Evaporative Cooling

Evaporative cooling uses the principle of evaporation to lower the air temperature. Hot, dry air is passed through wetted

filters and is converted to refreshingly cooled air. Essick Coolers make the best use of the evaporative process by

controlling the flow of water, spreading the water evenly over the filters, and keeping a steady stream of cooled air

entering your home. It is exhausted out open windows or doors, carrying heat, smoke and odors along with it. Essick

evaporative coolers are 80% less costly to operate than refrigerated air conditioners.

Cautions: To prevent harm to yourself and others, and to avoid damage to your cooler, PLEASE follow these guidelines.

SAFETY GUIDE LINES & CAUTIONS

When Installing When Operating When Servicing

Make sure that unit is installed on a sound

structure that will support the full operating

weight of the cooler. See page 3.

Make sure that circuit cooler is wired into is

equipped with a (slow blow) breaker large

enough to support the full amperage of the

cooler.

Always shutoff power to the cooler, at the

breaker, before attempting service of any

kind. If not, it can be turned on from inside

the house and start unexpectedly.

Before attempting to transport the cooler to the

mounting location, plan a safe way to move the

cooler and remove the louvers to reduce weight.

To reduce the risk of fire or electrical shock, DO

NOT use this fan with any Solid-state speed

control device.

Never drain cooler water onto your roof.

Water residue may cause you to slip or may

stain your roof.

Do Not connect power to cooler before

installation is complete.

This cooler is equipped with an automatic

thermally protected motor. If it shuts off on its

own for any reason, it can restart without

warning.

If the motor shuts off because of thermal

overload, check into the problem

immediately. If allowed to continue,

permanent damage will occur.

When servicing or installing, always wear gloves,

protective eyewear, and other applicable safety

gear. Never wear slippery-soled shoes when

working on a roof.

Never use a cooler without connecting it to a

duct system or without a sturdy mesh guard over

the outlet.

Never install or service a cooler during a

storm or high wind conditions.

Tools & Materials Required

1. Pliers

2. Screwdrivers 2. Screwdrivers

3. Adjustable wrenches 3. Adjustable wrenches

4. Tubing cutter 4. Tubing cutter

5. 5/32 hex wrench 5. 5/32 hex wrench

6. Electric drill 6. Electric drill

7. Drill bits 7. Drill bits

8. Hammer 8. Hammer

9. Duct caulking 9. Duct caulking

10. #10 sheet metal screws 10. #10 sheet metal screws

11. Safety glasses 11. Safety glasses

12. Wiring supplies (as required by local electric

codes)

12. Wiring supplies (as required by local electric

codes)

13. Duct, as required. A local sheet metal shop can

supply ducting or it may be purchased as a kit.

13. Duct, as required. A local sheet metal shop can

supply ducting or it may be purchased as a kit.

14. Level 14. Level

15. Air diffuser 15. Air diffuser

16. Equipment suitable for cutting hole in roof or wall 16. Equipment suitable for cutting hole in roof or wall

17. ¼” water line 17. ¼” water line

18. saddle valve or faucet adapter 18. saddle valve or faucet adapter

19. ECR-6 wall switch (6 position) 19. ECR-6 wall switch (6 position)

20. Roof stand (if cooler is roof mounted) 20. Roof stand (if cooler is roof mounted)

Location

Location

1. Your cooler installation must comply with local codes. If you are not qualified to install a cooler, get professional help. 1. Your cooler installation must comply with local codes. If you are not qualified to install a cooler, get professional help.

2. Do not install the cooler near vent pipes, chimneys or exhaust pipes. The cooler will draw in fumes into your house. 2. Do not install the cooler near vent pipes, chimneys or exhaust pipes. The cooler will draw in fumes into your house.

3. The drain fitting in the bottom of the cooler must have adequate room for service access. 3. The drain fitting in the bottom of the cooler must have adequate room for service access.

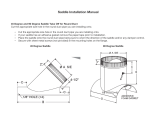

Side discharge

connected to

duct work

Down discharge

into hall

70932

Rev. 6/02

2