Grundfos Unilift CC 7 Installation And Operating Instructions Manual

- Type

- Installation And Operating Instructions Manual

UNOLIFT, DUOLIFT

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

2

English (GB)

3

English (GB) Installation and operating instructions

Original installation and operating instructions

These installation and operating instructions

describe Grundfos Unolift and Duolift lifting stations.

They apply to the tank and installation kits. For

detailed information on installing and operating the

pumps and controller, see the installation and

operating instructions supplied with these products.

Sections 1-6 give the information necessary to be

able to unpack, install and start up the product in a

safe way.

Sections 7-16 give important information about the

product, as well as information on service, fault

finding and disposal of the product.

CONTENTS

Page

1. General information

1.1 Symbols used in this document

1.2 Symbols on the product

2. Receiving the product

2.1 Transporting the product

1. General information

3

1.1 Symbols used in this document

3

1.2 Symbols on the product

3

2. Receiving the product

3

2.1 Transporting the product

3

2.2 Inspecting the product

4

2.3 Scope of delivery

4

3. Installing the product

6

3.1 General guidelines

6

3.2 Choice of tank inlets

6

3.3 Location

6

3.4 Tools

8

3.5 Installation overview

8

3.6 Positioning the product

8

3.7 Installing the tank

8

3.8 Drilling holes in the tank

8

3.9 Fitting the cable glands

9

3.10 Fitting the air vent

9

3.11 Fitting the venting pipe

9

3.12 Connecting the inlet pipes

9

3.13 Installing the pump in the tank

10

3.14 Inner connecting pipes

10

3.15 Installing the level sensor tube

13

3.16 Installing an alarm float switch

13

3.17 Assembling the discharge pipes

13

3.18 Installing a diaphragm pump

15

3.19 Installing the controller

15

3.20 Electrical connection

15

3.21 Setting the controller before start-up

15

4. Starting up the product

16

5. Monitor the increasing liquid level in the

tank up to the start level and check that

the pumps start and stop at least twice.

16

4.3 Storing the product

16

4.4 Storing the product

16

5. Product introduction

17

5.1 Product overview

17

5.2 Applications

17

5.3 Pumped liquids

17

5.4 Automatic operation

17

5.5 Identification

18

5.6 Diaphragm pump

18

5.7 Level sensor tube

18

6. Operating the product

19

6.1 Setting the start levels

19

7. Starting up the product after standstill

21

8. Servicing the product

21

9. Taking the product out of operation

21

10. Technical data

22

10.1 Operating conditions

22

10.2 Material

22

10.3 Electrical data

22

10.4 Dimensions and weights

22

11. Fault finding the product

23

12. Disposing of the product

25

Prior to installation, read this document.

Installation and operation must comply

with local regulations and accepted codes

of good practice.

DANGER

Indicates a hazardous situation which, if

not avoided, will result in death or serious

personal injury.

WARNING

Indicates a hazardous situation which, if

not avoided, could result in death or

serious personal injury.

CAUTION

Indicates a hazardous situation which, if

not avoided, could result in minor or

moderate personal injury.

European Conformity

WARNING

Falling objects

• Death or serious personal injury

• Secure the product during

transportation to prevent it from tilting

or falling down.

English (GB)

4

2.2 Inspecting the product

1. Check that the product is as ordered.

2. Check that no visible parts have been damaged.

3. If parts are damaged or missing, contact your

local Grundfos sales company and refer to the

product numbers in section 2.3 Scope of delivery.

2.3 Scope of delivery

The scope of delivery depends on your order.

Pumps, tank and pipework are delivered separately

and are to be assembled.

Description of kits

CAUTION

Back injury

• Minor or moderate personal injury

• Get assistance from another person or

use lifting equipment to carry the

product.

CAUTION

Crushing of feet

• Minor or moderate personal injury

• Wear safety shoes when moving the

product.

Tank

Designation

Quantity

270 litres

tank

540 litres

tank

Tank 1 1

Cover with gasket 1 2

Screw, M8 x 30 12 24

Washer 12 24

Fastening brackets for

level sensor tube

22

Screws for fixing tank 4 4

Plugs for fixing tank 4 4

Socket seal, DN 40 1 1

Socket seal, DN 100 1 1

Inner connection pipes

Designation

Quantity

KP/

CC

SEG APB

Adaptor Rp 2 -

R 1 1/2

11-

Double socket

R 2 - R 2

111

Nut, PVC, 2" 1 1 1

O-Ring Ø60,

EPDM

--1

Nozzle adaptor,

F

222

Clamp,

stainless steel

222

Flexible

connecting

piece ∅50

111

Elbow 90° - 1 1

Flange ∅50 - 1 -

Screw,

for flange

-4-

Washer,

for flange

-8-

Inner connection pipes

Designation

Quantity

KP/

CC

SEG APB

English (GB)

5

Accessories

The following components are not part of the tank

delivery. They are recommended accessories which

must be ordered separately.

* The Unilift CC and KP pumps are delivered with

non-return clap valves.

Nut, M16,

for flange

-4-

O-ring ∅50,

for flange

-1-

Adaptor, KP

M1"1/2-M1"1/4

1--

Adaptor, CC

M1"1/2-F1"1/4

1--

Thread tape,

PTFE

111

Venting port

Sleeve, PVC

75 x 63 x 2"

111

Flat gasket,

EPDM ∅63

111

Nut, PVC 2" 1 1 1

Other

Power plug

SCHUKO

1-1

Cable gland,

M20

212

Cable gland,

M25

- 1 -

Inner connection pipes

Designation

Quantity

KP/

CC

SEG APB

Discharge pipe

Designation

Quantity

Uno-lift Duolift

CC/

KP

APB/

SEG

CC/

KP

APB/

SEG

Non-

return

valve

-* 1 -* 2

Double

socket

-135

Isolating

valve

1111

Fitting

union

--22

T-part,

PVC 90°

--11

Elbow,

PVC 90°

--22

Pipe,

∅50,

2 m

--11

Thread

tape

1111

Glue,

PVC-U

--

125

g

125

g

English (GB)

6

3. Installing the product

3.1 General guidelines

Guidelines for correct mechanical installation of

lifting station are according to EN 12056-4.

• If the lifting station is installed in a basement with

regular penetrating groundwater, we recommend

to install a drainage pump in a separate pump

sump below floor level (mandatory in certain

countries). If there is only a risk of penetrating

groundwater, we recommend to install a float

switch outside the lifting station and to connect it

a controller, which will indicate an high level

alarm in case of flooding.

• The collecting tank must be fixed to the floor.

• We recommend that you connect a diaphragm

pump to the collecting tank in order to be able to

empty the tank manually.

• All outlet pipes from the lifting station, diaphragm

pump and drainage pump must have a backwater

loop, i.e. a bend above the local backwater level.

Commonly, the highest point of the bend must be

above street level. See fig. 2.

• Surface water must not be discharged into the

lifting station inside the building. It must be

collected and discharged outside the building.

• A non-return valve must be installed at the

discharge of the lifting station to prevent back

flow from the sewer for example.

• Install isolating valves at the inlet and outlet of

the lifting station.

• The volume of the outlet pipe above the non-

return valve up to the backwater loop (bend in the

pipe) must be smaller than the effective tank

volume.

• In general, a lifting station for black wastewater

must be vented above roof level. However, it is

permitted to lead the ventilation into the main

building ventilation system. Special two-way

venting valves must be placed outside the

building.

• If the wastewater is discharged into a collecting

line, the collecting line must have a filling ratio of

at least h/d = 0.7. The collecting line must be at

least one nominal diameter bigger after the outlet

pipe connection.

• 45 degrees bends must be used to avoid

sedimentation in pipework.

3.2 Choice of tank inlets

It is optimal to lead your pipework to the top inlets of

the tank, as it will prevent backflow and

sedimentation in the inlet pipe and give you the

possibility to use a high start level for the pump. A

high start level increases the effective tank volume

and decreases the numbers of start/stop of the

pumps.

If you use the bottom inlet, you have to select the

lowest start level. If the start level is above the inlet

height, there will be backflow in the inlet pipe. thus

increasing the risk of sedimentation in the pipework.

3.3 Location

The lifting station must be installed in a properly lit

and vented room with 60 cm free space around all

parts to be serviced and operated.

The tank must not be exposed to direct sunlight. UV

can affect the properties of its composite material,

resulting in a shorter life.

The product is designed for indoor operation. If

installed outside, it must be placed in a closed pit.

The tank can be flooded and may be installed in a

basement with risk of penetrating groundwater.

English (GB)

7

Fig. 1 Installation example with tank in a pit and with a controller. The diaphragm pump is not shown.

Fig. 2 Installation example with tank directly mounted on basement floor (the diaphragm pump is not

shown)

TM065789 0216

Pos. Description

1 Isolating valve, inlet

2 Controller

3 Drainage pump

4

Non-return valve,

discharge

5

Isolating valve,

discharge

6 Venting pipe

6

2

3

4

5

1

TM065790 0216

Pos. Description

1 Isolating valve, inlet

3 Drainage pump

4

Non-return valve,

discharge

5

Isolating valve,

discharge

6 Venting pipe

16

3

4

5

English (GB)

8

3.4 Tools

• Thread tape

•Glue

Not delivered with the product:

• Drilling machine

• Drilling bits: Ø6, Ø16, Ø25

• Cup saw: Ø40, Ø100

• Deburring tool for polyethylene

3.5 Installation overview

Depending on your product type, you must go

through different steps in order to install and setup

your system. The steps below are necessary steps in

order to start your system. You may need to go

through extra steps if you have additional

accessories.

Unolift/Duolift with pumps with float switches

1. Fix tank to the floor

2. Drill holes for inlet pipes

3. Connect inlets to tank

4. Fit venting port and cable glands

5. Adjust length of float switch cable to set start

levels

6. Install pumps inside tank

7. Fit inner connecting pipe

8. Fit venting pipe

9. Fit discharge pipes

Unolift/Duolift with controller and level sensor

tube

1. Fix tank to the floor

2. Drill holes for inlet pipes

3. Connect inlets to tank

4. Fit venting port and cable glands

5. Install pumps inside tank

6. Install sensor tube inside tank

7. Fit inner connecting pipes

8. Fit venting pipe

9. Fit discharge pipes

3.6 Positioning the product

Position the tank so that all components are easily

accessible during operation and maintenance.

3.7 Installing the tank

Fix the tank to the floor to prevent uplift and twist.

Use the mounting brackets to fix the tank with

screws.

3.8 Drilling holes in the tank

Depending on the size, the the tank has three to four

pre-moulded holes ∅ 100 for the inlet pipes. The

tank also has a pre-mouled hole ∅ 40 for the

diaphragm pump. See section 5.1 Product overview.

These holes must be cut opened in order to be used.

Holes for discharge pipes, venting pipe and minimum

required cable glands are already opened.

The minimum required cable glands depend on the

model:

• Unolift, APB, CC, KP: one hole opened for pump

cable

• Unolift SEG: two holes opened for pump cable

and sensor hose

• All Duolifts: three holes opened for pump cables

(2) and sensor hose (1)

3.8.1 Drilling holes for pipes

1. Determine which inlets you want to use.

See “Choice of tank inlets” on page 6.

2. Drill holes with a cup saw.

The diameter of the cup saw must be the same

as the diameter of the pipe.

Inlet: Ø100

Outlet, pipe for diaphragm pump: Ø40

3. Deburr the holes.

Fig. 3 Drilling holes for pipes

CAUTION

Back injury

• Minor or moderate personal injury

• Get assistance from another person or

use lifting equipment to carry the

product.

CAUTION

Crushing of feet

• Minor or moderate personal injury

• Wear safety shoes when moving the

product.

TM065780 0116

CAUTION

Sharp element

• Minor or moderate personal injury

• Wear protective gloves.

TM065851 0216

English (GB)

9

3.8.2 Drilling holes for cable glands

1. Determine where to lead the pressure hose from

the level sensor tube and cable from the alarm

float switch, if any.

2. Drill holes.

Pressure hose: Ø20

Alarm float switch cable: Ø25

3. Deburr the holes.

3.9 Fitting the cable glands

Choose the appropriate cable gland for the

application:

Cable gland for Unilift cable: M20

Cable gland for level sensor hose: M20

Cable gland for SEG cable: M25

Cable gland for alarm switch: M20

Fig. 4 Fixing the cable glands

3.10 Fitting the air vent

1. Fit the seal on the sleeve.

2. Fit the sleeve in the hole for the air vent. The air

vent is located on top of the tank.

3. Fit the nut from inside the tank and tighten it.

Fig. 5 Fitting the air vent

3.11 Fitting the venting pipe

You can connect your venting pipes to the air vent in

three different ways.

• By means of a PVC venting pipe with an outer

diameter of 63 mm and the glue delivered with

the product.

• By means of a flexible pipe connection with an

inner diameter of 75 mm and with clamps.

A flexible pipe connection with clamps is

available as an accessory.

• By means of a PP double socket with an inner

diameter of 75 mm. The socket must comply with

EN 1451.

3.12 Connecting the inlet pipes

You can connect up to three or four inlet pipes to the

tank, depending on the size of the tank. First you

must cut the holes open. See section 3.8 Drilling

holes in the tank.

1. Fit the socket seal in the inlet.

2. Connect the isolating valve to the inlet pipe.

The isolating valve is an accessory and is not

part of the tank delivery.

3. Insert the inlet pipe into the socket seal.

Fig. 6 Fitting an inlet pipe with an isolating

valve (type gate)

The isolating gate valve can be ordered as

accessory. Use product number 96615831.

TM065779 0116TM065924 0316

Note

The venting pipe is not delivered with the

product

TM065859 0216

English (GB)

10

3.13 Installing the pump in the tank

Pumps with float switches: before installing the

pump, make sure that you have set the length of the

float switch. See “Installing the pump in the tank” on

page 10.

1. Remove the plug from the power cable of the

pump. You may need to cut the cable.

2. Position the pump in the tank.

If the pump has a float switch, make sure it can

move freely.

Unilift CC, KP, APB: Position the pump between

the three positioning dots at the bottom of the

tank so that it stays in place during operation.

See figures 7 and 8.

SEG: The pump weight ensures that the pump

stays in place.

3. Lead the supply cable through the cable gland of

the tank.

4. Tighten the cable gland.

Fig. 7 Correct position of Unilift CC and KP

pumps

Fig. 8 Correct position of Unilift APB pumps

3.14 Inner connecting pipes

3.14.1 Cutting the flexible connecting piece

The inner connecting pipe is delivered with a flexible

connection piece Ø50. You need to cut it to a specific

size, which depends on the pump type. Use the

dimensions in the table below:

3.14.2 Assembling the inner pipes

Use the thread tape delivered with the assembly kit

to seal the threads.

1. Assemble all the parts of the connecting pipe

outside the tank, except for the outlet connecting

piece. See pos. 1 in fig. 9.

2. Fit the connecting pipe to the pump in the tank.

3. Fit the outlet connecting piece to the discharge

port of the tank. Make sure that the pump is in

position and that the float switch, if any, can

move freely, before you tighten the outlet

connecting piece.

Fig. 9 Example with Unilift KP pumps

TM065965 0316TM065966 0316

Pump type

Delivered

size

[mm]

Cut to size

[mm]

Unilift CC

350

240

Unilift KP

350

(no cut)

Unilift APB

500

423

SEG 375

TM04 9563 2014

1

English (GB)

11

Fig. 10 Unilift CC, KP

TM0 59630 3913

English (GB)

12

TM0 59633 3913

TM0 59632 3913

Fig. 11 Unilift AP35B, AP50B Fig. 12 SEG

x4

English (GB)

13

3.15 Installing the level sensor tube

If your pump is not equipped with a float switch, you

must install a level sensor tube in the tank.

1. Fix the level sensor tube to the clamps inside the

tank.

The locking ring of the tube must be under the

top clamp to prevent the pipe from rising with the

water level.

2. Lead the level sensor hose through the cable

gland.

3. Tighten the cable gland.

Fig. 13 Correct positioning of the level sensor

tube

3.16 Installing an alarm float switch

If you have an alarm device, you can install an

additional float switch inside the tank and connect it

to the alarm device in order to trigger a high level

alarm.

If you have a controller LC 220 or LC 221, you do not

need an additional alarm float switch as the high

level alarm is triggered by the level sensor.

1. Use a strip to attach the cable of the float switch

to the inner connecting pipe.

• Make sure that there is a free cable length of

minimum 70 mm.

• Make sure that the float switch can move freely

from its lowest position to its highest position.

2. Tighten strip.

3. Lead the cable through the cable gland.

4. Tighten the cable gland.

Fig. 14

3.17 Assembling the discharge pipes

The discharge pipes described in this section are

accessories.

3.17.1 Cutting the pipe (Duolift only)

The discharge pipe kit is delivered with a 2 meter

pipe ∅50. You need to cut it into 2 pieces of a

specific size, which depends on the Duolift model

and the pump type. Use the dimensions in the table

below:

3.17.2 Assembling

Assemble the discharge pipes according to the

drawing below.

Tip for Duolift:

1. Assemble the whole discharge pipe before

connecting anything to the tank.

2. Connect the assembled discharge pipe to the

tank by tightening the two fitting unions onto the

tank outlets. See pos. 3.

TM065728 5312

TM065899 0216

Model

Cut to size

[mm]

Duolift CC/KP/SEG, 270 L 2 x 180

Duolift CC/KP/SEG, 540 L 2 x 430

Duolift APB, 270L 2 x 163

Duolift APB, 540L 2 x 413

PP

English (GB)

14

* The Unilift CC and KP pumps are delivered with non-return clap valves.

** The adaptor Rp 2 - R 1 1/2 for the Duolift SEG is not shown on the drawing.

TM066220 3913

TM066512

Fig. 15 Discharge pipe for Duolift CC/KP* Fig. 16 Discharge pipe for

Unolift CC/KP*

TM0 59635 3913

TM0 59634 3913

Fig. 17 Discharge pipe for Duolift APB/SEG** Fig. 18 Discharge pipe for

Unolift APB/SEG**

1

3

3

1

1

2

33

2

1

2

English (GB)

15

3.18 Installing a diaphragm pump

The diaphragm pump is optional.

1. Cut open the inlet for the diaphragm pump. See

section 3.8 Drilling holes in the tank.

2. Fit the DN 40 socket seal in the opening for the

diaphragm pump at the bottom of the tank. See

figures 19 and 20.

3. Insert the pipe from the diaphragm pump into the

inlet.

4. Secure the diaphragm pump and connect it to the

building discharge pipe according to the

installation and operating instructions for the

pump.

3.19 Installing the controller

Mount the controller on a wall with screws through

the mounting holes of the back plate.

The cable entries must point downwards, and the

user interface must be easily accessible.

See the installation and operating instructions for the

controller.

3.20 Electrical connection

3.20.1 Connecting the pump

Connecting the pump to a socket

1. Lead the pump cable through the cable gland.

2. Install the plug on the cable.

A Schuko plug is provided with the product.

3. Insert the plug into a socket.

Connecting the pump to a controller

1. Lead the cable through the cable gland.

2. Connect the cableto the controller.

See wiring diagram provided with the controller.

3.20.2 Connecting the level sensor hose to the

controller

1. Lead the hose through the corresponding cable

gland.

2. Connect the level sensor hose to the pneumatic

entry underneath the controller.

The hose is connected properly when it is pushed

all the way in and locked in position. See the

installation and operating instructions for the

controller.

3.20.3 Connecting an alarm switch to the

controller

1. Lead the cable through the corresponding cable

gland.

2. Connect the alarm switch cable to the terminal

for the high-water level alarm. See the

installation and operating instructions for the

controller.

3.21 Setting the controller before start-up

LC 220

Select settings via the DIP switches. See the

installation and operating instructions for the

controller.

LC 221

You must set the start level and rated current of the

motor to be able to start the product. All other

settings are preset.

1. Close the isolating valves.

2. Make sure the pump switches on the controller

are in position "OFF".

3. Switch on the controller.

4. When "L_01" is displayed (start level menu),

press [OK].Select the start level using the left and

right arrows, and press [OK].

For more information on which start level to

select, see “Setting start levels with controller” on

page 20.

5. Go to "L_02" (rated current menu) using the left

and right arrow and select the rated motor

current [A] according to the nameplate of the

pump motor.

Some of the factory settings can be changed. See

the installation and operating instructions for the

controller.

DANGER

Electric shock

• Death or serious personal injury.

• Before starting any work on the

product, make sure that the power

supply has been switched off and that

it cannot be accidentally switched on.

LC 220 LC 221

QR98503252

QR98503253

http://net.grundfos.com/

qr/i/98503252

http://net.grundfos.com/

qr/i/98503253

English (GB)

16

4. Starting up the product

4.1 Starting up with a controller

Make sure that all pipes and connections are tight.

Make sure that the controller is set correctly. See

“Setting the controller before start-up” on page 15.

1. Switch on the controller.

2. Set the selector switch to "Auto".

3. Open the isolating valves.

4. Flush a toilet or open a tap connected to one of

the inlets.

5. Monitor the increasing liquid level in the tank up

to the start level and check that the pumps start

and stop at least twice.

4.2 Starting up without a controller

1. Make sure that all pipes and connections are

tight.

2. Open the isolating valves.

3. Switch on the power supply to the pump.

4. Activate a sanitary appliance connected to one of

the inlets.

5. Monitor the increasing liquid level in the tank up

to the start level and check that the pumps start

and stop at least twice.

4.3 Storing the product

4.4 Storing the product

The tank must not be exposed to direct sunlight. UV

can affect the properties of its composite material.

For storing the pumps and the controller, see the

installation and operating instructions for the

product.

CAUTION

Back injury

• Minor or moderate personal injury

• Get assistance from another person or

use lifting equipment to carry the

product.

CAUTION

Crushing of feet

• Minor or moderate personal injury

• Wear safety shoes when moving the

product.

English (GB)

17

5. Product introduction

5.1 Product overview

Fig. 19 Unolift 270 / Duolift 270

Fig. 20 Duolift 540

5.2 Applications

The lifting station is designed for pumping grey and

black water from family houses and commercial

buildings where the liquid cannot be led directly to

the sewer due to lack of a natural downward slope.

5.3 Pumped liquids

Unilift CC, Unilift KP, Unilift APB

Grey wastewater: domestic wastewater, excluding

toilet discharge.

SEG pumps

Grey water and black water: domestic wastewater,

including toilet discharge.

The SEG pump has a grinder system.

Surface water must not be discharged into a lifting

station inside the building.

5.4 Automatic operation

The Unolift, Duolift is designed to operate

automatically according to the liquid level inside the

tank.

The system can be set in two ways in order to

operate automatically. It must be either be equipped

with float switches, fitted directly on the pumps, or

with a level sensor tube and a controller.

TM06 1069 1614TM06 1068 1614

Pos. Description

1 Horizontal main inlets, DN 100

2 Mounting brackets

3

Connection, DN 40, for optional

diaphragm pump

4 Pump outlet

5

Holes for cable glands or pump power

cables, alarm float switch and pressure

hose

6 Outlet for venting pipe ∅ 60

7 Vertical main inlet, DN 100

8 Hole for pressure hose

English (GB)

18

5.5 Identification

5.5.1 Nameplate

Fig. 21 Nameplate

5.5.2 Type key

5.6 Diaphragm pump

We recommend to connect a diaphragm pump to the

tank. It is a positive displacement pump which can

be operated manually. It can be used to drain the

tank before service or during power cuts. The tank

has a pre-built inlet DN 40 especially designed for it.

5.7 Level sensor tube

The level sensor is an accessory, which works

together with a controller LC 220 or LC 221.

The level sensor tube is connected to a

piezoresistive level sensor in the controller via its

pressure hose.

The rising liquid level compresses the air inside the

pressure tube and pressure hose, and the

piezoresistive sensor transforms the changing

pressure into an analogue signal. The controller

uses the analogue signal to start and stop the pump

and to indicate high water level alarm.

TM061249 3414

Pos. Description

1 Product number

2 Production site

3 Type of designation

4 Country of origin

5Weight

6 Production code

7

Installation and operating instructions,

publication number

8 Not filled in

UNOLIFT 270. 40. CC

Model

Unolift: one pump

Duolift: two pumps

Tank volume

[L]

270

540

Outlet DN 40

Pump

CC

KP

APB, APB

SEG

Type

Standards used: EN 12050-1 or EN 12050-2

Model

Weight

P.c.

Made in

EU declaration of performance

Denmark

P10

98646710

1325

Notified body:0197

DK-8850 Bjerringbro, Denmark

98495490

1 32

7

4

85

6

English (GB)

19

6. Operating the product

The lifting station is designed to operate

automatically according to the liquid level in the tank.

With a controller, you can easily change settings,

monitor the system or perform troubleshooting.

You can download the installation and operating

instructions for the controller with the following links

and QR codes.

6.1 Setting the start levels

The start level is closely related to the chosen inlets.

Choose a start level which will ensure a minimum

backflow in the inlet pipe, thus avoid risk of blockage

by sedimentation in the inlet pipe.

Set the start level as high as you can according to

your setup.

A high start level increase the tank effective volume

and decrease the numbers of start/stop of the

pumps.

The following illustrations show the allowed start

levels according to the inlet. Theses specific values

can only be selected with the LC 221 controller.

Fig. 22 Recommended start levels according to inlet

LC 220 LC 221

QR98503252

QR98503253

http://net.grundfos.com/

qr/i/98503252

http://net.grundfos.com/

qr/i/98503253

TM066491 1516

TM066489 1516

TM066490 1516

TM066488 1516

180

350

450

250

500

Start

level

180

350

450

250

500

Start

level

180

350

450

250

500

Start

level

180

350

450

250

500

Start

level

English (GB)

20

6.1.1 Setting start levels with controller

LC 220

Select the start levels via the DIP switches. Choose

between LOW and HIGH. The stop and alarm levels

are setup automatically according to the chosen start

level.

See the installation and operating instructions of the

controller for more information about the DIP

switches.

The preset values of start, stop and alarm levels can

be changed via the PC tool, which can be ordered as

accessory. Use product number 96705378.

LC 221

Go go [Setup], then [L_01] and choose between the

following start levels. The stop and alarm levels are

setup automatically according to the chosen start

level.

6.1.2 Setting start levels with float switches

Set the start and stop level by adjusting the length of

the free cable (L).

Fig. 23 Example start/stop levels for Unilift CC

We recommend start and stop levels corresponding

to a cable length between the minimum and

maximum indicated below.

LOW HIGH

Start level

[mm]

180 500

Stop level

[mm]

100 100

Alarm level

[mm]

350 600

12345

Start level

[mm]

180 250 350 450 500

Stop level

[mm]

100 100 100 100 100

Alarm level

[mm]

350 400 550 600 600

TM03 0829 0505

Unilift KP

Cable length (L)

70 mm (min) 150 mm (max)

Start Stop Start Stop

Unilift KP

150

290 140 335 100

Unilift KP

250

Unilift KP

350

300 150 345 110

Unilift CC

Cable length (L)

100 mm (min) 200 mm (max)

Start Stop Start Stop

Unilift CC

5

350 115 400 55

Unilift CC

7

Unilift CC

9

350 150 435 90

Unilift

APB

Cable length (L)

100 mm (min) 400 mm (max)

Start Stop Start Stop

Unilift

AP35/50B

430 320 460 140

Start

Stop

L

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

Grundfos Unilift CC 7 Installation And Operating Instructions Manual

- Type

- Installation And Operating Instructions Manual

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Grundfos UNILIFT AP35B Installation And Operating Instructions Manual

-

Grundfos Sololift2 CWC-3 Installation And Operating Instructions Manual

-

Grundfos Unilift KP 150 Installation And Operating Instructions Manual

-

Grundfos UPS2 Instructions Manual

-

Grundfos MQ User manual

-

Grundfos Unilift AP35 Installation And Operating Instructions Manual

-

Grundfos JP PT-V Installation And Operation Instructions Manual

-

Grundfos UNILIFT AP35B Installation And Operating Instructions Manual

-

Grundfos Unilift AP35 Installation And Operating Instructions Manual

-

Grundfos Unilift AP12 User manual

Other documents

-

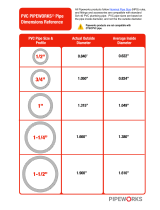

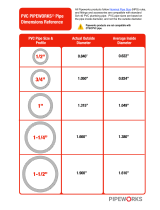

PVC Pipeworks 125-X-W-4 Dimensions Guide

PVC Pipeworks 125-X-W-4 Dimensions Guide

-

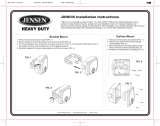

Jensen Heavy Duty JXHD35 User manual

Jensen Heavy Duty JXHD35 User manual

-

Jung Pumpen compli 300 User manual

Jung Pumpen compli 300 User manual

-

Oatey 43905 Specification

-

Oatey 42724 Specification

-

Wilo Wilo-DrainLift XS-F Minisystem for Faecal Water User manual

-

Wilo Wilo-DrainLift XS-F Minisystem for Faecal Water User manual

-

KSB Evamatic-Box N 200 I Installation & Operating Manual

-

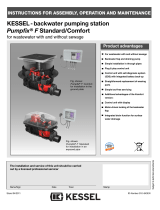

Kessel Pumpfix F Standard Nstructions For Assembly, Operation And Maintenance

Kessel Pumpfix F Standard Nstructions For Assembly, Operation And Maintenance

-

elco Minifill T Installer Guide