Tel: (215) 535-8900 • Fax: (215) 535-9736 • www.crownboiler.com

Manufacturer of Hydronic Heating Products

P.O. Box 14818 3633 I. Street

Philadelphia, PA 19134

BWF Series

Gas-Fired Fan Assisted Hot Water Boilers

INSTALLATION INSTRUCTIONS

These instructions must be affixed on or adjacent to the boiler

WARNING: Improper installa-

tion, adjustment, alteration,

service or maintenance can

cause property damage, injury,

or loss of life. For assistance or

additional information, consult a

qualified installer, service

agency or the gas supplier.

This boiler requires a special

venting system. Read these

instructions carefully before

installing.

Models:

• BWF061

• BWF095

• BWF128

• BWF162

• BWF195

• BWF229

CROWN

Boiler Co

1

I Product Description………………………... 2

II Specifications……………………………….. 2

III Before Installing……………………………..

3

IV Locating the Boiler…………………………..

3

V Air for Combustion and Ventilation………… 5

VI Venting……………………………………….

9

Horizontal Vent System Design………..

9

Vertical Vent System Design…………... 14

Vent System Assembly…………………. 18

VII Gas Piping………………………………… 25

VIII System Piping………………………………. 26

IX Wiring……………………………………….. 31

X Start-up and Checkout……………………… 36

XI Service and Maintenance………………….. 40

XII Troubleshooting Charts…………………….. 43

XIII Parts…………………………………………. 47

Table of Contents

2

I Product Description

The BWF series boiler is a cast iron gas fired boiler designed for use in forced hot water heating systems. The BWF is

intended for installations where a usable chimney is not available. The BWF is normally vented using an approved vertical or

horizontal AL29-4C stainless steel venting system, which is not included with the boiler. If a suitable chimney is available, the

BWF series can be vented into it using an optional BWF Category I Vent Kit available from Crown. The BWF requires an

adequate source of clean combustion air in the boiler room.

The BWF boiler is not designed for use in gravity or “open” heating systems. Where an adequate source of clean indoor

combustion air cannot be guaranteed, use a direct vent boiler such as the Crown CSC series.

II Specifications

BWF061EN 3 61,000 51,000 44,000 83.3 14 1/4 3.2

BWF095EN 4 95,000 78,000 68,000 83.1 17 1/2 4.0

BWF128EN 5 128,000 106,000 92,000 82.8 20 3/4 4.7

BWF162EN 6 162,000 134,000 117,000 82.5 24 5.5

BWF195EN 7 195,000 161,000 140,000 82.3 27 1/4 6.3

BWF229EN 8 229,000 189,000 164,000 82.0 30 1/2 7.0

4

* MODELS SHOWN ARE FOR NATURAL GAS. REPLACE "N" WITH "L" SUFFIX FOR PROPANE MODEL NUMBER (e.g. BWF061EL).

PERFORMANCE RATINGS ARE THE SAME FOR BOTH FUELS

3

3

3

4

WATER

CONTENT

(GAL.)

TABLE 1: SPECIFICATIONS

AFUE (%)

FIG. 1

DIMENSION

"A" (IN.)

D.O.E.

HEATING

CAPY.

(BTU/hr)

VENT DIA.

(IN.)

3

MODEL*

NO.

SECTIONS

INPUT

(BTU/hr)

IBR NET

RATING

(BTU/hr)

3

III Before Installing

1) Safe, reliable operation of this boiler depends upon installation by a professional heating contractor in strict accordance

with this manual and the authority having jurisdiction.

• In the absence of an authority having jurisdiction, installation must be in accordance with this manual and the

National Fuel Gas Code, ANSI Z223.1

• In Canada, installation must be in accordance with CSA B149 (Installation Code for Gas Burning Appliances and

Equipment).

• Where required by the authority having jurisdiction, this installation must conform to the Standard for Controls and

Safety Devices for Automatically Fired Boilers (ANSI/ASME CSD-1)

2) Read Section VI to verify that the boiler can be vented in accordance with these instructions.

3) Make sure that the boiler is correctly sized:

• For heating systems employing convection radiation (baseboard or radiators) use an industry accepted sizing method

such as the I=B=R Heat Loss Calculation Guide (Pub. #H21 or #H22) published by the Hydronics Institute in

Berkeley Heights, NJ.

• For new radiant heating systems refer to the radiant tubing manufacturer’s boiler sizing guidelines.

• For systems including a Crown Mega-Stor indirect water heater, size the boiler to have either the DOE Heating

Capacity required for the Mega-Stor or the net rating required for the heating system, whichever results in the larger

boiler.

• For systems that incorporate other indirect water heaters, refer to the indirect water heater manufacturer’s instructions

for boiler output requirements.

4) Make sure that the boiler received is configured for the correct gas (natural or LP).

5) For installations at altitudes above 2000ft, special orifice and pressure switches may be required. Make sure that the boiler

is configured for use at the correct altitude.

IV Locating the Boiler

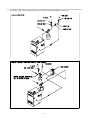

1) Clearances:

• Observe the minimum clearances shown below. These clearances apply to all combustible construction, as well as non-

combustible walls and doors. Also see Figure 2.

Front – 6”

Left Side – 1”

Right Side – 4”

Rear – 1”

Top – 36”

Vent Pipe – 5”

• A 24” service clearance from the jacket is recommended on the left, right, and front of the boiler. These clearances may

be reduced to those shown in Figure 2, however servicing the boiler will become increasingly difficult as these service

clearances are reduced.

• If the right side 24” service clearance is reduced, adequate clearance must be maintained to easily read both the gauge and

the limit control. Alternatively, access to the gauge and limit may be provided using a door.

2) The boiler must be installed on a hard level surface. This surface may be combustible.

4

3) Do not install this boiler in an area where large amounts of airborne dust will be present, such as a workshop. Do not

install in a location where sources of hydrocarbons will be stored or used. Some common sources of hydrocarbons include

bleaches, fabric softeners, paints, cleaners, refrigerants, and cat boxes. Traces of these chemicals can be drawn into the

boiler, causing severe corrosion damage to the boiler and/or objectionable odors.

4) The boiler should be located so as to minimize the length of the vent system while still meeting the requirements in

Section VI.

5) Do not install this boiler over carpeting.

6) Do not install this boiler directly on a surface that may get wet. Raise the boiler on a pad.

5

V Air for Combustion and Ventilation

Sufficient fresh air must be supplied for both combustion and ventilation. Provisions for combustion, ventilation, and

dilution air for gas utilization equipment must be made in accordance with local building codes, or in the absence of such

codes, in accordance with Sections 5.3.3 and 5.3.4 (“Air for Combustion and Ventilation”) of the National Fuel Gas Code,

NFPA 54/ANSI Z223.1.

To ensure an adequate combustion and ventilation air supply, start by determining whether the boiler is to be installed in a

building of unusually tight construction. A building of unusually tight construction is defined by the National Fuel Gas Code

as having all

of the following features:

• Walls and ceilings exposed to outside atmosphere have a continuous water vapor retarder with a rating of 1 perm or

less with openings gasketed and sealed.

• Weather stripping has been added on openable windows and doors.

• Caulking and sealants are applied to areas such as joints around window and door frames, between sole plates and

floors, between wall-ceiling joints, between wall panels, at penetrations for plumbing, electrical, and gas lines, and at

other openings.

If the building is of unusually tight construction, see the instructions on page 6. Otherwise, follow the instructions below.

For Buildings of Other than Unusually Tight Construction

1) Determine whether the boiler is to be installed in a confined space - A confined space is defined by the National Fuel Gas

Code as having a volume less than 50 cubic feet per 1000 BTU/hr input of all appliances installed in that space. To determine

whether the boiler room is a confined space:

a. Total the input of all appliances in the boiler room in thousands of BTU/hr. Round the result to the next highest 1000

BTU/hr.

b. Find the volume of the room in cubic feet. The volume of the room in cubic feet is:

Length (ft) x width (ft) x ceiling height (ft)

In calculating the volume of the boiler room, consider the volume of adjoining spaces only if no doors are installed

between them. If doors are installed between the boiler room and an adjoining space, do not consider the volume of the

adjoining space, even if the door is normally left open.

c. Divide the volume of the boiler room by the input in thousands of BTU/hr. If the result is less than 50, the boiler room is a

confined space

.

Example:

A BWF229 and a water heater are to be installed in a room measuring 6ft – 3 in x 7ft with an 8 ft ceiling. The water

heater has an input of 30000 BTU/hr:

Total input in thousands of BTU/hr = (229000 BTU/hr + 30000 BTU/hr) / 1000 = 259

Volume of room = 6.25 ft x 7 ft x 8 ft = 350 ft3

350/259 = 1.35 Since 1.35 is less than 50, the boiler room is a confined space.

If the boiler is in an unconfined space

– Natural infiltration into the boiler room will normally provide adequate air for

combustion and ventilation without additional louvers or openings into boiler room.

6

If the boiler is in a confined space

– Provide two openings into the boiler room, one near the floor and one near the ceiling.

The top edge of the upper opening must be within 12” of the ceiling and the bottom edge of the lower opening must be within

12” of the floor (Fig 3).

• Each opening must have a free area of 1 square inch per 1000 BTU/hr input of all gas burning appliances in the boiler

room. The minimum opening dimension is 3 inches. Minimum opening free area is 100 square inches per opening.

• If the total volume of both the boiler room and the room to which the openings connect is less than 50 cubic feet per

1000 BTU/hr of total appliance input, install a pair of identical openings into a third room. Connect additional rooms

with openings until the total volume of all rooms is at least 50 cubic feet per 1000 BTU/hr of input.

• The “free area” of an opening takes into account the blocking effect of mesh, grills, and louvers. Where screens are

used, they must be no finer than ¼” (4 x 4) mesh.

• If providing openings into adjacent rooms is undesirable, combustion and ventilation air can be brought to the boiler

room from outdoors. See the instructions under “For Buildings of Unusually Tight Construction”

For Buildings of Unusually Tight Construction

a) Openings must be installed between the boiler room and the outdoors or a ventilated space, such as an attic or crawl

space, which communicates directly with the outdoors.

b) Two openings are required. The top edge of the upper opening must be within 12 inches of the ceiling. The bottom

edge of the lower opening must be within 12 inches of the floor.

c) Size openings and ducts as follows:

• Vertical ducts or openings directly outdoors (Fig 4, Fig 5, Fig 6) – Each opening must have a free cross sectional area

of 1 square inch per 4000 BTU/hr of the total input of all gas-fired appliances in the boiler room. Minimum opening

size is 3 inches. Ducts must have the same cross sectional area as the openings to which they connect.

• Openings to outdoors via horizontal ducts (Fig 7) - Each opening must have a free cross sectional area of 1 square

inch per 2000 BTU/hr of the total input of all gas-fired appliances in the boiler room. Minimum opening size is 3

inches. Ducts must have the same cross sectional area as the openings to which they connect.

• The “free area” of an opening takes into account the blocking effect of mesh, grills, and louvers. Where screens are

used, they must be no finer than ¼” (4 x 4) mesh.

7

8

9

VI Venting

There are three basic ways to vent the BWF boiler:

• Horizontal (“side wall”) venting using an approved AL29-4C stainless steel vent system.

• Vertical venting using an approved AL29-4C stainless steel vent system.

• Chimney venting using a masonry or “B” vent chimney and a special Category I Vent Kit available from Crown.

Table 3 summarizes these three venting options. One of the columns in Table 3 must describe the planned vent system exactly

.

The following instructions describe the design and installation of Horizontal and Vertical Direct Exhaust (Category III)

systems only. Instructions for Chimney (Category I) venting are provided with the Crown Category I vent kit or are available

from Crown.

WARNING

DO NOT ATTEMPT TO VENT A BWF SERIES BOILER INTO A MASONRY OR “B”

VENT CHIMNEY WITHOUT THE CROWN CATEGORY I VENT KIT SHOWN IN

TABLE III

STRUCTURE PENETRATION WALL ROOF ROOF

MAXIMUM LENGTH:

BWF061 - BWF162 45 FT + 1 EL 39.5 FT + 2 ELS

BWF195,BWF229 (using 4" Pipe) 45 FT + 1 EL 37 FT + 2 ELS

BWF195,BWF229 (using 3" Pipe) 30 FT + 1 EL 24.5 FT + 2 ELS

MINIMUM LENGTH:

BWF061 - BWF162 2 FT + 1 EL 6 FT + 2 ELS

BWF195,BWF229 2 FT + 1 EL 6 FT + 2 ELS

NOMINAL DIA.:

BWF061 - BWF162 3" 3"

BWF195,BWF229 3" or 4" 3" or 4"

BWF061 - BWF162

BWF195,BWF229 (using 4" Pipe)

BWF195,BWF229 (using 3" Pipe)

90 ELBOW OR

TEE

CATEGORY I VENT KIT:

BWF061 - BWF128 CROWN # 650140

BWF162 - BWF229 CROWN # 650141

LISTED CHIMNEY CAP

EXHAUST TERMINAL:

90 ELBOW, TEE,

OR VH-1 TERM. BY VENT MFR.

(TABLE 6)

(*) FLEX-L-INTL STAR-34 , ZFLEX SVE SERIES III, HEAT FAB SAF-T VENT ,

PROTECH SYSTEMS FASNSEAL

NATL. FUEL GAS CODE

CLASSIFICATION

CATEGORY III CATEGORY III

MATERIAL AL29-4C(*) AL29-4C(*)

TABLE 3: SUMMARY OF VENTING OPTIONS

N/A N/A

SIZE PER NATIONAL

FUEL GAS CODE

VENTING TABLES FOR

FAN ASSISTED

APPLIANCE

"B" VENT OR LINED

MASONRY CHIMNEY

(SEE N.F.G.C.)

CHIMNEY VENT

VERTICAL DIRECT

EXHAUST

HORIZONTAL

DIRECT

EXHAUST

CATEGORY I

CLASSIFICATION USED IN THIS

MANUAL

10

Horizontal Vent System Design

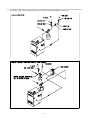

1) See Figure 8 for the general horizontal exhaust configuration. For the purposes of this manual, a “horizontal exhaust

system” is one that exits the structure through a wall.

2) Approved Systems – Use one of these four approved vent systems:

• Flex-L-International Star-34

• Z-FLEX SVE Series III (“Z-Vent II”)

• Heat Fab Saf-T Vent

• ProTech Systems FasNSeal

3) Vent Pipe Size:

• BWF061 to BWF162– 3”

• BWF-195, BWF-229 –3” or 4”

4) Maximum Vent Pipe Length:

• BWF061 to BWF162: 45 ft + (1) 90 degree elbow + terminal

• BWF195 to BWF229 (using 4” vent pipe): 45 ft + (1) 90 degree elbow + terminal

• BWF195 to BWF229 (using 3” vent pipe): 30 ft + (1) 90 degree elbow + terminal

• Reduce the maximum straight pipe run by the equivalent length from Table 4 for each additional

elbow.

Example:

A vent system is planned for a BWF162 which has the following components:

2 ft vertical pipe

1 90 elbow

5 ft horizontal pipe

1 90 elbow

3 ft horizontal pipe

1 45 elbow

4 ft horizontal pipe

1 termination elbow

Since the boiler is a BWF162, all piping must be done in 3” pipe. The first 90 degree elbow and the termination

elbow are not considered. From Table 4, the equivalent length of the 3” 45 elbow is 4.5ft. The equivalent length of

the 3” 90 degree elbow is 5.5ft. The maximum allowable run of straight pipe on this system is therefore:

45ft – 4.5 ft –5.5ft = 35ft

Since the planned installation has only 14 ft of straight pipe, the planned vent system length is acceptable

FITTING 3 INCH 4 INCH

90 DEG. ELBOW 5.5 8

45 DEG. ELBOW 4.5 4.5

HORIZONTAL CONDENSATE TEE TREATED AS STRAIGHT PIPE

NOMINAL SIZE

TABLE 4: VENT SYSTEM ELBOW EQUIVALENT

LENGTHS

11

5) Minimum Vent Pipe Length: 2 ft + (1) 90 degree elbow + terminal

6) Permitted Terminals:

• Choice of Tjernlund VH1 series terminal, a 90-degree elbow with rodent screen, or a termination tee with a rodent

screen. The Tjurnlund VH1 terminals may not be used on BWF195s and BWF 229s when they are vented with 3”

pipe. If the Tjurnlund terminal is used, select one of the following:

BWF061 to BWF162: Tjernlund VH1-3 (Crown #50-032) 3” terminal

BWF195, BWF229: Tjernlund VH1-4 (Crown #50-042) 4” terminal

• If an elbow or tee is used for the vent termination, it must be of the same type and manufacture as the rest of the vent

system.

• If a tee is used for the termination it must be installed with the run of the Tee vertical.

7) Wall thimbles – Wall thimbles are required where the vent pipe passes through combustible walls with less than a 5”

clearance. Use the appropriate wall thimble shown in Table 5.

8) Pitch of horizontal piping – A ¼” per foot pitch towards the outside is preferred. Alternatively, the horizontal piping may

be pitched ¼” per foot towards the boiler, however a condensate trap is required. See (9).

9) Condensate traps –In some horizontal installations, condensate traps may be needed to prevent condensate from running

into the boiler or collecting in the vent system. A condensate trap must be used if the horizontal piping does not have a

continuous slope to the outside. If this is the case, put a trap in the lowest section of horizontal piping (Fig 8b).

10) Use only a “horizontal” type condensate Tee (Fig 9).

11) Vertical and horizontal sections of piping must be properly supported. See the “Vent System Assembly” section of this

manual for more information.

12

12) Location of Horizontal Vent Terminal – Observe the following limitations on the terminal location:

• Terminal must be at least 4 feet below or 4 feet horizontally from any window, door, or gravity air inlet into the

building (Fig. 10).

• The bottom of the terminal must be at least 12” above the normal snow line. In no case should it be less than 12”

above grade level (Fig 10).

• The bottom of the terminal must be at least 7 feet above a public walkway.

• The bottom of the terminal must be at least 3 feet above any forced air inlet located within 10 feet.

• A clearance of at least 4 feet horizontally or 4 feet vertically must be maintained between the terminal and gas meters,

electric meters, regulators, and relief equipment.

• Do not locate the terminal under decks or similar structures.

• Top of terminal must be at least 4 feet below eves, soffits, or overhangs. Overhang may not exceed 3 feet (Fig. 12).

Do not use the Tee terminal under an overhang deeper than 6”.

• Terminal must be at least 3 feet from an inside corner.

• Under certain conditions, water in the flue gas may condense on the structure in areas around the terminal. If these

areas are made of materials subject to damage by flue gas condensate, they should be protected.

• If possible, install the terminal on a wall away from the prevailing wind. Reliable operation of this boiler cannot be

guaranteed if the terminal is subjected to winds in excess of 40 mph.

• The noise level in the vicinity of the terminal is approximately 65 dB (roughly the level of a normal conversation).

Care should be taken when the terminal is positioned in areas where this might be objectionable, such as near

bedroom windows.

TABLE 5: WALL THIMBLES

VENT MANUFACTURER'S PART #

VENT SYSTEM 3 INCH 4 INCH

FLEX-L-INTL

STAR-34

SRWT-03 SRWT-04

Z-FLEX

SVE SERIES II

I

2SVSWTF03 2SVSWTF04

HEAT FAB

SAF-T VENT

7393GC 7493GC

PROTECH SYSTEMS

FASNSEAL

FSWT3 FSWT4

13

14

Vertical Vent System Design

1) See Figure 13 for the general vertical stainless steel venting configuration. For the purposes of this manual, a “vertical

exhaust system” is a Category III vent system that exits the structure through a roof.

2) Approved Systems – Use one of these four approved vent systems:

• Flex-L-International Star-34

• Z-FLEX SVE SeriesIII (“Z-Vent III”)

• Heat Fab Saf-T Vent

• ProTech Systems FasNSeal

3) Vent Pipe Size:

• BWF061 to BWF162– 3”

• BWF195, BWF229 – 4”

TABLE 6: CAPS FOR VERTICAL VENT SYSTEMS

VENT MANUFACTURER'S PART #

VENT SYSTEM 3 INCH 4 INCH

FLEX-L-INTL

STAR-34

SRRC-03 SRRC-04

Z-FLEX

SVE SERIES II

I

2SVSRCF03 2SVSRCF04

HEAT FAB

SAF-T VENT

5300CI 5400CI

PROTECH SYSTEMS

FASNSEAL

FSRC3 FSRC4

15

4) Maximum Vent Pipe Length:

• BWF061 to BWF162 – 39.5 ft + (2) 90 degree elbows + cap

• BWF195, BWF229 (using 4” vent pipe): 37 ft + (2) 90 degree elbows + cap

• BWF195, BWF229 (using 3” vent pipe): 24.5 ft + (2) 90 degree elbows + cap

• Reduce the above maximum straight pipe runs by the equivalent length from Table 4 for each additional

elbow

beyond the first two.

Example:

A vertical vent system is planned for a BWF162 that has the following components:

2 ft vertical pipe

1 90 Elbow

1 condensate trap which has an is 18 inch long run

1 90 Elbow

1 ft vertical pipe

1 45 elbow

2 ft sloped pipe

1 45 elbow

7 ft vertical pipe

1 Cap

Since the boiler is a BWF162, all piping must be done in 3” pipe. The first two 90 elbows and the termination cap are

not considered. The condensate trap is treated as a straight length of pipe 1.5 feet in length. The result is 13.5 ft of

straight pipe and two 45 elbows. From Table 4, the equivalent length of the 45 elbow is 4.5ft. The maximum

allowable run of straight pipe on this system is therefore:

37.5 ft – 4.5 ft – 4.5 ft = 28.5ft

Since the planned installation has 13.5 ft of straight pipe, the planned vent length is within the maximum limit.

5) Minimum Vent Pipe Length - 6 ft + (2) 90 degree elbows + cap

6) Permitted Terminals – A cap must be used which is compatible with the rest of the vent system. See Table 6 for the

appropriate cap.

7) Condensate traps – A condensate trap is required on all vertical-venting systems. Install this trap as shown in Figure 13. If

there are additional sections of horizontal piping in the vent system, they must either be equipped with their own

condensate Tees or pitched so that condensate will run into the one required trap.

8) Use only a “horizontal” type condensate Tee (Fig. 9).

9) Pitch of horizontal piping – Pitch the lowest horizontal section of piping ¼” per foot towards the boiler. Other horizontal

sections (if any) must be pitched so that condensate will run towards a condensate Tee.

10) Fire-stops and wall thimbles – A wall thimble is required where the exhaust pipe passes through combustible walls with

less than a 5” clearance. Firestops are required where the vent passes through ceilings. These components must be

compatible with the rest of the exhaust system. Table 5 shows wall thimble model numbers for the approved vent systems.

Table 7 shows firestop model numbers for the approved vent systems.

16

11) Piping supports – Vertical and horizontal sections of piping must be properly supported. See the “Vent System Assembly”

section of this manual for more information.

12) Location of vent cap– The lowest discharge opening on the cap must be at least 2 feet above any object located within 10

feet (Fig. 14):

17

Removing an Existing Boiler From a Common Chimney

In some cases, when an existing boiler is removed from a common chimney, the common venting system may be too large

for the remaining appliances. At the time of removal of an existing boiler, the following steps shall be followed with each

appliance remaining connected to the common venting system placed in operation, while the other appliances remaining

connected to the common venting system are not in operation.

(a) Seal any unused openings in the common venting system.

(b) Visually inspect the venting system for proper size and horizontal pitch and determine there is no blockage or restriction,

leakage, corrosion and other deficiencies which could cause an unsafe condition.

(c) Insofar as practical, close all building doors and windows and all doors between the space in which all the appliances

remaining connected to the common venting system are located and other spaces of the building. Turn on clothes dryers

and any appliance not connected to the common venting system. Turn on any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at maximum speed. Do not operate a summer exhaust fan. Close fireplace

dampers.

(d) Place in operation the appliance being inspected. Follow the lighting instructions. Adjust thermostat so the appliance will

operate continuously.

(e) Test for spillage at the draft hood relief opening after 5 minutes of main burner operation. Use the flame of a match or

candle, or smoke from a cigarette, cigar, or pipe.

(f) After it has been determined that each appliance remaining connected to the common venting system properly vents when

tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other gas-burning appliances to

their previous condition of use.

(g) Any improper operation of the common venting system should be corrected so the installation conforms with the National

Fuel Gas Code, ANSI Z223.1. When resizing any portion of the common venting system, the common venting system

should be resized to approach the minimum size as determined using the appropriate tables in Part 11 of the National Fuel

Gas Code, ANSI Z223.1.

TABLE 7: FIRESTOPS FOR VERTICAL VENT SYSTEMS

VENT MANUFACTURER'S PART #

VENT SYSTEM 3 INCH 4 INCH

FLEX-L-INTL

STAR-34

SRFS03 SRFS04

Z-FLEX

SVE SERIES III (SUPPORT)

2SVSFSSF03 2SVSFSSF04

Z-FLEX

SVE SERIES III (SPACER)

2SVSFSF03 2SVSFSF04

HEAT FAB

SAF-T VENT

7373GC 7473GC

PROTECH SYSTEMS

FASNSEAL

FSFS3 FSFS4

18

Vent System Assembly

1) General Assembly Notes:

a) Where the use of “silicone” is called for in the following instructions, use only the following sealants:

• Flex-L-International Star-34 – GE RTV106 or GE IS806

• Z-FLEX SVE Series III (“Z-Vent III”) – Silicone not required for joints between pipe sections.

• Heat Fab Saf-T Vent – GE RTV 106

• ProTech Systems FasNSeal - Silicone not required for joints between pipe sections.

• Use the same silicone used to seal vent pipe sections to seal the boiler vent collar and the Tjurnlund VH-1 terminal (if

used). For ProTech FasNSeal or Z-Flex Z-Vent III, use GE RTV 106 for the vent collar and Tjurnlund terminal.

b) Longitudinal welded seams should not be placed at the bottom of horizontal sections of vent pipe.

c) Do not drill holes in vent pipe.

d) Do not attempt to mix vent components of different vent system manufacturers.

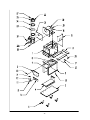

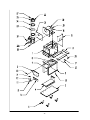

2) Vent Collar Installation – The vent collar is shipped loose in the accessory bag along with two collar gaskets, the outlet

orifice, and four 10-32 mounting screws. The outlet orifice will be marked with either the boiler model number or a

Crown part number for the orifice. Verify that the number marked on the outlet exhaust orifice matches that of either the

boiler model number or the part number shown in the chart in Figure 15. Mount the collar and orifice as shown in Figure

15. If desired, the first piece of exhaust pipe can be connected to the collar before mounting the collar on the boiler.

3) Tjernlund VH-1 terminal Installation – If the Tjernlund VH-1 terminal is used, follow the instructions provided with the

terminal to mount it in the wall. This terminal may be installed in direct contact with combustible construction.

19

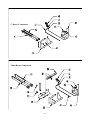

4) Assembly of Flex-L-Intl. Star-34 Vent System:

a) Star-34 General Notes:

• Do not cut Star-34 vent components.

• Support horizontal piping sections at intervals of 48” or less.

• Vertical venting systems must be supported by at least one Star-34 Firestop. An additional vertical support is required

after any offset.

• Orient Star-34 components so that the arrows on the piping labels are in the direction of flue gas flow.

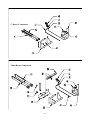

b) Start assembly of the vent system at the boiler. Remove the hose clamp shipped on the BWF vent collar. Bend the three

hose clamp tabs on this collar outward slightly.

c) Clean the exterior of the male end of the first piece of pipe and the inside of the vent collar on the boiler. Use a cleaner

such as Methyl Ethyl Keytone (MEK) or naptha.

d) On the male end of the pipe, apply a ¼” wide bead of silicone approximately ¼” from the end of the pipe and another ¼”

bead against the joint side of the stop bead (Fig 17).

e) Insert the male end of the pipe into the boiler vent collar until it bottoms out.

f) Apply an additional bead of silicone over the outside of the joint and smooth out. Also apply silicone over the seams in

the vent collar (Fig 17).

g) Replace and tighten the clamp on the vent collar.

h) Clean the female end of the first piece of pipe. Also clean the male end of the next piece of pipe.

i) Apply silicone as in step (d) (Fig 18).

j) Align the longitudinal seams of the pipe and insert the male end of the second pipe into the female end of the first pipe.

k) Insert a StaR joiner band into the inlet of the beaded channel. Feed the joiner band in so that it makes its way around the

channel and overlaps by approximately ½” (Fig 18).

l) Cut the excess joiner band so that it lays flat in the beaded channel (Fig 18).

m) Fill the inlet of the beaded channel with silicone. Smooth the silicone over the channel inlet as well as the silicone

between the female end and the stop bead of the male end (Fig 18).

n) Repeat Steps (h) – (m) for the remaining Star-34 components. If a termination elbow or tee is used, use this procedure to

complete the exhaust system.

o) To connect Star-34 to the VH-1 terminal, the vent system must be configured so that the female end of the last piece of

Star-34 will fit over the vent connection on the terminal. Before permanently making this joint, clean both the male end of

the terminal and the female end of the last piece of pipe with Methyl Ethyl Keytone or Naptha. Apply a ¼ inch bead of

silicone ¼” from the male end of the terminal. Also apply a ¼” bead of silicone along the weld seam on the inside of the

female section of the Star-34 pipe. Slip the female end of the vent pipe over the male end of the terminal until it is over at

least 1 ¼ inches of the terminal. Apply a second bead of silicone over the joint between the vent pipe and the terminal as

well as over the channel inlet. Do not attempt to use a locking band at this joint. Install a pipe support or other means to

prevent the Star-34 pipe from separating from the terminal.

p) Allow the silicone to cure for 24 hours before operating the boiler.

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Crown Boiler BWF195 User manual

-

Crown Boiler BWF162 Installation guide

-

Crown Boiler Profile Installation guide

-

Crown Boiler AWR070ENST2PSU User guide

-

Crown Boiler Freeport ODV-125 User manual

-

Crown Boiler BWC-150ENST1PSU User guide

-

Crown Boiler Bali Series BWF User manual

-

Crown Boiler Bali Cat 1 Vent Kit Operating instructions

-

Crown Boiler BIMINI BWC225 Operating instructions

-

Crown Boiler BWF195 User manual

Other documents

-

U.S. Boiler Company INDEPENDENCE IN4PV Installation & Operating Manual

-

Columbia CDVB SERIES Installation, Operation & Maintanance Manual

-

Columbia CDVB SERIES Installation, Operation & Maintanance Manual

-

Quadra-Fire TPVNT-7 Pellet Adapter Installation guide

-

Smith GVSC User manual

-

TRIANGLE TUBE HM Delta Saf-T-Vent SC Concentric Vent Operating instructions

-

Honeywell Heating System 96-6127-2 User manual

-

Burnham 20_PV_I User manual

-

Bosch 250SX User manual

-

HeatStar 9050360 Owner's manual