Page is loading ...

System V900063

2002 - 2005 GMC 2500 HD - 3500

6.6L Duramax Diesel

www.vmacair.com

VR70 UNDERHOOD

AIR COMPRESSOR

INSTALLATION MANUAL

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201 1

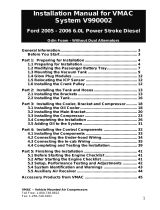

Installation Manual for VMAC

System V900063

General Motors 2002 – 2005 Duramax Diesel

2500 HD – 3500

General Information..................................................................... 3

Before You Start ....................................................................... 3

Special Installation Notes ......................................................... 4

Part 1: Preparing for Installation............................................... 5

1.1 Preparing for Installation................................................. 5

Part 2: Installing the Tank and Hoses....................................... 10

2.1 Installing the Tank and Brackets ........................................ 10

2.2 Installing the Tank Assembly.............................................. 13

Part 3: Installing the Main Bracket and Compressor.............. 15

3.1 Installing the Main Bracket ................................................. 15

3.2 Installing the Cooler............................................................ 18

3.3 Connecting the Hoses ........................................................ 19

3.4 Mounting the Fuel Module and Hoses ............................... 20

3.5 Completing the Installation ................................................. 26

3.6 Adding Oil to the System.................................................... 29

Part 4: Installing the Control Components .............................. 30

4.1 Installing the Components.................................................. 32

4.2 Connecting the In-cab Wiring ............................................. 33

4.3 Connecting the Under-hood Wiring.................................... 33

4.4 Connecting the Power Supply Wire ................................... 36

4.5 Completing and Testing the Installation ............................. 37

Part 5: Finishing the Installation................................................ 38

5.1 Before Starting the Engine Checklist ................................. 38

5.2 After Starting the Engine Checklist..................................... 39

5.3 Setup, Performance Testing and Adjustments................... 40

5.4 System Identification and Warnings................................... 41

5.5 Auxiliary Air Receiver ......................................................... 42

Accessory Products from VMAC............................................... 43

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201

2

Installation Manual - Document #1930014

Installation Manual for VMAC System V900063

General Motors 2002 – 2005 Duramax Diesel

2500HD - 3500

Changes and Revisions

Version Revision Details Revised by/date Approved Implemented

00 Original manual IB 10 Feb 2004 SC 23 Apr 2004 23 Apr 2004

a General revisions IB 14 Oct 2004 SM/BC 18 Jan 2005 18 Jan 2005

b Sched. review, minor graphic IB 13 Apr 2005 SC 13 Apr 2005 15 Apr 2005

c Main bracket mount IB 15 Sep 2005 SM 20 Sep 2005 23 Sep 2005

d ECN 06-179 main brkt bolt IB 13 Aug 2006

Important Information

The information in this manual is intended for certified VMAC

installers who have been trained in installation procedures and for

people with mechanical trade certification who have the tools and

equipment to properly and safely perform the installation. Do not

attempt this installation if you do not have the appropriate

mechanical training, knowledge and experience.

Follow all safety precautions for underhood mechanical work. Any

grinding, bending or restructuring operations for correct fit in modified

vehicles must follow standard shop practices.

These instructions are a general guide for installing this system on

standard production trucks and do not contain information for

installation on non-standard trucks. This system may not fit special

order models or those which have had other changes without

additional modifications. If you have difficulty with the installation,

contact VMAC.

The VMAC warranty form is located at the back of this manual. This

warranty form must be completed and mailed or faxed to VMAC at

the time of installation for any subsequent warranty claim to be

considered valid.

To order parts, contact your VMAC dealer. Your dealer will ask for

the VMAC serial number, part number, description and quantity. To

locate your nearest dealer, call 1-800-738-8622.

Copyright 2005

All trademarks used in this manual are the property of the respective copyright holder.

The contents of this manual may not be reproduced in any form without the express

written permission of VMAC, 1333 Kipp Road, Nanaimo, BC V9X 1R3.

Printed in Canada

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201 3

General Information

Before You Start

Read this manual before attempting installation so that you can

familiarize yourself with the components and how they fit on the

vehicle. Identify variations for different model years and different

situations that are listed in the manual. Open the package, unpack

the components and identify them.

All fasteners must be torqued to specifications. Use manufacturers

torque values for OEM fasteners. Apply Loctite 242 or equivalent on

all engine-mounted fasteners. Torque values are with Loctite applied

unless otherwise specified.

STANDARD GRADE 8 NATIONAL COARSE THREAD

Size 1/4 5/16 3/8 7/16 1/2 9/16 5/8 ¾

Foot-pounds (ft-lb) 9 18 35 55 80 110 170 280

Newton meter (N•m) 12 24 47 74 108 149 230 379

STANDARD GRADE 8 NATIONAL FINE THREAD

Size 3/8 7/16 1/2 5/8 ¾

Foot-pounds (ft-lb) 40 60 90 180 320

Newton meter (N•m) 54 81 122 244 434

METRIC CLASS 10.9

Size M8 M10 M12 M14 M16

Foot-pounds (ft-lb) 19 41 69 104 174

Newton meter (N•m) 25 55 93 141 236

Hose Coding

Different frame designations will affect the tank mounting position.

You may have to move the tank rearward from the standard position

on your application. If you must move the tank, the lines may be too

short. If this is the case, measure the hose shortfall and order a

Hose Extender Kit. The following table shows the color code used

by VMAC to define the different hose diameters.

Hose Diameter Colour-Coded Label

1/4 inch

5/16 inch

1/2 inch

5/8 inch

3/4 inch

1 inch

Yellow

Orange

Blue

Blue

Green

Green

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201

4

Special Installation Notes

The following special tools are required:

• 36 mm 12 point 1/2 inch drive socket for removing the OEM

crankshaft bolt

• crankshaft locking tool (GM #J-44643) or VMAC equivalent

(Part #5900010)

• VMAC crankshaft pin extraction tool (Part #5900076)

The following additional materials are recommended:

• assorted sizes of fireproof protective plastic loom

• assorted lengths of nylon tie-straps

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201 5

Part 1: Preparing for Installation

1.1 Preparing for Installation

Preparation for installation is very important. Missing an item can

cause problems in the installation or even damage to components.

Check off each item as it is completed so that you do not miss any

preparation steps.

□ Disconnect the batteries.

□ Drain the coolant.

□ Disconnect the MAF sensor wire from the air cleaner and

remove the complete air intake assembly, complete with rubber

air intake pipe, air ducting and the plastic intake resonator

chamber from the top of the engine.

□ Remove the plastic inner fender liner on the passenger side.

□ Disconnect the hoses from the coolant expansion tank,

disconnect the level sensor connector and remove the tank.

□ Remove the air cleaner base mounting plate and the air cleaner

support bracket.

□ Remove the top radiator hose.

□ On trucks with an automatic transmission, remove the automatic

transmission control module (ATCM) and cover assembly from

the driver’s side of the upper fan shroud. Move the module out of

the way but do not disconnect the wire harness.

□ Remove the upper fan shroud.

□ Remove the fan using the appropriate fan wrench.

□ Remove the passenger side intercooler tube and hoses.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201

6

□ Remove and discard the metal coolant tube between the heater

hose and the lower radiator hose.

□ Remove the bolt securing the oil filler tube to the front of the

intake manifold.

□ Disconnect the fuel inlet and outlet banjos from the fuel

management module, remove the module and move it out of the

way. Remove the rubber washers, plastic spacers, mounting

bolts and banjo fitting seals so they will not get lost.

□ Remove the OEM belt.

□ Remove all wire harness retainers from the OEM alternator

mount bracket.

□ Remove the alternator.

□ Remove the OEM idlers and tensioner from the alternator mount

bracket.

□ Remove the OEM alternator mount bracket.

□ Remove the rock guard from under the front of the truck. Keep

the bolts.

□ Remove the lower radiator hose.

□ Install a crankshaft locking tool, remove the crank pulley bolt and

remove the crank pulley. If you are using the VMAC tool:

• put the socket on the nut

• put the single-pin end of the tool on the front of the pulley with

the locking tool hanging straight down

• put a short extension and long flex-bar on the socket

• turn the engine until the pin on the tool makes contact and the

tool jams against the protruding center-piece of the cross-

member under the front of the engine

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201 7

□ Remove the crankshaft pin using the VMAC extraction tool:

• fit the split end of the tool (on the end of the shaft) over the

crankshaft pin and tap downward with the slide-hammer to

make sure that it is seated correctly

• tighten the pinch bolt securely

• use the hammer action of the slider in an upward motion to

remove the pin from the crankshaft

□ Install the replacement crankshaft/harmonic balancer locating pin

and tap it home using a brass drift and a small hammer. Ensure

that the head of the pin is aligned with the crankshaft by twisting

it into position with a crescent wrench (Figure 1.1).

High-strength

crank pin

Figure 1.1

□ Apply a light wipe of oil to the inside of the OEM crank pulley and

install the pulley back onto the crankshaft.

□ On trucks after 2004.5, remove and discard the OEM cast

mounting bracket from the front of the engine.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201

8

1.1.1 Trucks prior to 2004.5

□ Remove the breather hose from between the lower engine block

and the check valve in the bottom of the breather chamber

casting (Figure 1.2).

Breather check valve

Figure 1.2

□ Remove the 8 mm bolt from the cast alternator mounting bracket

that holds the breather tube and wire harness (Figure 1.3).

□ Remove the bolt securing the engine breather hose and steel

pipe from the breather chamber in the cast aluminum bracket

and remove the hose and pipe.

□ Cut the tie wrap holding the loom and breather tube together.

□ Remove and discard the steel breather pipe from the end of the

rubber breather hose.

□ Remove the two nuts from the fuel bleed valve studs.

□ Remove the short fuel outlet hose and angled banjo fitting from

the engine-side fuel rail. Remove the banjo from the hose and

discard the hose.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201 9

Engine breather chamber

Fuel bleed valve studs

8 mm bolt

for breather

tube clamp

Breather tube

Figure 1.3

□ On trucks up to 2004.5, remove the OEM check valve fitted in

the bottom of the casting.

□ Remove and discard the cast mounting bracket.

□ Remove the two OEM studs from the engine block, located

below the alternator mount, that held the OEM bracket in place.

□ Unclip the top of the wire harness plastic channel attached to the

engine fuel rail, carefully lift out the wiring and cut the ties

holding the module-end of the channel.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201

10

Part 2: Installing the Tank and

Hoses

2.1 Installing the Tank and Brackets

The tank will mount to the passenger side frame rail between the two

body mounts (Figure 2.1).

1/4” line

5/16” line

3/4” hose fitting

1/2” hose fitting

C-clamp

Tank strap mount

Tank strap cable

Tube clamp

Oil filter

5/16” nuts and

washer

Tank strap flat bar

Figure 2.1

□ Remove the oil filter from the front of the tank, fill it with

compressor oil, cover it and place it out of the way.

□ Place the tank on a work bench with the front (oil filter end) of the

tank to your left.

□ Remove the two 1/4 inch pinch bolts from the C-clamps. Expand

the clamps slightly, slide them over the front of the tank and

position them about 6 inches from each end of the tank.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201 11

□ Place the two L-shaped tank strap mounts under the C-clamps

with the right-angle ends facing you and hanging over the edge

of the work bench.

□ Apply Loctite and thread 5/16 x 1/2 inch bolts with flat washers

into the bottom hole on each bracket, but do not tighten.

□ Install the 1/4 inch pinch bolts into the C-clamps so that the

heads of the bolts face toward you and install the nuts.

□ Rotate the tank so that the directional arrow on the end of the

tank is parallel to the work bench and faces toward you (Figure

2.2), check the distance of each C-clamp from the ends of the

tank and tighten the pinch bolts so that the clamps grip the tank

securely.

Figure 2.2

□ Thread the 1/4 and 5/16 inch fittings on the steel lines to the

matching fittings on the back end of the tank, but do not tighten

the fittings. Route the lines along the top of the tank across the

two C-clamps.

□ Place the two insulated tube clips over the steel lines with the

mounting holes downward and align them with the top C-clamp

mounting holes (Figure 2.3).

□ Apply Loctite and insert 5/16 x 1/2 inch bolts through the clips

and the C-clamp and thread them into the mount brackets.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201

12

□ Center the bolts in the C-clamp slots and tighten them.

Tank strap mount

5/16" tub

e

1/4" tube

Insulated double tube clamp

5/16" x 1/2" bolt

Figure 2.3

□ Apply Loctite pipe thread sealant and install a 90 degree fitting to

the outlet on the tank. Tighten it to about the four O’clock

position (Figure 2.4) for testing, then reposition as required for

operational connections.

Figure 2.4

□ Thread the 1/2 inch 45 degree elbow and the 3/4 inch 90 degree

elbow onto the matching fittings on the front of the tank, but do

not tighten them.

□ Push the insulated tube clips toward the tank to provide

clearance for the mounting cables (Figure 2.5).

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201 13

Push forward slightly for cable clearance

Figure 2.5

2.2 Installing the Tank Assembly

□ On 2500 HD models, install the 1/2 inch spacer on each cable

strap and slide them to the stop ends of the cables.

□ Insert the threaded ends of the cable straps through the end hole

on each of the bar straps.

□ Place the bar straps in position on the inside of the frame, one in

front of the transmission cross-member and one behind, with the

cable straps over the top of the frame (Figure 2.6).

□ Lay the tank assembly under the passenger side of the vehicle

and route the 5/16 and 1/4 inch hoses over the top of the body

mount into the engine compartment.

□ Lift the tank assembly and support it in position so the tops of the

two tank strap mounts fit over the top of the frame rail. If there is

an OEM wire harness, make sure that it is outside the mounts

and is not pinched between the mounts and the frame.

□ Wrap the two tank cable straps around the tank strap mounts.

Make sure that they fit in the upper and lower cut-outs of the tank

strap mounts (Figure 2.6).

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201

14

Cable must fit

in the grooves

Figure 2.6

□ Insert the threaded end of the cable through one of the lower

holes on the tank strap flat bars. Select the appropriate hole that

best matches the frame of the vehicle.

□ Place a 5/16 flat washer and nut on each tank cable strap and

tighten just enough to hold the tank in place but loose enough to

allow the tank to be positioned along the frame.

□ Slide the tank rearward on the frame to provide clearance for

attaching the hoses.

□ Route the straight ends of the 3/4 inch hose and longest 1/2 inch

hose from the engine compartment over the body mount to the

tank, connect them to the matching fittings on the tank, but do

not tighten.

Make sure that the cable straps are behind the two steel

lines and that no OEM lines or wires are pinched

between the cable and the mount.

!

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201 15

Part 3: Installing the Main Bracket

and Compressor

3.1 Installing the Main Bracket

□ Remove the three socket head bolts and remove the belt

tensioner assembly (complete with mounting pad) from the VR

main bracket.

□ On trucks before 2004.5, transfer the OEM check valve from

the alternator cast bracket to the bottom of the VR main bracket.

□ Remove the plastic caps and remove the four M10 x 85 mm low

profile socket head screws from the bracket. Place the bracket in

position on the front of the engine.

Install OEM

back idler here

M10 x 85 mm

socket head bolts

(one behind the VR tensioner

)

Install the OEM

tensioner here

Figure 3.1

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201

16

□ Apply Loctite and thread the four M10 x 85 low profile socket

bolts in just enough to hold the bracket in place (Figure 3.1).

Check the fit of the bracket against the engine to make sure that

it fits flat and has no obstructions, tighten the bolts evenly and

then torque them to specifications.

□ Apply Loctite and install the VR tensioner, the OEM belt

tensioner and one OEM back idler (Figure 3.1).

□ Install the alternator.

□ Place the VR crank pulley in position with the two roll pins on

both sides of the counter balance weight of the OEM pulley

(Figure 3.2).

Position the roll pins here

Figure 3.2

□ Apply Loctite and thread the M18 x 100 mm center bolt with

OEM washer into the crankshaft. Install an engine-locking tool

and torque the center bolt to 200 ft-lbs (280 N.m).

□ Install the OEM belt (Figure 3.3) on trucks built before 2004.5; on

trucks after 2004.5, use the replacement belt.

□ Remove the nuts and bolt holding the compressor to the

packaging base.

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201 17

OEM ribbed idler

OEM tensioner

Alternator

OEM back idler

A/C

P/S

Fan

OEM crank pulley

Figure 3.3

□ Attach the straight end of the short 1/2 inch hose to the fitting on

the side of the compressor with the hose routed over the top of

the compressor just behind the clutch assembly. Tighten the

fitting.

□ Place the compressor on the mounting bracket, apply Loctite and

install the two nuts and the supplied bolt (shorter than the one

you discarded) to the underside of the compressor. Torque them

to 19 ft-lbs (25 N.m).

□ Install the VR drive belt (Figure 3.4).

VMAC – Vehicle Mounted Air Compressors

Toll Free: 1-800-738-8622

Fax: 1-250-740-3201

18

VR70 Tensioner

VR70 Ribbed idler

VR70 Compressor

VR70 Idler

Crankshaft pulley

Figure 3.4

3.2 Installing the Cooler

□ Apply Loctite and attach the cooler to the rock guard, (with the oil

hose connections facing to the rear) using the 5/16 x 1/2 inch NC

bolts, then install the assembly to the vehicle using the OEM

fasteners (Figure 3.5).

1/2” hose

to compressor

1/2” hose from tank

Figure 3.5

□ Remove and discard the coolant fill hose plastic alignment clips

from the OEM lower radiator hose.

□ Cut the lower radiator hose to length (Figure 3.6). The third cut

may vary slightly according to vehicle model.

/