12

7b

METTEZ L’EMBALLAGE AU REBUT

GAS

ON

GAS

ON

1

2

Fibre washer

Floating nut

Elbow (½” BSP external thread)

Foam Tape

Adhesive side

20 mm

50 mm

+50 mm

NG

ALL Models

Make sure the connection point will be accessible with the cooktop installed.

To enable the gas supply to be readily shut o by the customer, make sure the connection

is tted with an isolating valve close to the cooktop.

Make sure to t the supplied

washer and regulator.

Adjust to obtain a test point

pressure of 1 kPa with the two

semi-rapid burners operating at

highest setting.

Ensure the hose is long enough to allow for removal of cooktop for servicing.

Make sure the connector is located as shown in step 5 CLEARANCE DIMENSIONS.

The hose assembly must be AS/NZS 1869 Class B or D certied, with an Rp ½” (ISO 7‐1) female thread connection.

The hose assembly must be as short as practicable and comply with relevant AS 5601/NZS 5261 requirements.

The hose must not be kinked, subjected to abrasion or permanently deformed.

The hose must not be near or in contact with any hot surfaces

(e.g. base of metal hotlplate, ue, or chassis of underbench oven etc.)

If connecting the gas with a exible hose:

LPG

recessed to 50 mm

check all connections

Make sure to t the supplied

washer and test point adaptor.

Make sure the supply pressure

is regulated to 2.75 kPa, with

the two semi-rapid burners

operating at highest setting.

Washer

Washer

If converting to LPG, see 16 'Converting to a dierent gas type'

To check that the ignition system operates correctly, light each burner by itself, then all burners in combination.

Check for a well‐dened blue ame without any yellow tipping.

If any abnormality is evident, check that the components of the burner assembly are located properly

If proper operation cannot be obtained, contact your nearest F&P Authorised Service Centre.

The cooktop must not be used by the customer until proper operation has been achieved.

yellow tiplifting o

good ame

Arrow

Recyclez de façon

responsable

Le modèle peut être différent des illustrations présentées

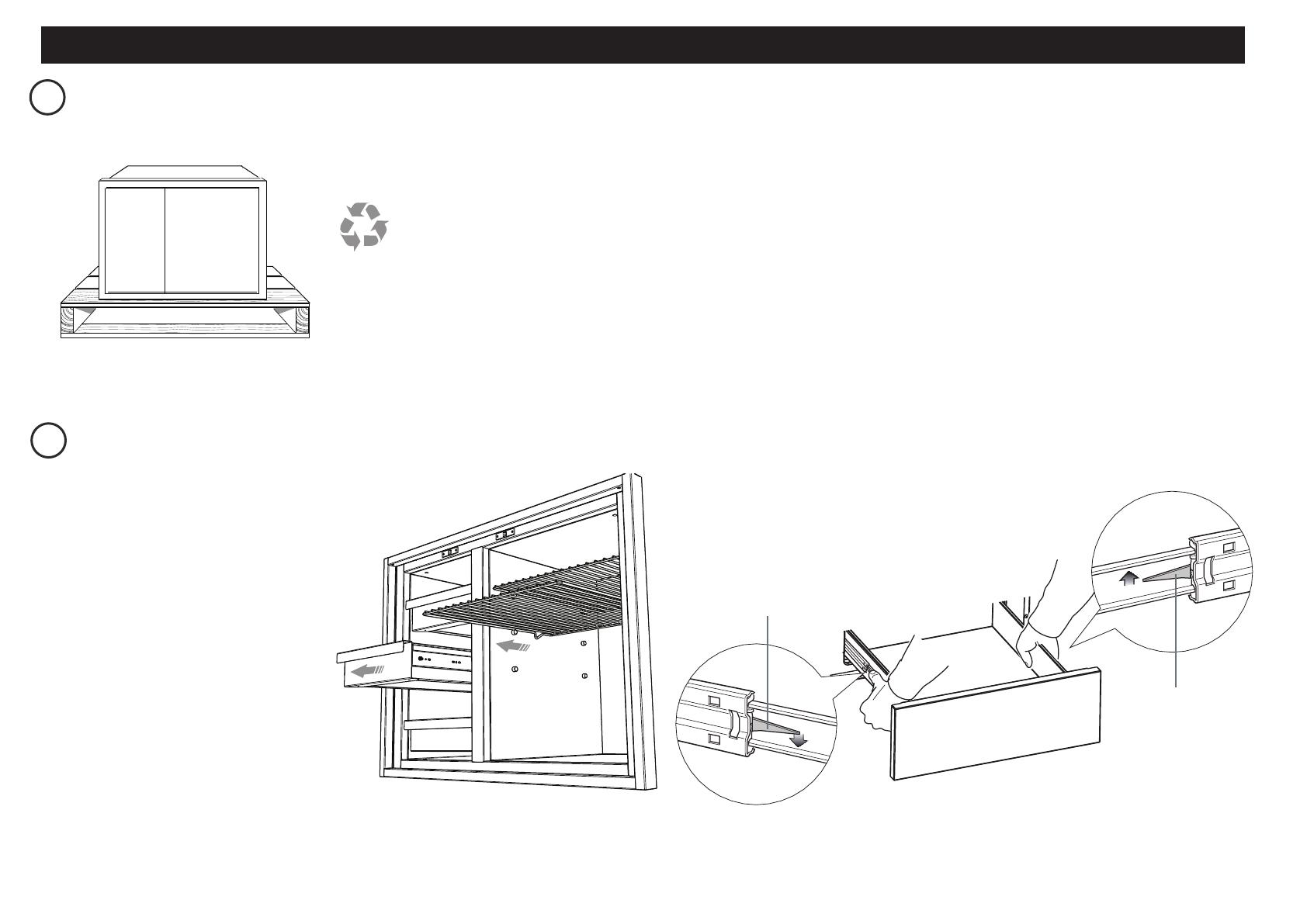

8b

RETIREZ TOUS LES TIROIRS ET TOUTES LES TABLETTES POUR ACCÉDER AUX

EMPLACEMENTS DES OUVERTURES DE VIS

Inspectez le(s) produit(s) pour vous assurer qu’aucun dommage n’a été causé lors de l’expédition.

En cas de dommage, communiquez avec l’expéditeur pour faire une demande d’indemnisation.

DCS par Fisher&Paykel n’est pas responsable des dommages causés lors de l’expédition.

REMARQUE: Ne mettez pas au rebut les matériaux d’emballage avant d’avoir terminé l’inspection de

l’appareil.

Utilisez les tiroirs et les tablettes afin de vous assurer qu’ils glissent en douceur.

Examinez les pièces à l’avant afin de vous assurer qu’elles ne présentent aucune bosselure, égratignure

oudécoloration.

Faites preuve de prudence lors de l’ouverture complète des portes de garde-manger. Le cadre extérieur

pourrait marquer le devant des portes.

Pour retirer le(s) tiroir(s)

1

Retirez les tiroirs en les tirant vers

l’extérieur jusqu’à ce que le loquet

deglissière soit visible.

2

Enfoncez doucement le loquet sur

lecôté gauche, tout en soulevant

leloquet sur le côté droit.

3

Sortez le tiroir du cadre.

Remarque: pour éviter d’endommager

lessurfaces, placez les tiroirs sur une surface

stable recouverte d’une serviette ou d’une

nappe protectrice.

Loquet de glissière

gauche

Loquet de glissière

droite

INSTALLATION DU GARDE-MANGER

INSTALLATIONS DANS UN COIN