Page is loading ...

1LX Series Heat Pump Unit Controller User’s Guide

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Feature Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sensor Configuration Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LonMark Functional Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Units in LONWORKS Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Language Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Selecting a Measurement System or Selecting a Language . . . . . . . . . . . . . . . . . . . . . 16

Heat Pump Unit Controller Installation Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

10k Ohm or Digital Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Analog Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4 to 20 mA Analog Input, Externally Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sensors and Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Auxiliary Alarm Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Bypass Contact Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Coil Differential Pressure Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Coil Frost Contact Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Discharge Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Emergency Contact Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fan Speed Selector Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fan State Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Mode Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Occupancy Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Outdoor Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

LX Series Heat Pump Unit Controller

User’s Guide

Code No. LIT-12011484

Issued June 22, 2009

LX Series Heat Pump Unit Controller User’s Guide2

Pump State Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Refrigerant Temperature Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Setpoint Offset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Space Humidity Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Space Temperature Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Water Temperature Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Window Contact Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Analog Output Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Digital Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Staged Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Output Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Fan Speed 1 - 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Heating Outputs 1 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cooling Outputs 1 - 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Reversing Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Humidifier and Dehumidifier Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Mode Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Network Variables Used for Mode Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Occupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Starting Occupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ending Occupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Unoccupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Starting Unoccupied Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ending Unoccupied Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Starting Bypass Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Ending Bypass Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Starting Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

LX Series Heat Pump Unit Controller User’s Guide 3

Ending Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Slave Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

State Selection and Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Supervisory Control and Scheduling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Calculating the Space Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

The Effect of nviSetPoint on the Active Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

The Effect of a Setpoint Offset on the Active Setpoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Defrost cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Cooling State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Mechanical Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Cooling Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cooling Output Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Ending the Cooling State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Heating State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Heating Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Heating Output Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Cooling Outputs Used to Heat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Ending the Heating State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Night Purge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Morning Warm-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Fan Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Terminal Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Heating Terminal Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cooling Terminal Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Networking Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Slave Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Load Shedding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Setting Up Network Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Network Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

LX Series Heat Pump Unit Controller User’s Guide4

Optimum Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Requirements for Optimum Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Emergency Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Emergency Initiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Normal Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

The PID Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Proportional . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Integral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

How It Is Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Derivative . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Dead Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Alarm Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Alarm Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Alarm Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Alarm Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Heartbeat Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Disconnect Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Emergency Mode Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

User-Set Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setting up the Heat Pump Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Persistent Network Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Setting Units. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Input Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Heartbeat (Max Send Time). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Throttle (Min Send Time). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Delta Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

LX Series Heat Pump Unit Controller User’s Guide 5

Override Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Default Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Sensor Hardware Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Input Signal Interpretation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Signal Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Thermistor Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Max Value, Min Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Reverse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Increment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

TransTable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Get Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Configuring an Input Represented as a L

ONMARK Object . . . . . . . . . . . . . . . . . . . . . . . 66

Output Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Output Signal Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configuring an Output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Creating a Functional Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Configuring an Output Represented as a Functional Block. . . . . . . . . . . . . . . . . . . . . . . . . 70

Heating-Cooling Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Fan-Valve Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

PID Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Alarm Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Space Temperatures and Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Discharge Temperature and Auxiliary Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Fan Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Pump Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

General Settings Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Radiation Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Options Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Optimum Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

LX Series Heat Pump Unit Controller User’s Guide6

Frost Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Defrost Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Humidity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Network Input Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Heartbeat Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Network Output Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Object Manage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Object Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Communication Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Electrical Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Out of Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Disabled. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

In Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

In Override. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Out of Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Network Variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

nviApplicMode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

nviCoilDiffPress. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

nviDischargeTemp. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

nviEmergCmd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

nviExtCmdOutputx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

nviFanSpeedCmd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

nviFanState. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

nviHotWater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

nviOccCmd & nviOccManCmd. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

nviOutdoorTemp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

nviPumpState. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

nviRefrigTemp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

nviSetPoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviSetPtOffset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

LX Series Heat Pump Unit Controller User’s Guide 7

nviShedding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviSlave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviSpaceRH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviSpaceTemp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

nviWaterTemp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nvoCtrlOutput. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nvoDischargeSetPt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nvoEffectSetPt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nvoFanSpeed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nvoHPalarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

nvoHPstate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

nvoHwInput . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

nvoOccState. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

nvoSpaceTemp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

nvoTerminalLoad. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

nvoUnitStatus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Standard Network Variable Types (SNVT). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

SNVT_hvac_emerg (103 HVAC Emergency Mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

SNVT_hvac_mode (108) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

SNVT_hvac_status (112). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Alarm State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

SNVT_lev_percent (81) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

SNVT_occupancy (109) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

SNVT_switch (95). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Switch Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

SNVT_temp_p (105) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

SNVT_tod_event (128) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

LX Series Heat Pump Unit Controller User’s Guide8

LX Series Heat Pump Unit Controller User's Guide 9

LX Series Heat Pump Unit Controller

User's Guide

Introduction

Feature Description

The LX Series Heat Pump Unit (HPU) Controller integrates into a LONWORKS®

network for the control of almost any heat pump unit due to its wide range of

output types and LONMARK® certification.

The LX Series Heat Pump Unit Controller controls the following equipment:

• four stages of mechanical heating or cooling

• modulating heating or cooling valves

• reversing valves

• floating valves for heating or cooling

• pump for geothermal application

• three fan speeds or variable speed fans

• humidifier and dehumidifier

The Heat Pump Unit Controller has five digital outputs supplying 1.0 ampere at

24 VAC. These outputs produce digital or Pulse Width Modulated (PWM) signals.

Also, two tri-mode analog outputs are on the circuit board. These outputs provide

the following signals:

• linear signals over a 0 to 10 VDC range

• 10 VDC digital or PWM signals

• digital signal of 60 mA at 12 VDC

The Heat Pump Unit Controller has six inputs, each capable of one of 18 possible

input types. Inputs have 12-bit resolution and are configured entirely by software.

For easy maintenance and installation, the controller is equipped with wizard

connectors that can accept flat cable or wires. The controller uses a TP/FT 10;

78 kbps network configuration.

The information in this guide helps you to set up the Heat Pump Unit Controller,

understand the operation of the device, and troubleshoot problems. Information is

organized to follow the Heat Pump Unit Controller configuration wizard menu.

LX Series Heat Pump Unit Controller User's Guide10

Sensor Configuration Wizard

The Heat Pump Unit Controller incorporates the Johnson Controls® sensor

configuration wizard. The wizard provides powerful and simple configuration

tools for the hardware inputs. You can only select digital or analog inputs through

the software. You do not need to move any circuit board jumpers.

Analog input signal types–resistive, voltage, current–are selected in software

without hardware jumpers. Built-in conversion tables are provided for a large

number of thermistors or other sensor types. You can easily create custom

conversion tables by setting the offset, minimum, and maximum values in one

dialog box for the input.

The sensor configuration wizard also provides direct access to network properties

of the analog or digital input including the Standard Network Variable Type

(SNVT), Heartbeat, Send on Delta, Override, Default Value, and Throttle settings.

All of the input features are in one place; therefore, it is not necessary to switch

back and forth between screens to fully configure an input.

The sensor configuration wizard provides warnings of configuration errors as they

occur, allowing you to correct mistakes quickly.

The sensor configuration wizard is accessible in the LX-HPUL wizard view of an

LX-HPUL device in FX Workbench. Each hardware input is represented by a

separate LONMARK object. To configure each input, select the desired hardware

input on the left side of the LX-HPUL wizard view and Sensor Configuration in

the Wizard column of the view and click the Launch button. The sensor

configuration wizard opens. Through use of the wizard, you can configure network

inputs not directly controlled by the HPU Controller.

Control Features

The Heat Pump Unit Controller provides Proportional plus Integral plus Derivative

(PID) loops for advanced control of humidity, discharge temperature, and space

temperature. Each PID loop has an individual, configurable dead band; and,

provides gain and time adjustment for the integral and derivative terms, and gain

adjustment for the proportional term.

Humidification and dehumidification sequences provide the Heat Pump Unit

Controller with the ability to maintain space humidity at the desired level. Defrost

cycles are started by the HPU when the differential pressure is high, or by a

sequence in conjunction with the refrigerant temperature sensor. Space

temperature control is done with a PI loop only, but the presence of the derivative

term provides the HPU Controller with the ability to precisely adjust space

temperature. Precision adjustment ensures both increased comfort and savings.

Often associated with air handlers, the HPU Controller provides advanced control

settings including Optimum Start and load shedding.

LX Series Heat Pump Unit Controller User's Guide 11

The Optimum Start function maintains statistics that enable the Heat Pump Unit

Controller to predict the warm-up or cool-down time period needed to make the

building ready for occupancy. The precise Optimum Start period is calculated

every day using the current outdoor air temperature.

LONMARK Functional Profile

The LX Series Heat Pump Unit Controller uses the LONWORKS protocol. The Heat

Pump Unit Controller is LONMARK certified for interoperability on any

LONWORKS network. The controller is set up through its own configuration wizard

and through the Sensor configuration wizard. Use FX Workbench to install the

device onto the network and bind the network variable connections.

Figure 1 shows the Heat Pump Unit Controller meets the LONMARK standard by

providing the network variable inputs, network variable outputs, and configuration

properties specified by the profile. In addition, the Heat Pump Unit Controller

provides extra network variable inputs and outputs. These extra variables provide

greater flexibility and a number of functions than required in the profile.

For example, functions determined by the network variables include slaving the

controller to another unit through nviSlave or enabling the controller to act as the

master node through nviUnitStatus.

LX Series Heat Pump Unit Controller User's Guide12

Figure 1: LX Series Heat Pump Unit Controller:

L

ONMARK Objects and Network Variables

LX- HPUL- 1 HeatPump

Object Type #8051

Configuration Properties

Occ. Temperature Set Points(mandatory)

Maximum Send Time (mandatory)

Minimum Send Time (optional)

nviSpaceTemp

SNVT_temp_p

Mandatory

Network

Variables

Optional

Network

Variables

Manufacturer

Network

Variables

nviSetPoint

SNVT_temp_p

nvoFanSpeed

SNVT_ switch

nvoTerminalLoad

SNVT_lev_percent

nviFanSpeedCmd

SNVT_switch

nvoDischargSetPt

SNVT_temp_p

nviOccCmd

SNVT_xx

nvoSpaceTemp

SNVT_temp_p

nviApplicMode

SNVT_hvac_mode

nvoEffectSetP

SNVT_temp_p

nviSetPtOffset

SNVT_temp_p

nvoOccState

SNVT_ occupancy

nviWaterTemp

SNVT_temp_p

nvoUnitStatus

SNVT_hvac_status

nviDischargeTemp

SNVT_temp_p

nvoCtrlOutput1

SNVT_switch

nviRefrigTemp

SNVT_temp_p

nviShedding

SNVT_ switch

nviHotWater

SNVT_switch

nviSlave

SNVT_lev_percent

nviOutdoorTemp

SNVT_temp_p

nviOccManCmd

SNVT_ occupancy

nvoCtrlOutput7

SNVT_switch

.

.

.

Manufacturer Configuration Properties

Please see the manual for details.

Wizard for configuration provided.

nviSpaceRH

SNVT_lev_percent

nviEmergCmd

SNVT_hvac_emer

nviFanState

SNVT_switch

nviPumpState

SNVT_switch

nviCoilDiffPress

SNVT_press_p

LX Series Heat Pump Unit Controller User's Guide 13

The HPU Controller also has network inputs that permit the use of outside

enthalpy sensors and space enthalpy sensors. These inputs provide better

calculation of the cooling or heating effect of the outside air upon the conditioned

space.

The input object has configurable conversion tables and hardware properties in the

area marked Manufacturer Configuration Properties. Choose from a list of

standard thermistors to select conversion properties and create your own custom

tables. Hardware properties configuration allow you to modify your input from the

software object. Figure 2 shows the output and input objects.

Figure 2: Output and Input Objects

LX-HPUL- 1 Hardware Input

Object Type #1

nvoHwInputx

SNVT_xxx

Offset (optional)

Maximum Range (optional)

Minimum Range (optional)

Minimum Send Delta (optional)

Minimum Send Time (optional)

Maximum Send Time (optional)

Override Value (optional)

Configuration Properties

Mandatory

Network

Variables

Object Major Version

Object Minor Version

Output Signal Conditioning

PWM Period

Hardware Properties

Default Value

Manufacturer Configuration Properties

LX-HPUL-1 Hardware Output

Object Type #3

nviExtCmdOutputx

SNVT_switch

Maximum Receive Time (optional)

Override Value (optional)

Configuration Properties

Mandatory

Network

Variables

Object Major Version

Object Minor Version

Output Signal Conditioning

PWM Period

Hardware Properties

Default Value

Manufacturer Configuration Properties

LX Series Heat Pump Unit Controller User's Guide14

The node object displays the nvoHPstate and nvoHPalarm variables as

manufacturer’s variables. The node objects provide information about the alarm

conditions in the Heat Pump Unit Controller and about the operating state of the

device (Figure 3).

Units in LONWORKS Networks

Note: Use this section if you are using the Imperial System of measurement.

The Imperial System and the International System (SI) are the two main

measurement systems used today. Table 1 compares Imperial units and SI units.

Table 1: Comparing Imperial and SI Units

Imperial Units SI

inch centimeter

yard meter

mile kilometer

degrees Fahrenheit degrees Centigrade/Celsius

Figure 3: Heat Pump Unit Controller Node

LX- HPUL-1 Node

Object Type #0

nvoStatus

SNVT_obj_status

Location (optional)

Device Major Version (optional)

Device Minor Version (optional)

Configuration Properties

nviRequest

SNVT_obj_request

Mandatory

Network

Variables

Optional

Network

Variables

Manufacturer

Network

Variables

nvoFileDirectory

SNVT_address

nvoHPstate

SNVT_state_64

nvoHPalarm

SNVT_state_64

Manufacturer Configuration

Properties

Maximum Send Time

LX Series Heat Pump Unit Controller User's Guide 15

The LONWORKS network and Echelon® SNVTs are based upon SI units. This

basis creates some unavoidable problems in data conversion if you are using

Imperial Units.

The LX-HPUL view in FX Workbench and other utilities provide some automatic

conversion between SI and Imperial units. However, these are not ideal

conversions because a whole number in one system becomes a long decimal

fraction in the other. For example, 72°F is approximately equal to 22.22222°C.

The values created by converting Imperial to SI or SI to Imperial are subject to

rounding errors. If you enter an Imperial value into a LONWORKS SNVT by using

the HPU Controller configuration wizard, the value is converted, then rounded and

written to the SNVT. When you want to monitor the SNVT, the value must be read

from the SNVT, converted, and rounded again before it is displayed. Due to the

two conversions and two rounding operations, the value may differ slightly from

what you originally entered (Figure 4).

The same process and resulting rounding error applies to Standard Configuration

Property Types (SCPTs).

Instructions for changing or modifying the units of measure used on your computer

are provided in the Selecting a Measurement System or Selecting a Language

section.

Language Selection

The following may require you to change your language settings:

• You changed your regional settings by selecting a different region in the

Regional and Language Options dialog box.

• You work on a site that is in a linguistic region other than your own.

Figure 4: Imperial Units in the LONWORKS Network

Value is written in

Imperial Units.

Value is translated

to SI units.

Value is rounded.

Value is read

from SNVT.

Value is translated

to SI units.

Value is rounded.

Data is displayed

for monitoring in

Imperial Units.

Units

Value is stored

in SNVT.

LX Series Heat Pump Unit Controller User's Guide16

• You are dissatisfied with the language displayed on program menus and dialog

boxes.

You can change your language settings in the Advanced tab of the Regional and

Language Options dialog box. Instructions are provided in the Selecting a

Measurement System or Selecting a Language section.

Selecting a Measurement System or Selecting a Language

To select units of measurement or to select a language:

1. In Microsoft® Windows XP® Operating System, click Start > Control Panel.

The Control Panel appears.

2. In the Control Panel, open Date, Time, Language, and Regional Options.

3. Under the list titled Pick a Task, select and open the second item: Change the

format of numbers, dates, and times (Figure 5).

Figure 5: Date, Time, Language and Regional Options Screen

LX Series Heat Pump Unit Controller User's Guide 17

4. Select your language region from the drop-down list. The number, time, and

date formats fill automatically (Figure 6).

5. In the Number box, verify the number format uses a decimal point to indicate

numerals representing values less than 1. For example, use 123,456,789.00, not

123 456 789,00. You must use a decimal point for the correct display of

numerals.

6. In the Regional Options dialog box, click Customize.

Figure 6: Regional and Language Options

LX Series Heat Pump Unit Controller User's Guide18

7. Click on the drop-down arrow next to the box labeled Measurement system,

and select Metric (Figure 7).

8. Verify the Decimal symbol box contains a decimal point. If the Decimal

symbol box does not contain a decimal point, select the symbol in the box and

click Apply.

9. Click OK.

10. Click the Advanced tab and choose a language region by selecting from the

drop-down list. Verify the correct language appears on program menus.

11. Click OK.

You have now set the units to appear in the LX-HPUL view in FX Workbench. If

you select to have Imperial units appear, remember that the SNVTs still use SI

units. If you are viewing the data in Imperial units, you are viewing a converted

rounded value.

Figure 7: Customize Regional Options

LX Series Heat Pump Unit Controller User's Guide 19

Heat Pump Unit Controller Installation Overview

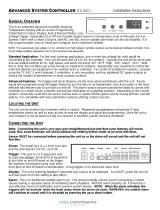

Figure 8 shows one possible installation of the Heat Pump Unit Controller. Inputs,

outputs, heating, and cooling units have been marked.

Note: Not all possible sensors appear.

Inputs

The Heat Pump Unit Controller has six universal inputs. You can use the HPU

Controller Configuration wizard to configure universal inputs. There are two

possible configurations for universal inputs:

• digital inputs or 10k ohm resistance inputs

• analog inputs sensing either current or voltage

Note: As the Heat Pump Unit Controller can connect to a maximum of six

sensors, you may want to connect some sensors using the L

ONWORKS

network. All valid network inputs have priority over hardware inputs.

10k Ohm or Digital Input

The universal input, when configured as a 10k ohm or digital input, accepts a 10k

ohm resistance input or a digital input such as a switch (cold contact).

Figure 8: Possible HPU Installation

Heating

Filter

Cooling

Humidifier

Intake Air

DATOAT

Setpoint Offsett

Temperature

Humidity

Conditioned Space

Occupancy

LX- HPUL-1 Installation Overview

OAT Outside Air Temperature

DAT Discharge Air Temperature

Sensor Symbols

Humidity

Temperature

Digital Input

Heat Pump Enclosure

Window contact

3 Fan Speeds

Heat Pump Enclosure

Discharge

Air

LX Series Heat Pump Unit Controller User's Guide20

The 10k ohm resistance range accommodates 10k ohm thermistors used in space

temperature sensors or duct temperature sensors, or 10k ohm potentiometers used

as setpoint offsets.

Use the conversion table for resistance input of more than 10k ohm. The digital

range accommodates the occupancy contact, bypass switch, and window switch.

See Figure 9 for wiring information regarding both digital and 10k ohm resistance

inputs.

Figure 9: 10k Ohm or Digital Input

I

1

I

2

I

3

I

4

I

6

I

5

–

++++++

––

Contact

NO -

NC

Thermistor

10k Ohm

LX- HPUL-1

Both inputs are configured as 10k ohm or

digital inputs. Configuration can be done in

either the LX HPUL-1 wizard

/