Page is loading ...

4

PFAFF

63

Light-Weight

Portable

Electric

Sewing

Machine

(Central

Bobbin

Machine)

For

Straight-Away

Stitching

INSTRUCTION

BOOK

•1

1.

What

Belongs

to

Your

Machine?

1

package

of

assorted

needles,

System

705

R

I

tape

measure

5

bobbins

No.

2030

1

shuttle

screw

driver

No.

29070

1

screw

driver

No.

29002,

short

1

screw

driver

No.

29007,

long

1

hinged

presser

foot

No.

43729

1

guide

No.

25820

1

guide

fastening

screw

No.

112

1

edge

stitcher

with

quilting

guide

No.2555

3

1

hemmer,

2.5

mm,

No.

25576

1

hemmer,

4.0

mm,

No.

25579

1

folder

No.

25594

1

feed

cover

plate

No.

25997

1

darning

hook

No

46128

1

oil

can

No.

29168,

flat

1

bottle

of

oil

No.

29180

1

instruction

booklet

I

Foreword

Youarenowthe

proud

ownerof

a

Portable

Electric

PFAFP

63.

The

material

of

which

is

made

and

the

workmanship

it

embodies

ore

of

the

same

high

standards

as

used

n

today’s

High

Speed

Sewers

for

industrial

purposes.

t’ou

can

use

your

PFAFF

everywhere

at

will.

It

can

be

set

up

and

put

away

after

the

ewing

quickly,

is

easy

to

operate,

and

requires

little

attention

and

service.

lust

follow

these

smple

instructions

and

sewing

will

become

a

lasting

pleasure.

G.M.PFAFF

AG

2

3

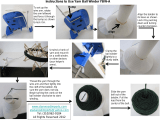

Photo

1

Li

j

2.

Do

You

Know

Your

Machine?

1.

Full-length

arm

cover,

removable

2.

Thread

take-up

3.

Upper

thread

guide

4.

Collapsible

spool

pins

5.

Winder

spindle

6.

Winder

engaging

lever

7,

Balance

wheel

8.

Milled

screw

for

engaging

the

sewing

mechanism

9,

Stitch

length

limiting

lever

10.

Stitch

length

lever

11.

Motor

support

12.

Spool

pins

13.

Pin

cushion

14.

Sewing

machine

base

15.

Accessory

receptacle

cover

plate

16.

Push

button

for

sew

light

17.

Feed

lowering

button

18.

Sewing

machine

arm

19.

Sew

light

lowering

lever

20.

Needle

clamp

screw

21.

Needle

plate

22.

Presser

foot

23.

Fold

away

support

for

bed

plate

ex

tension

24.

Bed

plate

extension

25.

Bed

plate

slide

26.

Needle

threader

27.

Lower

face

plate

thread

eyelet

28.

Upper

thread

tension

29.

Upper

face

plate

thread

eyelet

30.

Face

plate

45

N

25

Photo

2

56

22

16

15

I

1.

Full-length

arm

cover,

removable

2.

Thread

take-up

3.

Upper

thread

guide

4.

Collapsible

spool

pins

5.

Winder

spindle

6.

Winder

engaging

lever

7.

Balance

wheel

14.

Sewing

machine

base

17.

Feed

lowering

button

2L

Needle

plate

23.

Fold-away

support

for

bed

plate

extension

24.

Bed

plate

extension

25.

Bed

plate

slide

26.

Needle

threader

30.

Face

plate

31.

Winder

thread

tension

32.

Needle

threader

lever

33.

Presser

bar

lever

34.

Hinge

for

case

top

35.

Bed

plate

36.

Swivel

support

for

tilting

the

head

37.

Plug

for

motor

cable

38,

Electric

motor,

Type

KU

52

39.

Belt

guard

—

I

J

Do

You

Know

Your

Machine?

L.

hoto

3

67

r—---

Li

3.

Setting

Up

the

Machine

Place

the

sewing

machine

case

on

table

and

unlock

it.

Pull

the

flap

lighti

and

the

snap

bow

will

release

the cas

top.

Lift

the

top

and

remove

it,

holding

th

cable

bag

in

your

left

hand.

Take

pedal

starter

from

top

cover

on

unpack

cable.

Photo

4

Place

pedal

starter

under

the

table

and

plug

the

cable

into

the

motor

socket.

Attention

Dont

plug

your

machine

into

the

line

unless

you

have

made

sure

that

the

line

voltage

corresponds

to

the

voltage

given

on

the

motor plate

of

your

machine

(check

the

cur

rent

meter to make

sure of

the

line

voltage).

Place

the

pedal starter

within

convenient

reach.

A

sliqht

pressure

exerted

with

the

foot

cuts

in

the

machine

and

it

commences

swina

The

farther

you

depress

the

starter,

the

faster

will

the

machine

sew.

9

I

Type

of

Material:

Very

fine

linen,

Shirting,

ccmbrcs,

muH

Net,

finest

s

k

Foulard

silk

Fine

linen,

cambric

Crêpe

de

Chine

Crêpe

Marocain

Crêpe

Satin,

Nylon,

Perlon

Muslin,

fine

taffeta

Fine

sheets,

table

cloths

Silk

cloths

Linen,

calico,

quilts

with

Silk

covers

Cotton,

kid

leather,

etc.

Fine

cloth

Heavy

silk

and

linen,

inlets

Clothing,

general

Fine

leather

Heavy

woollens

and

linen

silk

100-120

00-

0

80-100

60-

70

/

-D

0

0

C),

o_

:-‘

i5•-

D

D

Q

.

C

•

CD

CD

(0

-,

-.

CD

CD

:3-n

-,-CD

0(0

(D

—

0

—

m

D

a

CD

0

‘,,

—-0-

0

<CD

0

—

:c•

;•

•-

0

D

0(0

D3

CD

3

0

a

=

CD

,

w

C

5.

Relative

Sizes

of

Needles

and

Threads

—

—

Needle

Size

Type

of

Thread:

Size:

60

(6)

cotton

120-150

silk

COO-

00

schappe

silk

100-150

embroidery

yarn

60-

80

70

(7)

cotton

silk

schappe

silk

embroidery

yarn

80

(8)

cotton

S

•55

SS

r-rt----

—

80-100

00-

0

(100/3)

schappe

silk

70-80

embroidery

yarn

50-70

90

(9)

cotton

silk

schappe

silk

embroidery

yarn

100

(10)

cotton

thread

silk

I

60-80

A-B

70

30-40

40-60

B-C

Cloth,

calico,

etc.

110

(11)

schappe

silk

60

1.

Disengage

the

sew

ing

mechanism.

2.

Place

cotton

reel

on

the

right

reel

pin.

3.

Pass

the

thread

from

cotton

reel

1,

around

tension

2,

crossing

the

theod.

4.

Thread

end

of

thread

inside—out

through

the

bobbin

slot.

5.

Place

bobbin

3

on

spindle

4.

6.

Press

lever

5

against

bobbin.

The

winder

will

throw

off

automatically

when

bobbin

is

filled.

I

6.

Changing

the

Needle

Loosen

needle

clamp

screw.

7.

Winding

the

Bobbin

Thread

Insert

needle

into

the

opening

of

the

needle

bar

as

far

as

it

will

go,

taking

care

that

the

flattened

side

of

the

shank

faces

to

the

right.

Tighten

needle

clamp

screw.

Photo

7

Photo

6

12

13

I

Pull

out

bobbin

case,

holding

the

latch.

it

While

the

latch

remains

open,

bobbin

cannot

fall

out.

the

N

8.

Taking

Out

Bobbin

Case

Raise

needle.

9.

Inserting

the

Bobbin

into

the

bobbin

case.

by

Hold

bobbin

as

shown

in

the

photo;

the

thread

unwinding

toward

the

operator.

Photo

8

14

15

Photo

9

I

Draw

thread

through

slot,

as

illustrated.

Photo

10

16

Hold

bobbin

in

bobbin case

and

draw

thread

beneath

the

tension spring

so

that

it

comes

out

from

underneath

its

end.

17

Photo

11

I

Hold

bobbin

case

with

thumb

and

midd

le

finger

of

your

left

hand.

While

the

index

finger

holds

the

latch

open,

the

bobbin

cannot

fall

out.

Photo

12

18

Place

bobbin

case

on

the

center

stud

of

the

shuttle

and

release

latch.

Turn

bobbin

case

with

thumb

and

index

finger

so

that

bobbin

case

retainer

H

engages

in

the

recess.

Push

the

bobbin

in

farther

until

it

clicks

with

an

audible

sound.

19

Photo

1

3

4L

V

0

0

C

-

0

o

0

-

C

C

CD

(9cQ

•-‘

CD

‘

-

0

CD

0

D

—

CD

CD

CD

C

;c-

0

-+,

C

CD

CD

-‘

<

—‘CD

CD

Z

-

3

0

-

(0

—

L1

CD

co

-

CD

CD

CD

•

CD

—

—

—

CD

-

Cl)

D

0

c0

0

0’

o

S.

C

0

D

;;

D

C)

CD

‘

,$)

.!‘

(D

CD

0

D

-,

(0

—

CD

c

—

-

-

D

C

CD

z

<

c2_

CD

CD

0

CD

2D

CD

—

D

CD

CD

D

I

•

.

.

holding

it

loosely

over

the

protrud

ing

prong

3,

making

sure

Ihatthread

lies

properly

in

the

lop

of

the

prong.

Photo

17

4.

Release

lever

1

4

Photo

16

The

thread

is

pulled

through

the

needle

eye

by

the

reversing

prong

3.

22

23

Photo

18

0

0

‘0

n

0

3

CD

CD

0

0

CD

n

CD

t

—

—0

CD

<

CD

-

o

:r

0

CD

0

0

0

0

n

C

C

0

CD

CD

-

0

ö-CD

o

—

a

<

3.

C

Cr1

=

-,

C

—

CD

D

0

CD

D_.

CDCD

C

—(‘-C

CD

C3

CD

o

CD

-

-

CD

0

-4

C

C

D

0

a

C

(

CD

D

CD

CD

C

C

C

CD

CD

0

CD

C

a

In

0

0.

C-

CD

CD

C

0

0

-$,

C-

CD

C

CD

-I

C

-I

CD

a

FL

-v

(0

C

0

0

U-

-I

0

0

0

-4

CD

—

C

CD

—

C

C

Ifl

C

CD

--‘

—

C

C

CO

CD

-,

Q_

-,,

CD

a

0

-

VI

CD

o

C

C

(D

-

G

o

—

VI

(0

C

(0

C

C

3

Oo

—

CD

?‘

CD

I,

0

—

—

=0

C

2:

CD

0

-In

e

C

0

CDQ

(00

a-

-‘

z

VI

C

C

9

0

()

CD

C

a

-‘

C”C

—

.

0

0

0C

0

-

-CD

o

—.

(0

<

•<

—

0.

a

0

U)

C-

3

0

—.

0

—

-.

0

a

—.

V

C

0

0

k)

cD

14.

Adjusting

the

Bobbin

Thread

Tension

For

Lighter

tension,

turn

tension screw

left

—((,

using

the

small

screw

driver.

Turning

the

screw

right

will

in

crease

the

tension.

Photo

22

Perfect

stitch

Photo

24

Photo

21

Upper

tension

too

weak

or

lower

tension

too

tight

26

27

15.

Correct

Tension

Regulation

with

perfect

interlocking

of

upper

and

lower

threads

in

the

center

of

the

ma

terial

results

in

neat

and

elastic

seams.

Photo

23

Upper

tension

to

Pght

or

lower

tension

too

weak

w

1

16.

Setting

the

Stitch

Length

17.

Removing

the

Top

Cover

1.

Set

stitch

length

limiting

lever

B

at

With

all

oil

points

covered

up,

there

is

the

desired

stitch

length

indicated

on

no

soiling

of

the

material!

the

scale.

The

full-length

top

cover

can

be

easily

2.

Push

stitch

length

lever

A

to

its

right

taken

off

with

both

hands.

stop

to

obtain

a

forward

stitch

of

the

length

of

stitch

set.

3.

For

reverse

stitching,

turn

lever

A

to

its

left

stop.

Photo

25

Photo

26

28

29

18.

Correct

Regulation

of

the

19.

Taking

off

the

Face

Plate

Pressure

on

the

Material

is

only

necessary

when

the

presser

bar

assures

uniformity

of

the

stitch

length

has

to

be

turned

for

the

proper

fasten-

and

prevents

injury

of

the

material

by

ing

of

attachments.

the

feed

dog.

1.

Remove

screw

k,

let

face

plate

slide

Turning

screw

V

left

cE(

will

ease

the

downwards,

and

take

it

off.

pressure

for

thin

and

flimsy

fabrics;

2.

When

replacing

it

make

sure

that

flap

turning

it

right

will

increase

the

L

engages

in

the

slot

N

and

stud

S

pressure

for

heavy

materials.

in

the

notch

K.

\V[ien

inserting

the

face

plate,

see

that

stud

F

catches

in

hole

H

fir

si,

then

push

face

plate

up

in

position.

Photo

27

Photo

28

30

31

-

20.

For

Taking

off

the

Balance

When

replacing

the

dog

ring,

make

Wheel

sure

that

its

bent-up

prongs

face

outside.

to

remove

odd

thread

between

balance

If

the

large

milled

screw

should

not

wheel

and

arm

shaft

bushing,

tighten

firmly,

turn

dog

ring

180°.

1.

Loosen

screw

a.

2.

Loosen

milled

screw

b,

turning

it

to

Photo

29

the

left.

3.

Remove

dog

ring

1

(photo

30),take

off

balance

wheel,

and

remove

thread.

Photo

30

32

33

A

Photo

31

Photo

32

21.

Servicing

and

Maintenance.

The

oiling

points

underneath

the

carriage.

Regular

and

proper

oiling

serves

to

increase

the

life

of

your

machine,

Apply

oil

only

at

the

points

marked

by

arrows.

Brush

off

regularly

lint

and

fluff

between

needle

plate,

feed

dog,

and

bobbin!

Do

not

forget

to

oil

the

rear

arm

shaft

bushing,

half

covered

by

the

winder

wheel

34

35

Apply

a

drop

of

oil

from

time to time

22.

Removing

the

Shuttle

in

the

shuttle

race.

becomes

necessary

when

thread

has

A

dry

race

will

wear

off

rapidly.

entered

into

the

race.

1.

Loosen

wing

screw

a

and

push

gib

b

downwards.

Photo

33

Photo

34

36

37

/