Heat Controller HWW120 Operating instructions

- Category

- Heat pumps

- Type

- Operating instructions

This manual is also suitable for

Heat Controller, Inc. • 1900 Wellworth Ave. • Jackson, MI 49203 • (517)787-2100 • www.heatcontroller.com

INSTALLATION, OPERATION

& MAINTENANCE MANUAL

R-410A Water-to-Water Series:

HWW Water-Source Heat Pumps

1

Model Nomenclature ..................................................2

Storage .......................................................................4

Pre-Installation............................................................4

Physical Data..............................................................5

Dimensional Data .......................................................6

Unit Installation ...........................................................7

Piping Installation .......................................................7

Load Plumbing Installation .........................................8

Water Loop Applications .............................................9

Open Loop - Ground Water Systems .......................10

Water Quality Standards ..........................................10

Ground Loop Applications ...................................11-13

Electrical - Line Voltage .......................................14,16

Electrical - Accessories.............................................15

Water Valve Wiring ...................................................15

Electrical - Low Voltage Wiring .................................17

Electrical Wiring Schematics ...............................18-19

CXM Controls ......................................................20-22

Piping System Cleaning & Flushing .........................23

Unit and System Checkout Procedure .....................24

Start Up Procedure ..............................................25-26

Operating Pressures............................................27-28

Preventive Maintenance ...........................................29

Refrigeration Troubleshooting Form .........................30

TABLE OF CONTENTS

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

2

Heat Controller, Inc. WATER-TO-WATER (HWW) SERIES Installation & Operation

Page 21

7 May, 2009

HEAT CONTROLLER OEM PRICE LIST

HWW HIGH EFFICIENCY Water-to-Water HFC-410a Heat Pumps

The basic unit price includes sealed heat pump refrigerant circuit.

• Cabinet - Heavy gauge galvanized steel with black polyester powder

coat paint – multiple removable panels for service access – stainless

steel front access panel(s) – interior surfaces lined with ½ inch dual

density acoustic type glass ber insulation – IPT water connections –

high and low voltage knockouts.

• Controls - Solid state control system with seven standard safeties

including anti-short cycle, over voltage, under voltage, high refrigerant

pressure, loss of refrigerant charge, low source water temperature,

low load water temperature – run and fault lights on cabinet exterior –

alarm contact for remote monitoring of fault condition ( eld selectable

for dry contact or 24vac).

• Refrigerant Circuit - Compressor(s) – coaxial source and load heat

exchangers – revering valve(s) – lter driers(s) – thermal expansion

valve(s) – high pressure and loss of charge switches – high and low

side Schrader ports for service – non-ozone depleting HFC-410a

refrigerant.

• Compressor(s) - High ef ciency scroll compressor - internally sprung

and externally isolated using dual vibration isolation system for

quiet operation. Mounting system includes rubber grommet mounts

between the compressor and a mounting tray then another set of

rubber mounts between the mounting tray and unit base pan.

• Reversing Valve - 4-way pilot operated, solenoid activated in cooling

mode.

• Safety Agency Listing - Product is ETL Listed.

• Application - May be applied in water loop heat pump, ground water

heat pump, and ground loop heat pump applications.

Entering Water Temperature Range: 20 - 110°F (-6.7 - 43.3°C)

Sizes 036, 060 & 120

HWW Model Structure

Basic Unit Description:

H W W A0 3 6 C1 1 0 C F C

1 2 3 4 5 6 7

8

9 10 11 12 13 14

HW = HEAT CONTROLLER SERIES HIGH EFFICIENCY

MODEL TYPE

W = WATER TO WATER

CONFIGURATION

UNIT SIZE

036 - 1,3,4

060 - 1,3,4,5

120 - 1,3,4,5

REVISION LEVEL

A = CURRENT

VOLTAGE

CONTROLS

0 = RESIDENTIAL ( 208-230/60/1 ONLY)

CABINET INSULATION

HOT WATER GENERATOR OPTIONS

C = Copper

SOURCE WATER COIL OPTIONS

N = Cupro-Nickel

C = Copper

LOAD WATER COIL OPTIONS

N = Cupro-Nickel

0 = NONE

1 = HWG w/INTERNAL PUMP (RESIDENTIAL)

F = FRONT

WATER CONNECTION LOCATION

1 = COMMERCIAL EXTENDED RANGE

VOLTAGE

2 = HWG COIL ONLY (COMMERCIAL)

C = CXM (ETL for USA & CANADA)

1 = 208-230/60/1 - 410A

3 = 208-230/60/3 - 410A

4 = 460/60/3 - 410A

5 = 575/60/3 - 410A

}

polyster powder

R-410A

HWW HIGH EFFICIENCY Water-to-Water R-410A Heat Pumps

• Cabinet- Heavy gauge galvanized steel with polyester powder

coat paint – multiple removable panels for service access – interior

surfaces lined with 1/2 inch dual density acoustic type glass

ber insulation – IPT water connections – high and low voltage

knockouts.

A=CURRENT 036

B=CURRENT 060, 120

3

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

General Information

� WARNING! �

� WARNING! �

� CAUTION! �

Safety

Warnings, cautions and notices appear throughout this

manual. Read these items carefully before attempting any

installation, service or troubleshooting of the equipment.

DANGER:Indicates an immediate hazardous situation, which

if not avoided will result in death or serious injury. DANGER

labels on unit access panels must be observed.

WARNING: Indicates a potentially hazardous situation, which

if not avoided could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation or an

unsafe practice, which if not avoided could result in minor or

moderate injury or product or property damage.

NOTICE: Notication of installation, operation or maintenance

information, which is important, but which is not hazard-

related.

WARNING! To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must be

serviced only by technicians who meet local, state, and

federal prociency requirements.

WARNING! All refrigerant discharged from this unit must

be recovered WITHOUT EXCEPTION. Technicians must

follow industry accepted guidelines and all local, state,

and federal statutes for the recovery and disposal of

refrigerants. If a compressor is removed from this unit,

refrigerant circuit oil will remain in the compressor. To

avoid leakage of compressor oil, refrigerant lines of the

compressor must be sealed after it is removed.

CAUTION! To avoid equipment damage, DO NOT use

these units as a source of heating or cooling during the

construction process. The mechanical components and

lters will quickly become clogged with construction dirt

and debris, which may cause system damage.

4

Heat Controller, Inc. WATER-TO-WATER (HWW) SERIES Installation & Operation

General Information

Inspection

Upon receipt of the equipment, carefully check the shipment

against the bill of lading. Make sure all units have been re-

ceived. Inspect the carton or crating of each unit, and inspect

each unit for damage. Assure the carrier makes proper nota-

tion of any shortages or damage on all copies of the freight bill

and completes a common carrier inspection report. Concealed

damage not discovered during unloading must be reported

to the carrier within 15 days of receipt of shipment. If not led

within 15 days, the freight company can deny the claim without

recourse. Note: It is the responsibility of the purchaser to

le all necessary claims with the carrier.

Storage

Equipment should be stored in its original packaging in a

clean, dry area. Store units in an upright position at all times.

The stack limit for HWW36, 060 and 120 is three.

Unit Protection

Cover units on the job site with either shipping packaging,

vinyl lm, or an equivalent protective covering. Cap the open

ends of pipes stored on the job site. In areas where painting,

plastering, and/or spraying has not been completed, all due

precautions must be taken to avoid physical damage to the

units and contamination by foreign material. Physical damage

and contamination may prevent proper start-up and may result

in costly equipment clean-up.

Examine all pipes, ttings, and valves before installing any of

the system components. Remove any dirt or trash found in or

on these components.

Pre-Installation

Installation, Operation, and Maintenance instructions are

provided with each unit. The installation site chosen should

include adequate service clearance around the unit. Before

unit start-up, read all manuals and become familiar with the

unit and its operation. Thoroughly check the system before

operation.

Prepare units for installation as follows:

1. Compare the electrical data on the unit nameplate with

ordering and shipping information to verify that the cor-

rect unit has been shipped.

2. Keep the cabinet covered with the shipping packaging

until installation is complete and all plastering, painting,

etc. is nished.

3. Verify refrigerant tubing is free of kinks or dents and that

it does not touch other unit components.

4. Inspect all electrical connections. Connections must be

clean and tight at the terminals.

� CAUTION! �

CAUTION! All three phase scroll compressors must

have direction of rotation veried at start-up. Verication

is achieved by checking compressor Amp draw. Amp

draw will be substantially lower compared to nameplate

values. Additionally, reverse rotation results in an ele-

vated sound level compared to correct rotation. Reverse

rotation will result in compressor internal overload trip

within several minutes. Verify compressor type before

proceeding.

� CAUTION! �

CAUTION! DO NOT store or install units in corrosive

environments or in locations subject to temperature or

humidity extremes (e.g., attics, garages, rooftops, etc.).

Corrosive conditions and high temperature or humid-

ity can signicantly reduce performance, reliability, and

service life. Always move and store units in an upright

position. Tilting units on their sides may cause equip-

ment damage.

� CAUTION! �

CAUTION! CUT HAZARD - Failure to follow this caution

may result in personal injury. Sheet metal parts may

have sharp edges or burrs. Use care and wear appropri-

ate protective clothing, safety glasses and gloves when

handling parts and servicing heat pumps.

NOTICE! Failure to remove shipping brackets from

spring-mounted compressors will cause excessive

noise, and could cause component failure due to

added vibration.

5

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

Unit Physical Data

Model 036 060 120

Compressor (qty) Scroll (1) Scroll (2)

Factory Charge R410A (lbs) [kg] Per Circuit 4.5 [2.04] 5.5 [2.49] 5.5 [2.49]

Water Connection Size

Source/Load (in)

Residential 1" Swivel 1” Swivel

1-1/2 IPT

Commercial 3/4” IPT 1” IPT

HWG (in)

Residential 1" Swivel 1” Swivel

1/2" IPT

Commercial 1/2” IPT 1/2” IPT

Weight - Operating (lbs) [kg] 348 [158] 360 [163] 726 [329]

Weight - Packaged (lbs) [kg] 373 [169] 385 [175] 770 [349]

Water Volume (Source)

Gallons (Liters) 0.96 (3.64) 1.33 (5.04) 2.65 (10.02)

Dual isolated compressor mounting

Balanced port expansion valve (TXV)

Insulated Source and Load Water Coils standard

Insulated Refrigerant Circuit standard

Compressor on (green) and fault (red) light

6

Heat Controller, Inc. WATER-TO-WATER (HWW) SERIES Installation & Operation

Unit Dimensional Data: HWW 036–120

B

C

A

M

L

K

1.0

(2.5 cm)

1

2

3

4

5

6

J

H

G

F

E

D

1

2

3

4

5

6

Required

Service Access

Optional

Service Access

Required

Service Access

Optional

Service Access

B

C

A

1.0

(2.5 cm)

1.8

(4.6 cm)

1.3

(3.3 cm)

2.7

(6.9 cm)

7.3

(18.5

cm)

1.7

(4.3 cm)

B

C

A

M

L

K

1.0

(2.5 cm)

1

2

3

4

5

6

J

H

G

F

E

D

1

2

3

4

5

6

Required

Service Access

Optional

Service Access

Required

Service Access

Optional

Service Access

B

C

A

1.0

(2.5 cm)

1.8

(4.6 cm)

1.3

(3.3 cm)

2.7

(6.9 cm)

7.3

(18.5

cm)

1.7

(4.3 cm)

Notes:

1. Front & side access is preferred for service

access. However, all components may be

serviced from the front access panel if side

access is not available.

2. While clear access to all removable panels

is not required, installer should take care

to comply with all building codes and allow

adequate clearance for future eld services.

Water to

Water

Overall Cabinet

Water Connections

Electric Access Plugs

1 2 3 4 5 6

A

Depth

B

Width

C

Height

D

Source

(Outdoor)

Water In

E

Source

(Outdoor)

Water Out

F

Load

(Indoor)

Water In

G

Load

(Indoor)

Water Out

H

HWG

Return In

J

HWG

Water

Out

K

Low

Voltage

L

External

Pump

M

Power

Supply

036-060

in. 30.6 25.4 33 2.7 9.4 19.4 24.5 27.9 30.4 20.9 22.9 30.9

cm. 77.8 64.5 83.8 6.9 23.9 49.3 62.2 70.9 77.2 53.1 58.2 78.5

120

in. 30.6 52.9 37 25.2 25.2 30.1 30.1 34.9 34.9 29.9 31.9 34.4

cm. 77.8 134.4 94 64.0 64.0 76.5 76.5 88.6 88.6 75.9 81.0 87.4

7

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

Unit Installation

HWW Unit Location

These units are not designed for outdoor installation. Locate

the unit in an INDOOR area that allows enough space for ser-

vice personnel to perform typical maintenance or repairs.

The installation of water source heat pump units and all as-

sociated components, parts and accessories which make up

the installation shall be in accordance with the regulations of

ALL authorities having jurisdiction and MUST conform to all

applicable codes. It is the responsibility of the Installing Con-

tractor to determine and comply with ALL applicable codes and

regulations.

Locate the unit in an indoor area that allows easy removal of

access panels, and has enough space for service personnel

to perform maintenance or repair. Provide sufcient room to

make water and electrical connections.. Any access panel

screws that would be difcult to remove after the unit is in-

stalled should be removed prior to setting the unit. These units

are not approved for outdoor installation and, therefore, must

be installed inside the structure being conditioned. Do not

locate in areas where ambient conditions are not maintained

within 40-100°F [4-38°C].

Installation of Supply and Return Piping

Follow these piping guidelines.

1. Install a drain valve at the base of each supply and

return riser to facilitate system ushing.

2. Install shut-off / balancing valves and unions at each

unit to permit unit removal for servicing.

3. Place strainers at the inlet of each system

circulating pump.

4. Select the proper hose length to allow slack between

connection points. Hoses may vary in length by +2% to

-4% under pressure.

5. Exceeding the minimum bend radius may cause the

hose to collapse which reduces water ow rate. Install

an angle adapter to avoid sharp bends in the hose

when the radius falls below the required minimum and

causes a slight kink.

Insulation is not required on loop water piping except where

the piping runs through unheated areas or outside the build-

ing or when the loop water temperature is below the minimum

expected dew point of the pipe ambient temperature. Insula-

tion is required if loop water temperature drops below the dew

point.

Pipe joint compound is not necessary when Teon threaded

tape is pre-applied to hose assemblies or when ared-end

connections are used. If pipe joint compound is preferred,

use compound only in small amounts on the pipe threads of

the tting adapters. Prevent sealant from reaching the ared

surfaces of the joint.

Note: When anti-freeze is used in the loop, assure that it is

compatible with Teon tape or pipe joint

compound employed.

Maximum allowable torque for brass ttings is 30 ft-lbs [41

N-m]. If a torque wrench is not available, tighten nger-tight

plus one quarter turn. Tighten steel ttings as necessary.

Piping Installation

� WARNING! �

� WARNING! �

Piping must comply with all applicable codes.

Do not bend or kink supply lines or hoses.

Optional pressure-rated hose assemblies designed specically

for use with Heat Controller units are available. Similar hoses

can be obtained from alternate suppliers. Supply and return

hoses are tted with swivel-joint ttings at one end to prevent

kinking during installation.

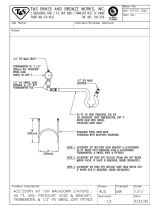

Refer to Figure 1 for an illustration of a Supply/Return Hose

Kit. Male adapters secure hose assemblies to the unit and ris-

ers. Install hose assemblies properly and check them regularly

to avoid system failure and reduced service life.

� CAUTION! �

Corrosive system water requires corrosion resistant ttings

and hoses and possibly water treatment.

Figure 1: Supply/Return Hose Kit

Rib Crimped

Length

(2 ft [0.6m] Length Standard)

Swivel

Brass

Fitting

Brass

Fitting

EPT

Reborde Acanalado

Longitud

(Long. Estándar de 2 pies)

Accesorio

Giratorio

de Bronce

Accesorio

de Bronce

MPT

Gasket

Swivel Nut

Stainless steel

snap ring

Brass Adaptor

Hand Tighten

Only !

Do Not

Overtighten !

8

Heat Controller, Inc. WATER-TO-WATER (HWW) SERIES Installation & Operation

Load Plumbing Installation

HWW Unit Load Plumbing

The applications are too varied to describe in this document.

However, some basic guidelines will be presented. Much of

the discussions on water loop applications would be valid for

the load plumbing discussion as well. All plumbing should

conform to local codes with the following considerations:

Wide temperature variation applications such as

heating/cooling coils:

- Employ piping materials that are rated for the maxi-

mum temperature and pressure combination. This

excludes PVC for most heating applications.

- Insure that load water ow in high temperature heat-

ing applications is at least 3 gpm per ton [3.9 l/m per

kW] to improve performance and reduce nuisance

high pressure faults.

- DO NOT employ plastic to metal threaded joints

- Utilize a pressure tank and air separator vent system

to equalize pressure and remove air.

Swimming Pool Hot Tub Applications:

- Load coax should be isolated with secondary heat

exchanger constructed of anti-corrosion material in all

chlorine/bromine uid applications.

Potable Water Applications:

- Load coax material should always be vented double

walled for use in potable water systems.

- Insure load water ow in high temperature heating

applications is at least 3 gpm per ton to improve

performance and reduce nuissance to high pressure

faults.

NOTE:

Heat Controller strongly recommends all piping

connections, both internal and external to the unit, be

pressure tested by an appropriate method prior to any

nishing of the interior space or before access to all

connections is limited. Test pressure may not exceed

the maximum allowable pressure for the unit and all

components within the water system. Heat Controller

will not be responsible or liable for damages from

water leaks due to inadequate or lack of a pressurized

leak test, or damages caused by exceeding the

maximum pressure rating during installation.

Piping Installation

9

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

Water-Loop Heat Pump Applications

Commercial systems typically include a number of units

plumbed to a common piping system. Any unit plumbing

maintenance work can introduce air into the piping system,

therefore air elimination equipment is a major portion of the

mechanical room plumbing. In piping systems expected to

utilize water temperatures below 50°F [10°C], 1/2” [13mm]

closed cell insulation is required on all piping surfaces to

eliminate condensation. Metal to plastic threaded joints should

never be employed due to their tendency to leak over time.

Teon tape thread sealant is recommended for FPT water

connections (commercial class) to minimize internal fouling

of the heat exchanger. Do not overtighten connections and

route piping so as not to interfere with service or maintenance

access. Hose kits are available from Heat Controller in

different congurations for connection between the system.

The piping system should be ushed to remove dirt, piping

chips, and other foreign material prior to operation. See

Piping System Cleaning and Flushing Procedures later in this

document. The ow rate is usually set between 2.25 gpm and

3 gpm per ton [2.9 l/m and 4.5 l/m per kW] of cooling capacity.

Heat Controller recommends 2.5 gpm per ton [3.2 l/m per

kW] for most applications of water loop heat pumps. To insure

proper maintenance and servicing, P/T ports are imperative

for temperature and ow verication, as well as performance

checks. See Figure 2 for typical water-loop application

installation.

Cooling Tower/Boiler Systems typically utilize a

common loop maintained 60-90°F [16-32°C]. The use of a

closed circuit evaporative cooling tower with a secondary

heat exchanger between the tower and the water loop

is recommended. If an open type cooling tower is used

continuously, chemical treatment and ltering will be

necessary.

Low Water Temperature Cutout Setting

CXM Control: When an antifreeze is selected, the FP1

jumper (JW3) should be clipped to select the low temperature

(Antifreeze 15°F [-9.4°C]) setpoint to avoid nuisance faults.

See Figure 5: Low Water Temperature Cutout - FP1.

� WARNING! �

� CAUTION! �

Never jumper terminal “A” from CXM board #1 to CXM

board #2 on multi-compressor/control bound units. See

Figure 6 [Page 15] in electrical section of this document

for motorized valve wiring.

CAUTION! Many units are installed with a factory or

eld supplied manual or electric shut-off valve. DAMAGE

WILL OCCUR if shut-off valve is closed during unit

operation. A high pressure switch must be installed on

the heat pump side of any eld provided shut-off valves

and connected to the heat pump controls in series with

the built-in refrigerant circuit high pressure switch to

disable compressor operation if water pressure exceeds

pressure switch setting. The eld installed high pressure

switch shall have a cut-out pressure of 300 psig and a

cut-in pressure of 250 psig.

Air Pad or

Extruded

polystyrene

insulation board

Unit Power

Disconnect

Thermostat Wiring

Load Plumbing

Connection

Optional

Balancing

Valve

Water Out

Optional Low

Pressure Drop

Water Control

Valve

Ball Valve with

integral P/T plug

Stainless steel braid

hose with integral “J”

swivel

Y-Strainer

with blow-off

valve

Water In

Ball Valve with

integral P/T plug

Building

Loop

Figure 2: Typical Water-Loop Application

10

Heat Controller, Inc. WATER-TO-WATER (HWW) SERIES Installation & Operation

Ground-Water Heat Pump Applications

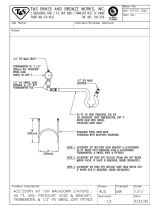

Typical open loop piping is shown in Figure 3 [See Page 11].

Shut off valves should be included in case of servicing. Boiler

drains or other valves should be ‘tee’d’ into the line to allow acid

ushing of just the heat exchanger. Pressure temperature plugs

should be used so that ow and temperature can be measured.

Piping materials should be limited to PVC SCH80 or copper.

Due to the pressure and temperature extremes, PVC SCH40

is not recommended. Water quantity should be plentiful and of

good quality. Consult Table 1 for water quality guidelines.

The unit can be ordered with either a copper or cupro-nickel

water heat exchanger. Copper is recommended for closed

loop systems and open loop ground water systems that are

not high in mineral content or corrosiveness. In conditions an-

ticipating heavy scale formation or in brackish water, a cupro-

nickel heat exchanger is recommended.

In ground water situations where scaling could be heavy or

where biological growth such as iron bacteria will be present,

a closed loop system is recommended. It is recommended to

install an intermediate heat exchanger to isolate an open loop

from the heat pump loop on open well systems. Heat exchang-

ers may over time lose heat exchange capabilities due to a

build up of mineral deposits inside. These can be cleaned only

by a qualied service mechanic as acid and special pumping

equipment are required.

Table 1: Water Quality Standards

WaterÊQuality

Parameter

HX

Material

Closed

Recirculating

OpenÊLoopÊandÊRecirculatingÊWell

ScalingÊPotentialÊ-ÊPrimaryÊMeasurement

pH/CalciumÊHardness

All

-

pHÊ<Ê7.5ÊandÊCaÊHardnessÊ<100ppm

Method

IndexÊLimitsÊforÊProbableÊScalingÊSituationsÊ-Ê(OperationÊoutsideÊtheseÊlimitsÊisÊnotÊrecommended)

Ryznar

All

- 6.0Ê-Ê7.5

StabilityÊIndex IfÊ>7.5ÊminimizeÊsteelÊpipeÊuse.

Langelier

All

-

-0.5ÊtoÊ+0.5

SaturationÊIndex

IfÊ<-0.5ÊminimizeÊsteelÊpipeÊuse.ÊBasedÊuponÊ150¡FÊ[66¡C]ÊHWGÊand

DirectÊwell,Ê85¡FÊ[29¡C]ÊIndirectÊWellÊHX

IronÊFouling

IronÊFe

2+

(Ferrous)

All

-

<0.2ÊppmÊ(Ferrous)

(BacterialÊIronÊpotential)

IfÊFe

2+

Ê(ferrous)>0.2ÊppmÊwithÊpHÊ6Ê-Ê8,ÊO2<5ÊppmÊcheckÊforÊironÊbacteria

IronÊFouling

All

-

<0.5ÊppmÊofÊOxygen

AboveÊthisÊlevelÊdepositionÊwillÊoccur.

CorrosionÊPrevention

pH

All

6Ê-Ê8.5

6Ê-Ê8.5

Monitor/treatÊas

needed

MinimizeÊsteelÊpipeÊbelowÊ7ÊandÊnoÊopenÊtanksÊwithÊpHÊ<8

HydrogenÊSulfideÊ(H

2

S)

All

- <0.5Êppm

AtÊH

2

S>0.2Êppm,ÊavoidÊuseÊofÊcopperÊandÊcopperÊnickelÊpipingÊorÊHX's.

RottenÊeggÊsmellÊappearsÊatÊ0.5ÊppmÊlevel.

CopperÊalloyÊ(bronzeÊorÊbrass)ÊcastÊcomponentsÊareÊOKÊtoÊ<0.5Êppm.

AmmoniaÊionÊasÊhydroxide,Êchloride,Ê

nitrateÊandÊsulfateÊcompounds

All

-

<0.5Êppm

Maximum

MaximumÊAllowableÊatÊmaximumÊwaterÊtemperature.

ChlorideÊLevels

50¡FÊ(10¡C) 75¡FÊ(24¡C) 100ϒF (38ϒC)

Copper - <20ppm NR NR

CuproNickel - <150Êppm NR NR

304ÊSS - <400Êppm <250Êppm <150 ppm

316ÊSS - <1000Êppm <550Êppm < 375 ppm

Titanium - >1000Êppm >550Êppm >375 ppm

ErosionÊandÊClogging

ParticulateÊSizeÊand

Erosion

All

<10ÊppmÊofÊparticles

andÊaÊmaximum

velocityÊofÊ6ÊfpsÊ[1.8Êm/s].

FilteredÊforÊmaximum

800ÊmicronÊ[800mm,

20Êmesh]Êsize.

<10ÊppmÊ(<1ÊppmÊ"sandfree"ÊforÊreinjection)ÊofÊparticlesandÊaÊmaximum

velocityÊofÊ6ÊfpsÊ[1.8Êm/s].ÊFilteredÊforÊmaximumÊ800ÊmicronÊ[800mm,

20Êmesh]Êsize.AnyÊparticulateÊthatÊisÊnotÊremovedÊcanÊpotentially

clogÊcomponents.

Notes:

Rev.: 01/21/09B

• NR - Application not recommended.

• "-" No design Maximum.

• Closed Recirculating system is identified by a

closed pressurized piping system.

• Recirculating open wells should observe the open recirculating design considerations.

AboveÊtheÊgivenÊlimits,ÊscalingÊisÊlikelyÊtoÊoccur.ÊÊScalingÊindexesÊshouldÊbeÊcalculatedÊusingÊtheÊlimitsÊbelow

ScalingÊindexesÊshouldÊbeÊcalculatedÊatÊ150¡FÊ[66¡C]ÊforÊdirectÊuseÊandÊHWGÊapplications,ÊandÊatÊ90¡FÊ[32¡C]ÊforÊindirectÊHXÊuse.Ê

AÊmonitoringÊplanÊshouldÊbeÊimplemented.

11

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

Ground-Water Heat Pump Applications

In areas with extremely hard water, the owner should be

informed that the heat exchanger may require occasional acid

ushing.

Expansion Tank and Pump

Use a closed, bladder-type expansion tank to minimize mineral

formation due to air exposure, as shown in Figure 3. The

expansion tank should be sized to handle at least one minute

run time of the pump to prevent premature pump failure using

its drawdown capacity rating. Discharge water from the unit

is not contaminated in any manner and can be disposed of in

various ways depending on local building codes; i.e. recharge

well, storm sewer, drain eld, adjacent stream or pond, etc.

Most local codes forbid the use of sanitary sewer for disposal.

Consult your local building and zoning department to assure

compliance in your area.

Low Water Temperature Cut-Out Setting

For all open loop systems the 35°F [1.7°C] FP1 setting (factory

setting-water) should be used to avoid freeze damage to the unit.

See Figure 4 [Page 14]: “Low Water Temperature Cutout - FP1”.

Water Control Valve

Note the placement of the water control valve in Figure 3.

Always maintain water pressure in the heat exchanger by

placing water control valves at the outlet of the unit to prevent

mineral precipitation. Pilot operated or Taco slow closing

valve’s solenoid valves are recommended to reduce water

hammer. If water hammer persists, a mini-expansion tank can

be mounted on the piping to help absorb the excess hammer

shock. Insure that the total ‘VA’ draw of the valve can be

supplied by the unit transformer. For instance the Taco slow

closing valve can draw up to 35VA. This can overload smaller

40 or 50 VA transformers depending on the other controls

employed. A typical pilot operated solenoid valve draws

approximately 15VA.

Flow Regulation

Flow regulation can be accomplished by two methods. First,

most water control valves have a built in ow adjustment. By

measuring the pressure drop through the unit heat exchanger,

ow rate can be determined and compared to Table 8 [Page

28]. Since the pressure is constantly varying, two pressure

gauges might be needed. Simply adjust the water control

valve until the desired ow of 1.5 to 2 gpm per ton is achieved.

Secondly, a ow control device may be installed [see Figure

3]. The devices are typically an orice of plastic material that is

designed to allow a specied ow rate. These are mounted on

the outlet of the water control valve. On occasion, these valves

can produce a velocity noise that can be reduced by applying

some back pressure. This is accomplished by slightly closing

the leaving isolation valve of the well water setup.

� WARNING! �

� CAUTION! �

Never jumper terminal “A” from CXM board #1 to CXM

board #2 on multi-compressor/control bound units. See

Figure 5 [Page 15] in electrical section of this document

for motorized valve wiring.

CAUTION! Many units are installed with a factory or eld

supplied manual or electric shut-off valve. DAMAGE WILL

OCCUR if shut-off valve is closed during unit operation.

A high pressure switch must be installed on the heat

pump side of any eld provided shut-off valves and

connected to the heat pump controls in series with the

built-in refrigerant circuit high pressure switch to disable

compressor operation if water pressure exceeds pressure

switch setting. The eld installed high pressure switch

shall have a cut-out pressure of 300 psig and a cut-in

pressure of 250 psig.

� CAUTION! �

Low temperature limit system will not allow leaving load

water temperature (cooling mode) or leaving source water

temperature (heating mode) to be below 42°F [5.6°C].

Air Pad or

Extruded

polystyrene

insulation board

Unit Power

Disconnect

Pressure

Tank

Flow

Regulator

Water

Control

Valve

P/T Plugs

Water Out

Shut-Off

Valve

Boiler

Drains

Water In

Optional

Filter

Thermostat Wiring

Figure 3: Typical Open

Loop/Well Application

12

Pre-Installation

Prior to installation, locate and mark all existing underground

utilities, piping, etc. Install loops for new construction before

sidewalks, patios, driveways, and other construction has

begun. During construction, accurately mark all ground loop

piping on the plot plan as an aid in avoiding potential future

damage to the installation.

Piping Installation

All earth loop piping materials should be limited to only

polyethylene fusion for inground sections of the loop.

Galvanized or steel ttings should not be used at any time

due to their tendency to corrode. All plastic to metal threaded

ttings should be avoided due to their potential to leak in

earth coupled applications and a anged tting substituted.

P/T plugs should be used so that ow can be measured

using the pressure drop of the unit heat exchanger in lieu of

other ow measurement means. Earth loop temperatures can

range between 25 to 110°F [-4 to 43°C], and 2.25 to 3 gpm of

ow per ton [2.9 l/m to 3.9 l/m per kW] of cooling capacity is

recommended in these applications. Upon completion of the

ground loop piping, pressure test the loop to assure a leak free

system. Horizontal Systems: Test individual loops as installed.

Test entire system when all loops are assembled. Vertical

U-Bends and Pond Loop Systems: Test Vertical U-bends and

pond loop assemblies prior to installation with a test pressure

of at least 100 psi [689 kPa].

Flushing the Earth Loop

Upon completion of system installation and testing, ush the

system to remove all foreign objects and purge to remove all

air. Flush the loop rst with the unit isolated to avoid ushing

debris from the loop into the unit heat exchanger

Heat Controller, Inc. WATER-TO-WATER (HWW) SERIES Installation & Operation

Ground-Loop Heat Pump Applications

� CAUTION! �

The following instructions represent industry accepted

installation practices for Closed Loop Earth Coupled Heat

Pump Systems. They are provided to assist the contrac-

tor in installing trouble free ground loops. These instruc-

tions are recommendations only. State and Local Codes

MUST be followed and installation MUST conform to ALL

applicable Codes. It is the responsibility of the Installing

contractor to determine and comply with ALL applicable

Codes and Regulations.

Table 2: Antifreeze Percentages by Volume

Type

Min. Temp. for Low Temp. Protection

10°F

[-12.2°C]

15°F

[-9.4°C]

20°F

[-6.7°C]

25°F

[-3.9°C]

Methanol

100% USP

food grade

Propylene

Glycol

Ethanol*

25%

38%

29%

21%

25%

25%

16%

22%

20%

10%

15%

14%

* Must not be denatured with any petroleum based product

Antifreeze

In areas where minimum entering loop temperatures drop

below 40°F [5°C] or where piping will be routed through areas

subject to freezing, anti-freeze is needed. Alcohols and glycols

are commonly used as antifreezes, however your local sales

manager should be consulted for the antifreeze best suited

to your area. Freeze protection should be maintained to 15°F

[9°C] below the lowest expected entering loop temperature.

For example, if 30°F [-1°C] is the minimum expected entering

loop temperature, the leaving loop temperature would be

25 to 22°F [-4 to -6°C] and freeze protection should be at

15°F [-10°C] e.g. 30°F - 15°F = 15°F [-1°C - 9°C = -10°C]. All

alcohols should be premixed and pumped from a reservoir

outside of the building when possible or introduced under

water level to prevent fuming. Initially calculate the total

volume of uid in the piping system using Table 1. Then use

the percentage by volume shown in Table 2 for the amount of

antifreeze. Antifreeze concentration should be checked from

a well mixed sample using a hydrometer to measure specic

gravity.

Low Water Temperature Cut-Out Setting CXM Control:

When an antifreeze is selected, the FP1 jumper [JW3] should be

clipped to select the low temperature (Antifreeze 15°F [-9.4°C])

setpoint to avoid nuisance faults. See Figure 5 [Page 14].

Table 1: Approximate Fluid Volume

(gallon) per 100' of Pipe

Fluid Volume (gal [liters] per 100’ [30 meters) Pipe)

Pipe Size Volume (gal) [liters]

Copper

1” 4.1 [15.3]

1.25” 6.4 [23.8]

2.5” 9.2 [34.3]

Rubber Hose 1” 3.9 [14.6]

Polyethylene

3/4” IPS SDR11 2.8 [10.4]

1” iPS SDR11 4.5 [16.7]

1.25” IPS SDR11 8.0 [29.8]

1.5” IPS SDR11 10.9 [40.7]

2” IPS SDR11 18.0 [67.0]

1.25” IPS SCH40 8.3 [30.9]

1.5” IPS SCH40 10.9 [40.7]

2” IPS SCH40 17.0 [63.4]

Unit Heat Exchanger Typical 1.0 [3.8]

Flush Cart Tank

10” Dia x 3ft tall

[254mm x 91.4cm tall]

10 [37.9]

13

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

Air Pad or

Extruded

polystyrene

insulation board

Unit Power

Disconnect

Thermostat Wiring

Figure 1: Typical Ground-Loop Application

Figure 4: Typical Ground-Loop Application

14

Heat Controller, Inc. WATER-TO-WATER (HWW) SERIES Installation & Operation

Electrical-Line Voltage

HWW Electrical Data

General Line Voltage Wiring

Be sure the available power is the same voltage and phase as

that shown on the unit serial plate. Line and low voltage wiring

must be done in accordance with local codes or the National

Electric Code, whichever is applicable.

HWW Power Connection

Line voltage connection is made by connecting the incoming

line voltage wires to L1, L2, and L3 on power distribution

block. Consult electrical data table for correct fuse size.

208 Volt Operation

All 208-230 Volt units are factory wired for 208 Volt. The

transformers may be switched to 230V operation as illustrated

on the wiring diagram by switching the Red (208V) and the

Orange (230V) at the contactor terminal L2.

All eld installed wiring, including electrical ground, must

comply with the National Electrical Code as well as all

applicable local codes.

Refer to the unit wiring diagrams for fuse sizes and a

schematic of the eld connections which must be made by the

installing (or electrical) contractor.

Consult the unit wiring diagram located on the inside of the

compressor access panel to ensure proper electrical hookup.

All nal electrical connections must be made with a length of

exible conduit to minimize vibration and sound transmission

to the building.

� CAUTION! �

Use only copper conductors for eld installed electrical

wiring. Unit terminals are not designed to accept other

types of conductors.

� WARNING! �

To avoid possible injury or death due to electrical shock,

open the power supply disconnect switch and secure it in

an open position during installation.

� WARNING! �

Disconnect electrical power source to prevent injury or

death from electrical shock.

Thermostat Connections

The aquastat/thermostat should be wired directly to the CXM board

#1. Note: The HWW second stage is wired directly to the CXM #2.

Low Water Temperature Cutout - FP1

The CXM control allows the eld selection of source uid low tem-

perature cutout points. The factory setting of FP1 is set for water

(35°F [1.7°C]). In cold temperature applications jumper JW3 (FP1-

antifreeze 15°F [-9.4°C]) should be clipped as shown in Figure 4 to

change the setting to 10°F [-12.2°C], a more suitable temperature

when using antifreezes. Never clip JW3 prior to antifreeze being

added to the loop.

Figure 5: Changing FP1-Low Water Temperature Cutout Setpoint

CXM PCB

JW3-FP1

jumper

should be

clipped

when

antifreeze

is used.

Model

Voltage

Code

Voltage

Min/Max

Voltage

Compressor

HWG

Pump

FLA

EXT Loop

Pump

Fla

Total

Unit

FLA

Min

Circuit

Amps

Max

Fuse/

HACR

QTY RLA LRA

HWW036

1 208-230/60/1 187/254 1 16.7 79 0.4 4 16.7 20.8 35

3 208-230/60/3 187/254 1 10.4 73 - - 10.4 13.1 20

4 460/60/3 414/506 1 5.8 38 - - 5.8 7.2 15

5 575/60/3 518/633 1 3.8 36.5 - - 3.8 4.7 15

HWW060

1 208-230/60/1 187/254 1 26.3 134 0.4 4 26.3 32.9 50

3 208-230/60/3 187/254 1 15.6 110 - - 15.6 19.5 35

4 460/60/3 414/506 1 7.8 52 - - 7.8 9.8 15

5 575/60/3 518/633 1 5.8 38.9 - - 5.8 7.3 15

HWW120

1 208-230/60/1 187/254 2 26.3 134 0.4 4 52.6 59.2 80

3 208-230/60/3 187/254 2 15.8 110 - - 31.2 35.1 50

4 460/60/3 414/506 2 7.8 52 - - 15.6 17.6 25

5 575/60/3 518/633 2 5.8 38.9 - - 11.6 13.1 15

HACR circuit breaker in USA only

15

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

Electrical-Accessories

Accessory Connections

A terminal paralleling the compressor contactor coil has been

provided on the CXM control of the HWW line. “A” has been

provided to control accessory devices, such as water valves,

electronic air cleaners, humidiers, etc. Note: This terminal

must be used only with 24 Volt signals and not line voltage

signals. This signal operates with the compressor contactor.

See the wiring schematic for details.

Figure 6: Field Wiring of 24 Volt Motorized Valve of Units Size 120

Coil

Coil

VR 1

VR2

6

8

Refrigerant

HP Switch

Circuit #1

VR3

NO

RED

RED

2

4

Refrigerant

HP Switch

Circuit #2

VR3

NO

RED

RED

6

8

Refrigerant

HP Switch

Circuit #1

VR3

NO

RED

RED

2

4

Refrigerant

HP Switch

Circuit #2

VR3

NO

RED

RED

Coil

Valve

Relay 3

Water

High Pressure

Switch NC

Coil

Valve

Relay 3

Water

High Pressure

Switch NC

Notes - Disconnect red wire at refrigerant HP switch connect to N.O. contact,

connect new red wire from N.O. contact to refrigerant HP switch.

Valve Relay 1, 2 - 13B0001N01 (SPDT) VR1, VR2

Valve Relay 3 - 13B0004N01 (DPDT) VR3

Coil

Coil

VR 1

VR2

6

8

Refrigerant

HP Switch

Circuit #1

VR3

NO

RED

RED

2

4

Refrigerant

HP Switch

Circuit #2

VR3

NO

RED

RED

6

8

Refrigerant

HP Switch

Circuit #1

VR3

NO

RED

RED

2

4

Refrigerant

HP Switch

Circuit #2

VR3

NO

RED

RED

Coil

Valve

Relay 3

Water

High Pressure

Switch NC

Coil

Valve

Relay 3

Water

High Pressure

Switch NC

Notes - Disconnect red wire at refrigerant HP switch connect to N.O. contact,

connect new red wire from N.O. contact to refrigerant HP switch.

Valve Relay 1, 2 - 13B0001N01 (SPDT) VR1, VR2

Valve Relay 3 - 13B0004N01 (DPDT) VR3

24 Volt Accessory Wiring for Units Size 036 and 060

These terminals may be

used to power 24 volt

water valves on units

size 036, 060

CXM Terminal Strip

Never jumper terminal “A” from CXM board #1 to CXM

board #2 on multi-compressor/control bound units. See

Figure 6 in electrical section of this document for motor-

ized valve wiring.

� WARNING! �

16

Heat Controller, Inc. WATER-TO-WATER (HWW) SERIES Installation & Operation

Electrical-Line Voltage

All eld installed wiring, including electrical ground, must

comply with the National Electrical Code as well as all ap-

plicable local codes.

Refer to the unit wiring diagrams for fuse sizes and a sche-

matic of the eld connections which must be made by the

installing (or electrical) contractor.

Consult the unit wiring diagram located on the inside of

the compressor access panel to ensure proper electrical

hookup.

All nal electrical connections must be made with a length of

exible conduit to minimize vibration and sound transmission

to the building.

208 Volt Operation

All 208-230 Volt units are factory wired for 208 Volt. The

transformers may be switched to 230V operation as illustrat-

ed on the wiring diagram. By switching the Red (230V) and

the Orange (208V) at the contactor terminal L2.

Capacitor

Transformer

CXM Control

Circ Brkr

Contactor -CC

Low Voltage

Connector

CB

HWG PB2

T2

T1

Rev .: 01/21/09B

Unit Power Supply

See electrical table for

wire and breaker size

L2

L1

External Pump

Power Supply

See electrical table for

wire and breaker size

Grnd

Loop PB1

T2

T1

Install HWG Pump

Power after insuring

water is in HWG circuit

Yellow

Grnd

L2

L3

L1

Contactor -C

Grnd

Capacitor

Transformer

CXM Control

Circ Brkr

Contactor -CC

Low Voltage

Connector

CB

HWG PB2

T2

T1

Rev .: 01/21/09B

Unit Power Supply

See electrical table for

wire and breaker size

L2

L1

External Pump

Power Supply

See electrical table for

wire and breaker size

Grnd

Loop PB1

T2

T1

Install HWG Pump

Power after insuring

water is in HWG circuit

Yellow

Grnd

L2

L3

L1

Contactor -C

Grnd

HWW036-060 Series Line Voltage Field Wiring Commercial Class (3 phase shown)

HWW120 Series Line Voltage Field Wiring Commercial Class

17

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

Electrical-Low Voltage

Thermostat Connections

The aquastat/thermostat should be wired directly to the CXM

board as shown in Figure 7a for HWW036-060 and Figure

7b for the HWW120. Note the HWW second stage is wired

directly to the CXM #2.

Low Water Temperature Cutout - FP1

The CXM control allows the eld selection of source uid

low temperature cutout points. The factory setting of FP1 is

set for water (30°F). In cold temperature applications jumper

JW3 (FP1- antifreeze 10°F) should be clipped as shown in

Figure 8 to change the setting to 10°F, a more suitable tem-

perature when using antifreezes. It should be noted that the

extended range option should be specied to operate the

HWW Series at entering water temperatures below 60°F.

Figure 7a. HWW036-060 Low Voltage

Field Wiring (CXM board shown)

Figure 7b: HWW120 Low Voltage Field

Wiring (CXM board shown)

Figure 8: Changing FP1-Low Water

Temperature Cutout Setpoint

JW3-FP1 jumper

should be clipped

when antifreeze

is used.

CXM Board

Capacitor

Transformer

CXM Control

Contactor -CC

Low Voltage

Connector

CB

L2

L1

Rev.: 01/21/09B

Low Voltage

Wiring

Contactor -CC1

Transformer

Grnd

L2

L3

L1

Contactor -CC2

CXM Control #2

Power Distribution

Block

CXM Control #1

Rev .: 01/22/09B

Low Voltage

Wiring

Second Stage Call

(Not needed on DXM Models

all low voltage wires to DXM #1)

Low Voltage

Connector

Low Voltage

Connector

Capacitor

Transformer

CXM Control

Contactor -CC

Low Voltage

Connector

CB

L2

L1

Rev.: 01/21/09B

Low Voltage

Wiring

Contactor -CC1

Transformer

Grnd

L2

L3

L1

Contactor -CC2

CXM Control #2

Power Distribution

Block

CXM Control #1

Rev .: 01/22/09B

Low Voltage

Wiring

Second Stage Call

(Not needed on DXM Models

all low voltage wires to DXM #1)

Low Voltage

Connector

Low Voltage

Connector

18

Heat Controller, Inc. WATER-TO-WATER (HWW) SERIES Installation & Operation

Typical Wiring Diagram Three Phase:

HWW120 Units with CXM Controller

19

Installation & Operation WATER-TO-WATER (HWW) SERIES Heat Controller, Inc.

Typical Wiring Diagram Single Phase:

HWW036-060 Units with CXM Controller

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

Heat Controller HWW120 Operating instructions

- Category

- Heat pumps

- Type

- Operating instructions

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Heat Controller HBH048 Installation, Operation & Maintenance Manual

-

Heat Controller HBH048 Installation, Operation & Maintenance Manual

-

Heat Controller Flow Controllers Installation, Operation & Maintenance Manual

Heat Controller Flow Controllers Installation, Operation & Maintenance Manual

-

Heat Controller Geothermal WSHP HTV/HTD/HTH Operating instructions

Heat Controller Geothermal WSHP HTV/HTD/HTH Operating instructions

-

Heat Controller HP048 Installation, Operation & Maintenance Manual

Heat Controller HP048 Installation, Operation & Maintenance Manual

-

Heat Controller HCH006 Operating instructions

-

Heat Controller HSS Series User manual

Heat Controller HSS Series User manual

-

Heat Controller HEV/H User manual

Heat Controller HEV/H User manual

-

Heat Controller HEV042 Installation, Operation & Maintenance Manual

-

Heat Controller HTD024C1C01ALK User manual

Other documents

-

ClimateMaster ATM11H03 Install Manual

-

First Co WSVX SERIES User manual

-

COMFORT-AIRE HWW Series Operating instructions

-

ClimateMaster CXM Controls Install Manual

-

ClimateMaster CXM Controls Application Manual

-

Danfoss S42 P Installation guide

-

T & S Brass & Bronze Works MV-0770-05C Datasheet

T & S Brass & Bronze Works MV-0770-05C Datasheet

-

Johnson Controls RW SERIES Installation Operation & Maintenance

-

Lochinvar CREST 2.5 User manual

-

Lochinvar CREST 2.5 User manual