Page is loading ...

M-0221201113 Page 1 of 7

Revision 4

Aries FilterWorks

Reverse Osmosis System

HPL-RO

Installation and Service Guide

M-0221201113 Page 2 of 7

Revision 4

Introduction:

Read this entire service guide before beginning installation. The Aries HPL-RO system has been

designed for quick and simple installation and maintenance. By carefully reading this instruction

manual and following the operational guidelines, successful installation and reliable operation

will be insured.

System Description:

The Aries HPL-RO system is a 4-stage filtration system designed to remove more than 93% of

dissolved solids of a potable water supply. The purpose of each stage is described below:

Stage (1) – Sediment Filter: 5.0 micron filter designed to remove suspended particles like silt,

sand, or clay.

Stage (2) – Granular Activated Carbon: 20 x 50 mesh carbon designed to remove chlorine and

organics.

Stage (3) – Membrane Pre Filter: 1.0 micron filter designed to trap carbon fines and other

smaller suspended particles.

Stage (4) – Thin Film Composite Membrane: Polyamide reverse osmosis membrane that uses a

cross flow design to produce two product streams: permeate and concentrate. Permeate is the

purified stream that has >93% of dissolved solids removed. Concentrate is the removed salt

content that is sent to drain.

Conditions for Operation - Thin Film Composite Membrane:

Source Water Supply

System Pressure – 2.1 – 6.9 bar (30-100 psi)

Temperature – 4 - 38 ºC (40 - 100 ºF)

ph Range – 3.0 to 11.0

Maximum Supply TDS level – 2000 mg/L

Turbidity - < 1.0 net turbidity (NTU)

Chemical Parameter

Hardness - < 350 mg/L (<20 gpg)

Iron (Fe) - < 0.1 mg/L

Manganese - < 0.05 mg/L

Hydrogen Sulfide (H

2

S) – 0.00 mg/L

Chlorine (Cl

2

) – 0.00 mg/L

CAUTION: DO NOT USE THIS SYSTEM WHERE THE WATER IS MICROBIOLOGICALLY UNSAFE OR

OF UNKNOWN QUALITY. THIS SYSTEM IS FOR USE ON POTABLE WATER ONLY. SOURCE WATER

EXCEEDING CHEMICAL PARAMETERS REQUIRES PRETREATMENT.

M-0221201113 Page 3 of 7

Revision 4

System Installation:

Preparation:

Check the following components to ensure that all parts are packed with your system:

1 – Storage Tank

1 – Reverse Osmosis System

1 – Tubing Accessories

Determine the location for the installation of the RO system. Avoid locations where the system

might come in contact with hot water and other hazards. Make sure that a drain location is

provided for the RO system. An air gap is required to ensure that contamination is avoided from

other water sources. Determine the location of the storage tank. A maximum distance from RO

system to tank is 4.5 meters (15 feet).

All inlets and outlets are individually labeled for ease of installation:

(1/4”) FEED – Connects the feed water supply to the inlet of the sediment filter.

(1/4”) DRAIN – Connect the membrane brine port to drain.

(3/8”) TANK – Connect the membrane pure water port to storage tank.

(3/8”) SAMPLE – Connects the storage tank to the Gemini or Aries High Purity system inlet

(3/8”) OUTLET – Any additional outlets for RO water.

Fittings and Tubing:

Quick disconnect fittings are used throughout the system. To ensure an optimal seal, tubing

should be cut with the end square. An angled cut or distortion of the tubing will not provide an

efficient seal and may cause leaks.

To install a tube, push in the collet until it seats firmly. To remove a tube, push in the collet and

pull out the tube.

Secure connections are simple:

1) Cut the tube square and push past the O-ring to the tube stop

2) Tube is secured in position

3) Disconnection is just as easy

Push collet against body

Slide tube out of fitting

M-0221201113 Page 4 of 7

Revision 4

System Diagram:

Use good plumbing practices when installing the system. Isolation valves are recommended for

system isolation and maintenance. Connection to the Aries FilterWorks High Purity Water

system will be done only after the HPL-RO has been properly flushed.

System Set Up and Installation:

The system should be set up according to the diagram above. The tubing connections are labeled

for easy installation. Follow all local plumbing codes for correct installation.

DO NOT TURN ON THE WATER SUPPLY UNTIL AFTER ALL CONNECTION

HAVE BEEN MADE

1. Attach a 1/4” OD tube from the cold water supply to the FEED system inlet.

2. Attach a 1/4” OD tube to the DRAIN connection. The other end of the tube should be

connected to a drain or sink for the membrane reject water to flow. An air gap must

be left in this drain line so waste water does not back up into the membrane.

3. Connect the 3/8” OD tube from the TANK outlet on the RO system to the connection

on the RO storage tank assembly.

4. Connect a 3/8” OD tube from the RO-WATER connection on the RO system

assembly to polishing system.

5. DO NOT make the final connection to the polishing unit until the RO system and

cartridges have been properly flushed per the instructions below.

M-0221201113 Page 5 of 7

Revision 4

Activating the System for the First Time:

RO system must be properly flush prior to commissioning. A temporary line is required from the

storage tank to a drain or sink. Do not connect this line to the Aries Unit until the flush steps

have been complete.

DO NOT USE THE FIRST TWO RESERVOIRS OF WATER.

1. Make sure all water supply / drain lines are secure and free from leakage

2. Slowly open isolation valve on the inlet of the RO system. Check for leaks.

3. Open the storage tank valve.

4. While the final product valve is closed, allow the Storage tank to fill completely (this

should take about 4-6 hours). The concentrate flow to drain will stop when the tank is

full.

5. Dispense all of the water in the system to drain. This process removes the factory

installed sanitizing solution from the entire system and sends it to drain. Repeat this

process one more time. Allow the tank to fill for 4-6 hours and dispense to drain.

6. Connect the dedicated final product line to the Aries Filterworks HP unit for system

commissioning.

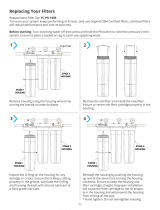

Maintenance:

Routine maintenance is essential to the longevity and performance of the system. Filters

should be changed quarterly and the RO membrane every six to twelve months depending on

the water quality.

Note that filters are labeled for easy servicing

1. Close the RO feed supply and Aries Filterworks HP valves. Close storage tank isolation

valve.

2. Using spanner wrench, remove 5 micron, GAC, and 1 micron filters. Replace with

cartridge kit AFK-005. Check o-ring seals to see if lubricant is needed. Use a silicone

based – petroleum free grease. Reassemble bowls. Avoid over-tightening.

3. If membrane replacement is required – proceed to the next step. Otherwise, turn open

isolation valves and inspect for leaks.

4. For membrane replacement, remove membrane feed line and unscrew housing cap.

Remove membrane from housing (pliers may be required). Install membrane (part

number AM-12-7010), screw on cap, and reconnect hose.

5. Open sample /drain valve upstream of Aries Filterworks system. Open RO Feed valve

and flush membrane for 4-6 hours to remove sanitant.

6. After system flush, close sample / drain valve and open storage tank and Aries

Filterworks valves.

M-0221201113 Page 6 of 7

Revision 4

Troubleshooting:

1. Problem: Not enough product water pressure

Reason: Storage tank air pressure is low

Solution: Empty storage tank and set pressure to 55kPa (8 psi)

2. Problem: Not Enough Water

Reason: Water supply is blocked

Solution: Clear restriction or check water supply

Reason: Storage tank is depleted

Solution: Consider an increase in tank size or membrane capacity

Reason: Clogged sediment cartridge

Solution: Replace sediment cartridge, drain tank, and sanitize system

Reason: Low water pressure

Solution: If line pressure is below 2.1 bar (30 psi), install a booster pump.

3. Problem: No drain water

Reason: Clogged flow restrictor

Solution: Replace membrane

Spare Parts:

Part Number: AFK-005

Replacement Filter Kit (5.0 micron filter, GAC, 1.0 micron filter)

Part Number: AM-12-7010

Membrane: TFC 100 GPD, Residential style

M-0221201113 Page 7 of 7

Revision 4

Limited Warranty:

Aries FilterWorks warrants its HPL-RO reverse osmosis system to be free from defects in

materials and workmanship under normal use within the operating parameters as stated.

Warranty period is for 12 months for any part of the RO unit with the exception of the membrane

and filters. Warranty shall not apply to any part of the system package that is damaged because

of neglect, misuse, alteration, bacteria attack, sediment or damage by fire, freezing, hot water, or

an Act of God.

Warranty Service:

Aries FilterWorks will provide warranty service under the following conditions:

1. Contact Aries Filter Works to obtain return authorization instructions.

2. Ship the unit or part freight prepaid to Aries FilterWorks for warranty evaluation. Unit

must be returned in the original carton or prepackaged to prevent possible damage.

Systems or parts covered under the warranty shall be repaired (or, at our option replaced)

and returned without charge.

Contact Information

Aries FilterWorks

Division of ResinTech, Inc.

Berlin, NJ 08009

Ph: (856) 626-1550

Fax: (856) 626-1551

email: [email protected]

www.ariesfilterworks.com

/