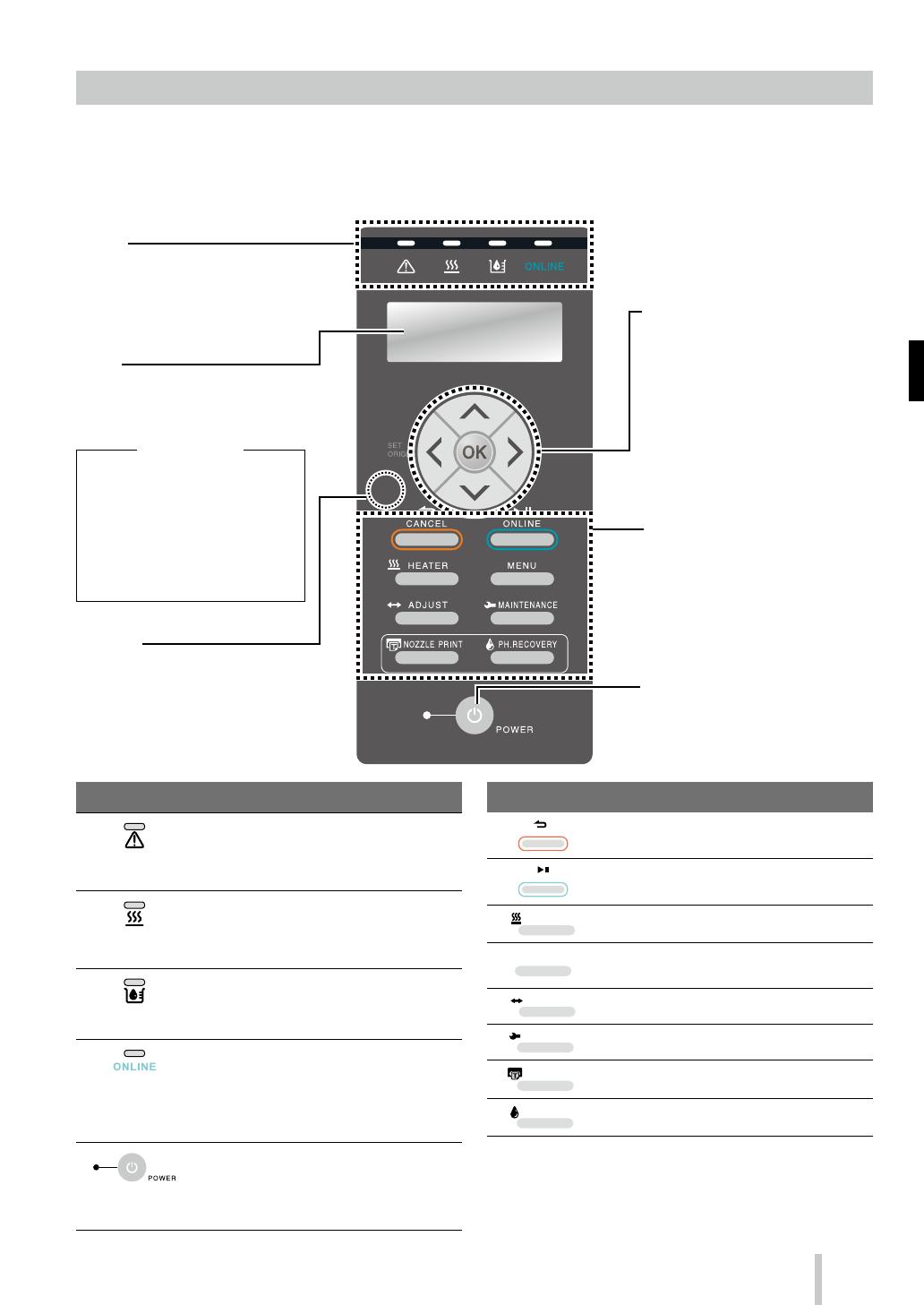

Operation panel

The buttons, LEDs and LCD are placed on the printer's operation panel as shown below. In addition, the operation

panel is also equipped with a buzzer to draw attention in case an error occurs or an invalid button is pressed.

The printer enters waiting mode if it is not used for a given length of time.

Buttons

CANCEL

Cancels entered parameters or returns back to the

upper menu.

ONLINE

Switches between online and oine states, and

puts the printer in pause or resumes printing.

HEATER

Enters heater control menu.

Used to display information about the printer and

change printer settings.

Used to enter the adjustment menu.

Used to enter the maintenance menu.

Used to perform a nozzle print.

Used to enter the cleaning menu.

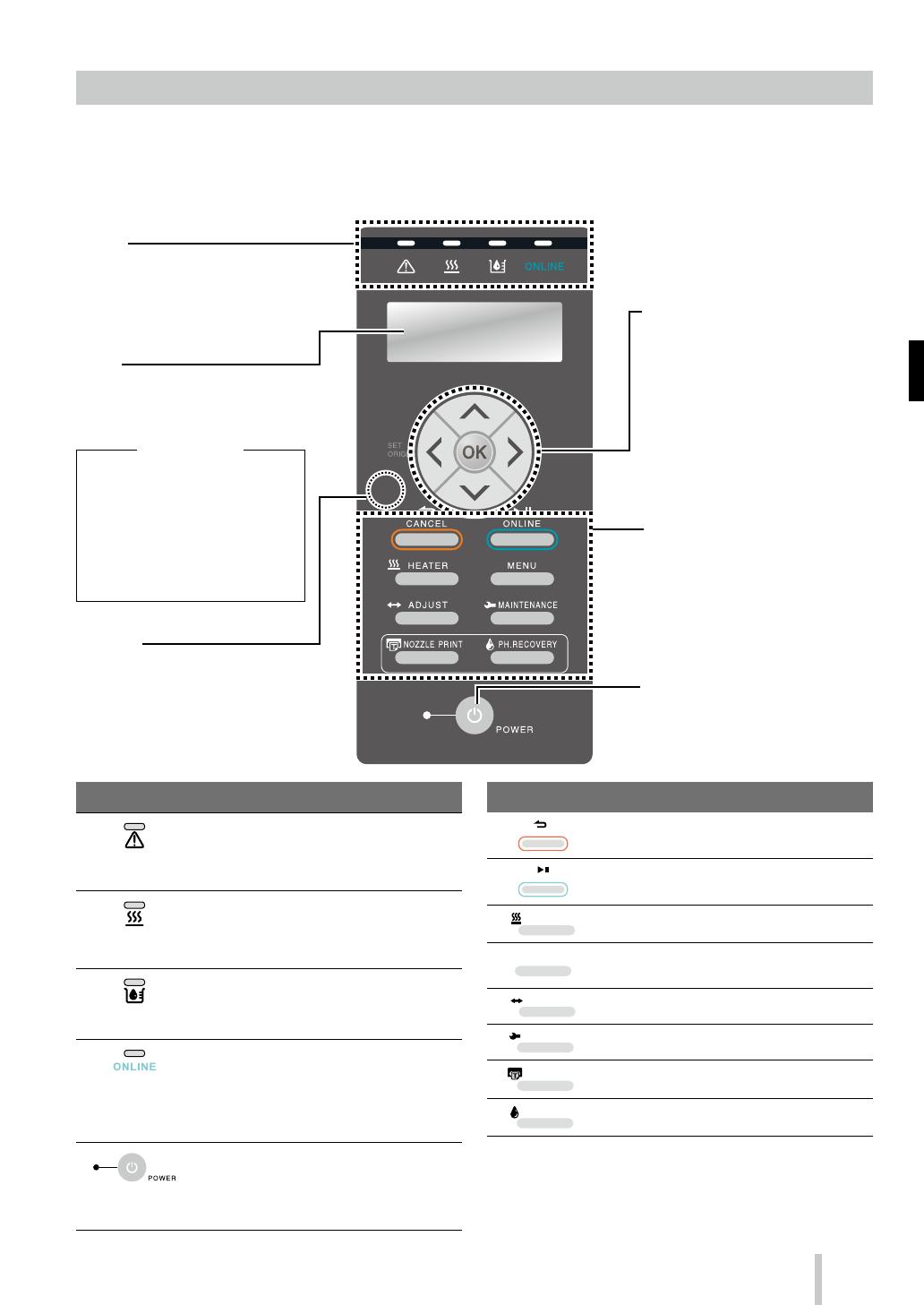

LED

Error LED

(Orange)

Indicates whether an error has occurred.

ON: An error has occurred.

Blink: Warning state.

OFF: Normal (no error)

Media heater LED

(Green)

Indicates the status of the media heater.

- ON: The set temperature has been reached

- Blink: Currently heating

- OFF: Media heater is o

Ink LED (Green)

Indicates whether ink is remaining.

ON: Ink of all colors is present.

Blink: Ink near-end (The level of any color is low.)

OFF: No ink.

ONLINE LED

(Green)

Indicates the online, oine, data reception, and

pause status.

- ON: Online

- Blink (slowly): In pause

- Blink (fast): Data reception

- OFF: Oine

Power LED

(Green)

Indicates whether the printer is turned on or o.

- ON: The printer is turned on.

(The LED is lit also when the printer is in waiting

mode.)

- OFF: The printer is turned o.

31

•

Power switch

Used to turn on or off the power of the

printer.

Used to manually enter and exit waiting

mode.

•

Buttons

Use these buttons to operate the menu

of the printer.

Refer to the table below.

•

Up, Down, Left, Right buttons

Used to select menu options, switch

between menus (selection, increasing/

decreasing values), etc.

•

OK button

Used to confirm the menu and

parameters.

•

LCD

It shows the status of the printer and

displays the menu window (2 rows, 20

characters).

•

Buzzer

Sounds when an error occurs or an

invalid button is pressed, and warns of

daily maintenance and when the print

heads are uncapped.

•

LED

ON, blinking and OFF indicate the

status of the printer.

Refer to the table below.

Waiting mode

(During waiting mode)

LCD: Display and backlight turned o

Online LED: Flashes slowly

Other LEDs: O

(Exiting waiting mode)

The printer exits waiting mode when

- any button is pressed,

- the printer receives print data.