Page is loading ...

For service or repairs to boiler, call your heating contractor. When seeking information on boiler,

provide Boiler Model Number and Serial Number as shown on Rating Label.

Boiler Model Number

FORCESTEAM0 _

Boiler Serial Number Installation Date

Heating Contractor Phone Number

Address

106324-04 - 4/18 Price - $5.00

INSTALLATION, OPERATING

AND

SERVICE INSTRUCTIONS

FORCESTM™ SERIES

GAS BOILER

9700609

2

106324-04 - 4/18

FOLLOW ALL INSTRUCTIONS and warnings

printed in this manual and posted on the boiler.

INSPECT THE BOILER ANNUALLY. To keep

your boiler safe and efficient, have a service

technician follow the Service checklist near the

end of this manual.

IF YOU ARE NOT QUALIFIED to install or service

boilers, do not install or service this one.

THE BOILER MAY LEAK WATER at the end of its

useful life. Be sure to protect walls, carpets, and

valuables from water that could leak from the

boiler.

PROTECT YOUR HOME IN FREEZING

WEATHER. A power outage, safety lockout, or

component failure will prevent your boiler from

lighting. In winter, your pipes may freeze and

cause extensive property damage. Do not leave

the heating system unattended during cold

weather unless alarms or other safeguards are in

place to prevent such damage

DO NOT BLOCK AIR FLOW into or around the

boiler. Insufficient air may cause the boiler to

produce carbon monoxide or start a fire.

KEEP FLAMMABLE LIQUIDS AWAY from the

boiler, including paint, solvents, and gasoline.

The boiler may ignite the vapors from the liquids

causing explosion or fire.

KEEP CHILDREN AND PETS away from hot

surfaces of the boiler, boiler piping, and vent

pipe.

CARBON MONOXIDE (CO) is an odorless,

deadly gas that may be introduced into your

home by any malfunctioning fuel-burning product

or vent system failure. Consider installing CO

alarms near bedrooms in all levels of the building

to warn you and your family of potential CO

exposure.

WARNINGS FOR THE HOMEOWNER

3

3

106324-04 - 4/18

READ THIS ENTIRE MANUAL before attempting

installation, start-up, or service. Improper

installation, adjustment, alteration, service,

or maintenance may cause serious property

damage, personal injury, or death.

DO NOT DISCONNECT PIPE FITTINGS on

the boiler or in the heating system without first

verifying that the system is cool and free of

pressure and that your clothing will protect you

from a release of hot water or steam. Do not rely

solely on the boiler’s temperature and pressure

gage when making this judgment.

USE PROPER PERSONAL PROTECTION

EQUIPMENT when servicing or working near the

boiler. Materials of construction, flue products,

and fuel contain alumina, silica, heavy metals,

carbon monoxide, nitrogen oxides, and/or

other toxic or harmful substances that can are

hazardous to health and life and that are known

to the State of California to cause cancer, birth

defects, and other reproductive harm.

INSTALL ALL GUARDS, cover plates, and

enclosures before operating the boiler.

SIZE THE BOILER PROPERLY relative to the

design heat load or, if using domestic hot water

priority, the peak hot water load, whichever

is larger. A grossly oversized boiler will cycle

excessively and this will lead to premature failure

of the boiler and its components. Our warranty

does not apply to damage from excessive

cycling.

ADHERE TO ALL LOCAL CODE

REQUIREMENTS. Contact your local code

inspector prior to installation. In the absence of a

local code, adhere to the National Fuel Gas Code

ANSI Z223.1/NFPA 54.

ALL WIRING must comply with the National

Electrical Code ANSI/NFPA 70.

WARNINGS FOR THE INSTALLER

4

106324-04 - 4/18

TheFORCESTMseriesboilersarelowpressurecastirongasredsteamboilersdesignedforuseinclosedsteam

heatingsystems.TheseboilersareCategoryIdraftdiverterequippedappliances,whichmustbeventedbynaturaldraftusing

alinedmasonryorlistedmetalchimneysystem.Anadequatesupplyofairforcombustion,ventilationanddilutionofue

gasesmustbeavailableintheboilerroom.Theseboilersarenotdesignedforuseinprocessorother“open”steamsystems

TABLE OF CONTENTS

I. Product Description.................................................................................... 4

II. Specications............................................................................................ 5

III. Pre-Installation........................................................................................... 6

IV. Locating the Boiler..................................................................................... 6

V. Air for Combustion & Ventilation................................................................ 7

VI. Venting....................................................................................................... 8

VII. Gas Piping................................................................................................. 10

VIII. System Piping............................................................................................ 11

IX. Indirect Water Heater Piping...................................................................... 14

X. Electrical.................................................................................................... 15

XI. System Start-Up........................................................................................ 20

XII. Service Instructions................................................................................... 25

XIII. Troubleshooting.......................................................................................... 29

XIV. Repair Parts.............................................................................................. 33

Appendix A - Tapping Locations................................................................. 44

I. Product Description

5

5

106324-04 - 4/18

TABLE 1: FORCESTM SPECIFICATIONS

II. Specications

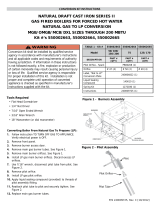

FIGURE 1: FORCESTM BOILERS - GENERAL CONFIGURATION

Boiler Model

Approx.

Shipping

Weight

Lbs.

Dimensions (in inches)

Recommended Min.

Round

Chimney Size

(Diameter x Height)

(1)

Gas

Conn.

(NPT)

Water Volume

(Gal.)

'A' 'B' 'C' 'D'

Steam

Boiler

(2)

FORCESTM03 350 12¾

28

40-7/16

4 4" x 15 ft.

1/2"

5.1 3.9

FORCESTM04 420 16 5 5" x 15 ft. 6.5 5.0

FORCESTM05 485 19¼

6 6" x 15 ft.

7.9 6.1

FORCESTM06 555 22½ 9.3 7.2

FORCESTM07 620 25¾

30 7 7" x 15 ft. 3/4"

10.7 8.3

FORCESTM08 690 29 12.1 9.4

(1) 15' chimney height is from bottom of Draft Hood opening to top of Chimney.

(2) Steam boiler's "steamable water volume": water volume from NWL (normal water level) to low water cutoff level.

Heating Surface: 4.35 sq. ft. per ueway (steam); 5.72 sq. ft. per ueway (water)

6

106324-04 - 4/18

1) Safe,reliableoperationofthisboilerdependsuponinstallationbyaprofessionalheatingcontractorinstrictaccordance

withthismanualandtherequirementsoftheauthorityhavingjurisdiction.

• Intheabsenceofanauthorityhavingjurisdiction,installationmustbeinaccordancewiththismanualandthe

National Fuel Gas Code,ANSIZ223.1/NFPA54.

• Whererequiredbytheauthorityhavingjurisdiction,thisinstallationmustconformtotheStandard for Controls and

Safety Devices for Automatically Fired Boilers(ANSI/ASMECSD-1).

2) Makesurethataproperlysizedchimneyisavailablewhichisingoodcondition.Consulttheauthorityhaving

jurisdiction,PartVIofthismanual,andtheNational Fuel Gas Codeforadditionalinformationonventingrequirements.

3) Makesurethattheboileriscorrectlysized.UseanindustryacceptedsizingmethodsuchastheI=B=R Installation

Guide for Residential Hydronic Heating Systems (Pub. #200) and I=B=R Heat Loss Calculation Guide(Pub.#H21or

#H22).

4) Makesurethattheboilerreceivedisconguredfornaturalgas.

5) GasConversionKitsarelistedbelow:

FORCESTM03 FORCESTM04 FORCESTM05 FORCESTM06 FORCESTM07 FORCESTM09

Natural to LP

(Propane)

106567-01 106567-02 106567-02 106567-03 106567-04 106567-04

LP (Propane) to

Natural

106568-01 106568-02 106568-02 106568-03 106568-04 106568-04

Warning

This Product Must be Installed By A Licensed Plumber Or Gas Fitter

when Installed Within The Commonwealth Of Massachusetts

IV. Locating the Boiler

1) Clearances:

• Observetheminimumclearancesshownbelow.Theseclearancesapplytoallcombustibleconstruction,aswellas

noncombustiblewalls,ceilingsanddoors.AlsoseeFigure2.

Front–18”

RightSide–18”

LeftSide–6”

Rear–6”

Top–17”

• A24”serviceclearancefromthejacketisrecommendedontheleft,right,andfrontoftheboiler.Theseclearances

maybereducedtothoseshowninFigure2,howeverservicingtheboilerwillbecomeincreasinglydifcultasthese

serviceclearancesarereduced.

• Iftherightside24”serviceclearanceisreduced,adequateclearancemustbemaintainedtoeasilyreadandaccessthe

controls.Alternatively,accessmaybeprovidedusingadoor

2) Thisboilermaybeinstalleddirectlyoveranon-carpetedcombustibleoor.

I. Pre-Installation

7

7

106324-04 - 4/18

3) Theboilermustbeinstalledonahardlevelsurface.

4) Donotinstallthisboilerinalocationwheregasolineorotherammablevaporsorliquidswillbestoredorused.Donot

installthisboilerinanareawherelargeamountsofairbornedustwillbepresent,suchasaworkshop.

5) Theboilershouldbelocatedasclosetothechimneyaspossible.

6) Donotinstallthisboilerdirectlyonasurfacethatmaygetwet.Raisetheboileronapad.

FIGURE 2: FORCESTM BOILERS - CLEARANCES TO ALL TYPES OF COMBUSTIBLE CONSTRUCTION

AND NONCOMBUSTIBLE CEILINGS, WALLS, AND DOORS.

V. Air for Combustion & Ventilation

IV. Locating the Boiler

(continued)

Sufcientfreshairmustbesuppliedforcombustion,ventilationanduegasdilution.Provisionsforcombustion,ventilationand

uegasdilutionairforgasutilizationequipmentventedbynaturaldraftmustbemadeinaccordancewithlocalbuildingcodesor,

inabsenceofsuchcodes,inaccordancewith“AirforCombustionandVentilation”oftheNational Fuel Gas Code,ANSIZ223.1/

NFPA54.

8

106324-04 - 4/18

VI. Venting

Ventinstallationmustbeinaccordancewithlocalbuildingcodes,orthelocalauthorityhavingjurisdiction,ortheNational Fuel

Gas Code,ANSIZ223.1/NFPA54.

1. AtypicalventinstallationisillustratedbyFigure3.Thecomponentsofventinstallationaretheventdamper(ifused),

ventconnectorandchimney.

2. Installventdamper(seeFigure4)asfollows:

a) Openventdampercartonandremoveinstallationinstructions.Readtheinstructionsthoroughlybeforeproceeding.

Verifythatventdamperissamesizeasdraftdiverteroutlet.SeeFigure1.Unpackventdampercarefully.Do not

force closed damper blade. Forcingventdamperclosedmayresultindamagedgeartrainandvoidwarranty.

b) Ventdamperisfactoryshippedhavingapproximately¾”diameterholeintheventdamperblade,whichmust be left

openforboilersequippedwithstandingpilot,andshouldbepluggedonboilerswithanintermittentpilotsystem,

usingtheplugsuppliedwiththedamper.

Mounttheventdamperontheuecollarwithoutmodicationtoeitherandsecurewithsheetmetalscrews.Make

surescrewsdonotinterferewithdamperbladeoperation.Ventdamperbladepositionindicatormustbevisibleto

users.

c) Thedamperwireharnessisshippedwiredintotheboilerjunctionbox.Plugthelooseendofthisharnessintothe

damperandsecuretheexibleconduittothedamperusingaconnectornutprovided.

d) Installventconnectorpipeandventttingsfromventdamperoutlettochimneyorgasvent.Securewithsheetmetal

screwsandsupportasrequired.

3. GasVentTermination

Gasventslocatednotlessthan8ft.(24m)fromaverticalwallorsimilarobstructionshallterminateabovetheroofin

accordancewithFigure5andTable2.

FIGURE 3: FORCESTM BOILER TYPICAL VENT SYSTEM INSTALLATION AND COMPONENTS

9

9

106324-04 - 4/18

FIGURE 4: VENT DAMPER INSTALLATION DETAILS

VI. Venting (continued)

Listed

cap

Listed

gas vent

H (minimum) -

Minimum height from roof

to lowest discharge opening

Roof pitch is x/12

12

x

Lowest discharge opening

FIGURE 5: TERMINATION LOCATIONS FOR GAS VENTS

WITH LISTED CAPS AT LEAST 8 FT (2.4 M)

FROM A VERTICAL WALL:

Roof Slope H (minimum)

ft m

Flat to 6/12 1.0 0.30

Over 6/12 to 7/12 1.25 0.38

Over 7/12 to 8/12 1.5 0.46

Over 8/12 to 9/12 2.0 0.61

Over 9/12 to 10/12 2.5 0.76

Over 10/12 to 11/12 3.25 0.99

Over 11/12 to 12/12 4.0 1.22

Over 12/12 to 14/12 5.0 1.52

Over 14/12 to 16/12 6.0 1.83

Over 16/12 to 18/12 7.0 2.13

Over 18/12 to 20/12 7.5 2.27

Over 20/12 to 21/12 8.0 2.44

TABLE 2: ROOF SLOPE HEIGHTS

10

106324-04 - 4/18

FIGURE 6: GAS CONNECTION TO BOILER

VII. Gas Piping

*

*StateofMassachusettsRequiresManual

Shut-offValvetobe“T”HandleType

Gaspipingtotheboilermustbesizedtodeliveradequategasfortheboilertoreatthenameplateinputatalinepressure

betweentheminimumandmaximumvaluesshownontheratingplate.Formoreinformationongaslinesizing,consultthe

utilityorChapter2oftheNational Fuel Gas Code.

Figure6showstypicalgaspipingconnectiontotheFORCESTMboiler.Asedimenttrapmustbeinstalledupstreamof

allgascontrols.Installamanualshut-offvalveoutsidethejacketandgroundjointunionasshown.

Theboileranditsgasconnectionmustbeleaktestedbeforeplacingtheboilerinoperation.Whendoingthis,theboiler

anditsindividualshut-offmustbedisconnectedfromtherestofthesystemduringanypressuretestingofthatsystemat

pressuresinexcessof1/2psi.Whenpressuretestingthegassystematpressuresof1/2psiorless,isolatetheboilerfromthe

gassupplysystembyclosingitsindividualmanualshut-offvalve.

11

11

106324-04 - 4/18

CAUTION

• INSTALLBOILERSOTHATTHEGASIGNITIONSYSTEMCOMPONENTSAREPROTECTED

FROMWATER(DRIPPING,SPRAYING,RAIN,ETC.)DURINGAPPLIANCEOPERATIONANDSERVICE

(CIRCULATORREPLACEMENT,ETC.).

• OPERATIONOFTHISBOILERINASYSTEMHAVINGSIGNIFICANTAMOUNTSOFDISSOLVED

OXYGENCANCAUSESEVEREHEATEXCHANGERCORROSIONDAMAGE.

VIII. System Piping

General Piping Notes

Figure7showsrecommendednearboilerpipingformostcommontypesofgravityreturnsteamsystems.Additional

informationonsteamsystemdesignmaybefoundinInstallation Guide for Residential Hydronic Heating Systems(Pub.

#200).

Oneoftheprimarypurposesofthisnearboilerpipingistoseparatetinywaterdropletsfromthesteamexitingtheboiler

sothat“dry”steamissenttothesystem.Ifthenearboilerpipingisnotcorrect,wetsteamwillenterthesystemandthe

followingproblemsmayoccur:

• Short cycling on low water

• BoilerorsystemFlooding

• Hammering

• Failuretoheatoneormoreradiators

AvoidthethreecommonpipingmistakesshowninFigure8.Thisapplieseveniftheexistingboilerhasoneofthepiping

mistakesshowninFigure8andappearstobeworking.Iftwoormoresteammainsmustbeconnectedtotheboiler,connecta

separatetake-offforeachmainintotheheaderbetweentheriser(s)andequalizer.Alsonotethefollowingpoints:

1) Asizereductionmustbemadetoconnecttheheadertotheequalizer.Thisreductionmustbemadeintheequalizerline.

Donotmakethissizereductioninthehorizontalheader.

2) Onepipesteamsystemsrequireairventsoneachradiator,aswellasattheendofeachmain.Forthesystemtowork

properly,theseventsmustbeproperlyinstalled,sized,andbeingoodcondition.Inspectandreplaceanydefectivevents.

Iftherearenoventsattheendsofthemains,installthem.

3) DonotattempttomanifoldmultipleFORCESTMboilerswithgravityreturns.

4) Forinstallationswithcondensateorboilerfeedpumps,followthepumpmanufacturer’spipinginstructions.Such

systemsgenerallydonotrequireHartfordloops.

5) Donotuseacheckvalveinplaceof,orinadditionto,aHartfordlooponagravityreturnsystem.

6) Pipethellconnectionfromacleansourceofcoldwater.Whenthewatersupplyisfromawell,makesurethatastrainer

isinstalledinthewellsystem.

7) PipingwithaChiller-Iftheboilerisusedinconjunctionwithachiller,pipetheboilerinparallelwithchiller.Use

isolationvalvestopreventchilledwaterfromenteringtheboiler.

12

106324-04 - 4/18

Piping Installation

1) Removepartsbagfromboilercrate.

2) Installsafetyvalve(spindlemustbeinverticalposition)intotappingonboilerleftside(seeFigure1)usingthe3/4”NPT

nippleandelbowsupplied.

3) Pipethedischargeofthesafetyreliefvalvetoalocationwherewaterorsteamwillnotcreateahazardorcauseproperty

damageifthevalveopens.Theendofthedischargepipemustterminateinanunthreadedpipe.Ifthesafetyvalve

dischargeisnotpipedtoadrainitmustterminateatleast6inchesabovetheoor.Theterminationofthesafetyvalve

dischargepipingmustbeinanareawhereitisnotlikelytobecomepluggedbydebrisorsubjectedtofreezing.

4) Installdrainvalveintotappingonboilerleftsideusingthe2x3/4bushingprovided(seeFigure1).

5) Connectsystemsupplyandreturntoboiler.SeeFigure7.FORCESTM03throughFORCESTM06maybepipedwith

oneortworisers.Install2”pluginTappingGifoptionalsecondsupplyAisnotused.Twosupplyrisersarerequiredon

theFORCESTM07andFORCESTM08.

6) PipingwithaChiller-Iftheboilerisusedinconjunctionwithachiller,pipetheboilerinparallelwithchiller.Use

isolationvalvestopreventchilledwaterfromenteringtheboiler.

DANGER

•

PIPESAFETYVALVEDISCHARGETOASAFELOCATION.

• DONOTINSTALLAVALVEINTHESAFETYVALVEDISCHARGELINE.

• DONOTMOVESAFETYVALVEFROMFACTORYLOCATION.

• DONOTPLUGSAFETYVALVEDISCHARGE.

• DONOTINSTALLASAFETYVALVEWITHASETTINGGREATERTHAN15PSI.

VIII. System Piping (continued)

13

13

106324-04 - 4/18

FORCESTM03 /

FORCESTM04 /

FORCESTM05 /

FORCESTM06

FORCESTM07 /

FORCESTM08

A

2** 2

B

2 3

C

1½ 1½

D

1¼ ¼

** Optional

FIGURE 8: COMMON NEAR-BOILER PIPING MISTAKES

FIGURE 7: STEAM BOILER PIPING FOR GRAVITY RETURN

MINIMUM PIPE SIZE

VIII. System Piping (continued)

14

106324-04 - 4/18

AllFORCESTMseriesboilersareequippedwithtappingstopermittheconnectionofaLinkSL™IndirectWater

Heater,orotherindirectwaterheater.Inthistypeofsystem,hotboilerwaterisdrawnfrombelowthewaterlineand

passedthroughtheheatexchangerintheindirectwaterheater.Thissectiondescribesboiler-sidepipingonly.RefertoLink

SL™Installation,OperatingandServiceInstructionsforadditionalinformation

.Thecomponentsinthissystemandtheir

functionsareasfollows:

1) Circulator-MountthecirculatorasshowninFigure9.Thecirculatorshouldbelocatedaslowandasclosetothe

boileraspractical.Donotinstallvalves,orotherdeviceshavingasignicantpressuredrop,betweentheboiler

andthecirculatorinlet.Allpipingbetweentheboilerandthecirculatorinletshouldbe1”,regardlessofthesizeof

thepipingrequiredintherestofthesystem.SeeFigure10inPartXforwiringinformation.

2) “Y”Strainer-Installa“Y”strainertopreventsedimentfromaccumulatinginsidetheindirectwaterheater.

3) CheckValve-Preventsgravitycirculationthroughtheindirectwaterheaterwhentheboilerisrespondingtoacall

forheat.

4) BoilerLimitControl-UseaSPSTbreak-on-risetemperaturelimitcontrolsuchastheHoneywellL4006A.Donot

setthelimitabove180°Fasdoingsomaycausetheboilertosteamwhenthereisnocallforheat.SeeFigure10

forwiringinformation.

5) ValvesandUnions-Installshut-offvalves,drainvalves,andunionsinlocationsthatwillfacilitatemaintenanceof

thesystem.Donotinstallanyvalvesbetweentheboilerandcirculatorinlet.

IMPORTANT

• Someindirectwaterheatersmaynotbesuitableforusewithasteamboiler.Consultthewaterheater

manufacturer’sguidelinesbeforeinstallingitinthistypeofsystem.

• Boilerwatertemperaturesandowratesinthistypeofsystemmaybeconsiderablylowerthanthoseupon

whichthewaterheatermanufacturer’sratingsarebased.Thismayresultinsubstantiallylongerwaterheater

recoverytimes.

FIGURE 9: INDIRECT WATER HEATER BOILER-SIDE PIPING

IX. Indirect Water Heater Piping

15

15

106324-04 - 4/18

1) 120VoltWiring-Theboilershouldbeprovidedwithitsown15Abranchcircuitwithfuseddisconnect.All120volt

connectionsaremadeinsidethejunctionboxontheleftsideoftheboiler.Removethetransformertogainaccesstothis

box(alsoseeFigures11and12):

• Hot(“black”)-Wirenuttoblacktransformerlead

• Neutral(“white”)-Wirenuttowhitetransformerlead

• Ground(“green”orbare)-Groundscrewinsidejunctionbox.

2)ThermostatWiring-Followthermostatmanufacturerinstructions.Toinsureproperthermostatoperation,avoid

installationinareasofpooraircirculation,hotspots(nearanyheatsourceorindirectsunlight),coldspots(outside

walls,wallsadjacenttounheatedareas,locationssubjecttodrafts).ProvideClassIIcircuitbetweenthermostatand

boiler.Connectthermostatwireleadstothebluetransformerleadandbrownrelayleadinsidethejunctionbox.Setthe

heatanticipatorto0.2A.

WARNING

Allwiringandgroundingmustbedoneinaccordancewiththeauthorityhavingjurisdictionor,intheabsenceofsuch

requirements,withtheNationalElectricalCode(ANSI/NFPA70)

X. Electrical

16

106324-04 - 4/18

FIGURE 10: WIRING INDIRECT WATER HEATER TO BOILER

Indirect Water Heater Wiring

Figure10showseldwiringforanindirectwaterheater.AHoneywellR845AorequivalentDPSTrelayandtransformer

isrequired.ThehighlimitdescribedinPartIXmustalsobesuppliedbytheinstaller.Acallforheatfromtheindirectwater

heaterthermostatwillenergizetherelaymakingbothsetsofcontacts.Onesetofthesecontactsthenenergizesthecirculator.

Theothersetofcontactswillmakethe“T”and“T”contactsontheburnerprimarycontrol,ringtheburner.Iftheboiler

watertemperatureexceedsthehighlimitsettingof180°F,thehighlimitwillopenthe“T”-“T”circuitandtheburnerwill

shutdown.

Ifthereisacallforspaceheat,theheatingthermostatwillmakethe“T”-“T”circuitandtheboilerwillrewithoutregard

tothestatusoftheindirectwaterheater.Thelowwatercut-offandpressurelimitcontrolwillinterrupt120voltpowertothe

burnerintheeventofalowwaterorexcessivepressurecondition.

X. Electrical (continued)

17

17

106324-04 - 4/18

FORCESTM Control System – Sequence of Operation

(RefertoFigures11&12forladderandconnectiondiagrams)

Sequence of Operation, Intermittent Ignition

1)Whentheboilerisenergized,24voltsisimmediatelyappliedtoterminals“1”(blue)and“4”(yellow)onthevent

damper.Assumingthatthereisnocallforheat,andthatthedamperswitchisinthe“automatic”position,thedamper

willclose.OnboilersequippedwithHydrolevelCG400Aprobetypelowwatercut-offs,voltageisalsoalwaysapplied

toterminals“1”(blue)and“2”(yellow)onthelowwatercut-offtopowerthewaterlevelsensingcircuit.

2)Assumingthatwaterisabovethecut-offlevel,powerwillappearatterminal“3”ontheCG400ALWCO.

3)Assumingthatsteampressureisbelowthepressurelimitsetting,powerwillappearononesideofrelaycontact1R1

(Graylead).Relay1RistheR8225mountedunderthejunctionbox.

4) Acallforheatfromthethermostatenergizesrelaycoil1Rcausingcontacts1R1tomake.Currentthenowsthrough

contacts1R1topinterminal“2”(orange)attheventdamperandthedamperopens.

5) Oncetheventdamperisfullyopen,anendswitchinsidethedamperwillmake,energizingpin“3”(red)atthedamper.

6) Currentpassesfromterminal“3”ontheventdamperthoughtheamerolloutandblockedvent(“spill”)switches.Under

normalconditions,bothoftheseswitchesaremadeandvoltagewillthereforeimmediatelyappearacrossterminals

“24V”and“24V(GND)”ontheignitionmodule.

7) Uponapplicationofvoltageacrossthe“24V”and“24V(GND)”terminals,theignitionmodulewillstartanignition

sparkatthepilotandapply24voltsacrossthepilotvalve(terminals“PV”and“MV/PV”).

8) Oncethepilotisestablished,thepilotamewillactasadiode,convertingtheACcurrentattheelectrodetoahalfwave

DCcurrentatthepilot’sgroundstrap.ThisDCcurrentowsthroughtheboilertothe“GND(BURNER)”connectionon

theignitionmodule.Fortheignitionmoduletorecognizethatapilotameispresent,theDCcurrentowingintothis

terminalmustbeinexcessofapproximately1.0uA.

9) Oncetheignitionmoduledetectsthepresenceofapilotame,voltageisappliedacrossthemainvalve(terminals“MV”

and“MV/PV”),openingthevalveandestablishingmainame.

10) Formoreinformationonmoduleoperation,consulttheignitionmoduleinstructionssuppliedwiththeboilerorthelocal

Fergusonrepresentative.

Safety Control Operation - Intermittent Ignition

HydrolevelCG400ALowWaterCut-off-Interruptsburneroperationifthewaterintheboilerdropsbelowasafelevel.Asthe

waterdropspastthecut-offpoint,theamberlampontheCG400Awillglow.TheCG400Awillinterruptpowertotheburners

15secondsafterthewaterleveldropspastthecut-offpoint.Thisfeaturepreventsshortcyclingoftheburnersduetoabouncing

waterline.Theburnerswillthenremainoffuntil30secondsafterthewaterlevelhasbeenraisedabovethecut-offpoint.

TheCG400Aisalsoequippedwithafeaturewhichwillshutdowntheburnersaftertheyhavebeenringfor10minutes,

regardlessofthewaterlevelstatus.TheCG400Athenkeepstheburnersofffor90seconds,allowingthewaterlevelandanyfoam

whichispresenttosettle.Duringthis90secondinterval,thegreenLEDontheCG400Awillglow.Ifthewaterlevelisstillabove

thecut-offlineattheendofthis90secondinterval,theCG400Awillrestarttheburners.

Theventdamperwillclosewhenthelowwatercut-offinterruptsburneroperation.

PressureLimitControl-Interruptsburneroperationwhenthepressureintheboilerexceedsthe“Cut-in”settingplusthe

differentialsetting.The“Cut-in”settingisshownontheoutsideofthecontrolandisadjustedusingthescrewonthetopofthe

control.Thedifferentialisadjustedusingthewhitethumbwheelontheinsideofthecontrol.Burneroperationisrestoredwhen

thepressureintheboilerdropstothe“Cut-in”pressure.

Theventdamperwillclosewhenthepressurelimitcontrolinterruptsburneroperation.

BlockedVentSwitch(BVS)-Automaticallyinterruptsburneroperationintheeventthatuegasspillsfromthedraftdiverter

opening.Thisswitchisequippedwitharesetbuttonwhichmustbepressedtorestorenormalburneroperation.Anopenblocked

ventswitchisindicativeofaproblemwiththeventsystem.Iftheblockedventswitchopens,thecauseoftheventingproblem

mustbefoundandcorrectedbyaqualiedgasservicetechnicianbeforetheblockedventswitchisreset.

FlameRolloutSwitch(FRS)-Automaticallyinterruptsburneroperationwhenamesorexcessiveheatarepresentinvestibule.

Theamerolloutswitchisasingleusedevicewhichmustbereplacedbyanidenticalswitchinordertorestorenormaloperation.

Anopenamerolloutswitchisusuallyindicativeofapluggedheatexchanger.Thecauseoftheamerolloutmustbefound

andcorrectedbyaqualiedgasservicetechnician,andtheswitchreplacedwithanidenticalone,beforetheboilerisreturnedto

operation.

X. Electrical (continued)

18

106324-04 - 4/18

FIGURE 11: WIRING DIAGRAM, HYDROLEVEL CG400A LOW WATER CUTOFF

X. Electrical (continued)

19

19

106324-04 - 4/18

FIGURE 12: LADDER DIAGRAM, HYDROLEVEL CG400A LOW WATER CUTOFF

X. Electrical (continued)

20

106324-04 - 4/18

Usethefollowingprocedureforinitialstart-upoftheboiler:

1) Makesurethattheboilerislledwithwatertothenormalwaterline(283/4inchesabovetheoororpadonwhichthe

boilerisinstalled)

2) Checkallnewgaspipingforleaksandpurgepipingsectionsthatarelledwithair.SeePart4oftheNational Fuel Gas

Codeforadditionalinformationontestingandpurginggaslines.

3) Verifythatventsystemiscompleteandfreeofobstructionsbeforeattemptingtoreboiler.

4) Inspectallwiringforlooseoruninsulatedconnections.

5) Makesurethemainburnersareseatedproperlyintherearofburnertrayandonorices.

6) Adjuststeampressurelimitcontrolforacut-inpressureof0.5psiandadifferentialpressureof1psi.

7) Adjustthermostattothehighestsetting.

8) StarttheboilerusingtheOperatingInstructions.SeeFigure14.

9) Uponinitialstart-up,thegastrainwillbelledwithair.Evenifthegaslinehasbeencompletelypurgedofair,it

maytakeseveraltriesforignitionbeforeaameisestablished.Onceaamehasbeenestablishedforthersttime,

subsequentcallsforburneroperationshouldresultinaameonthersttry.

10) Observepilotburnerame.Pilotburnerproducesthreeames.Thecenteroneshouldbeasteadymediumblueame

coveringaround3/8”to½”ofsparkelectrode/amerod.SeeFigure13.

12) Makesureventdamperisinopenpositionwhenmainburnersarering.

13) Inspectthemainburneramesvisiblethroughtheobservationportinburneraccesspanel.Theameshouldbestable

andmostlyblue(seeFigure15).Noyellowtippingshouldbepresent;however,intermittentecksofyellowandorange

intheamearenormal.

14) Checkentiregastrainforleaksusingsoapandwaterorotherapprovedleakdetectionmethodwhileboilerisring.Fix

anyleaksfoundimmediately.

15) Rungasvalvesafetyshutdowntest.Withmainburnersring,disconnectignitioncablefromignitionmodule.Both

pilotburnerandmainburnersshouldstopring.

WARNING

•

NEVERUSEAFLAMETOCHECKFORGASLEAKS.

• MAKESURETHATTHEAREAAROUNDTHEBOILERISCLEARANDFREEFROM

COMBUSTIBLEMATERIALS,GASOLINE,ANDOTHERFLAMMABLEVAPORSANDLIQUIDS.

• DAMPERMUSTBEINOPENPOSITIONWHENAPPLIANCEMAINBURNERISOPERATING.

XI. System Start-up

/