VSeries

Acidic Condensate Wastewater and

Air Conditioning Non-Acidic

Wastewater Removal System

Models: V-125

V-250 / V-250 Combi

V-252 / V-253

Revised - June, 2018

Installation Operation & Maintenance

14 Coleman Ave. Westeld, MA 01085

413-527-1893

690 Island Way Unit 206, Clearwater, FL 33767

413-427-3373

jjmboilerworks.com

1

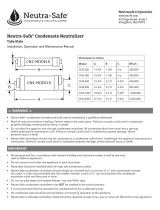

How much reside condensate will my equipment develop?

Hot water heaters / Boilers / Furnaces / Economizers

Multiple Boiler Common Flue drains: 33.3% of total BTU input of connected equipment.

Example: (3) Boilers @ 100,000 BTU Input would need a pH treatment kit rated @ 100,000

BTU for the stack drain and a flow rate of .725 to .798 depending on efficiency.

Consider the following when choosing a neutralizer for less maintenance during operation

of your heating equipment.

1. Your location in relation to weather (Very Cold, Cold, Moderately Cold)

2. System Design (Process, Radiate, Snow Melt, Heating, etc.)

3. Yearly Operating Hours

4. pH level out of heating equipment (3.2 to 4.0 is normal)

5. If pH out of the heating equipment is below 3.2 pH contact the factory for sizing.

6. Abnormally low pH out of the equipment condensate drain can be caused by the following:

A. Improper Combustion

B. Contaminated Combustion Air

C. High Sulfur Content in Gas Supply

D. pH below 2.0 is considered hazardous waste by EPA. Contact JJM Technical

Service at 413-427-3373 or 413-527-1893

JJM highly recommends operating your heating equipment for 24-48

hours prior to connecting a neutralizer so as to flush out dirt, grease, and

oils from connected piping and the heater. This is also the best time to check

the heater condensate pH level for sizing your neutralizer.

!

WARNING

JJM neutralizers are sized by BTU input to establish a ow rating.

Job site conditions will determine neutralizer design. See GPH chart below.

Equipment Efciency GPH Condensate

90% .725 / Per 100,000 BTU Input

91% .733 / Per 100,000 BTU Input

92% .741 / Per 100,000 BTU Input

93% .750 / Per 100,000 BTU Input

94% .758 / Per 100,000 BTU Input

95% .766 / Per 100,000 BTU Input

96% .774 / Per 100,000 BTU Input

97% .782 / Per 100,000 BTU Input

98% .790 / Per 100,000 BTU Input

99% .798 / Per 100,000 BTU Input

ALL JJM NEUTRALIZING PRODUCTS

Inspect frequently

Installer — Instruct the building owner to frequently inspect

the V Series cannister cartridge neutrazlier and all condensate

connections. e owner must notify a qualied technician if any

problems are noticed.

Recharge as required

Follow the requirements on page 2 for recharging or replacing

the V Series cartridge. Follow instructions at right.

Replacement parts

Contact JJM® Boiler Works, your local wholesaler or manufac-

turer’s representative for replacement parts and rell kit.

Maintenance

!

DANGER

Install all electrical wiring in accordance with the National

Electrical Code and local requirements.

Indicates a condition or hazard which will cause severe

personal injury, death or major property damage.

!

WARNING

Indicates a condition or hazard which may cause severe

personal injury, death or major property damage.

!

CAUTION

Indicates a condition or hazard which will or can cause

minor personal injury or property damage.

!

NOTICE

Indicates special attention is needed, but not directly related

to potential injury or property damage.

!

NOTICE

is unit when installed must be electrically grounded in

accordance with the requirements of the authority having

jurisdiction or , in the absence of such requirements, with

the current edition of the National Electrical Code, ANSI/

NFPA 70 and/or the Canadian Electrical Code, Part 1, CSA

C22.1, Electrical Code.

!

CAUTION

Label all wires prior to disconnection when servicing con-

trols. Wiring errors can cause improper and dangerous

operation. Verify proper operation aer servicing.

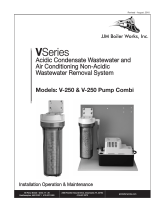

Model V-250 Combi

Electrical Rating: 115/1/60 Amps: 1.5A/Single Pump

ermally Protected

Indoor use only

Model: VCMA-20UL / Little Giant

Head: 8.6 PSI Max

Application:

e V Series canister neutralizer is best applied to wall mounted

condensing hot water heaters, boilers. e V-250 pump combi

model is best applied when a condensate pump is needed to

transfer the treated acidic condensate wastewater to a remote

drain location. All acidic condensate wastewater is gravity fed

from the appliance condensate outlet port to the V-250 inlet

port. e V-250 pump combi can also be used for non acid air

conditioning condensate removal. Simple pipe to either of the

spare inlet ports on the pump tank.

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

2

Read before proceeding

Failure to comply with these guidelines could

result in severe personal injury, death or

substantial property damage.

Canister and lines must be wet

Before operating a V-series neutralizer with a hot

water heater, boiler, furnace, or ue stack drain

ll the V-series canister and all “P” traps with

fresh tap water. NEVER operate with the canister

or “P”traps dry

Application restrictions

• Flue stack drains, condensing boilers, furnaces and hot

water heaters

• Flue pipe condensate drains

• DO NOT exhaust ue gases through the V Series canister,

is not rated for boiler or furnace ue gases. Operating

the V Series canister as exhaust vents can cause injury

or death from carbon monoxide.

• Gas traps must be installed between the boiler, vent drains,

hot water heaters and furnace condensate outlet and the

inlet of all V Series canisters.

• e V Series canister must be installed below sysem P-

traps, boiler, furnace, and breeching condensate drains.

Combined piping options

Flue pipe condensate drains

• Boiler/furnace condensate drain/hot water hearter and

ue condensate drain can be commonly piped to a V

Series canister. Also, the ue pipe must be terminated

so rain water cannot enter the ue pipe.

Recharge canisters regularly

• Canisters should be recharged when pH level moves

below 5.0. e pH should be checked regularly (at least

twice during the rst year of operation) to determine the

required recharging schedule.

!

DANGER

What is pH?

e pH measurement of a uid is an indicator of the acidity or

alkalinity. Neutral uids have pH of 7.0. Acid uids have pH below

7. And alkaline uids have pH above 7 (up to 14). e pH can be

easily measured using digital pocket pH probe

Condensate pH from condensing boilers and furnaces is typically

around 4. e condensate pH needs to be increased (made more

neutral) to prevent possible damage to cast iron soil pipe, ABS

pipe, septic tanks, plants, wastewater treatment plants and other

materials handling waste water.

V-series condensate neutralizing canisters

increase pH (reduce acidity).

V-series commercial re-side condensate treatment canisters are

designed to raise the pH level of the condensate discharged by

high-eciency boilers and warm air furnaces.

Each change of 1.0 in pH is a 10-times reduction (or increase) in

concentration. e pH of condensate is increased by approxi-

mately 1.0 to 4.0 higher aer passing through NB neutralizing

tanks.

Applying V-series neutralizing canisters

Condensate can be collected from ueways and boiler/furnace/

hot water heater condensate trap outlets. See WARNING section

at le for guidelines on application.

See the JJM sizing chart located on our website,

www.jjmboilerworks.com.

Discharge lines may be mounted overhead with the V-250 pump

combi model.

Follow the guidelines in this manual, the boiler/furnace manual

and all applicable local codes when installing, using and main-

taining V-series Condensate pH treatment canisters.

Installation sequence

1. e V Series must be wall mounted a minimum of 1.75” above

the oor level to be able to remove the canister when replacing the

inner cartridge.

2. e V-250 pump combi can be oor or wall mounted since it is a

factory packaged unit already maintaining the 1.75” for canister

removal.

3. All V-series units must be installed below the appliance condensate

outlet drain. is will allow for gravity ow into the neutralizer inlet

port, through the V-series canister and out the V-series outlet port.

Never use any pumps BEFORE the V-series inlet port. Use only PP

tubing, PVC Pipe, CPVC Pipe, or stainless steel pipe when connect-

ing any JJM neutralizing product.

4. Use PP tubing from the V-250 pump combi units pump outlet port

to the nearest house waste drain.

5. Always use a water trap between the appliance condensate outlet

port and the V Series inlet port.

6. NOTE: Always consult the local authority regarding any require-

ments concerning ue gas condensate handling codes.

7. Connect piping using today’s modern piping practices. See Figures

1,2,3, & 4 for JJM® piping.

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

Overview

3

Recharging procedure

To recharge any V-250 series product order part number 4003 for each neutralizer. Shut o all electrical power to all heating units. Remove the

outer canister by turning it counter-clockwise. Remove the inner pellet cartridge and clean out any debris le in the canister. Replace the inner

pellet cartridge with a new cartridge. Return the outer canister to the V-250 cap by twisting it on clock-wise. Return system to full operation

and check for any leaks.

Never pipe the outlet of a neutralizer directly to a pipe, outlet should be piped to an open drain or open

wastewater trap.

LEGEND

1. Flue Pipe

2. Trap

3. V-250 Inlet

4. V-250 Outlet

5. Drain Line

6. Drain

7. V-250 / V-125

8. Tee Vent Open To Atmosphere

BOILER

OR

HOT WATER

HEATER

Installation

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

4

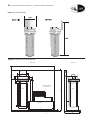

Figure 1 Piping diagram for wall hung heater/V Series vertical

pH treatment canister to drain.

LEGEND

1. Flue Pipe

2. Trap

3. V-250 Inlet

4. V-250 Outlet

5. Drain Line

6. Drain

7. V-250 Combi

8. Tee Vent Open To Atmosphere

BOILER

OR

HOT WATER

HEATER

MODEL MBH GPH

V-250 250 1.90

V-125 125 .90

Figure 2 Piping diagram for wall hung heater/V-Series vertical pH treatment canister with receiver pump.

Figure 4 Piping diagram for wall hung heater / V-253 vertical pH treatment canisters.

Figure 3 Piping diagram for wall hung heater / V-252 vertical pH treatment canisters.

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

Installation

5

LEGEND

1. Flue Pipe

2. Trap

3. V-252 Inlet

4. V-252 Outlet

5. Drain Line

6. Drain

7. V-252

8. Tee Vent Open To Atmosphere

BOILER

OR

HOT WATER

HEATER

B2

B1

MODEL MBH GPH

V-252 500 3.80

MODEL MBH GPH

V-253 750 5.70

LEGEND

1. Flue Pipe

2. Flue Drain

3. V-253 Inlet

4. V-253 Outlet

5. Drain Line

6. Drain

7. Traps

8. V-253

9. Common Drain

10. Tee Vent Open To Atmosphere

B2

B1

B3

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

Installation

6

Figure 5 Exploded View of V-125

RATING: 125 MBH

V-125 CANISTER

rev. 12/19/17

4.5”

9.375”

6.75”

INLET/OUTLET PORT 1/2” NPT

RATING: 125 MBH

7

Bracket

4.5" x 2.5" x 3"deep

1

3

5

2

Sump Pump

7

8

9

1011

12

13

Wiring Harness

115vac / 6ft.

Bracket Screws

4x, 8-18 x 1"

4

6

SGNA

06/21/16----

V-250 Pump Combination Unit Parts

JJM BOILER WORKS INC.

Figure 7 Exploded view of V-250 pump combi

Figure 6 Exploded View of V-250

4

1

2

"

2

1

2

"

Bracket

4.5" x 2.5" x 3"deep

1

3

4

5

2

Bracket Screws

4x, 8-18 x 1"

4

Bracket Screws

4x, 8-18 x 1"

D:\6_praca\firmy\YourSpreadsheets\_ icons and history\YS logo.jpg

SGNA

06/13/16----V250 part numbers

V-250 Part Numbers

JJM BOILER WORKS INC.

DETAIL PART PART NUMBER

1 Bracket 4001

2 10” Outer Canister with gasket 4002

3 Inner Cartridge with pH Power Pellets® 4003

4 4x; 8-18 x 1” bracket screws 4004

5 Canister Cover with inlet and outlet ports 4005

JJM Boiler Works, Inc.

V-250 Part Numbers

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

Installation

V250 Pump Combination

Unit Dimensions

4

1

2

"

1

1

4

"

3

4

"

3

4

"

3

5

8

"

9

1

4

"

1'-6"

1'-4

1

2

"

1

2

"

3

1

2

"

4

3

4

"

1

1

2

"

3

1

2

"

2"

Sump Pump

9

5

8

"

6

1

2

"

FRONT VIEW

SIDE VIEW

Sump Pump

V250

V250

D:\6_praca\firmy\YourSpreadsheets\_ icons and history\YS logo.jpg

SGNA

06/21/16----

V-250 Pump Combination Unit Dimensions

JJM BOILER WORKS INC.

Figure 9 V-250 pump combi dimensions

Figure 8 V-250 dimensions

V-250 CANISTER

rev. 07/13/2017

8

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

Figure 11 V-253 dimensions

Installation

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

+

+

+

+

+

+

+

+

+

+

+

+

17.375”

6.5”

17.375”

14.5”

14.5”

6.5”

+

+

+

+

+

+

+

+

+

+

+

+

17.375”

6.5”

17.375”

14.5”

14.5”

6.5”

Figure 10 V-252 dimensions

+

+

+

+

+

+

+

+

10.75”

6.5”

10.75”

14.5”

14.5”

6.5”

9

Install all electrical wiring in accordance with the National Electrical Code and local requirements.

!

NOTICE

is unit when installed must be electrically grounded in accordance with the requirements of the authority having juris-

diction or , in the absence of such requirements, with the current edition of the National Electrical Code, ANSI/NFPA 70

and/or the Canadian Electrical Code, Part 1, CSA C22.1, Electrical Code.

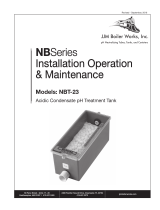

Figure 12 V-125, V-250, V-252 & V-253 / Wall Mounting

V-200 Vertical Mount Canister

1/2” x 4” Single Stud Wall Mount 1/2” x 4” Double Stud Wall Mount

Mount at least 1 3/4” above oor

STUD STUD STUD

FLOOR

Installation

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

10

Revised - June, 2018

14 Coleman Ave. Westeld, MA 01085

413-527-1893

690 Island Way Unit 206, Clearwater, FL 33767

413-427-3373

jjmboilerworks.com

Installation

Vseries Acidic Condensate pH Treatment Kits –– Installation/Operation & Maintenance

Maintenance Procedures

Getting the most out of your JJM

®

Neutralizer

Acidic wastewater neutralizers like all ltering devices need both maintenance and replacing. e average pH level of acidic waste-

water produced by today’s condensing boilers, hot water heaters, furnaces, ue stack drains, and stack economizers is 3.2pH. When

using a passive Inline Tube, Tank, or Canister the range of pH modication will fall in between 5.0 and 9.5 pH.

When the pH falls below 5.0 at the outlet port of any neutralizer the active ingredient must be replaced. Media replacement schedule

will depend on several factors including Operating Hours, Eciency, System Design, and Neutralizer Piping Scheme. e active

ingredient in the case of JJM® products is Magnesium Hydroxide Pellets. e trade name is pH Power Pellets®.

Before changing the pellets when the pH level falls below 5.0 you can get the most out of your neutralizer by rst agitating the pellets.

In the case of an inline tube products try lightly tapping the outer sides of the tube with a rubber mallet several times and then check

the pH level once again at the outlet port. You may nd that your pH level has risen back into the 5.0 to 9.5pH range.

When your neutralizer is a tank product with loose pellets you can simply use a wooded dowel to stir the pellets and again use

fresh tap water to ush out the tank.

If your neutralizer pellets are incased in a porous pellet bag there are three methods to agitating the pellets:

1. Remove the pellet bag or bags from the tank and using your hands move the pellets around inside the bags.

2. Using a ve gallon bucket lled with fresh tap water, use step one with the bag under water.

3. Using a fresh water hose slowly pour fresh water over both sides of the pellet bag and also use method one.

If the pH level is has not risen back into the safe range of 5.0 to 9.5 pH the pellets must be replaced.

If you have our Model V-250 or V-250 Combi vertical canisters try the following method:

1. Twist o the outer canister to get access to the inner pellet cartridge and over a ve gallon pail shake the Cartridge several times

to agitate the pellets.

2. Again using a ve gallon pail lled with fresh tap water let the cartridge soak for ve minutes under water and then drain and hand

shake the cartridge to agitate the pellets. Also clean out any sediment which may be held within the outer canister.

DURING ALL OF THE ABOVE PROCEDURES THE FOLLOWING SAFETY ITEMS MUST BE USED:

1. WEAR SAFETY GLASSES

2. WEAR RUBBER OR LATEX PROTECTIVE GLOVES

3. SHUT OFF ALL ELECTRICAL POWER TO THE HEATING UNIT OR UNITS BEFORE SERVICING YOUR

NEUTRALIZERS.

e pellets are Non-Hazardous and can be disposed of in your normal refuge.

MSDS sheets can be found online at www.jjmboilerworks.com.

Any questions can be directed to JJM Boiler Works, Inc. at

413-527-1893 or at www.jjmboilerworks.com

George Carney, President, JJM Boiler Works, Inc.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

JJM Boiler Works V-125 Operating instructions

- Type

- Operating instructions

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Other documents

-

ESAB CC-11 Pump Replacement User manual

-

JJM 4000 User manual

JJM 4000 User manual

-

Green Gobbler GGPSIM-35 User manual

Green Gobbler GGPSIM-35 User manual

-

Green Gobbler GGPSIM-25 User manual

Green Gobbler GGPSIM-25 User manual

-

Green Gobbler GGPSIM-15 User guide

Green Gobbler GGPSIM-15 User guide

-

Little GIANT VCMA-20 Owner's manual

-

JJM 2009 User guide

JJM 2009 User guide

-

JJM CBM-225R User manual

JJM CBM-225R User manual

-

JJM 2009 Operating instructions

JJM 2009 Operating instructions

-

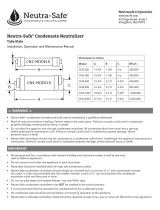

Neutrasafe Corporation CN2-220 Installation guide

Neutrasafe Corporation CN2-220 Installation guide