Page is loading ...

TorqueMaster™ & idrive™

9900/9600/9200/9100

INSTALLATION INSTRUCTION

SUPPLEMENT

When installing an idrive™ opener with this door use

this supplement to the main door instructions as follows:

1) Begin with Step 1 of the main door instructions.

2) Replace Step 8 of the main door instructions with

Step 8 of the attached supplement.

3) Replace Steps 12 through 17* of the main door in-

structions with the Steps 12 through 17b of the attached

supplement.

*Supplement replaces Steps 12 - 18 on single spring doors

© Copyright 2002 Wayne-Dalton Corp. Part No. 301528 New 07/02

1

®

Follow the corresponding steps in this insert with the steps in the installation manual provided with the door. These

modifications are designed to accommodate the new idrive™ garage door opener.

Top Bracket Installation

TOP SECTION

RIB

(2) CARRIAGE

BOLTS

TOP

BRACKET

TOP

BRACKET

SLIDE

3) 9200/9100 Foamcore™

(below) will have galvanized hard-

ware, with a laminated (soft) back-

ing on the sections.

(4) SELF-TAPPING

SCREWS

2

ND

SET OF HOLES ON

9600 THERMOGARD®

AND

9200/9100 FOAMCORE™

(2) HEX

NUTS

1

ST

SET OF HOLES ON

9900 THERMOWAYNE™

To install the L-shaped top brackets, align the top holes in the top bracket with the first set of holes in the endcap for 9900

Thermowayne™ doors and second set of holes for 9600 Thermogard

®

doors and 9200/9100 Foamcore™ doors. Fasten

using (4) 1/4-20 x 5/8” self tapping screws. Secure the top bracket slide to the bracket using

(2) 1/4-20 x 5/8” carriage bolts and nuts. Insert rollers. (see Fig. 1)

NOTE: To differentiate between a 9900 Thermowayne™, 9600 Thermogard® and 9200/9100 Foamcore™ door mod-

els, look for the following characteristics:

TorqueMaster™ & idrive™

9900 Thermowayne™

9600 Thermogard®

9200/9100 Foamcore™

INSTALLATION INSTRUCTIONS INSERT

ROLLER

1) 9900 Thermowayne™

(below) will have painted hard-

ware (top brackets, bottom brack-

ets, end caps, etc.) with a steel

backing on the sections.

2) 9600 Thermogard® (right)

will have galvanized hardware, with

a steel backing on the sections.

GALVANIZED

HARDWARE

STEEL

BACKING

GALVANIZED

HARDWARE

LAMINATED

(SOFT) BACKING

PAINTED

HARDWARE

STEEL BACKING

FIG. 1

2

8

TORQUE TUBE

PLUG MOTOR

INTO THE OPENER

POWER HEAD

SLIDE OPENER

POWER HEAD

LABEL

(LEFT SIDE)

TORQUE

TUBE

INSERT THIS END FROM LEFT SIDE OF

OPENER

Continue sliding the opener power head onto the torque

tube. Align the right hand bearing with the torque tube and

slide the opener power head completely onto the torque

tube until the torque tube exits the opener power head’s

right hand bearing. Continue sliding the opener power head

to the center of the torque tube and plug the motor into the

opener power head.

IMPORTANT! Right and left hand are always

determined from inside the garage looking out.

Power Head Assembly

Lay the torque tube on the floor (inside garage) in front

of the door with the labeled end to the left. NOTE:

Opener will not slide over a torque tube label.

Attempting to slide opener over the left end of the torque

tube can damage the internal electronics.

NOTE: Hold opener by the main body. Do NOT hold

by the motor.

Look into the opener’s left side to ensure the left hand bearing

and the internal (black) sleeve are aligned with the torque

tube profile. Once aligned, slide the opener power head

onto the right hand end of the torque tube. As the right end

of the torque tube enters the internal (black) sleeve, rotate

the opener back and forth slightly to help aid alignment.

NOTE: Do not force the opener onto the torque tube

if misalignment occurs.

OPENER POWER HEAD

TORQUE TUBE AND

BEARINGS PROFILES

ALIGNED

OPENER POWER

HEAD

LEFT HAND

BEARING

OPENER

POWER

HEAD

RIGHT HAND

BEARING

The idrive™ garage door opener is best installed in combination with the door installation steps. Refer to this

idrive™ installation insert when you reach Step 12 TorqueMaster™ installation, in the main door installation instructions and

owners manual. When instructed to slide the center bracket/bushing onto the torque tube, replace that step with the follow-

ing instructions below, which will provide the steps necessary to install the TorqueMaster™ system, as well as the preliminary

installation steps for the idrive™ garage door opener.

MOTOR

FIG. 5

FIG. 4

3

FIG. 3

FIG. 2

12

Refer back to the main door manual and continue door installation at the

REAR SUPPORT INSTALLATION Step 18. (Step 19 in the Single Spring

TorqueMaster™ Installation Instructions)

After door installation is completed, refer to the idrive™ owner’s manual,

starting at the PRE-OPERATION INSTALLATION section to complete

the opener installation.

NOTE: Refer to the main door manual for counterbalance adjustments.

Drum Wrap Installation

FIG. 21

DRUM

FRONT HALF

BACK HALF

INBOARD

SNAP

OUT BOARD

CATCH

FLAGANGLE

TIGHT JOINT

APPLY

PRESSURE

UNDERNEATH

WITH THE

THUMB AND

FINGERS

WRAPPED

OVER TOP

OF

SNUBBER.

Locate right hand drum wrap. Slide back half of the drum wrap behind drum placing the right end wall between the

drum and flag angle. Close front half of the drum wrap around drum, engage inboard snap and press firmly until a

distinct snap is felt. Outboard catch must be engaged as shown. Confirm both snap and catch are fully engaged by

lightly tugging against them. Repeat for the left side.

REAR SUPPORT INSTALLATION

PERFORATED

ANGLE (NOT

SUPPLIED)

HORIZONTAL

TRACK

8

17b

Drum Installation

TORQUE TUBE

WINDING SHAFT

DRUM

TORQUE TUBE

LOOSE WINDING SHAFT

DRUM

WINDING

SHAFT GROOVE

ROUND

NOTCH

FLAG ANGLE

Shake the torque tube gently to extend the winding shafts

out about 5" on each side. For single spring applications,

there will be no left hand winding shaft in the torque tube.

Lift the torque tube and rest on top of flagangles. Orient

torque tube so that back of opener is flat against header/

spring pad. See Figure 12

Cable drums and torque tube are cam shaped to fit together

only one way. To install the cable drum, slide the drum

over the winding shaft until the drum seats against the torque

tube. The winding shaft must extend past the drum far

enough to expose the splines and the groove. Align the

winding shaft groove with the round notch in the flagangle.

Repeat for opposite side.

NOTE: On single spring applications, take care in

handling the loose winding shaft (left side) so that it

does not slide back into the torque tube.

Single Spring Applications: Insert the left hand loose

winding shaft into the left hand drum prior to sliding the

drum over the torque tube.

FIG. 8

SPLINES

FIG. 6

FIG. 7

4

Drive Gear/End Bracket Installation

Ensure that torque tube is centered and level with door.

Beginning with the right hand side, lubricate entire

circumference of the drive gear with the oil provided in

the packet. Slide the drive gear onto the winding splines

until it touches the flagangles.

NOTE: No drive gear is required for the left side on

single spring applications.

END BRACKET

FIG. 10

FIG. 9

DRIVE GEAR

OIL PACKET

DRUM

WINDING SHAFT

DRIVE GEAR

INSTALLED

(2) 1-5/8” LAG

SCREWS

FIG. 11

13

14a

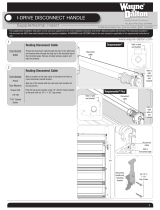

Using the emergency disconnect, pull disconnect handle

downwards and place it in the manual door operated

position. Use disconnect label for reference. Motor

will be rotated 90° from its packaged position.

NOTE: If motor does not pivot 90°, see troubleshooting

section in the idrive™ main installation manual.

Wind Counterbalance Springs

7

IMPORTANT! Adjustments to the recommended number

of turns may be required. AFTER REAR SUPPORT

ASSEMBLY IS COMPLETE (located in main door manual

instructions), check door balance. If door raises off of floor

under spring tension alone, then reduce turns until door will

rest on floor. A “hot” door such as this can cause idrive™

operation problems.

FIRST

GROOVE

SET SCREW

PULL

CABLE

Adjust the counter balance cables by rotating the drum until

the set screw faces directly away from the header. Loosen

the set screw no more than 1/2 turn. Pull on the end of the

cable to remove all cable slack. Check to ensure the cable

is aligned and seated in the first groove of the cable drum.

Snug the set screw, then tighten an additional 1-1/2 turns.

Cut off excess cable.

DRUM

CABLE

Cable Adjustments

7/16” WRENCH

LOCK NUT

CONOE CLIP

WINDING BOLT

COUNTER

FIG. 20

Clamp locking pliers onto both vertical tracks just above

third roller. This is to prevent garage door from rising while

winding counterbalance springs.

IMPORTANT! DO NOT USE IMPACT GUN TO

WIND SPRING(S)

Beginning with the right hand side. Press and hold in the

canoe clip. Ensure the cable is in the first groove of the

drum. Using an electric drill (high torque gear reduced to

1300 RPM preferred) with a 7/16" socket, carefully rotate

right hand winding bolt clockwise, until counter shows 2-3

turns. This will keep the counterbalance cable taut while

adjusting the left hand side counterbalance cable.

Repeat for left side on double spring TorqueMaster™

systems.

Single spring applications will require no spring pre-winding.

Ensure counterbalance cable tension is equal for both sides

prior to fully winding spring(s) to appropriate number of

turns.

Carefully rotate the winding bolt head clockwise until the

counter show the correct number of turns for your door.

See the chart below. Repeat for the opposite side on double

spring TorqueMster™ systems.

If door raises off of floor remove 1/2 - 1 full turn from

each spring before proceeding.

After spring is wound, hold the lock nut stationary with a

7/16” wrench while rotating the winding bolt clockwise until

snug. Tightening of the lock nut prevents spring from

unwinding. Repeat for opposite side if necessary.

6’0” Door Height = 14-1/2 turns (Double

Spring) and 15 turns (Single Spring)

6’-3” Door Height = 15 turns

6’-5” Door Height = 15-1/2 turns

6’-6” Door Height = 15-1/2 turns

6’-8” Door Height = 16 turns

6’-9” Door Height = 16 turns

7’-0” Door Height = 16-1/2 turns

7’-3” Door Height = 17 turns

7’-6” Door Height = 17-1/2 turns

7’-9” Door Height = 18 turns

8’-0” Door Height = 18-1/2 turns

Door Height = Spring Turns

FIG. 19

16b

17a

Slide the right hand end bracket over the drive gear. Attach

end bracket and the flagangle to the jamb with (2) 5/16 x

1-5/8” lag screws. (see Fig. 11)

5

OPENER

POWER

HEAD

SPRING PAD

TORQUE TUBE

MOUNTING

STUDS

Power Head/

Support Bracket Installation

(2) 2” LAG SCREWS

SUPPORT

BRACKET

MOTOR

(2) 1/4-20 FLANGE NUTS

Locate the spring pad. The spring pad is a vertical running

board directly above the door. Remove (2) 1/4-20 flange

nuts from bottom of opener power head. NOTE: Do not

discard flange nuts. Place the support bracket underneath

opener power head, to the right side of motor, centered on

spring pad.

Level the torque tube to the top of the door section with the

idrive™ resting on the support bracket. Once torque tube

is level, secure support bracket to the spring pad with (2)

1/4 x 2" lag screws.

SUPPORT BRACKET

Lift and slide the opener power head over the support

bracket, aligning the mounting studs with the bracket slots.

Loosely fasten to mounting studs with the (2) 1/4-20 flange

nuts. NOTE: Do not tighten 1/4-20 flange nuts to power

head studs at this time.

OPENER POWER HEAD

FIG. 13

FIG. 14

Counter Installation

Begining with the right side, install the counter gear with the

missing tooth toward the outside, away from the end bracket.

Press the counter gear onto the end bracket until snaps

engage. Select the right hand counter cover assembly and

align the hex of the counter cam with the end of the winding

shaft. Also, align the “0” on the counter cover with the

raised rib on the end bracket. Press the counter cover

assembly against the counter gear until it locks into place.

Repeat the Drive Gear/End Bracket Installation and

Counter Installation sections for the left hand side

installation.

NOTE: No drive gear, counter gear or counter cover

assembly is required on left hand side for single spring

applications. Only an end bracket is needed.

IMPORTANT! At this time do not wind counter balance

springs!

END BRACKET

COUNTER

GEAR

RIGHT HAND

COUNTER

COVER

ASSEMBLY

“0”

RAISED

RIB

MISSING TOOTH

(TOWARD OUTSIDE)

FIG. 12

14b

15

power head. With slack removed, secure bottom of handle

bracket with (1) 1/4 x 1-1/2" lag screw.

CAUTION: Pull handle just enough to remove the cable

slack. Pulling the cable more could cause the opener power

head to disconnect from the torque tube.

Rotate disconnect handle to one side exposing upper

mounting hole in handle bracket. Secure handle bracket

with a second 1/4 x 1-1/2" lag screw. Apply emergency

disconnect label next to the mounted bracket. Use

mechanical fasteners if adhesive will not adhere.

CABLE

1/4 X 1-1/2”

LAG SCREW

LABEL

bracket with mark on wall. Remove all cable slack between

the power head and top of handle bracket.

Insert and tighten #6-20 x 1/2" screw until snug, and then

tighten screw 1 to 1-1/2 additional turns to secure cable in

handle. Trim off excess cable from bottom of handle.

Holding handle bracket, remove all remaining slack between

Attach the loose disconnect cable (located in operator

hardware bag) to the opener power head with “S” hook.

Close both ends of “S” hook to lock assembly together.

Thread the disconnect cable through hole in right hand end

bracket and remove all slack between power head and right

hand end bracket.

Mark location on right door jamb, six feet above the ground

to mount disconnect handle. Thread disconnect cable

through handle bracket and then handle. Align top of handle

Disconnect Installation

HANDLE

HANDLE

BRACKET

6’

(to bottom

of door)

#6-20 X 1/2”

1/4 X 1-1/2”

LAG SCREW

OPENER POWER

HEAD

END

BRACKET

HOLE

LOOSE

DISCONNECT

CABLE

REMOVE ALL SLACK IN CABLE

“S” HOOK

INSTALLED

FIG. 15

FIG. 17

FIG. 16

6

LABEL

HANDLE

FIG. 18

16a

/