Page is loading ...

Form No. 3353-982 Rev A

Power Max™ 6000 Snowthrower

Model No. 38595 —Serial No. 260000001 and Up

Operator's Manual

Introduction

R ead this infor mation carefully to lear n ho w to operate and

maintain y our product properly and to a v oid injur y and

product damag e . Y ou are responsible for operating the

product properly and safely .

Y ou ma y contact T oro directly at www .T oro .com for

product and accessor y infor mation, help finding a dealer ,

or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts , or

additional infor mation, contact an A uthorized Ser vice

Dealer or T oro Customer Ser vice and ha v e the model and

serial n umbers of y our product ready . Figure 1 identifies the

location of the model and serial n umbers on the product.

W rite the n umbers in the space pro vided.

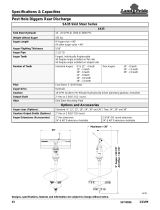

Figure 1

1. Model and serial number location

Model No.

Serial No.

T his man ual identifies potential hazards and has safety

messag es identified b y the safety aler t symbol ( Figure 2 ),

whic h signals a hazard that ma y cause serious injur y or

death if y ou do not follo w the recommended precautions .

Figure 2

1. Safety alert symbol

T his man ual uses 2 other w ords to highlight infor mation.

Impor tant calls attention to special mec hanical infor mation

and Note emphasizes g eneral infor mation w or th y of special

attention.

R eplacement Engine Owner’ s Man uals may be order ed

thr ough the engine man uf actur er .

© 2005—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Register at www.Toro.com. Original Instructions (EN)

Printed in the USA

All Rights Reserved

Safety

Bef or e Ope r a t ing

Ca u ti on : Im p r o p er u se ma y r e su lt

in lo ss o f fin g e r, h a n d s, o r fe e t.

Re a d a nd unders t a n d t he cont e n t s o f t hi s

manual b efo r e oper atin g t h e sn ow t hr o w e r.

Becom e fa m iliar wi t h a ll co n t r ols a n d kno w

ho w t o st o p t h e e ng ine q ui ckly.

Th e r e is a h ig h -sp e e d

im p e lle r clo se t o t h e

o p en in g .

Th e low -sp eed a ug e r h a s a m ovin g p in ch

po in t clo se t o t h e o pe n in g .

Oper at o r ’s

Posit ion

T his sno wthr o w er meets or ex ceeds the ISO standard

8437 in ef fect at the time of pr oduction.

R ead and under stand the contents of this man ual

bef or e the engine is ev er star ted.

T his is the safety aler t symbol. It is used to aler t y ou

to potential per sonal injur y hazards. Obey all safety

messa ges that f ollo w this symbol to a v oid possible

injur y or death.

Impr oper l y using or maintaining this sno wthr o w er

could r esult in injur y or death. T o r educe this potential,

compl y with the f ollo wing safety instr uctions.

T he follo wing instr uctions ha v e been adapted from the

ANSI/OPEI standard B71.3-1995 and the ISO 8437:1989

standard.

Training

• R ead the operator’ s man ual carefully . Be thoroughly

familiar with the controls and the proper use of the

equipment. Kno w ho w to stop the unit and diseng ag e

the controls quic kly .

• Nev er allo w c hildren to operate the sno wthro w er .

Nev er allo w adults to operate the sno wthro w er without

proper instr uction.

• K ee p the area of operation clear of all persons

(par ticularly small c hildren) and pets .

• Ex ercise caution to a v oid slipping or falling, especially

when operating the sno wthro w er in rev erse .

Preparation

• T horoughly inspect the area where y ou will use the

sno wthro w er . R emo v e all door mats , sleds , boards ,

wires , and other foreign objects .

• Before star ting the engine , diseng ag e all clutc hes . Shift

the sno wthro w er into neutral as w ell, if applicable .

• Do not operate the sno wthro w er without w earing

adequate winter g ar ments . W ear footw ear that will

impro v e y our footing on slipper y surfaces .

• Handle fuel with care; it is highly flammable .

– Use an appro v ed fuel container .

– Nev er add fuel to a r unning or hot engine .

– Fill the fuel tank outdoors with extreme care . Nev er

fill the fuel tank indoors .

– R e place the fuel tank cap securely and wipe up any

spilled fuel.

• Use only the po w er cord supplied with the sno wthro w er

and a rece ptacle appropriate for use with the po w er

cord for electric-star t motors .

2

• Adjust the aug er housing height to clear a g ra v el or

cr ushed-roc k surface .

• Nev er attempt to mak e any adjustments while the engine

is r unning, ex ce pt where specifically recommended b y

T oro .

• Let the engine and the sno wthro w er adjust to the

outdoor temperature before star ting to clear sno w .

• Operating any po w ered mac hine can result in foreign

objects being thro wn into the eyes . Alw a ys w ear safety

glasses or eye shields while operating, adjusting, or

re pairing the sno wthro w er .

Operation

• Do not put y our hands or feet near or under rotating

par ts . K ee p clear of the disc harg e opening at all times .

• Ex ercise extreme caution when crossing g ra v el dri v es ,

w alks , or roads . Sta y aler t for hidden hazards or traffic .

• After striking a foreign object, stop the engine ,

disconnect the wire from the spark plug, thoroughly

inspect the sno wthro w er for any damag e , and re pair the

damag e before operating the sno wthro w er .

• If the unit should star t to vibrate abnor mally , stop the

engine and c hec k immediately for the cause . Vibration

is g enerally a w ar ning of trouble .

• Stop the engine whenev er y ou lea v e the operating

position, before unclog ging the aug er/impeller housing

or disc harg e c hute , and when making any re pairs ,

adjustments , or inspections .

• W hen cleaning, re pairing, or inspecting, mak e cer tain

that the aug er/impeller and all mo ving par ts ha v e

stopped. Disconnect the spark plug wire and k ee p the

wire a w a y from the spark plug to prev ent someone

from accidentally star ting the engine .

• Do not r un the engine indoors , ex ce pt when star ting

it and for mo ving the sno wthro w er in or out of the

building . Open the outside doors; exhaust fumes are

dang erous .

• Do not clear sno w across the face of slopes . Ex ercise

extreme caution when c hanging direction on slopes . Do

not attempt to clear stee p slopes .

• Nev er operate the sno wthro w er without proper guards

or other safety devices in place .

• Nev er operate the sno wthro w er near glass enclosures ,

automobiles , windo w w ells , and drop-offs without

properly adjusting the sno w disc harg e angle . K ee p

c hildren and pets a w a y .

• Do not o v erload the mac hine capacity b y attempting to

clear sno w at too fast a rate .

• Look behind and use care when bac king up with the

sno wthro w er .

• Nev er direct the disc harg e at b ystanders or allo w any one

in front of the unit.

• Diseng ag e the po w er to the aug er/impeller when the

sno wthro w er is being transpor ted or when not in use .

• Use only attac hments and accessories appro v ed b y

T oro , suc h as wheel w eights , counterw eights , and cabs .

(Contact an A uthorized Ser vice Dealer for accessories

a v ailable for y our sno wthro w er .)

• Nev er operate the sno wthro w er without g ood visibility

or light. Alw a ys be sure of y our footing, and k ee p a fir m

hold on the handle . W alk; nev er r un.

Maintenance and Storage

• Chec k all fasteners at frequent inter v als for proper

tightness to be sure that the equipment is in safe

w orking condition.

• Nev er store the mac hine with fuel in the fuel tank inside

a building where ignition sources are present, suc h as

hot w ater and space heaters and clothes dr yers . Allo w

the engine to cool before storing in any enclosure .

• Alw a ys refer to this operator’ s man ual for impor tant

details if the sno wthro w er is to be stored for an

extended period.

• Maintain or re place safety and instr uction labels when

necessar y .

Toro Snowthrower Safety

T he follo wing list contains safety infor mation specific to

T oro products or other safety infor mation that y ou m ust

kno w .

• R otating auger/impeller can cut of f or injur e

finger s or hands. Sta y behind the handles and

a w a y from the disc harg e opening while operating the

sno wthro w er . K eep y our f ace, hands, feet, and an y

other par t of y our body or clothing a w ay fr om

mo ving or r otating par ts.

• Before adjusting, cleaning, inspecting, troubleshooting,

or re pairing the sno wthro w er , stop the engine, r emo v e

the k ey , and w ait f or all mo ving par ts to stop .

Disconnect the wir e fr om the spar k plug and k eep

it a w ay fr om the spar k plug to pr ev ent someone

fr om accidentall y star ting the engine.

• T o unclog the disc harg e c hute , sta y in the operating

position and release the left hand (traction) lev er . W hile

r unning the aug er/impeller , push do wn on the handles

to raise the front of the sno wthro w er a few inc hes

(centimeters) off the pa v ement. T hen lift the handles

quic kly to bump the front of the sno wthro w er on the

pa v ement. R e peat if necessar y until a stream of sno w

comes out the disc harg e c hute .

• If y ou cannot unclog the disc harg e c hute b y bumping

the front of the sno wthro w er , stop the engine, w ait

f or all mo ving par ts to stop , and use a stick; nev er

use y our hand.

3

• Do not w ear loose-fitting clothing that could g et caught

in mo ving par ts .

• If a shield, safety device , or decal is damag ed, illegible ,

or lost, re pair or re place it before beginning operation.

• Do not smok e while handling g asoline .

• Do not touc h the engine while it is r unning or soon

after it has stopped because the engine ma y be hot

enough to cause a bur n.

• W hen storing the sno wthro w er for more than 30 da ys ,

drain the fuel from the fuel tank to prev ent a potential

hazard. Store fuel in an appro v ed fuel container .

R emo v e the k ey from the ignition switc h before storing

the sno wthro w er .

• Purc hase only g en uine T oro re placement par ts and

accessories .

Sound Pressure

T his unit has a maxim um sound pressure lev el at the

operator’ s ear of 92 dB A, based on measurements of

identical mac hines per EN 11201.

Sound Power

T his unit has a guaranteed sound po w er lev el of 108 dB A,

based on measurements of identical mac hines per EN 3744.

Vibration

T his unit does not ex ceed a hand/ar m vibration lev el of

7.0 m/s

2

, based on measurements of identical mac hines

per EN 1033.

Safety and Instructional Decals

Important: Safety and instr uction decals ar e located near ar eas of potential danger . R eplace dama ged decals.

106-4523

1. Traction drive—squeeze the lever to engage; release the lever to

disengage.

4. Thrown object hazard—keep bystanders a safe distance from the

snowthrower.

2. Warning—read the Operator’s Manual .

5. Auger/impeller drive—squeeze the lever to engage; release the lever

to disengage.

3. Cutting/dismemberment hazard, impeller—stop the engine before

leaving the operator’s position and do not place your hand in the

chute.

4

106-4525

Reorder part no. 107-3826

1. Fast

3. Slow

2. Forward speeds 4. Reverse speeds

106-7309

1. Cutting/dismemberment hazard, impeller—stop the engine

before leaving the operating position and do not place your hand

in the chute.

107-3040

1. Cutting dismemberment, impeller and cutting dismemberment,

auger hazards—keep bystanders a safe distance from the

snowthrower.

1. Warning—hot surface, do not touch

Tecumseh Part No. 36501

1. Primer

1

2

3

4

5

6

5

7

Tecumseh Part No. 35077

1. Key ignition

5. Increasing scale

2. Engage to start the engine 6. Slow

3. Disengage to stop the engine 7. Stop the engine

4. Fast

5

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

Description

Qty.

Use

Handle bolts

4

Curved washers

4

1.

Locknuts

4

Install the upper handle.

2.

No parts required

–

Install the traction control linkage.

Carriage bolts

2

3.

Locknuts

2

Install the chute control rod.

4.

No parts required

–

Fill the engine with oil.

5.

No parts required

–

Check the tire pressure.

6.

No parts required

–

Check the skids and scraper.

1. Installing the Upper Handle

Note: Do not remo v e the r ubber band until y ou ha v e

installed the upper handle .

1. Lift and rotate the upper handle and position it o v er

the lo w er handle ( Figure 3 ).

Important: R oute the ca bles attached to the

Quick Stick inside the upper handle legs and

ensur e that the ca bles and the wir e f or the headlight

ar e not pinched betw een the handle sections.

Figure 3

1. Cables

2. Secure the upper handle with 4 handle bolts , 4 cur v ed

w ashers , and 4 loc kn uts from the loose par ts bag ( Figure

4 ).

Figure 4

2. Installing the Traction

Control Linkage

1. R emo v e the hair pin cotter and w asher from the lo w er

end of the speed control rod and inser t the lo w er end

of the rod into the lo w er link ar m so that the bent end

of the speed control rod faces rearw ard ( Figure 5 ).

6

Figure 5

2. Secure the lo w er end of the speed control rod with the

w asher and hair pin cotter that y ou previously remo v ed.

3. R emo v e the hair pin cotter and the outer w asher from

the tr unnion on the upper end of the speed control

rod ( Figure 6 ).

Figure 6

1. Speed selector lever

3. Trunnion

2. Wave washer 4. Flat washer

Note: T o mak e installation easier , lea v e the w a v e

w asher and the flat w asher on the tr unnion ( Figure 6 ).

4. Shift the speed selector lev er into P osition R2.

5. R otate the lo w er link ar m fully upw ard

(countercloc kwise) ( Figure 7 ).

Figure 7

6. Lift up on the speed control rod and inser t the tr unnion

into the hole in the speed selector lev er ( Figure 6 ).

Note: If the tr unnion does not fit into the hole when

y ou lift up on the speed control rod, rotate the tr unnion

upw ard or do wnw ard on the speed control rod until

it fits .

7. Secure the tr unnion and upper end of the speed control

rod with the outer w asher and a hair pin cotter y ou

previously remo v ed.

Note: F or easier installation, look do wn through the

opening in the speed selector ( Figure 8 ).

Figure 8

1. Speed selector

3. Installing the Chute Control

Rod

1. Unwrap the Quic k Stic k and rotate it so that it is upright

and in the center .

2. Hold the blue trig g er cap do wn and pull the lev er fully

rearw ard.

Note: T he disc harg e c hute and deflector should face

forw ard. If they do not, hold the blue trig g er cap

do wn (but do not mo v e the Quic k Stic k) and rotate the

disc harg e c hute until they do .

3. Align the flattened bac k end of the long c hute control

rod with the flattened front end of the shor t rod

that extends from the control panel so that they nest

tog ether ( Figure 9 ).

Figure 9

1. Short rod 2. Long chute control rod

7

4. Inser t the front end of the rod into the opening in the

bac k of the c hute g ear co v er until it slides into the c hute

g ear ( Figure 10 ).

Figure 10

5. Align the holes in the nested ends of the rods and inser t

2 car riag e bolts (in the loose par ts bag) through the

shor t rod from the left side of the sno wthro w er (from

the operating position).

6. Inser t the cable clip that suppor ts the deflector cable

onto the forw ard car riag e bolt, and secure the car riag e

bolts with loc kn uts from the loose par ts bag ( Figure 11 ).

Figure 11

1. Cable clip 2. Deector cable

7. Hold the blue trig g er cap do wn and rotate the Quic k

Stic k in a circle to ensure that the c hute and deflector

operate smoothly .

4. Filling the Engine with Oil

Y our sno wthro w er comes with 26 oz. of oil in the engine .

Note: Before star ting the engine , c hec k the oil lev el and

add oil if necessar y .

Max. fill: 26 oz. (0.77 l), type: automoti v e deterg ent oil with

an API ser vice classification of SF , SG , SH, SJ , SL, or higher .

• F or temperatures abo v e 32°F (0°C), use SAE 30W .

• F or temperatures betw een 0°F and 32°F (-18°C to 0°C),

use SAE 5W30 or SAE 10W .

• F or air temperatures belo w 0°F (-18°C), use SAE 0W30.

1. R emo v e the dipstic k and slo wl y pour oil into the oil

fill tube to raise the oil lev el to the Full mark on the

dipstic k. Do not o v erfill ( Figure 12 ).

Figure 12

2. Install the dipstic k securely .

Note: Do not spill oil around the oil fill tube; oil could

leak onto traction par ts and cause the traction to slip .

5. Checking the Tire Pressure

T he tires are o v erinflated at the factor y for shipping . R educe

the pressure equally in both tires to betw een 17 and 20 psi

(116 and 137 kP a).

6. Checking the Skids and

Scraper

R efer to Chec king and Adjusting the Skids and Scraper in

Maintenance .

8

Product Overview

Figure 13

1. Auger/impeller lever 7. Chute deector

2. Speed selector lever 8. Discharge chute

3. Quick Stick™ discharge chute

control

9. Fuel shutoff valve

4. Traction lever

10. Skid (2)

5. Fuel tank

11. Auger

6. Engine oil ll tube/dipstick

12. Scraper

Figure 14

1. Ignition switch

4. Primer

2. Choke 5. Recoil starter

3. Throttle

Operation

Note: Deter mine the left and right sides of the mac hine

from the nor mal operating position.

Freewheeling or Using the

Self-propel Drive

Y ou can operate the sno wthro w er with the self-propel

feature eng ag ed or diseng ag ed (freewheeling).

T o freewheel, slide the wheels inw ard and inser t the axle

pins through the outer axle holes , but not through the wheel

hubs ( Figure 15 ).

Figure 15

T o self-propel, slide the wheels outw ard and inser t the axle

pins through the holes in the wheel hubs and the inner axle

holes ( Figure 16 ).

Figure 16

Filling the Fuel Tank

Gasoline is extr emel y flamma ble and explosi v e. A

fir e or explosion fr om gasoline can bur n y ou and

other s.

• T o pr ev ent a static charge fr om igniting the

gasoline, place the container and/or sno wthr o w er

on the g r ound bef or e filling , not in a v ehicle or

on an object.

• Fill the tank outdoor s when the engine is cold.

W ipe up spills.

• Do not handle gasoline when smoking or ar ound

an open flame or spar ks.

• Stor e gasoline in an appr o v ed fuel container , out

of the r each of childr en.

9

Fill the fuel tank with fresh unleaded regular g asoline from

a major name-brand ser vice station ( Figure 17 ).

Important: T o r educe star ting pr oblems, add fuel

sta biliz er to the fuel all season, mixing it with gasoline

less than 30 days old. Do not add oil to the gasoline.

Figure 17

Starting the Engine

1. Connect the spark plug wire ( Figure 18 ).

Figure 18

2. Mo v e the throttle to the F ast position ( Figure 19 ).

Figure 19

3. R otate the fuel shutoff v alv e countercloc kwise to open

it ( Figure 20 ).

Figure 20

4. R otate the c hok e to the On position ( Figure 21 ).

Figure 21

5. Inser t the ignition k ey ( Figure 22 ).

Figure 22

6. Fir mly push in the primer 3 times with y our thumb ,

holding the primer in for a second before releasing it

eac h time ( Figure 23 ).

Figure 23

Note: T ak e y our glo v e off when y ou push in the

primer so that air cannot escape from the primer hole .

Note: Priming ex cessi v ely ma y flood the engine and

prev ent it from star ting .

7. Pull the recoil star ter ( Figure 24 ).

10

Figure 24

8. Disconnect the cord from the electric star ter and the

outlet.

9. W hen the engine star ts , set the c hok e to the

3/4 position. As the engine w ar ms up , set the c hok e

to the 1/2 position. W hen the engine is w ar m, set the

c hok e to the Off position.

Stopping the Engine

1. Mo v e the throttle to the Stop position ( Figure 25 ).

Figure 25

2. W ait for all mo ving par ts to stop before lea ving the

operating position.

3. Close the fuel shutoff v alv e b y rotating it cloc kwise

( Figure 26 ).

Figure 26

4. Pull the recoil star ter 3 or 4 times . T his helps prev ent

the recoil star ter from freezing up .

Operating the Traction Drive

Important: T o operate the traction dri v e, y ou

must operate the sno wthr o w er with the self-pr opel

featur e enga ged. R efer to F r eewheeling or Using the

Self-pr opel Dri v e.

1. T o eng ag e the traction dri v e , squeeze the left hand

(traction) lev er to the handg rip ( Figure 27 ).

Figure 27

2. T o stop the traction dri v e , release the traction lev er .

3. Chec k to ensure that the speed selector operates

properly:

• If the sno wthro w er does not mo v e or mo v es

forw ard when it is in P osition R1, remo v e the

tr unnion from the speed selector lev er , tur n the

tr unnion do wnw ard (cloc kwise) on the speed

control rod, then install the tr unnion.

• If the sno wthro w er does not mo v e or mo v es

rearw ard when it is in P osition 1 (forw ard), remo v e

the tr unnion from the speed selector lev er , tur n the

tr unnion upw ard (countercloc kwise) on the speed

control rod, then install the tr unnion.

Note: R efer to Installing the T raction Control

Linkag e .

Note: If the sno wthro w er mo v es when the

traction lev er is in the released position, c hec k the

traction cable (refer to Chec king and Adjusting

the T raction Cable) or tak e the sno wthro w er to an

A uthorized Ser vice Dealer for ser vice .

Operating the Speed Selector

T he speed selector has 6 forw ard and 2 rev erse g ears . T o

c hang e speeds , release the traction lev er and shift the speed

selector lev er to the desired position ( Figure 28 ). T he lev er

loc ks in a notc h at eac h speed selection.

11

Figure 28

Operating the Auger/Impeller

Drive

1. T o eng ag e the aug er/ impeller dri v e , squeeze the right

hand (aug er/ impeller) lev er to the handg rip ( Figure 29 ).

Figure 29

2. T o stop the aug er and impeller , release the right hand

lev er .

Important: W hen y ou enga ge both the

auger/impeller lev er and the traction lev er , the

traction lev er locks the auger/impeller lev er do wn,

fr eeing y our right hand. T o r elease both lev er s,

simpl y r elease the left hand (traction) lev er .

3. If the aug er and impeller contin ue to rotate when y ou

release the aug er/impeller lev er , do not operate the

sno wthro w er . Chec k the aug er/impeller cable (refer to

Chec king and Adjusting the A ug er/Impeller Cable) and

adjust it if necessar y . Otherwise , tak e the sno wthro w er

to an A uthorized Dealer for ser vice .

If the auger and impeller contin ue to r otate when

y ou r elease the auger/impeller lev er , y ou could

seriousl y injur e y our self or other s.

Do not operate the sno wthr o w er . T ak e it to an

Authoriz ed Ser vice Dealer f or ser vice.

Operating the Quick Stick™

Hold the blue trig g er cap do wn to use the Quic k Stic k to

mo v e the disc harg e c hute and the c hute deflector . R elease

the trig g er cap to loc k the disc harg e c hute and c hute

deflector into position ( Figure 30 ).

Figure 30

Moving the Discharge Chute

Hold the blue trig g er cap do wn and mo v e the Quic k Stic k

to the left to mo v e the disc harg e c hute to the left; mo v e

the Quic k Stic k to the right to mo v e the disc harg e c hute to

the right ( Figure 31 ).

Figure 31

• If the c hute does not mo v e , refer to Adjusting the

Disc harg e Chute Latc h.

• If the c hute does not tur n as far to the left as it does to

the right, ensure that the cable is routed to the inside of

the handles . R efer to Installing the Upper Handle .

• If the c hute does not loc k into place when y ou release

the trig g er cap , refer to Adjusting the Disc harg e Chute

Latc h.

Moving the Chute Deector

Hold the blue trig g er cap do wn and mo v e the Quic k Stic k

forw ard to lo w er the c hute deflector; mo v e it rearw ard to

raise the c hute deflector ( Figure 32 ).

12

Figure 32

Unclogging the Discharge

Chute

If the aug er/impeller is r unning but there is no sno w

coming out of the disc harg e c hute , the disc harg e c hute ma y

be clog g ed.

• T o unclog the disc harg e c hute , sta y in the operating

position and release the left hand (traction) lev er . W hile

r unning the aug er/impeller , push do wn on the handles

to raise the front of the sno wthro w er a few inc hes

(centimeters) off the pa v ement. T hen lift the handles

quic kly to bump the front of the sno wthro w er on the

pa v ement. R e peat if necessar y until a stream of sno w

comes out the disc harg e c hute .

• If y ou cannot unclog the disc harg e c hute b y bumping

the front of the sno wthro w er , stop the engine, w ait

f or all mo ving par ts to stop , and use a stick; nev er

use y our hand.

Important: Unclo g ging the discharge chute

by bumping the fr ont of the sno wthr o w er on the

pa v ement may cause the skids to mo v e. Adjust the

skids and tighten the skid bolts secur el y .

Preventing Freeze-up

• In sno wy and cold conditions , some controls and

mo ving par ts ma y freeze . Do not use ex cessi v e f orce

when tr ying to operate fr oz en contr ols. If y ou ha v e

difficulty operating any control or par t, star t the engine

and let it r un for a few min utes .

• After using the sno wthro w er , let the engine r un for

a few min utes to prev ent mo ving par ts from freezing .

Eng ag e the aug er/impeller to clear any remaining sno w

from inside the housing . R otate the Quic k Stic k to

prev ent it from freezing . Stop the engine , w ait for all

mo ving par ts to stop , and remo v e all ice and sno w from

the sno wthro w er .

• With the engine off , pull the recoil star ter handle sev eral

times to prev ent the recoil star ter from freezing up .

Operating Tips

W hen the sno wthr o w er is in operation, the impeller

and auger can r otate and cut of f or injur e hands and

feet.

• Bef or e adjusting , cleaning , inspecting ,

tr oubleshooting , or r epairing the sno wthr o w er ,

stop the engine and w ait f or all mo ving par ts

to stop . Disconnect the wir e fr om the spar k

plug and k eep it a w ay fr om the plug to pr ev ent

someone fr om accidentall y star ting the engine.

• R emo v e an obstr uction fr om the discharge chute;

r efer to Unclo g ging the Discharge Chute. If

necessar y , use a stick, not y our hands, to r emo v e

an obstr uction fr om the discharge chute.

• Stay behind the handles and a w ay fr om

the discharge opening while operating the

sno wthr o w er .

• K eep f ace, hands, feet, and an y other par t of y our

body or clothing a w ay fr om concealed, mo ving ,

or r otating par ts.

T he r otor blades can thr o w stones, toys, and other

f or eign objects and cause serious per sonal injur y to

the operator or to bystander s.

• K eep the ar ea to be clear ed fr ee of all objects that

the r otor blades could pick up and thr o w .

• K eep all childr en and pets a w ay fr om the ar ea

of operation.

• Alw a ys set the throttle to the F ast position when

thro wing sno w .

• If the engine slo ws do wn under a load or the wheels

slip , shift the sno wthro w er into a lo w er g ear .

• If the front of the sno wthro w er rides up , shift the

sno wthro w er into a lo w er g ear . If the front contin ues to

ride up , lift up on the handles .

13

Maintenance

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the rst 2 operating

hours

• Inspect the traction cable and adjust it if necessary.

• Inspect the auger/impeller cable and adjust it if necessary.

• Change the engine oil.

Before each use or daily

• Check the engine oil level and add oil if necessary.

Yearly

• Check the skids and the scraper and adjust them if necessary.

• Inspect the traction cable and adjust or replace it if necessary.

• Inspect the auger/impeller cable and adjust or replace it if necessary.

• Check the auger gearbox oil and add oil if necessary.

• Change the engine oil.

• Lubricate the hex shaft.

• Inspect the spark plug. Replace and/or gap it if necessary.

Yearly or before storage

• Check the air pressure in the tires and inate them to 17–20 psi (116–137 kPa).

• Drain the gasoline and run the engine to dry out the fuel tank and the carburetor

at the end of the season.

• Have an Authorized Service Dealer inspect and replace the traction drive belt

and/or the auger/impeller drive belt, if necessary.

Important: Y ou can find mor e inf or mation a bout maintaining and ser vicing y our sno wthr o w er at

www .T or o.com.

Important: R efer to y our engine operator’ s man ual f or additional maintenance pr ocedur es. F or engine

adjustments, r epair s, or w ar ranty ser vice not co v er ed in this man ual, contact an Authoriz ed T ecumseh Ser vicing

Dealer .

Preparing for Maintenance

1. Mo v e the sno wthro w er to a lev el surface .

2. Stop the engine and w ait for all mo ving par ts to stop .

3. Disconnect the spark plug wire ( Figure 33 ).

Figure 33

Checking the Engine Oil Level

Eac h time before using the sno wthro w er , c hec k the oil lev el

in the engine crankcase .

1. R emo v e the dipstic k, wipe it clean, then fully install the

dipstic k.

2. R emo v e the dipstic k and c hec k the oil lev el ( Figure 34 ).

If the oil lev el is belo w the Add mark on the dipstic k,

add oil. R efer to Filling the Engine with Oil.

14

Figure 34

Checking and Adjusting the

Skids and Scraper

Chec k the skids and the scraper to ensure that the aug er

does not contact the pa v ed or g ra v el surface . Adjust the

skids and the scraper as needed to compensate for w ear .

1. Chec k the tire pressure . R efer to Chec king the Tire

Pressure .

2. Loosen the n uts that secure both skids to the aug er

sides until the skids slide up and do wn easily ( Figure 35 ).

Figure 35

3. Suppor t the side plates so that they are at least 1/2 inc h

(1.3 cm) abo v e a lev el surface .

Important: T he auger blades must be suppor ted

a bo v e the g r ound by the skids.

4. Ensure that the scraper is 1/8 inc h (3 mm) abo v e and

parallel to a lev el surface .

Note: If the pa v ement is crac k ed, rough, or unev en,

adjust the skids to raise the scraper . F or g ra v el

surfaces , adjust the skids fur ther do wn to prev ent the

sno wthro w er from pic king up roc ks .

5. Mo v e the skids do wn until they are ev en with the

g round.

6. Fir mly tighten the n uts that secure both skids to the

aug er sides .

Note: T o quic kly adjust the skids if they loosen,

suppor t the scraper 1/8 inc h (3 mm) off the pa v ement,

then adjust the skids do wn to the pa v ement.

Note: If the skids become ex cessi v ely w or n, y ou can

tur n them o v er and set the un used side to w ard the

pa v ement.

Checking and Adjusting the

Traction Cable

Chec k and adjust the traction cable after the first 2 operating

hours , then yearly thereafter . If the sno wthro w er does not

dri v e in the forw ard or rev erse speeds or it dri v es when y ou

release the traction lev er , adjust the traction cable .

With the traction lev er diseng ag ed, c hec k the pin in the

elong ated slot in the left side of the sno wthro w er abo v e

the tire . T here should be a g ap of 1/32 to 1/16 inc h (1 to

1.5 mm) from the front of the slot to the front edg e of the

pin ( Figure 36 ).

Figure 36

1. Pin

If the left hand (traction) cable is not properly adjusted,

do the follo wing ste ps:

1. Loosen the jam n ut.

2. Loosen or tighten the tur nbuc kle to adjust the pin until

it is the proper g ap from the front edg e of the slot.

3. Tighten the jam n ut ( Figure 37 ).

15

Figure 37

1. Jam nut

2. Turnbuckle

Checking and Adjusting the

Auger/Impeller Cable

Chec k and adjust the aug er/impeller cable after the first

2 operating hours , then yearly thereafter .

1. R emo v e the 2 screws from the right side of the belt

co v er as sho wn.

2. Lift up the right side of the belt co v er ( Figure 38 ).

Figure 38

3. With the aug er/impeller lev er diseng ag ed, ensure that

the g ap betw een the aug er clutc h assembly and the tab

is 1/16 inc h (1.5 mm) ( Figure 39 ).

Figure 39

1. Tab

4. If the aug er/impeller cable is not properly adjusted, do

the follo wing ste ps:

5. Loosen the jam n ut ( Figure 40 ).

Figure 40

1. Jam nut

2. Turnbuckle

6. Loosen or tighten the tur nbuc kle that adjusts the

tension on the cable ( Figure 40 ).

7. Adjust the tur nbuc kle until y ou obtain the proper g ap .

8. Tighten the jam n ut.

9. Inser t the 2 screws y ou previously remo v ed on the belt

co v er .

10. If the aug er/impeller cable is properly adjusted but a

problem remains , contact an A uthorized Ser vice Dealer .

Checking the Auger Gearbox

Oil Level

Chec k the aug er g earbo x oil yearly and add oil if necessar y .

1. Mo v e the sno wthro w er to a lev el surface .

2. Clean the area around the pipe plug ( Figure 41 ).

Figure 41

3. R emo v e the pipe plug from the g earbo x.

16

4. Chec k the oil lev el in the g earbo x. T he oil should be at

the point of o v erflo wing at the filler opening .

5. If the oil lev el is lo w , add GL-5 or GL-6, SAE 85-95

EP transmission oil to the g earbo x until the point of

o v erflo w .

Note: Do not use synthetic oil.

6. Install the pipe plug in the g earbo x.

Changing the Engine Oil

Chang e the engine oil after the first 2 operating hours , then

yearly thereafter . If possible , r un the engine just before

c hanging the oil because w ar m oil flo ws better and car ries

more contaminants .

Max. fill: 26 oz. (0.77 l), type: automoti v e deterg ent oil with

an API ser vice classification of SF , SG , SH, SJ , SL, or higher .

• F or temperatures abo v e 32°F (0°C), use SAE 30W .

• F or temperatures betw een 0°F and 32°F (-18°C to 0°C),

use SAE 5W30 or SAE 10W .

• F or air temperatures belo w 0°F (-18°C), use SAE 0W30.

1. Clean the area around the oil drain cap ( Figure 42 ).

Figure 42

1. Oil drain cap

2. Slide an oil drain pan under the drain extension and

remo v e the oil drain cap .

3. Drain the oil.

Note: Dispose of the used oil properly at a local

recycling center .

4. Install the oil drain cap .

5. Fill the crankcase with oil. R efer to Filling the Engine

Crankcase with Oil.

Lubricating the Hex Shaft

Lightly lubricate the hex shaft yearly with automoti v e engine

oil ( Figure 43 ).

Figure 43

1. Hex shaft 3. Rubber wheel

2. Aluminum friction plate

Important: Do not get oil on the r ub ber wheel or

the alumin um friction dri v e plate because the traction

dri v e will slip ( Figur e 43 ).

1. Drain the g asoline from the fuel tank.

2. Tip the sno wthro w er forw ard onto its aug er housing

and bloc k it so that it cannot fall.

3. R emo v e the bac k co v er ( Figure 44 ).

Figure 44

1. Back cover

4. Mo v e the speed selector lev er to P osition R2.

5. Dip y our fing er in automoti v e engine oil and lightl y

lubricate hex shaft.

6. Mo v e the speed selector lev er to P osition 6.

7. Lubricate the other end of the hex shaft.

8. Mo v e the speed selector lev er forw ard and rearw ard

a few times .

9. Install the bac k co v er and retur n the sno wthro w er to

the operating position.

Inspecting and Replacing the

Spark Plug

Use a Champion RJ-19LM or equi v alent spark plug . Chec k

and g ap the spark yearly , and re place the plug if necessar y .

1. Clean around the base of the spark plug .

2. R emo v e the spark plug .

3. Examine the spark plug and re place it if it is crac k ed,

fouled, dir ty , or if the electrodes are w or n.

17

Important: Do not clean the electr odes because

g rit could enter the cylinder and dama ge the

engine.

4. Set the g ap betw een the electrodes on the spark plug at

0.030 inc h (0.76 mm) ( Figure 45 ).

Figure 45

1. 0.030 inch (0.76 mm)

5. Install the spark plug b y hand and then tor que it to 15

ft-lb (20.4 N·m).

Note: If y ou do not ha v e a tor que wrenc h, tighten

the plug fir mly .

Adjusting the Discharge Chute

Latch

If the disc harg e c hute does not loc k into the desired

position or does not unloc k so that y ou can mo v e it to

another position, adjust the disc harg e c hute latc h.

1. R emo v e the fastener on the g ear co v er ( Figure 46 ), lift

the front of the co v er up , and slide it bac k and out of

the w a y .

Figure 46

2. Loosen the bolt on the cable clamp ( Figure 47 ).

Figure 47

1. Cable conduit 2. Cable clamp

3. Grasp the cable conduit and mo v e it to w ard the front of

the mac hine until the disc harg e c hute latc h fully eng ag es

the g ear teeth ( Figure 47 and Figure 48 ).

Figure 48

1. Discharge chute latch 2. Gear teeth

Note: T he latc h is spring loaded and will naturally

mo v e into the teeth of the g ear ( Figure 48 ).

4. R emo v e any slac k in the cable b y pulling the cable

conduit rearw ard.

5. Tighten the bolt on the cable clamp .

6. Install and secure the g ear co v er .

Replacing the Drive Belts

If the aug er/impeller dri v e belt or the traction dri v e belt

becomes w or n, oil-soak ed, or otherwise damag ed, g o to

www .T oro .com for additional ser vice infor mation or ha v e

an A uthorized Ser vice Dealer re place the belt.

18

Storage

• Gasoline v apor s can explode.

• Do not stor e gasoline mor e than 30 days.

• Do not stor e the sno wthr o w er in an enclosur e

near an open flame.

• Allo w the engine to cool bef or e storing it.

Preparing the Snowthrower

for Storage

1. On the last refueling of the year , add fuel stabilizer to

fresh fuel as directed b y the engine man ufacturer .

2. R un the engine for 10 min utes to distribute the

conditioned fuel through the fuel system.

3. Loosen the hose clamp that secures the fuel line to the

v alv e and slide the fuel line off the fuel shutoff v alv e .

4. Open the fuel shutoff v alv e and allo w the fuel to drain

out of the fuel tank into an appro v ed fuel container .

5. Install the fuel line onto the fuel shutoff v alv e and

secure it with a hose clamp .

6. R un the sno wthro w er until the engine stops from

r unning out of fuel.

7. Prime the engine and star t it ag ain.

8. Allo w the engine to r un until it stops . W hen y ou can no

long er star t the engine , it is sufficiently dr y .

9. Stop the engine and allo w it to cool.

10. R emo v e the ignition k ey .

11. Disconnect the spark plug wire .

12. R emo v e the spark plug, add 1 oz. (30 ml) of oil through

the spark plug hole , and pull the star ter rope slo wl y

sev eral times to distribute oil throughout the cylinder to

prev ent cylinder cor rosion during the off-season.

13. Loosely install the spark plug .

14. Dispose of any un used fuel properly . R ecycle it

according to local codes , or use it in y our automobile .

Note: Do not store stabilized fuel for more than

90 da ys .

15. Clean the sno wthro w er thoroughly .

16. Tighten all loose screws , bolts , and loc kn uts . R e pair or

re place any damag ed par ts .

Removing the Snowthrower

from Storage

1. R emo v e the spark plug and spin the engine rapidly using

the star ter to blo w the ex cess oil from the cylinder .

2. Install the spark plug b y hand and then tor que it to

15 ft-lb (20.4 N·m).

3. Connect the spark plug wire .

4. P erfor m the ann ual maintenance procedures as gi v en in

the R ecommended Maintenance Sc hedule .

19

Troubleshooting

Problem

Possible Cause Corrective Action

1. The key is not in the ignition

or is in the Stop position.

1. Insert the key into the ignition

and turn it to the On position.

2. The choke is in the Off position

and the primer has not been

pressed.

2. Move the choke to the On

position and press the primer

3 times.

3. The fuel shutoff valve is not

open.

3. Open the fuel shutoff valve.

4. The throttle is not in the Fast

position.

4. Move the throttle to the Fast

position.

5. The fuel tank is empty or the

fuel system contains stale fuel.

5. Drain and/or ll the fuel tank

with fresh gasoline (not more

than 30 days old). If the

problem persists, contact an

Authorized Service Dealer.

6. The spark plug wire is loose or

disconnected.

6. Connect the wire to the spark

plug.

7. The spark plug is pitted,

fouled, or the gap is incorrect.

7. Check the spark plug and

adjust the gap if necessary.

Replace the spark plug if it is

pitted, fouled, or cracked.

8. The fuel vent cap is restricted. 8. Remove the vent restriction or

replace the fuel cap.

Engine does not start or starts

hard

9. The engine oil level in the

engine crankcase is too low or

too high.

9. Add or drain oil to adjust

the oil level in the engine

crankcase to the Full mark on

the dipstick.

1. The choke is in the On

position.

1. Move the choke to the Off

position.

2. The fuel shutoff valve is not

completely open.

2. Open the fuel shutoff valve.

3. The fuel tank is nearly empty

or contains stale fuel.

3. Drain and ll the fuel tank

with fresh gasoline (not more

than 30 days old). If the

problem persists, contact an

Authorized Service Dealer.

4. The spark plug wire is loose. 4. Connect the wire to the spark

plug.

5. The spark plug is pitted,

fouled, or the gap is incorrect.

5. Check the spark plug and

adjust the gap if necessary.

Replace the spark plug if it is

pitted, fouled, or cracked.

Engine runs rough

6. The engine oil level in the

engine crankcase is too low or

too high.

6. Add or drain oil to adjust

the oil level in the engine

crankcase to the Full mark on

the dipstick.

20

/