Form #43219020

15 June 09

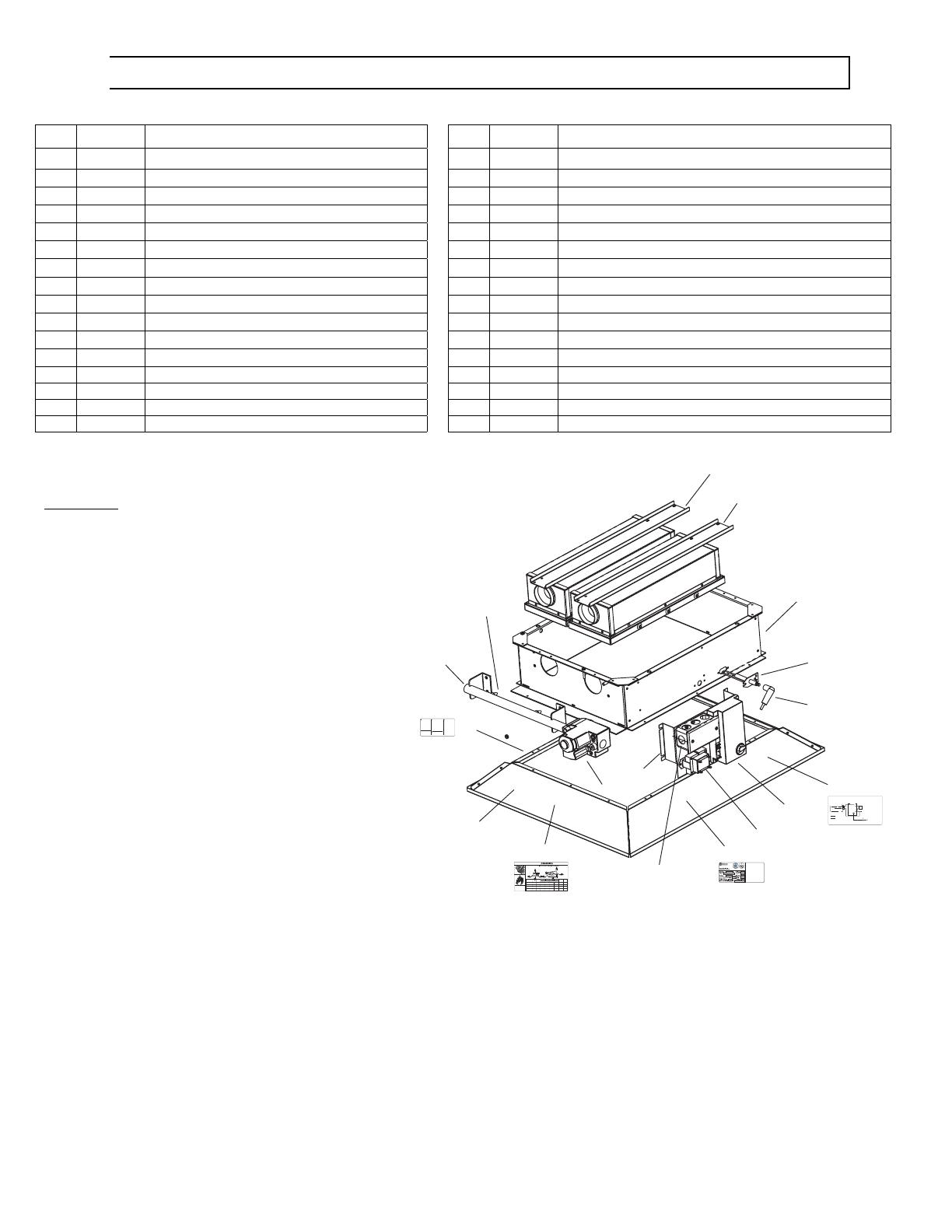

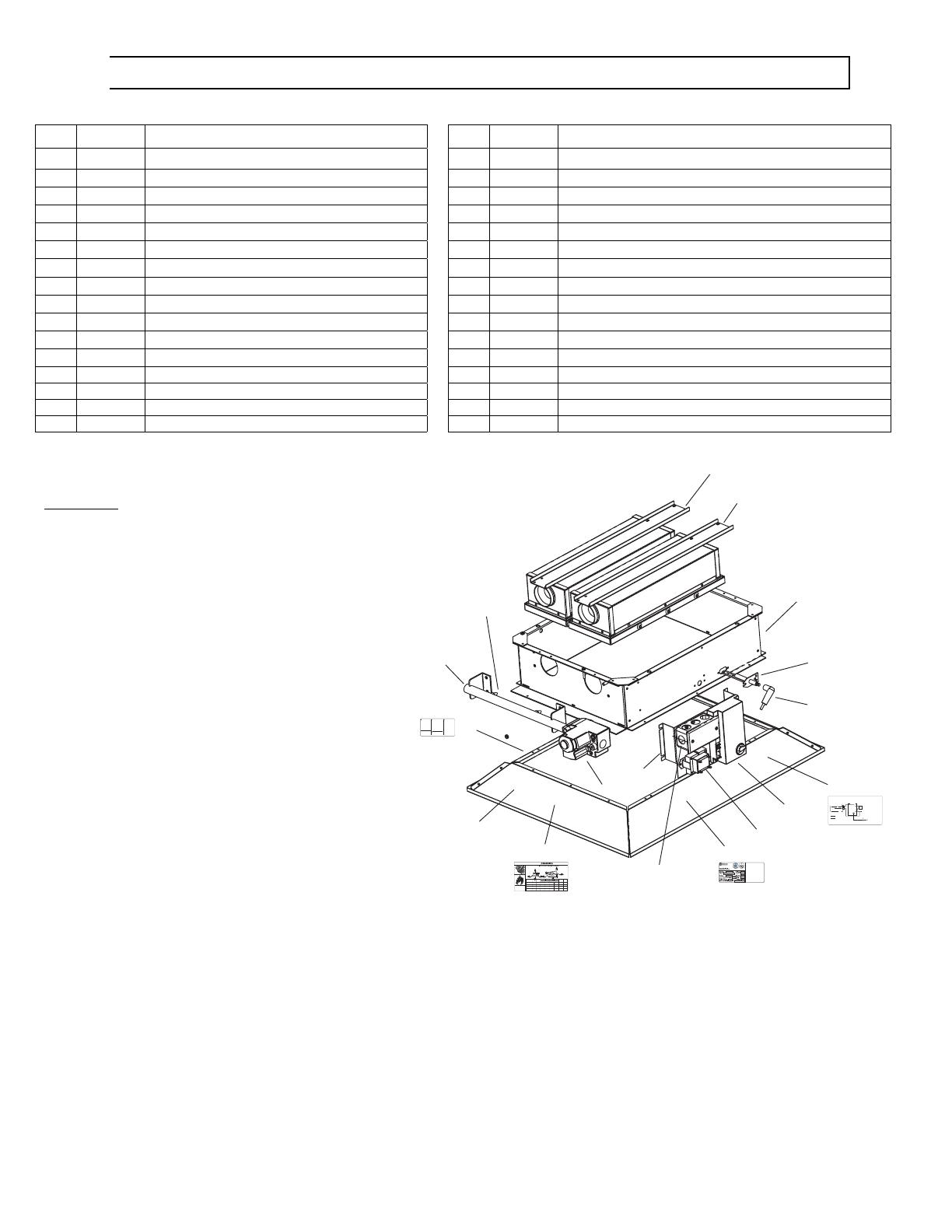

20) REPLACEMENT PARTS GUIDE

ITEM# PART # DESCRIPTION ITEM# PART # DESCRIPTION

1 30333040 Valve VR8205A-2081 @ 10” W.C. – Propane Gas 17 43908010 Frame Assembly (1 Burner Unit)

2 30333050 Valve VR8205A-2123 @ 6” W.C. – Natural Gas 18 43908020 Frame Assembly (2 Burner Unit)

3 30279000 Transformer AT120B1051 19 43908030 Frame Assembly (3 Burner Unit)

4 30632030 Spark Module, Fenwal #35-605950-015 20 43908040 Frame Assembly (4 Burner Unit)

5 30295020 Electrode PSE-GF9 21 03548000 Junction Box, 2 x 4 x 1½

6 30314100 Ignition Cable 10” 22 03606000 Cover Plate

7 43856029 Burner Assembly Kit (Ignition Unit) 23 43849000 Ignition Control Bracket

8 43856039 Burner Assembly Kit (2nd, 3rd, and 4th Unit) 24 43872380 Orifice #38 for SG4, SG8, SG12, SG15 – Natural Gas

9 43862010 Manifold for SG3, SG4 25 43872410 Orifice #41 for SG10, SG14 – Natural Gas

10 43862020 Manifold for SG6, SG8 26 43872980 Orifice 3/32” for SG3, SG6 – Natural Gas

11 43862030 Manifold for SG10, SG12 27 43872520 Orifice #52 for SG3, SG6, SG10, SG13– Propane Gas

12 43862040 Manifold for SG13, SG14, SG15 28 43219020 Installation and Operation Manual (Not Shown)

13 43847010 Reflector for SG3, SG4 29 42052030 Label - Connection Wire Diagram

14 43847020 Reflector for SG6, SG8 30 42849020 Label – Nameplate

15 43847030 Reflector for SG10, SG12 31 43247030 Label – Clearances to Combustibles

16 43847040 Reflector for SG13, SG14, SG15 32 42875000 Label – General Warnings

IMPORTANT:

Please order by Part Number, not by Item Number.

Refer to complete Model Number when ordering.

All replacement parts available when ordering.

Screws, nuts and washers are standard hardware

items and can be purchased at any local hardware

store.

ALL ILLUSTRATIONS ARE INTENDED TO GIVE THE

GENERAL IMPRESSION OF UNITS ONLY. WE

RESERVE THE RIGHT TO ALTER ANY SPECIFICATION

WITHOUT NOTICE

7

8

17, 18, 19, 20

5

6

4

3

21, 22

23

1, 2

13, 14, 15, 16

9, 10, 11, 12

24, 25, 26, 27

TH

V1

GND

V2

FC+

FC-

Thermostat

R

W

24VAC

120

VAC

MV

MV

BL

W

Ignition Module

Fenwal No.

2460D

Chaud

Neutral

Ground

CONNECTION WIRING DIAGRAMS

chéma de circuit de connexion

TRANSFORMER

120V PRIMARY

24V SECONDARY

If any of the original wire as supplied with the

appliance must be replaced. It must be

replaced with wiring material having a

temperature rating of at least 105oC. (18

AWG. - UL / CSA 600V Type TEW)

When connecting the supply circuit to the

heater, wiring material having a minimum size

of 14 AWG and a temperature rating of at

least 90oC shall be used.

Transformateur

bobine primaire 120ÊV

bobine secondaire 24ÊV

S'il faut remplacer un fil de l'appareil d'origine,

utiliser exclusivement des fils à température

de service nominale d'au moins 105C (18

AWG. - UL / CSA 600ÊV

Type TEW).

Pour raccorder le circuit d'alimentation au

radiateur, utiliser des fils de calibre 14 AWG

ou plus à température de service nominale

d'au moins 90C.

Neutre

HIGH VOLTAGE CABLE

Haute tension

Terre

GAS VALVE

Robinet à gaz

WIRE LEGEND

ENGLISH FRANCAIS

W WHITE BLANC

R RED ROUGE

BL BLUE BLEU

G GREEN VERT

Bloc d'allumage

FACTORY WIRING

FIELD WIRING

Circuit d'origine

Connexions client

Hot

42052030

Rev. A 3/05

ELECTRODE

GAP 3/16

Écartement

d'électrode

4,7Êmm

BL

42849000 Rev. H 2/08

LIGHTING & SHUTDOWN INSTRUCTIONS

1. Turn on gas & electrical supply.

2. Set thermostat to call for heat.

3. If ignition fails, the unit will spark for approximately 21 seconds

& go into safety lockout. Turn thermostat (or power) off for 60

seconds to take out of lockout.

4. If heater does not light, shut off gas completely for 5 minutes

before attempting to relight.

5. To shut down the heater, turn off the gas & electrical supply.

INSTRUCTIONS DALLUMAGE ET DE FERMETURE

1. mettre la valve a gaz et linterrupteur a ON.

2. Creer une demande de chauffage au thermostat.

3. Si lallumage ne se fait pas, le controle dallumage continu de

produire des etincelles sur une periode de 21 sec. et ensuite

tomber en securite. Mettre le thermostat (ou le courant) en

position darret (OFF) pour une periode de 60 sec. a fin

dinterrompre le processus de securite.

4. Si lappareil ne sallume pas, fermez le gaz completement pour

une period de 5 min. avant deffectuer une nouvelle tentative

dallumage.

5. Pour fermer lappareil, fermez le gaz et le courant electrique.

UNVENTED

RADIATEUR CÉRAMIQUE À INFRAROUGES

HIGH INTENSITY INFRARED RADIANT

CERAMIC HEATER

SANS AÉRATION

ANSI Z83.19b / CSA 2.35b-2007

Gas Fired products Inc. Charlotte, NC

Installation in:

1. Aircraft hangers must be in accordance with the

standard for Aircraft Hangers. ANSI/NFPA 409 (latest edition).

2. Public garages must be in accordance with the standard for

parking structures, ANSI/NFPA 88a (latest edition), or with the

standard for repair garages, ANSI/NFPA 88b (latest edition)

Combustible material must be located outside the clearance dimensions listed.

Failure to do so may result in death, serious injury or property damage

43247020 Rev. C 8/05

IMPORTANT!

When angle

mounting,

the control side

must be down.

Gas Valve CEILING

FRONT

REAR

ANGLE

BELOW

SIDE

Gas Manifold

Assembly

SIDE

CEILING

BELOW

36 50 30

(91cm) (127cm) (76cm)

48 68 36

(122cm) (173cm) (91cm)

60 84 48

(145cm) (213cm) (122cm)

64 90 48

(163cm) (229cm) (122cm)

DK30, DK35, 30 36 72 100

DK33, DK40 (76cm) (91cm) (183cm) (254cm)

DK60, DK70, 48 48 98 137

DK66, DK80 (122cm) (122cm) (249cm) (348cm)

DK100, DK120 48 64 128 180

122cm) (163cm) (325cm) (457cm)

DK132, DK160, 60 64 136 190

DK140 (145cm) (163cm) (345cm) (483cm)

SIDES CEILING

w/Standard

Reflector w/Reflector

Extension

BELOW

MODEL NO. FRONT REAR

w/Standard

Reflector w/Reflector

Extension

ANGLE

MTG.

(degree)

0 min.

35 max.

0 min.

35 max.

0 min.

35 max.

10 min.

35 max.

WARNING: Improper

installation, adjustment,

alteration, service or

maintenance can cause

property damage, injury

or death. Read the

Installation, Operating

and Maintenance

Instruction thoroughly

before servicing this

equipment.

AVERTISSEMENT: Une

installation, un réglage, une

modification, une réparation

ou un entretien incorrect peut

entraîner des dommages

matérials, des blessures ou

la mort. Lisez attentivement

les instructions dinstallation,

de fonctionnement et

dentretien avant de procéder

à linstallation ou à lentretien

de cet équipment.

WARNING: If not

installed, operated and

maintained in accordance

with the manufacturers

instructions, this product

could expose you to

substances in fuel or from

fuel combustion which can

cause death or serious

illness and which are

known to the State of

California to cause cancer,

birth defects or other

reproductive harm.

WARNING: This product

contains a chemical known

to the state of California to

cause cancer.

This heater can be

installed in various

configurations as shown

in the heater layout

section of the instructions

42875000 Rev. E 10/04

29

30

31

32