Page is loading ...

ModelNumber

SerialNumber

Themodel and serial numhers for your unit are located inside unit

on side of blower housing. Record this information in the space

allotted above.

Thismanualwasdesignedtoprovideyou

andyourinstallerwithinformationneeded

to mount,operate,inspect,maintain,and

troubleshootyourcooler.

Atthe end ofthis booklet there is a chart

providing useful hints for increasing the

benefits ofyour evaporativecooler.

Thefirstsection,InstallationandStart-Up,

isespeciallyforthe installer.

TheRegular Maintenance section contains

operation and maintenance instructions for

the owner, whilethe Troubleshooting

section includes information on commonly-

encountered problems.

mo_on ..........................2

Mountingof DownDischargeModels ......... 2

Mountingof HorizontalModels ............. 2

DuctPlacement......................... 3

Required ExhaustOpenings................ 3

ElectricalInstallation(Docted ModeLs) ....... 3

MotorInstallation(DuctedModels) .......... 3

OverflowStandpipeInstallation ............. 4

DrainLineInstallation .................... 4

Bleed-OffInstallation ..................... 4

AdjustingWater LevelandFloat Level......... 4

Ge.entlI__mxtion

Start-UpInspection...................... 4

Start-UpChecklist....................... 4

CabinetInspectionChecklist............... 4

_R..e_ularMainten_ce

ChangingCoolerPads .................... 5

AdjustingBeltTension.................... 5

Lubrication............................ 5

CleaningWaterPump .................... 5

DrainingandTouch-Up................... 5

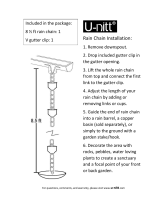

Flat SupportInstallation .................. 6

ChainKitInstallation ..................... 6

ElectricalWiringon W'mdowModels ......... 6

T_ ........................ 7

Th: , m • O_oer ......... 7

Note: Your warranty does not cover shipping damage. Report all shipping damage at once to dealer or carrier making deliver_

L907103A • 12/99

INTRODUCTION

Evaporativecoolingworkson the principleofheatabsorptionbymoistureevaporation.Whena swimmer

leavesthewater on a windyday,he feelscool becausethe moistureon his bodyis evaporatingand

absorbingheat.

Yourevaporativecooler drawsexteriorairintospecialpadssoakedwithwater,wheretileair iscooledby

evaporation,thencirculatedintoyourhome.

Yourevaporativecooler makesthe best possibleuseofthe evaporativeprocess bymeteringthe flowof

water,distributingit evenlythroughthefiltermedia,and blowinga steadystreamof cooledairintoyour

home.Theair isthen channeledthroughthebuildingand ventedout ofthe homethroughopen

windows, doors or vents.

5 l 3

678

Infiu__g_.L!are themajorpartsofyourcooler thatkeep thisprocess operatingefficientl_Themotor (1) __

drivesthe blower (2) whichdrawsair fromoutsidethroughthe pads (3) saturatedwithwaterfromthe

pump (4) viathe waterdistributionsystem(5). Thefloatvalve(6) and standpipe(7) holdthe waterin a

reservoir(8) at a constantlevel. FIGURE1

INSTALLATION

MountingOfDownDischargeAndHorizontalModels

1_ Read these instructions

carefully before installing,

operating or servicing your

evaporative cooler.

ShFETY

Caution:

Disconnect all

electrical power

to the cooler

before attempting

to install, open, or service your

cooler. If the cooler is

thermostatically controlled, the

thermostat is not to be used as a

disconnect as it may reset and start

the unit unexpectedly.

Evenwhileroutinelyinspectingor servicingthe

inside,thecoolercanbeaccidentallystacmd.Keep

childrenandpetsawayfromthecoolerand

electricalsupplywhenyouareworkingonit.

Mwaysusetherecommendedtoolslistedinthis

manual.Don'tattempttoperformanypartofthe

installationdescribedinthisbookunlessyouare

fully qualified to doso.MIelectricalworkmust

meetlocalcodesandmustbeperformedby

qualifiedpersonnelunl'_

Toinstallcooler cabinet, the followingtools are

required:

• wood Strip

• 5/32" bex keyAllenwrench

• Pliers

• Adjustablewrenches

• Tubingcutter

• Screwdrivers

Your cooler may be... a horizontal

discharge, a down discharge,or a windowmodel.

Horizontal discharge units are designed for

installationon the side ofa building,on a flat or

pitchedroof, or on a slab at ground level.Down

discharge coolers are designedfor flator pitched

roofs. Window models attach easilytowindow

apertures or throughthewall.Variousinstallation

techniquesare shownin thefollowingsection.

If the cooler you have selected is to be

mounted on the roof of your home, remember

these important rules:

• Neverattempt to install or service a cooler during

astorm or in high windconditions. Besiderisking

loss or damage to parts, youcouldbe risking

substantialinjury

• Neverwear shoes withslick soles whenworking

or walkingon a roof.Whenyou leastexpectit you

mayend up slipping.

• Neverdrain waterdirectlyon a roof. Usea drain

hose to runwater to the ground or toa rain gutter.

Beforeattemptingtoinstallthecooler,make

sure thefollowingpreparationshavebeen

made:

• Assurethatthe mountingsurface is strong enough

to bearthe weightof the cooler when in use;

remember thatwhen the systemfillswithwater,the

cooler will be much heavier thanwhen dry.For

operating weight,see accompanyingparts list.

• Makesure you haveadequate meansfor liftingthe

cooler in place.

• Checktheelectrical supplyto see that it matches

therequirements shownon the motor name plate.

• Makesure the mountingsurface is levelin all

directions.

• Makesure anyductwork and electrical needs

complywithlocal, state, countyand federal codes.

• Makesure cooler is secure to the standor leg kit

andthat is secure tothe roof.

ffthecooleristobemountedontheroof,construct

asuitableroofstandtosupporttheentireweightof

theunit.Aroofjackshouldnotbeusedtosupport

anyweightoftheunit.Werecommenda#785legkit

tosupporttheunitandtosecureittotheroof.Place

thecoolerovertheroofjackandpositionsothatit

islevel.Carefullysealthespacebetweentheroof

jackandbottomofcoolerwithcaulkingcompound,

silicone,asphaltor industrialsealingtapetoprevent

airleakage.Thencarefullysealtheroofjacktoroof

withasphaltor caulkingcompoundtopreventair

leakagefromcooleror rainwaterfromleaking

intoroof.

2 Evaporative Cooler Use and Care Manual

Duct Placement

Figures2-6showcommonmethodsofduct

placementforeffectivecooleroperation.

Required Exhaust Openings

Usingstandard CFMratings, a common methodfor

determininghowmuch to open doom or windows

for proper exchangeis: 2 square feet

per 1,000 CFM.

FIGURE2_

7?ansitionDuct_l_==_

, fin N N

Blower

Rt_er

- RoofSland I I ____[q_oof Stand_

Separately

, Ouct FIGURE6

Boxed

Opening

Electrical Installation

(DuctedModels)

C_ Disconnect all electrical

power to the cooler before

attempting to install, open, or

service your cooler. If the

cooler is thermostatically

trolled, the thermostat is

ot to be used as a disconnect

it may reset and start the unit

ctedly.

lio°

Locatediejunctionboxinstalledincabinetcorner.

Notethattherearetwoplug-ins,onefordiemotor

andonefordiepump(seeFigure7). Thesemaybe

indiejunctionboxorpartsbag.Thepowersupply

fromyourhousemustbeconnectedtothisjunction

boxtoprovidepumpandmotorpower.Thewiring

diagraminFigure8showstheseconnections.

Grounding

Installagroundwiretosuitableelectricalground.

Attic

Ceiling

I "- -.._ with g¢'giste_

Closed in/area sends as duct

FIGA_ . j

Oiling AngleIrotl

Supl_lrt

Alignment Pullel,

Set ,9_'rew Pitch Set

Scre_t

Motor Mounting Motor

Bracket B!ou_r Straps

PullO'

I I _" / _" rt I SuplJort

F_ [ _ Adjustment

\ Bracket

FIG_ U 1! I

FIGURE11

MotorInstallation(DuctedModels)

Installation

1.Adjustsupportbrackets,ffnecessary,towidthof

motor.

2. Placemotorin brackets,withclosedportionof

motorcaseontop.

3. Placemotorstrapovereachresilientringmotor,

atthetabs.

4. Securetobracketwithmachinescrewsandnuts.

5. Insertsheaveontodiemotorshaft.

6. Installbeltfrommotorsheavetodieblower

pulley.Alignthesheaveandpulleyas short;.

Movemotorsheavetoachievealignment;donot

moveblowerpulley(seeFigure9).

7. Tightenbelttothepropertension.When

correctlytightened,diebeltwilldeflectabout1/2

inchbyhand(seeFigure10).

8. Rotateblowerwheelbyhandtoseethatitmoves

freelywithoutrubbingagainsthousing.

Checkmotormountingto besureallscrewsand

nutsaretighteneddown.

checkmotoramperage.Topreventoverloadingof

motor,checkamperagewithallwindowsanddoors

openandallairreliefsystemsoperating.Notesheave

pitchsetscrew(seeFigure10).

Removal

Unplugmotorcordfromjunctionbox,loosenset

screwinmotorpulleytoremovebeltandpulley.

Loosenandremovenutsandscrewson support

brackets.Removemotorstrapsfrommotor.Pull

motorfrombrackets(seeFigure11).

Do not exceed maximum amperage

output as stamped on the motor

specification plate or motor can

overload. Only qualiJ'led persons A _ _

with proper electrical

equtpraent and knowledge

should adjust variable pitch _

sheaves. Do not allow water to _ I _

get on the motor, as it will burn _V_

out the windings. _

Disconnect all electrical

power to the cooler and insure that belt

is not rotating before adjusting belt tension by

changing diameter of adjustable sheave. Adjust

belt tension only by adjusting motor bracket.

ffcoolerisconnectedtoductwork,airdeliveryand

motoramperagewillbedecreasedduetoincreased

ductresistance.Tocompensateforthis,themotor

pulleyisadjustedoutor in,usinganammeterto

II5V l-Speed Electrical Wiring

(Tape backunused orange and red wires)

ll5V2-SpeedWectrical_Sring

(Tapebackunus_l_sg¢ w_re)

btot_r

230VI-sl_e_ ElectricalWiring

(Tapebackunusedwhitewire)

Evaporative Cooler Use and Care Ma_val 3

OverflowStandpipeand

DrainLineInstallation

I. Installoverflowdrain bushingin bottom of

cooler,

2. Screwoverflowstandpipe into drain bushingand

tightensnuglyto prevent leakage.

3. Slide rubber washer over drain bushing,push

drain bushing through bouom ofcooler, and

tightennut.

4. Connect(copper/pvc/garden hose) to drain

bushingand drain in accordance tolocal codes

(see Figure 12).

._Over)qow Standpipe

F_

Connect Water Supply

Awatervalveshouldbe installedataconvenient

locationtoallowthewatersupplytobe turnedon

andoff(seeFigure14);1/4"tubingisusedto

providewatertothecooler.Awaterconnectorkit,

availablefromyourdealer,providesthenecessary

items.

l. Remove7/16"knock-outfromcornerleg.

2. Insertendoftubingthroughthisopening.

3. Plaeetubenutandferruleoverendoftubing.

4. Installfloatvalvethroughbracketprovided.

5. Inserttubeintofloatvalveandtightentosecure.

Note:Softwaterequipmentshouldnotbe

attachedtoany waterlinesgoingtoa cooler

"Softwater"willcausecorrosionanddecrease

effectivelifeofa cooler

Bracket

ut LockWasher

Faucel Water

InstallBleed-Off

Ableed-offsystemhas been provided withyourcooler.

Its purpose is to eliminatea small quantityof water from

recirculation;this reduces scale build-up. Thisbleed-off

assemblymerelyrequires insertingthe bleed-offhose

into the pump assemblyand routingbleed-line hose

through standpipeopening.

1.Installbleed-lineintopumpassemblybleed-offtap.

2. Routefarendofbleed-lineintostandpipe.

3. Installclampwithscrewonbleed-hne.

4. Adjustscrewtoobtainflowrateforappropriate

modelindicatedintableatright.

Models Gallons Per Hour

Side/Bow_ Molor HP (Recommended)

wlrdow

S/D330 I/3 24

R_5aO

R_4aO0

,_)430 t/3 36

RW4500

S/D430 I/2 42

RgSO00

S/D630 I/2 47

S/I)630 3/4 _ 5

S/08OO 3/4 _5

S/OSO0 I 60

$t,_nd**

140

95

80

7O

60

60

53

*_t _p soa 12-ouncebeveragecanfilled by bleed-offin

thisntanyseconds.

Note:Bleedratemaydegradeslightlyaftertwoweeksandshould

becheckedtwotofour weeksafter initialsettingandreadjusted

AdjustingWaterLeveland FloatValve

Fillreservoiras follows:

1.Tornwatersupplyon. Checkfor good

pressure andflowfrom float valve.

2. Whenfloat valveshutsoff, check waterlevel.

Waterlevelshould be from 1/2"to 1" below

top edgeof overflowstandpipe.

3. Tornon waterand adjust floatvalveby

bendingthe rod (see Figure 15).

FIGURE15

Clamp with

BLEED-OFFKIT

GENERAL INSPECTION

Start-UpInspection

Beforestartingthe cooler motorand pump to check

outoperation,makesure allinstallationsand

adjustmentshavebeen properlyand thoroughly

made. Assurethat:

• Coolermountingis level;duetis sealed.

• Cabinetis securely fastened to mounting.

• Coolercabinetisgrounded.Electrical

connectionsare safeand secure.

• Motor,pump,endfloatinstalled.Motorend

pumppluggedintojunctionbox (on window

models, theyare factory-wired).

• Pumpimpellertoms freely.Removepumpend

basket.Removeimpeller cover(see illustration

on page6) andspin the impellerto assurefree

rotation.

• Waterlinesconnectedsecurelywithoutleaks.

Watersupplyturnedon.

• Floatadjustedfor properwaterlevel.

• Blower,shaft,collar,andpulleyset bolts are

snug(do not ovet_ightenpulleybolt).

• Pulleyalignmentokay;belttension okay(see

page3 and4 for instructions).

• Blowerbearingsare lubricated.Fill oil cupwith

agoodgrade SAE20Wor 30Woil.

• Padspresoakedend correctlyinstalled.

• Allfreeaspen fibers are removedfromboUom

panto preventblockageofwater distribution.

• Trimcontsolswitchto PUMPONLYposition.

Checkto see that pumpstartsend thatwater

flowsevenlythrough alldistributionoutlets.

Start-UpCheckList

Tocheckoutinstallation,aninitialsturt-up

procedureshouldbefollowed:

I. Turnelectricalsupplyon.

2. Turncontrolswitchto PUMPONLYposition.

Checkto see that pumpstartsandpadsare

evenlywet.

3. Openwindowsor vents in house.

4. Startblowerbyswitchingto COOL.

5. Checkfor cool airdelivery.(Note:anaromaof

dampwoodwill be presentduringinitialuse of

newpads.)

In caseof troublein anyof thesesteps,referto the

TmublesheotingChartonpageZ

Cabinet Inspection Check List

1. Checkfor leaks.

2. Checkto see that the cooler andtroughsare

level.

3. Checkcoolerpads forunevenwettingor open

spots.

4. Checkwaterlevel(see page 4).

5. Checkwulerdistribution systemfor lull even

flow.

6. Makesuretroughopeningsare unclogged.

7. Rotateblowerwheelfor free movement,Align

belt (see page3).

8. Checkbelt tension andcondition.

9. Checkthat set screwsandnutson pulleys,

blowerwheelend collarsare tight.

te caseoftroublein anyof thesesteps,referto the

TroubleshootingChartonpage Z

4 _orativeCoolerUseawACareManual

REGULAR MAINTENANCE

Regular,careful maintenancewill "allowyouto

enjoya long, more efficientservice life from

yourcooler. Befores'fartinganymaintenance

operation, read thorunghlyall operatingand

maintenance instructions andobserve atl

cautionsand warnings.

Changing Cooler Pads

Yourcooler padsshould be changed atleast

twicea year.., atthebeginningof a season and

midwaythrough.

PressRetainerWiresDownToClearFrame Butyour

tadPrrame_""'--"--'7_ padsmay

need to be

changedmore

frequently,

dependingon

localair and

waterconditions.

For instance,in

FIGURE 16 areas where

mineral content of

the water is high, deposits maybuild up in the

cooler pads, restricting air flovz

Replacepadsasfollows:

l. Removepad assemblyfrom cabinet.

2. Removepadframe stiffenerfrom frame, using

cautionas stiffener can spring back. Carefully

removeall pad from retainers. Removeand

discard pads (see Figure 17).

3. Usinga mild detergent,wash dirt and scalefrom

pad frames.Wirebrushing is not recommended.

Rinsewithfresh

water.

PadRetainer 4. Laynew pad in

frame,startingat

troughend, malting

sure pad is snug

againsttroughand

~stiffener outer edges withno

air spaces.

5. Padthickness

should be uniform

across the frame.

Note: Pad must

completelyfillframe or hot air mayenter house.

6. Replacepad retainers and lock under edgeof

frame.Sharp points mustbe buried in pad.

7. Pre-soak pads and reinstallpad flame.

8. Startpump and allowtroughs tofill.., check

waterlevel in troughsbyslightlytiltingeachpad

frameout.

Adjusting Belt Tension

Each timeyou inspect your cooler,be sore to check

belttensionon motor/blowerassembly.Checkbelt

CabinetInspection

ChangingCooler Pads

I.ubrication

AdjustingBeltTension

CleaningWaterPump

Cleaning& TouchUp

Drain MIWater Lin_

5

5

5

5

5

5

ft'

€'

t/

t/

€'

t/

it'

t/

€

condition and replace it iffraysor defectsappear.

Checkalignmentof blower pulleywithmotor pulley

(see page 3 for detailed steps).

Lubrication

Blowershaft bearingsneed periodic lubrication.The

oil cups onthe blowershaft bearingsshould befilled

with agood grade SAE20Wor 30Woil when

necessary.Under normaluse, oiling is required every

three monthsofoperation. Do Not Over-Oil. The

pump and blower motors do not require lubrication.

Cleaning Water Pump

Disassembleandcleanwaterpumpasfollows(see

Figure18):

1. Withpowersupplydisconnected,

unplug pump cord. _ FourSnap-Out

2. Removepump. _f/_Tabs

3. TOprevent

breakage, carefully

releasethe four soap-

out tabs, and lift

impellerbase plate

from thepump body

4. Usinga milddetergent FIGURE18

solution, washalldeposits

frominside

aroundimpeller

andimpellerbase

plate.

5, Spinimpellerto

dislodgeany

foreignmaterial.

6. Rinseand

reinstallimpeller

baseplate.

7. Reinstallpump.

8, Connectcord.

t_j

'/" lmm_

Bv,se P/ate

I

Caufion..Bonot allowpump to toppleowr and become

subraergedsince waterwiUdanutgepumprtmtor.

_ Neverwashyour coolercabtnetwithagardenhose

since watermayharmmotorandpump orseepinto ductumrk.

t/

€

Caution:

Disconnect all

electrical power to the

cooler before attempting to

install, open, or service

your cooler. If tbe cooler is

thermostatically controlled,

the tbennostat is not to be

used as a disconnect as it

may reset and start the unit

unexpectedly.

Note: Do Not Undercoat The

Water Reservoir

Yourcooler's water reservoir is finished

with a PolybondTuapphance-type finish.

It is so hard that asphalt-type cooler

undercoating will not stick to it.

Undercoat will break free and clog pump

and water disMbutor.

Do not use cooler cleaners, cooler

treatments, or other additives in this

evaporative cooler. The use of any of

these products will void your

warrantyand may impair the life of

your evaporative cooler.

Drainingand Touch-Up

Cleanthecoolercabinet(withpoweroffand

framesremoved)asfollows:

1. Connecta drain hose to the drain fittingto the

bottomof the reservoir.

2. Removestandpipefrom the drain fittingand

allowwater to drain(never drain wateronto a

roof,make sure drain hose is long enough to

reacha gutteror over edge ofhouse).

3. Cleanreservoir.

The hardness, adhesion and smoothnessofthe

internal and externalfinishon yourcooler makes

it extremelyunlikelythat scratches or chipping

willoccur. In dieevent thatfinishdamagedoes

occur, it shouldbe promptlyrepaired bythe

followingprocedures:

1. Sandthearea around bare metalspots.

2. Primeand paintwith a qualitypaint.

£vapo_tlve Cooler Use atuI Care Mam_l 5

MOUNTING WINDOW MODELS

Assurethatthemountingsurfaceis strong elmughto

beartheweightof thecooler ',','henin nse.

Rememberthatwhen timsystemfillswithwater;the

cooler willbe num]lIleavierthatl whendry For

operatingweigfu,see accompanyingPartsList.

To Install FIGURE19_

Cooler On A

Flat Support

"['he most conmlon

method of

installation _ _

involvesmounting :"

the cooler on a

llat support or

,...it

stand provided by

the installer.The

ductand grille

pmtinn are placed

through the

windowopening

andwindowpanels are fittedintoposition (see

Figure19).

• FlatSupport

Anothermethodofinstallationinvolvestheuseofa

chainkitandstandoffhardware.

To Install Cooler Using A Chain Kit

(seeFigures20,21, 22)

1. Attachscrewhooks tooutside windowframe

approximatelytwofeetabovecooler. Besure

hook is insertedto full depthin framefor

maximumstrength.Attachchain to eachhook.

2. If your cooler does not have holes

predrilled, drill 3/16" holes 1"aboveeach pad

framecorner at rear ofcooler cabinet. Bolt

hanger tabstocooler (notched end up) using

machine screwsand nuts provided.

3. Placeleglevelingbolts in holesin cabinetfront

withnut, washer and angleto outsideof cabinet.

4. Checkwindowsilloffset.., todetermine the

thicknessof the woodstrip for clearance. This

clearance willprovidespace for the grilleand

winterizingcover ffused. Secure woodstrip with

nailsor screws.Fastenthe twobrackets with

screwsprovided, makingsure theyace square

withthewindowsash.

5. Placecooler in windowallowingduct torest on

sill.Usingchain link that bringscooler closestto

levelposition,place link overhanger tab.Turn

link to lock it into notches on hanger tab.

6. Place leg levelingbracketon leglevelingbolt with

bracketagainstwall.Adjustbolts andchain to

levelcooler.Secure brackets to wall witheight

#10 Phillipshead screws provided.

Note: Cooler may need to be re-leveled later to

compensate for added weight of water

7. Optionalwindowfillerkit is availablefromyour

dealer (RK227).

: _ Wa#

:_ si_

FIGURE20

, m_l

LevelingBolts

WaftBracket_ if:

Wintenzin

Cover

SeparateO

FI_!9_._____

I

I

i

i

i

i

i

i

I

I

i

I

I

m

I

m

I

k

i

i

i

'J"Bo_s With

BracketUsed

Forlgveling

! !

Caution:To

reduce the risk

ofelectric

shock, connect only

to an outlet provided with a

ground fault circuit

interrupting device.

Electrical Wiring on Window Models

Yourunit has been pre-wired atthe factoryso

furtherwiringis not necessary Figure23 shows the

wiringdiagramof your unit in case ofelectrical

componentreplacement.For motor wiringuse

diagramon motor backplate.

Two Speed Motor Wiring

PUMP SWITCH MOTOR SWITCH

ON OFF LOW OFF NIGH

FIGURE23

Caution:All

by qualifled personnel.

6 Evaporative Cooler Use and Care Manual

Troubleshooting

Thefollowing troubleshooting guide is intended to address tilemost common symptoms and is by no means exhanmive. If

symptmns persist, call a qualified servicem_. Electricalwork should be completed bya certified electrician. Turn off all

power to the cooler before attempting to troubleshootany of the fulinwingsymptoms.

SYMPTOM POSSIBLE CAUSES REMEDY

Unitfailstostartordeliverair

1 NoelectricalpewerIntrait

A.Fuseblown

B.Orcuitbreakertripped

C.Cord(s)unpluggedor damaged

2. Beltimproperl)adjustedor broken

3. Motoroverheatedand/orfrozen

A.Belttootightor broken

B.Blowerwheelbearings

dry/shaftfrozen

C.Motoroverloaded

D.Faultywiringor shorts

I. Check power

A.Replace fuse*

B. Reset breaker*

• Ifcmtdition [_'rstsls tail el_:trtllan

C.Plug incord(s) or replace if

damaged

2. Adjustbelt tension

3. Replace motor

A.Adjust beh tensionor replace

B. hubricate or replace blower

bearings

C. Usingammeter, adjust motor to full

loadnameplate amps

D.Callelectrician

Unitstarts

butairdeliveryinadequate

1. Lackofsufficientair exhaust

2. Motoruuderloaded

(ductedunitsonly)

3. Belttooloose

1.Openwindowsor doors toincrease

ventilation

2. Usingammeter,adjustmotortofull

loadnameplateamps

3.Adjustbelttensionor replaceif

needed

Inadequatecooling

1. Inadequateexhaustin house

2. Airregistersimproperlypositioned

3. Insufficientwater/ pad not wet

A.Pads plugged

B. Dryor open spots on pads

C. Troughholes clogged

D.Pump not working

1.Openwindowsor doors toincrease

ventilation

2.Adjustto directair asdesiredor

insta!llowerrestrictionregisters

3.Checkwaterdistributionsystem

A.Replacepads

B. Repackpads

B.Cleantroughsandunplugholes

D.Unplugpomp.Cleanimpeller

housingofforeignmatterand

reinstall

E. Loose connections in water system ft.Check forleaks and correct

E Distributor clogged or corroded F.Clean or replace

Motorfailstooperate 1. Excessivebelt tension 1.Adjust belt tension

2. Blower shafttightor frozen 2. Lubricate blower bearings

3. Motor overloaded 3. Correct - do not exceed motor

nameplate amps

4. Incorrect sheaveadjustment 4. Serviceman shouldcorrect

5. Pulleysudsaligned 5. Check and correct alignment

Waterdrainingfrom 1.Floatarmimproperlyadjusted 1, Adjustfloat

overflowmadpipe 2. Seat in floatvalveleaking 2. Replace floatvalve

3. Standpipe not tight 3. 'lighten standpipe

inockingorbangingsound 1. Bearings dry 1. Lubricate blower bearings or replace

if badly worn.

2. Wheel rubbingblower housing 2. Inspect blower shaft, collars, belt and

or rotating off-balance pulley alignment and motor mounting

3. Loose parts 3. Resecure or reconnect

Blowershakesorraffles 1. Belt or pulley loose 1.Inspect and adjust, or replace belt

and/or pulley as needed.

Exctfah.'thnm_ity in house 1. Inadequate exhaust 1.Open doors or windows to increase

ventilation

Mustyoru#a_utt odor I. Staleor stagnant water in reservoir I. Drain, flush and clean reservoir,

install bleed-off kit

2. Replace pads

3. Turnon water before starting unit

2. Padsmildewedor dogged

3. Padsnotcompletelywetbefore

cooleris turnedon

GettingTheMost

FromYourCooler

Yotlr evaporative cooler is a finely crafted, economically

tolerating unit htllll on decades ofkno\_ffin_x and

research. It ser_es as the heart of an ovrrall air enoltilg

alld tnuvtug 5ystelu for yOtlrJlolne lllll Ihet'e are :tn_lulher

nf ways yml can maximizethecomfort,t'fficiellc}_ eeonom!,

and convenience of your Iota] coo]aig system

Maintenance

Regularmaintenmzeeasrecommendedhi titisinanualit,

essentialforcnolingcomfort,extendingtileIth'of}_tll

cooler,andmrnidingunnecessaryparts replaceamnt'_.

Start-up,mid-seasonand shut-do;vnseta,ictugshould

neverheoverinoked.Changepadsatleastt_icea year,or

sooner,ifmineraldepositsor dustbuild-up.

Add-OnCoolers

Coolerscome in a,,vide arrayof sizes,horsepower, and

capacities suitable for patio, garage, guestroom, mid so

forth.More thanone cooler in a singlehome improves the

cooling effectivenessof theentire system. Owners of

refrigerated air conditioning have found that the addition

ofan evaporativecooler rosilyreduces theirelectric bills.

insulation

Onceyourcooler fozees cooled air intoyour home and

pushes the hot air out, good insulation around your

duclwork willkeep theair as cool as possible. Whole

house insulation will prevent heat from seeping in and will

improve cooling comfort.

MniB-SpeedMotor

The coolingrate can be controlled by increasing and

reducing the amount ofcooled air blown intoyour home.

Two-speedmotors allowyou touse higher speeds during

the honest part of the day,lower speeds for milder

temperatures.

Bleed-off

Bleed-offcomponents are included _th each cooler and

should be installed as instructed in this manual.

AtticVents

Byexhausting cool air throughtheattic, you can reduce

thetemperatureofthishot spot and makeyour home

more comfortable. Itis imporiant to remember to provide

adequate exhaust in the area. Again,provide 2 square feet

ofrelief for every 1,0(_ CFMofair delivery.

ShadetheCooler

Shadingthecoolerkeepsdietemperatureofintakeair

lower.

ThermostatControl

Thecooler can he set to turn on and offautomaticallyat

the temperature desired.

TunerControl

Thecooler can be programmed to turn on and off

automaticallywhen desired.

ReplacementParts

When ordering replacement parts, alwaysrefer tothe

serial and model number of yourcooler. Usethe part

numbers listed in the accompanyingparts list, as

illustratedin the diagrams foryourmodel.

Evaporative Cooler Use atttl Care ara#ual 7

AdobeAir, Inc.

500 South 15thStreet * Phoenix,Arizona85034

8 Et_mtiveO_l*rtJse_ml_Mas_€l

/