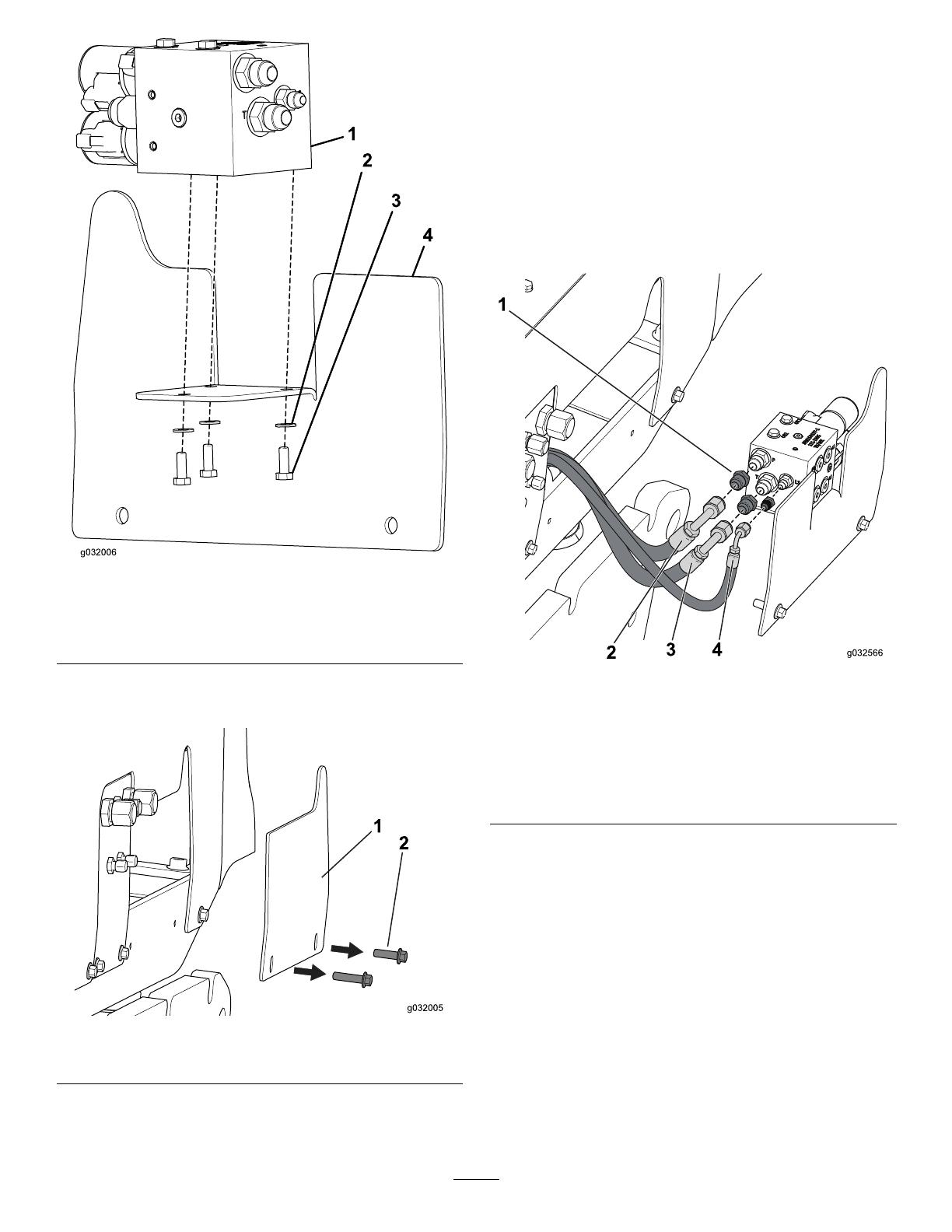

Figure2

1.Solenoidvalveand

attachedttings

3.Bolt(3)

2.Flatwasher(3)

4.Valve-mountplate

6.Removetheexistingcoverplatefromtherearofthe

machineasshowninFigure3.

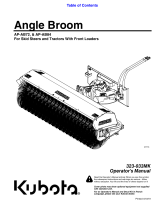

Figure3

1.Coverplate2.Bolt(2)

7.Installthevalve-mountplate(withtheattached

solenoidvalveandttings)ontotherearofthemachine

withtheboltsthatyoupreviouslyremovedinstep6.

8.Locatethehydraulichosesforthekitattherearofthe

machine,unbindtheunconnectedendofthehoses,

andremovetheendplugsorcaps.

Note:Eachhoseendislabelledastowhichtting

itconnects.

9.Attachthehydraulichosestothettingsonthe

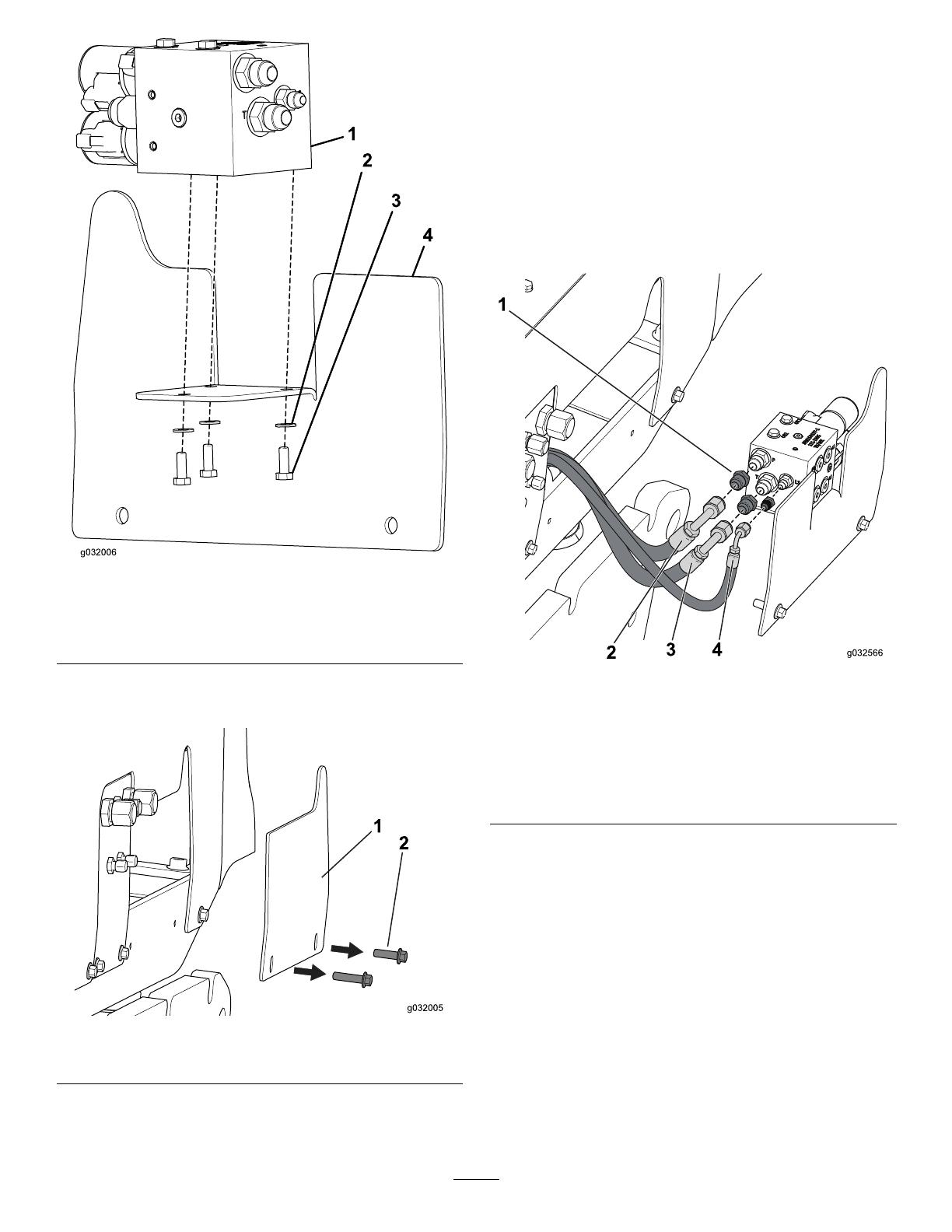

solenoidvalveasshowninFigure4.

Figure4

Valve-mountplateshownpulledawayfromthemachinefor

thepurposeofclarity

1.Removethecap(3)3.Hose(connecttothetting

attheTport)

2.Hose(connecttothetting

atthePport)

4.Hose(connecttothetting

attheLSport)

10.Torqueeachofthehosettingsonthelargestraight

ttingsonthehosesto58to72N∙m(43to53ft-lb)

andtorquethehosettingonthesmallstraighttting

to20to28N∙m(15to21ft-lb).

11.Locatetheconnectorsonthewireharnessforthekit,

unbindthem,andconnectthemtotheconnectorson

thesolenoidsasshowninFigure5.

Note:Eachpairofconnectorsonthewireharness

islabelledastowhichsolenoidconnectortheyareto

connect.

2