecompressor near the spray area.

,Whenyou arefinished:

7. Setthe "OFF-AUTO"leverto"OFF",

8. Turntheregulatorcounter-clock.viseand settheout_

I_ pressuretOz_ro,

9oRemovetMeair tooloraccessory,

!O.Openthe,'_egutatorandallow the airto slowlybleed

from theta.,'P_Closethe regulator when tankpres_

sumis approximately 20 psi.

1t, Drainwaterfrom air tank,

WATERWILL CONDENSE IN THE AIRTANK.

IF NOT DRAINED, WATER WILL CORRODE

AND WEAKEN THE AIR TANK CAUSING A

RISK OF AIR TANK RUPTURE.

With tank pressurest approximately20 psi,, open

theclan cock and allowmoisture to d_n.

NOTE

If drain cock valve Is p_ugged,release all air pros-

sure.Tile valvecanthenbe removed,cleaned,then

relnst=lled

!2o After thewater has been drained, olose the drsln

e.ock.The air compressorcan now be stored.

MAINTENANCE

UNIT CYCLES AUTOMATICALLY WHEN POWER IS ON. WHEN DOING MAIN_=.NANCE, YOUMAY

BE EXPOSED TO VOLTAGESOURGESt COMPRESSED AIR OR MOVING PARTS. PERSONAL

INJURIES CAN OCCUR.BEFORE PERFORMING ANY MAINTENANCE 0 RREPAIR,UNPLUG THE

COMPRESSOR AND BLEED OFF ALL AIR PRESSURE,

Atr Filter- Inspection

Safety Valve - Inspection

NOTE

Keepthe airfiltercleanatall times Do notoper-

ate the compressorwiththe airfilter removed,

A dirty air filterwillnot a.llowthe compressortooperate

at furlcapacity°Beforeyou use the compressor,check

the air filter tobe sum itisclean_

If ittsdirty,simplypullitout.Youmaywashitwitha mild

detergentandwarmwater,or repiaceIt,

Check Valve- Replecement

1. Release afl air pressure fromaTrlanf<and unplug

outfit.

2. Removeshroud,

3, Loosen the top and bottom nuts and remove the

outlet tube.

4. Removethepressurerelease tubeand fitting,

5oUnsorewthe chec_ valve (turn counterclockwise]

usinga =ockel w_nch.

6 ChScK_at the valve _Isc moves treatyinside the

chiCk:valveandthat thespring hOidSthe disc tn the

upper, €!o=_1 position.The check valve may be

cleaned with a solvent, such as paintand varnish

remover,

% ApplyaQeJenttothe checkvalve threeels Reinstall

theoPm¢_y=lvo(turn _lockwioe),

8, Replace the pressure release tubeand fittfng.

9, Replaoetheoutlet t',,=_)e€,ndtightenlop end bottom

nu_s.

!0, Rep!_cethe6hrOUd_

IF THE SAFETY VALVE DOES NOT WORK

PROPERLY, OVER-PRESSURIZATION MAY

OCCUR, GAUSING AIR TANt_RUFrTUREOR

AN EXPLOSION. OCCASIONALLY PULL

THE RING ON THE SAFETY VALVE 1"O

MAKE SURE THAT THE SAFETY VALVE

OPERATES FREELY. IF THE VALVE iS

STUCK OR DOES NOT OPERATE

SMOOTHLY,IT MUST BE REPLACED WITH

THE SAME TYPE OF VALVE.

Motor

The mow hasan automaticreset thermal overloadWo-

tenor. Hthe motor overheatsfor anyreason, the over-

ioa_ i)rot=_or will shutOffthe motor. The _ must be

allowed to¢ool€lownbeforerestarting,The comFessor

•willautoma.ticallyre-start after the motor oools,

Ifthe overtoadprotectorshutsthe motor off kecluently,

d_ci( fora possiblevoltageproblem, Low vOltagecan

also be suspectedwhen:

t.,_e motor aoe_ not get up tofull power or speed;

2_fuses blow outwhenstarlingthe motor;,lights dimand

remaindimwhen motor isstarted and is running.

STORAGE

Beforeyoustoretheair compressor,make sureyou do

thefoflowlng:

1,Reviewthe'Maintsr_n_e" section onthe precaeding

pages and perform maintenan;e as necessary, Be

sure todrainw=terfromthe air la_k.

2. Protectthe etectficaJcordand air hosefromdamage

(such s8 _:>etOgsteppedon or _n over).Wind them

looselyamUr_l_the compressorhandle,

Store _heaircompressorin a cleanand dry IocaUon.

PR0.u .

TROUBLESHOOTING GUIDE

PERFORMING REPAIRS MAY EXPOSE VOLTAGE SOURCES_ MOVING PARTS, OR COM-

PRESSED AIR SOURCES. PERSONAL INJURY MAY OCCUR. PRIOR TO ATTEMPTING ANY

REPAIRS UNPLUG THE AIR COMPRESSOR AND BLEED OFF TANK AIR PRESSURE.

...... cause............................CORR T .

Pressureswitchdoesnot shut olt" Move thepressureswitohleverto_e "OFF'IPo_i-

motor when compressorreaches lion.if the OUtfitdoesn1 shut off, an_ltheeleotricai

"cut-oUt"pressure, conlactsarewelc_edtogether,replacethepressure

switch.

Ex_essk,e _r_ pressure

safety valve Pol_soff,

Air leaks at fittings

Airleaks at checkvalve.

Airl@ak,_at pressure

_ltoh releasevalve

Defective pressure_witch

roleasevalve.

II the contactsam good, checktosee if thepinin

thebottomofthe pressure relays valvetsstucK,if

it does notmove freely,apace thevetve

Pressure switch "cut-out" tao Returnttleputfitto Sears ServleeCente_tocheck

high, anti aclju=,or replace switch,

ui, , .i. ,., , ...............................

Tubafiffingsare not_ht enough. Tightenfittingswl_re air can be he_a_esCaping_-_

Ohec!_fittings withsoapywatersolution,,DO NOT

OVER-TIGHTEN,

Defectiveor dirty check valve. A defective check valve resultsIn a constant air

reel<at the pressure release valve when there is

pressureInthetankand thecom_esaorisshutoff.

Remove and clean or replace check valve DO

NOT OVER-TIGHTEN.

Remove end replace the releasevalve..

Defectivech_;k v=lve,

Airleak_ inair tank_ Dofecttve air tank,

Air leaks betweenhead and

va_ #_te.

Pre=_ure reading on _he

regulated pressure gauge drop tooccur°

dropswhen_n a_c_sory Is

used.

A defective CHECK valveresultsin e constant_ir

leak at t_ pressure relgasevalve when there i_

pressurein thetank_nc_thecompressor isshut off.

Remove and clean or replace check valve. DO

NOT OVER-TiGHTEN,

AJrtank must be replaced Do notrepair tt_:leakl

i w.,.,.o....I

DO NOT DRILL INTO_ WELD, OR

OTHERWISE MODIFY AIR TANK OR tT

WILL WEAKEN,

Leakinggasket. Torqueheadscrewsto8 It, Ibs,Itthisdoes notstop

leak replace gasket

m

It IS normal for "some" pressure If t_ere is an excessiveamountof pressure drop

when the _essory is usecl,adjust _heregulator

following 1heinstructionson pg.6.,

Note

Adjust tt_eregulatedpressure under flow

conditibns (while a_cessory is being

use_,)

0 ..........

PROBLEM

Airleakfror_S_,fetyValve

KnockingN_ise

Compressorisnotsupply-

ingenough airtooperate

_ocessorl_s,

TROUBLESHOOTING GUIDE (Continued)

CAUSE CORRECTION

PossibledefectinSalety Valve. (_rate safetyvalvemanuaJlybypultingon dngoif

vaJvestill ieaks,itshouldbe re_laced.

Defective Check Valves. i_move and cleanor repl_ce.

v_,,,,,,,,_,,,,,,_ -. , , .....

Prolongedexcessive useof air. 0ecrease amount ofairusage.

Compressor is not large enough

for air requirement.

Restrictedair intakefilter.

Holetn hose.

Cheek Valve restricted.,

Airleaks.

Checktheaccessoryairrequimmerd.If itis higher

than the SCFM or pressuresupplied by youra_r

compressor, you needa _argercompressor.

Cleanorreplaceair intakefiller, Donc_operateIhe

air compressorinlhe paint spray area.

Checkand replaceifrequired,

Removesnd clean or r_place,.

Tighten fittings, (See Air Leaks Section of

Molor Wllt NotRurl

.... _ubleshooting Guide.)

Motor overloadprotectionswitch Lit motorcoo! offand overloads_tch wtftauto-

has tripped° n',atlcsllyreseL

Tank pressureexceedspressure

_witch "cut-in" pressure,

Motorwillstart automatlc_Jiywhen tank 1oreseure

dropsbelow °'cut-in"pressureofpressureswilch.

Wrong gauge wire or length of

extensioncord,

Che¢_forproper gauge wire andcordlength,

CheckValvestuck open.

Looseelectrical connecltonso

Possibledefective capacitor,

Paint spray on internal motor

parts.

Possible defective motor,

Fuse blown, circuit breaker

tripped,

Pressurerelease vatve on _res.

sure switch has no1 unloaded

I_ea0pressure,

Removeand clea.nor replace_

Check wiringconnection inside pressureswitch

and terminal box area.

Return to Sears Service Centertor ir.spectionor

replacementif necessary,

Have check,L_ at Sears Service Center. Do not

operate the compressorin the paintspray area,

Si_eflammable vaporwartungon p_ge 3.

Have checkedat a Ioce_Sears Servlce Center.

t._Che_kfuse box _r btownfuse randreplace if

necessary. Re-set circuitbreaker°Oo not use a

fuseor circuitl:_aker withhigherr_tJngthan that

s;)eotfied for your particularbranch circUlL

2. Check for properfuse: only 'Fusetren" type T

fusesare acceptable,

3, Checkfor low voltageconditionsandtor proper

extensioncord.

4,Disoonnecl theotherelec_icaiappliancesfrom

ctmult or operate theoompessoron itsownbranch

cir_uiL

Bleed thefineby pushingtheleveron thepressure

switch to the "Off" position;if the vaive does not

open, replaceit

R_guiatorknob - con|inu-

OUSsir leak,,Regulatorwltl

notshut-offat air outlet.

Dirtyor damaged re_ju_a_orinter-

nal p_,rts,

Cle_n or r_ptace regulator, or internal parts.

AIR COMPRESSOR DIAGRAM

t

4

44 45 46 47

X

42

23

33 32

25

21

18

22

2O

12

KEY

NO.

2

3

4

5

6

7

B

9

10

11

12

13

14

15

16

17

18

19

20

21

22

?.3

24

26

26

27

28

29

3O

31

32

33

34

35

38

37

3S

S9

4O

41

42

PARTMUMBER

LA-1976

LA-1979

LA.2035

LA4_;7

LA-IB_'7

LAd779

CAC.33t._

LA-1975

LA-2035

CAC-107;)

5SF-0129-ZN

CAC-1080

LA.1994,1

CAG.I062

CAC-1099

SSF-S05

CA,C-1098

TA-4136

TA-4135

TA.4140

TA-4139

STD541437

CAC,4293

CAC-4313

CAC-60

LA-1610-1

SUDL-B-1

LA-1gT8

CAC-1087

CAC.1086

CAC-334

SSF-t318-ZN

CAC,4290

SSP-7513

CAC-333-1

BSN-8001

SSP.71;21

CAC-1120

CAG-f083

C-GA,344

CAC-1084

SS-20"t2

88.2071

H-Z0S9

CAC-487

SS-3_-CD

CAC.36S

TIA-4-325

TIA-412S

CAC,61

8UDL-403-1

PARTS LIST

DESCRIPTION

Model No. Label (Model No. 919.154120)

Model No, Label (Model No, 91B,_4020)

Model No. Label (Model No.9t9,_4320)

Model No, Label (Model No.919,154420)

Maintenance Label

Hot Surfsoe Label

9kroud - front

Performan=e Label (Model No, _19.154120& 919.154020)

Performance Label (Model NO,_9.1S4320 & 919.1544:_0)

Not USed

Braolmt (2 ueed - included with _€11)

I,ooknut '/4"-20(2 used)

Tool troy

Advanoad toch. Label

Rear ahrou_ assembJy (include_ 2 ea. #7)

U-Channel isolator

Shoulder screw (2 used)

Isolator (2 used)

Air Tank (Model No. 919.154020)i

Air "lllnkASME (Model No. 919,1r_4120)

Air Tank (Model No. 919.154320)

Air Tank (Mod_l NO.919.154420)

Nut _/o"-16(2 u=ed)

Wheel (2 used) (Model No. 919,11_4020& 919.154120)

Wheel (z u_d) (,ModelN_. e_e.l_20 s _g._4420)

Shoulder bolt ¾ -tB × 21/=(2 ut_.)

Beam Craftsman Label

Rubber foot strip

Dmln Tank Label

Handle (black firdah)

Handlegrip

Control cover

Sorew - onntrol oaver

Check valve

Nut sleeve assembly (for %" O,D_,Tube)

Shroud Plate

RMchet Fastener (2 used)

Nut (Tighten until it SlOpsagainst head)

Silicone Sleeve

Outlet tube

Pmuure Gauge (2 used)

Rear cover

Nipple (%" NPT × 1Vd°tong)

Nipple (_/,"NPT× 1W' tong)

Adapter

Regulator

PIp_ plug T/_,NPT

Mtmlfold

SMIty valve {Model No. 919.1540;Z0& 919.154320)

Safety valve ASME (Model No. 9t9.164120& 919,154420)

Mounting Ring- control cover

Cord assembly- line

13

COMPRESSOR PUMP DIAGRAM

56

58

59

60

6t

62

63

ft

___ M_K TOWARDS MOTOR,

__,/64

65

PARTS LIST

KEY

NO. PARTNUMBER

43 CAC-4220-1

44 LA.153t-1

45 CAC-1085

46 STDSTS0";r_5

47 STDS75026

48 SSP-9013

49 LAo!535

SO 88P.6088

51 CAC-4215-t

52 5SW-7367

53 KK.4315

64 SSF-961

55 CAC-260-2

S6 CAC-t046

57 SSF-990

S8 CAG-1067

Sg SSF-6640

60 CA(;-1066

61 CAC-4281

62 SSG-8166

_,e3

U'64

65 €-MO-3006

68 CAC-4303

67 SSF.2043

68 CAG-1055

69 SSF-3101

70 88T302S

H-5796

9-16269

Sl-30-08-4-B

Key S3 & 64 Car, only be

DESCRIPTION

Pressure switch

On-Otf Labol

Pressure relief tuba (wurmltube before installing on #50,)

Nut (for !/4"O,D, Tube)

Farrulo (fOr ',_"O,D, Tube)

Tube insert

Warning Label

Barbed fitting

Cord assembly- motor

Stz,atn roller (2 used)

Pressure release valve mn_ mounting nut (included with #43)

Screw I/_,0AB x oI4_long (2 zINd)

Air Filter

intake muffler

SCrew 1/4"- 20 × 1t/4- (2 used, torque 7-10 it° lbs.)

Head

Stud V4"-20×11/..'(2 used, _rque 7-10 ft. Ibs°)

Gasket

Y_lVeplate ass4tmbly(inedddU vaJVes,rostrlctore,& screws)

O-ring

Connecting rod assembly (torque screw 30.,35 In. Ibs.)

Cylinder slsmve(position 10_etlngmark townrds motor)

Motor 2 HP

Eccentric/Bearing Assyo(In_ludai I ca, #70)

Screw (eccentric, torque 50.60 in. Ibs.)

Fen

Screw #10-24 × _/."long (torque 30.35 in. Ibs.)

Bearing (eccentric)

NOT ILLUSTRATED

Air Hose assembly (_/_"l.D._ 15')

Air Chuok

Ownare Manuel

purcJ18_hdampart of KK-4_t e-_onnectlngrod kit

15

SL A/RS

OWNERS

MANUAL

SERVICE

MODEL NO.

919.154020

9!9.154120

919.154320

919.154420

HOW TO ORDER

REPAIRPARTS

CRAFTSMAN

PERMANENTS,( LUBRICATED

AIR COMPRESSOR

Now "hat you have purchasedyo)JrSears Air Compressor shoulda

need ever e0dstfor repairpart_oi service sirt_ptycontaotanySears

Service Centerand mast Sears Floebuckand Co stores Be sure

toprovideall pertinentta_ whe_lyou catlor visit

The modet number ofyour Se=sfAir Compressoris919............. -_ ,

ThisnumberDartbe found on thei|_l:)e]WhiChfs IOOaledOnbe back

Offhe shroud

WHEN ORDERING REPAIR PAR_S ALWAYSGIVE THE

FOLLOWING INFORMATION:

PART NUMBER

IPART DESCRIPTION

, MODEL NUMBER INAME OF ITEM

Allparts listed may beorderedfm_nanySears Service Centerand

mosl Sears_tores

Iflhe parts youneed am notstork_dlooa|ly yourorderw/!l be elnc

ironicallytransmittedto a 8eat_ R_paJrParts DistributionCenl_t for

handllng

$1_lF084 9 10till

Sears, Roebuck and Co., _hlcago, IL 60684 U.S.A.

p'tin_di_U.S.A.

/