Page is loading ...

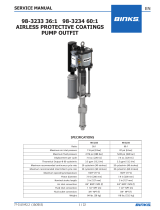

The Binks Model 84-120 Ceramic Fluid

Regulator is an industry-proven ceramic

regulator that assures uniform finishes

on part after part... day after day.

SPECIFICATIONS

• Pressure Range ............. 5 to 55 PSI

• Flow Rate ........ 128 oz./min. (max.)

• Inlet Pressure .......... 125 PSI (max.)

• Wetted Parts: 1. Nickel Plated Brass

2. Gun Rubber

REGULATING FLUID

PRESSURE

1. Increase Pressure: Turn in wing

screw (31).

2. Decrease Pressure: Turn out wing

screw (31) while gun is triggered.

3. Read instructions on back cover of

regulator.

SERVICE

1. Plugged Regulator: Use the bypass

screw (23) to open bypass while

triggering gun. Close bypass

and trigger gun. If regulator

fails to return to normal operation,

open bypass and blow back gun.

Close bypass and return to normal

operation. If these fail, remove

and inspect regulator and

connecting supply line.

2. A ruptured or worn actuator tube

(11) at valve section causes

regulated fluid pressure to climb to

line pressure when gun is not in

use. Replace actuator tube. Inspect

valve seat (20) and valve gate

assembly (19) for wear.

3. Standby or replacement regulators

should be stored with the bypass

screw (23) open and the wing

screw (31) turned out.

REPLACING THE

84-200 ACTUATOR TUBE (11)

Disassemble regulator. Do not

remove bonnet thread inserts (14) or

tubing seal bodies (25) except for

replacement.

Thoroughly clean all parts until free of

abrasive material. Grease all moving

parts. Assemble parts in back of regulator

body first, including back cover (24).

Turn body over. Insert tubing seal

(26) into one end of actuator tube

(11) and push other end into regulator

body (13) through outlet. Pull tube

into body until tube end with seal is

in place in the tubing seal body (25).

Wind tube into the spiral cast in

regulator body and push end out

through inlet. Turn tube if necessary

to remove any twists or kinks.

Insert tubing seal into end of tube and

secure tube in inlet tubing seal body.

Center the plate (15) on thread of rod

(16) and fasten plate down over tube

with lock nut (1).

Assemble the remaining parts on the

regulator body. Regulator is now

ready to be tested.

Connect inlet to water pressure supply

(60-80 lbs.) and outlet to a gun and

hose. Be sure bypass is closed.

While triggering gun, regulate the

pressure with wing screw (31) over

the range of pressures used on the

production line. If pressure cannot be

regulated low enough, adjust per the

following instructions.

ADJUSTING THE REGULATOR

Turn the wing screw (31) out so that no

spring pressure is exerted on plate (15).

Be sure bypass is closed. Remove set

screw (5) and loosen adjustment lock

nut (22). Connect inlet to fluid pressure

supply and turn adjustment screw (21)

down until outlet flow is just cut off.

Tighten lock nut and replace set screw

to cover thread.

Binks Model 84-120

FLUID PRESSURE REGULATOR

FOR CERAMIC FINISHING

Replaces

Part Sheet

77-1417R-4

Part

Sheet

77-1417R-5

2

Warning

!

In this part sheet, the words WARNING, CAUTION and NOTE are used to emphasize important safety information as follows:

CAUTION

Hazards or unsafe practices which could

result in minor personal injury, product

or property damage.

!

WARNING

Hazards or unsafe practices which could

result in severe personal injury, death or

substantial property damage.

!

NOTE

Important installation, operation or

maintenance information.

Read the following warnings before using this equipment.

READ THE MANUAL

Before operating finishing equipment, read and

understand all safety, operation and maintenance

information provided in the operation manual.

ELECTRIC SHOCK/GROUNDING

Improper grounding or sparks can cause a

hazardous condition and result in fire, explosion

or electric shock and other serious injury.

PROJECTILE HAZARD

You may be injured by venting liquids or gases

that are released under pressure, or flying debris.

INSPECT THE EQUIPMENT DAILY

Inspect the equipment for worn or broken parts

on a daily basis. Do not operate the equipment

if you are uncertain about its condition.

NEVER MODIFY THE EQUIPMENT

Do not modify the equipment unless the

manufacturer provides written approval.

FIRE AND EXPLOSION HAZARD

Improper equipment grounding, poor ventilation,

open flame or sparks can cause hazardous

conditions and result in fire or explosion and

serious injury.

KNOW WHERE AND HOW TO SHUT OFF THE

EQUIPMENT IN CASE OF AN EMERGENCY

STATIC CHARGE

Fluid may develop a static charge that must be

dissipated through proper grounding of the

equipment, objects to be sprayed and all other

electrically conductive objects in the dispensing

area. Improper grounding or sparks can cause a

hazardous condition and result in fire, explosion

or electric shock and other serious injury.

WEAR SAFETY GLASSES

Failure to wear safety glasses with side shields

could result in serious eye injury or blindness.

OPERATOR TRAINING

All personnel must be trained before operating

finishing equipment.

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equip ment to

rupture, malfunction, or start unexpectedly and

result in serious injury.

KEEP EQUIPMENT GUARDS IN PLACE

Do not operate the equipment if the safety

devices have been removed.

HIGH PRESSURE CONSIDERATION

High pressure can cause serious injury. Relieve all

pressure before servicing. Spray from the spray

gun, hose leaks, or ruptured components can

inject fluid into your body and cause extremely

serious injury.

PRESSURE RELIEF PROCEDURE

Always follow the pressure relief procedure in the

equipment instruction manual.

DE-ENERGIZE, DEPRESSURIZE, DISCONNECT

AND LOCK OUT ALL POWER SOURCES DURING

MAINTENANCE

Failure to De-energize, disconnect and lock out

all power supplies before performing equipment

maintenance could cause serious injury or death.

CA PROP

65

PROP 65 WARNING

WARNING: This product contains chemicals known

to the State of California to cause cancer and

birth defects or other reproductive harm.

FOR FURTHER SAFETY INFORMATION REGARDING BINKS AND DEVILBISS EQUIPMENT,

SEE THE GENERAL EQUIPMENT SAFETY BOOKLET (77-5300).

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PROVIDE THIS INFORMATION TO THE OPERATOR OF THE EQUIPMENT.

3

BINKS MODEL 84-120 FLUID PRESSURE REGULATOR

24

ITEM PART

NO. NO. DESCRIPTION QTY.

1 20-258 HEX NUT, 3/8-16 ................................. 1

2 20-537 HEX CAP SCREW, 1/4-20 X 3/4 ............ 6

3 20-854 RD. HD. M. SCREW, 1/4-20 X 3/8 ........ 4

4 20-1571 COTTER PIN, 1/16 DIA. X 1/2 LG. .......... 2

5 20-2042 SOC. HD. SET SCREW, S.S., 3/8-16 X 3/8 1

6 20-2135 HEX JAM NUT, 7/16-14 ....................... 1

7 54-788 CONNECTION, 3/8 NPS ....................... 1

8 72-59 TAILPIECE, 3/8 NPT ............................. 2

9 83-1355 GAUGE, 100 LB. .................................. 1

10 83-2052 GAUGE LENS, GLASS .......................... 1

11 84-200 ACTUATOR TUBE .............................. 1

12 84-201 BONNET ............................................ 1

13 84-202 REGULATOR BODY ........................... 1

14 84-203 THREAD INSERT ................................ 2

15 84-204 PLATE ................................................ 1

16 84-205 ROD ................................................... 1

ITEM PART

NO. NO. DESCRIPTION QTY.

17 84-206 PIN ..................................................... 1

18 84-207 LEVER ................................................ 1

19 84-208 VALVE GATE ASSEMBLY ................... 1

20 84-209 VALVE SEAT ...................................... 1

21 84-210 ADJUSTMENT SCREW ...................... 1

22 84-211 ADJUSTMENT LOCK NUT ................. 1

23 84-213 BYPASS WING SCREW ...................... 1

24 84-214 BACK COVER .................................... 1

25 84-215 TUBING SEAL BODY ......................... 2

26 84-216 TUBING SEAL .................................... 2

27 84-217 OUTLET ASSEMBLY .......................... 1

28 84-218 SWIVEL NUT ..................................... 2

29 84-220 “Y” BODY ......................................... 1

30 84-384 BUTTON ............................................ 1

31 85-90 WING SCREW ................................... 1

32 86-885 SPRING .............................................. 1

PARTS LIST

When ordering, please specify Part No.

19

34

16

17

18

11

21

13

22

5

2

1

14

6

31

30

12

23

32

15

14

20

26

25

9

28

8

29

78

28

25

26

10

27

INLET

ASSEMBLY

3/13 ©2013 Binks All rights reserved. Printed in U.S.A.

Binks Sales and Service: www.binks.com

WARRANTY

This product is covered by Binks’ 1 Year Limited Warranty.

77-1417R-5 Revisions: Trademark updates;

(P2) Added Prop 65 warning; (P4) Updated

contact information.

U.S.A./ Canada Customer Service

195 Internationale Blvd.

Glendale Heights, IL 60139

630-237-5000

Toll Free Customer Service

and Technical Support

800-992-4657

Toll Free Fax

888-246-5732

/