Page is loading ...

ULTIMATE REVERSE OSMOSIS SYSTEM

INSTALLATION INSTRUCTION

& OWNER’S MANUAL

All Rights Reserved © APEC Water Systems

www. FreeDrinkin gWater.com

Ver 4.0

All

Rig

h

ts

R

e

s

erve

d

© ©

APEC

Wa

ter

S

ystems

www

.F

reeD

r

r

i

i

n

n

kk

i

i

i

n

n

gW

a

t

er

.com

r

r

Ver 4.

0

Please keep this Owner’s Manual for future reference.

It contains useful information on how to maintain and care for your

APEC Reverse Osmosis water filter system.

TABLE OF CONTENT

1. Installation:

Preparation ................................................................... page 1

Filter housings assembly ................................................. page 5

Feed water connection .................................................... page 6

Drain saddle connection ................................................ page 10

Faucet mounting ............................................................ page 12

Connecting the whole system ......................................... page 13

2. Maintenance:

Filter change schedule & instructions ............................. page 18

3. Owner’s Manual - RO Basics:

System flow diagram ...................................................... page 23

Input water pressure: most important factor ................... page 24

TDS meter: testing your water quality ............................. page 24

Tank volume & delivery pressure ..................................... page 25

Misc. topics .................................................................... page 26

4. Trouble-shoot Guide:

RO Head diagram .......................................................... page 28

Humming noise ............................................................... page 29

No water at dispensing faucet ......................................... page 29

System slow shut-off ....................................................... page 31

TDS level higher than normal ......................................... page 33

Filter housing is leaking .................................................. page 34

Tank ball valve is leaking ................................................ page 35

Pure water still taste like Tap water ................................. page 35

Air bubble in cup or bottle when filling ........................... page 35

5. Other Information:

AirGap Faucet Installation ............................................. page 36

6. Warranty ........................................................................... page 38

Please keep this

OO

O

ww

n

n

n

er’s Manual

f

or

f

uture

r

r

e

e

f

f

erence.

It contains use

f

ul in

f

ormation on how to maintain and care

f

or

y

our

A

PEC Reverse Osmosis water

f

ilter system

.

TA

BLE OF CO

N

TE

TE

NTNT

N

1.

1.

I

n

s

t

a

ll

a

ti

o

n

:

Preparat

i

on ........................

..

..

..

..

..

..

.

..

................................. page

1

Filter housings assembly .

..

.

....

..

..

..

...................................... page

5

Feed water connection

..

..

....

..

.

..

.

.......................................... page

6

Dr

a

in

sadd

l

e

co

nn

e

ct

t

io

i

n

n

n

.

..

.

............................................. pa

ge

e

10

10

Faucet mount

i

ng

.

..

.

..

.

..

..

..

.

..

................................................. pa

ge

ge

1212

C

onnecti

ng

the

w

w

hoho

le

le

s

ys

tem .........................................

pa

ge

ge

13

13

1

2

.

M

ain

te

e

na

na

n

nc

nc

e:

e:

Filt

er

r

cc

haha

ha

ngng

e

e

schedule & instructions ............................. page 1

8

3

.

O

wner’s Manual - RO Basics:

System

f

low diagram .........................

..

.

..

.

.

..

..

..

..

................... page

23

Input water pressure: most importa

nt

nt

fafa

ctct

o

or

................... page

24

T

DS meter: testing your water

qu

u

alal

al

it

it

y

y

.

.

.

..

.......................... page

24

T

ank volume & deliver

y

pr

essu

re

re

e

..

..

..

.

...............................

TT

pa

ge

2

5

M

isc. topics ......................

..

..

..

..

..

.

..

...................................... page 2

6

4

.

T

ro

ub

le

-s

ho

ot

G

ui

de

:

:

TT

RO Head di

ag

ra

m

m

.

.

..

.

..

.

..

...................................................

pa

a

gege

28

28

2

Humming no

is

s

s

e e

e

.

..

.

..

..

.

.........................................................

pa

pa

gege

29

No water at

di

di

sp

sp

ensing

f

aucet .........................................

pa

pa

p

ge

29

System slo

w

w

sh

sh

u

ut

-o

ff

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

..

.

..

..

..

.

..

..

.

.

pa

pa

ge

31

TD

D

S

S

le

le

veve

v

l

l

hi

i

g

gh

er than normal ............................

..

..

.

..

....

..

..

.

..

..

.

..

page

33

Fi

ltlt

er

er

hh

ouou

o

s

si

ng is leaking .......................................

....

....

..

..

..

..

.

..

. page

34

Ta

a

nknk

b

b

alal

ll

v

va

lve is leaki

ng

................................................

pa

ge

3

5

Pu

re

e

w

w

a

at

er still taste like Tap water ................................. page

35

A

ir bubble in cup or bottle when

f

illing ........................... page 3

5

5

.

O

th

e

r In

fo

rm

a

ti

o

n:

A

irG

ap

Faucet Installation .............................................

pa

ge

36

6

.

W

arranty

W

W

.............................

.

..

..

..

..........................................

page

38

1

Thank you for choosing APEC reverse osmosis systems.

You now own the finest water filter in America.

Please read and become familiar with instructions and parts needed before proceeding with the

installation.

BEFORE INSTALLATION:

Inspect the system:

Please take the system and all the components out of the box. Inspect the system and all the

connection fittings carefully, make sure nothing is damaged during shipping. If any part is cracked

or broken, please do not proceed with the installation and contact APEC or your distributor for an

exchange or diagnosis.

Recommended tools list:

x Variable speed drill

x Drill bit:

1/4” (for the waste line), 1/8” (as pilot, not mandatory), and 1/2” (for standard

faucet hole, air-gap faucet requires 1&1/4” hole)

x 5/8”, 9/16” open-end wrench, or adjustable wrench, pliers

x Phillips screwdriver

x Utility knife, or scissors

x Teflon tape

Operating Parameter

x Operating pressure: 85psi maximum

x Feed water temperature: 40 – 100 °F (4-37 °C)

x Feed water TDS level: 2000ppm maximum

x Do not connect this unit to hot water source

x Install the RO in a sheltered environment, avoid exposure to hot and cold weather or under

direct sunlight.

Copyright:

This manual is copyrighted by APEC Inc. Under the copyright laws, this manual may not be reproduced in any form, in

whole or part, without the prior written consent of APEC Inc. Manual print ver. 4.0, 2018 Apr.

General Installation/Operation/Maintenance Requirements

x Installation needs to comply with state and local laws and regulations.

x System must be installed indoor away from possible environmental damage

x Do not use with water that is microbiologically unsafe or of unknown quality without

adequate disinfection before or after system. Systems certified for cyst reduction may be

used on disinfected water that may contain filterable cysts.

x This reverse osmosis system contains a replaceable treatment component critical for

effective reduction of total dissolved solids. The product water shall be tested periodically to

verify that system is performing satisfactorily.

1

Thank you

f

or choosin

g

g

AA

A

P

P

E

E

C reverse osmosis syste

m

m

ss

.

Y

ou now own th

e

e

f

f

f

i

i

n

n

est water

f

ilter in Am

e

e

rr

i

i

cc

aa

.

.

Please read and become

f

amil

ia

a

r r

r

wiwi

thth

i

i

nstructions and parts needed be

f

or

e

e

pr

pr

o

oc

eeding with the

in

st

al

la

ti

on

.

B

EFORE I

N

STALLATIO

N

:

I

n

sp

ect the

sy

stem:

P

lease take th

e

e

sy

sy

stem and all the components out o

f

t

he

e

b

b

oxox

x

.

Inspect the system and all the

c

onnection

f

it

it

titi

ngng

s

s

s

care

f

ully, make sure nothing is da

mama

gege

dd

during shipping. I

f

any part is crac

ke

e

d

d

o

r broke

n,

n,

p

p

le

le

as

as

e do not proceed with the installa

ti

ti

onon

a

a

nd

nd

contact APEC or your distributor

fo

o

r

r

an

n

n

e

xch

an

n

gege

o

o

r

r

d

di

agnosis.

Re

e

coco

mm

m

ended tools list:

x

V

ariable speed drill

V

V

x

D

rill

b

it

:

1/

4”

(f

or the w

as

s

tete

l

l

in

in

e)

)

,

1/

8” (as pilot, not mandatory), an

d

d

1/1/

/

2”

2”

(

(f

or standard

f

aucet hole, air-gap

f

au

u

ce

ce

t

t

re

re

quires 1&1/4” hole

)

x

5/8”, 9/16”

op

p

p

enen

en

--

en

en

d

wr

w

ench, or adjustable wrench, pliers

x

P

hillips screw

dr

r

iviv

v

e

er

x

U

tility kni

f

e, or

scsc

isis

s

soso

rs

rs

x

T

eflon tape

TT

O

perating Parameter

x

Operating pressure: 85psi maximu

m

x

x

F

e

ed water temperature: 40 – 100 °F

(

(

4-

4-

3737

°

°

C

)

x

x

F

e

ed water TDS level: 2000ppm m

ax

ax

imim

um

u

u

x

x

D

o

n

ot

connect this unit to h

ot

w

at

at

erer

sourc

e

x

I

nstall the RO in a sheltered

en

n

vi

vi

ro

o

nm

n

n

ent, avoid exposure to hot and c

ol

ol

d

d

wewe

w

a

at

her or unde

r

d

irect sunlight.

Copyright

:

This manual is copyrighted by APEC I

nc

nc

n

.

UnUn

U

d

de

r the copyright laws, this manual may not

bebe

e

r

r

epep

ro

ro

du

ced in any

f

orm, in

whole or

p

art, without the

p

rior wri

tt

t

enen

c

c

on

o

sent o

f

APEC Inc. Manual

p

rint ver. 4.0, 2

01

1

8

8

Ap

Ap

r.

G

eneral Installati

on

on

/O

/O

O

pe

pe

ra

a

tion/Maintenance Requireme

nt

t

s

s

x

I

nstallation n

ee

ee

ds

ds

t

t

o

o

comply with state and local laws and regulations.

x

System must be installed indoor away

f

rom possible environmental damag

e

x

D

o not use with water that is microbiologically unsa

f

e or o

f

unknown quality without

adequate disin

f

ection be

f

ore or a

f

ter system. Systems certi

f

ied

f

or cyst reduction may

be

be

used on disin

f

ected water that may contain

f

ilterable cysts.

x

This reverse osmosis system contai

ns

aa

r

r

eplaceable treatment component criti

ca

l

l

fofo

r

r

eff

ective reduction o

f

total dissolv

ed

ed

ss

olol

id

id

s. The product water shall be tested

pp

erer

ioio

di

d

cally to

veri

f

y that system is per

f

ormi

ng

g

s

s

at

at

is

is

fa

fa

ct

c

orily.

2

Components included with the RO system:

Make sure you have all these parts before starting installation.

1 RO system head

with pre installed membrane

3 Pre-filters in 3 Housings

1 Storage tank

Installation kit includes:

1 Faucet with

washers and nuts

(Faucet color may vary,

depends on the color

selected)

1 Feed water adaptor

3/8”- 1/2”

with needle valve kit

1 Drain saddle for waste water

3 Color tubing 1/4”

1 Tank’s Ball Valve 2 Wrenches

for opening filter and

Membrane housing

1 Faucet Adapter

2

C

C

o

m

m

ponents included with the

R

R

OO

s

s

ystem:

py

Make sure you have al

ll

tt

hh

e

e

ss

s

e

parts be

f

ore starting ins

t

t

a

a

l

l

l

l

a

a

tion.

1 RO system head

with pre installed membran

e

3

3

Pr

P

e-

fi

fi

l

lt

l

ers in 3 Housings

1 St

or

r

ag

ag

e

e

t

ta

n

k

I

n

s

t

a

ll

a

ti

o

n kit in

c

l

ude

s:

:

1 Faucet wit

h

washers and nuts

(Faucet color may vary,

d

epends on the color

selected

)

1 Feed

w

w

at

at

er

er

a

d

da

pto

r

3/

3/

3

8”

- 1

/

2

”

wi

wi

th

th

n

n

ee

ee

e

d

dl

e valve kit

1 Drain saddle

f

f

or

o

o

w

w

as

a

te wat

er

3

Color tubing 1/4”

1 Tank’s Ball Valv

e

2 Wrenches

Wr

e

f

or opening

f

ilter and

M

embrane housi

ng

1 Fauc

et

e

A

A

da

da

pt

t

e

r

3

Component Itemization:

1) Sediment pre-filter and housing (1

st

-stage filter)

2) Carbon block pre-filter and housing ( 2

nd

-stage filter)

3) Carbon block pre-filter and housing ( 3

rd

-stage filter)

4) Membrane and housing (4

th

-stage filter)

5) In-line carbon filter (5

th

-stage filter)

6) Storage tank

7) Tank ball valve

8) ASO – Automatic Shut Off valve

9) Check valve (Internal check valve encased in plastic fitting)

10) T-fitting

11) Feed water inlet

12) Product (filtered) water outlet

13) Bracket

3

C

C

o

m

m

ponent Itemization:

p

1)

1)

)

Sediment pr

e

-f

ilter and housing (

1

st

t

-s-s

tata

g

ge

f

ilter)

2)

2)

C

arbon block pr

e

-f

ilter and

ho

us

s

in

in

g

g

(

(

2

n

d

-

stage

f

ilter)

3)

C

arbon block pr

e

-f

ilter an

d

d

ho

h

h

us

i

in

g ( 3

r

d

-

stage

f

ilter)

4

)

Membrane and housi

ng

g

(

(

44

thth

-s

-s

t

ta

ge

f

ilter)

5

)

In-line carbon

f

ilte

r

(5(5

(5

thth

-s

-s

ta

ta

ge

f

ilter)

6) Storage tank

7)

T

ank ball

vv

alal

ve

v

ve

T

T

8

)

A

SO –

Au

u

to

to

mama

titi

c

c

Shut O

ff

valve

9)

C

heck va

lv

e

(

(

I

In

ternal check valve encased in plastic

f

itting)

10

)

T

-

f

itting

11

)

Feed water inl

et

12

)

Product (

f

iltered) water outle

t

13

)

Br

ac

k

et

4

2. Metal compression nut fitting:

(comes with 1 insert, 1 sleeve, 1 nut) This is for feed water adapter

-needle valve only.

Fitting Types: There are 2 types of fittings provided for connecting the system

Important! Use plastic sleeve and inserts on the plastic tubing we

provide. Do Not use metal sleeve or insert on plastic tubing or the

connection will leak!

Fig.1B

How to connect: - See Fig.1B. Slide the compression nut onto the tubing.

- Slide the

plastic sleeve onto the tubing.

- Insert the “insert” into the tubing.

- Insert the tubing into the opening of the fitting.

- Slide the brass nut up, then tighten nut with a wrench. No Teflon tape!

(An extra metal sleeve is provided in case you need to connect your own metal

tubing. Use Teflon tape if connecting metal tubing.)

1. Quick-Connect (QC) fitting: (no insert, sleeve, or nut) Most of the fittings on the RO unit are this

type.

How to Connect: - See Fig.1. Push the tubing into the Quick-Connect fitting, then gently

pull back on the tubing to make sure connection was secure.

- No inserts, sleeve, or nuts are needed to secure the connection.

- No Teflon tape is needed!

To Disconnect: - See Fig.1A. Push in and hold down on the collet ring square against

the fitting. With the collet held in this position the tube can be removed.

Fig. 1

Fig. 1A

4

2.

Metal compression nut

f

itting

:

(

c

omes with 1 insert

,

1 sleeve

,

1 nut

)

T

his is

f

or

f

eed water adapt

er

r

-needle valve only.

Fi

F

tt

in

in

g

g

Types:

There are 2 types of fit

ti

i

ng

ng

s s

pr

p

ovided for connecting the

sy

sy

st

st

em

e

yp

g

p

p

g

y

y

ImIm

popo

rt

rt

ant!

Use

plastic slee

ve

p

a

n

d

i

n

se

rt

s

o

o

n

n

thth

h

e

pl

astic tubing we

p

pr

ov

o

ide.

Do

N

ot

use metal sleeve or i

ns

s

er

er

t

t

on

on

plastic tubing or the

connection will leak!

F

i

g.

1B

B

H

ow to connect

:

-

-

SeSe

e

e

e

F

i

g.1B. Slide the compression nut onto the tubing.

-

Slide the plastic sleeve onto the tubing.

-

Insert the “insert” into the tubing.

-

Insert the tubing into the opening o

f

the

f

itting.

-

Slide the brass nut up, then tighten nut with a wrench. No

T

eflon

ta

a

pepe

!

!

T

T

(

An extra metal slee

ve

i

i

s

s

p

pr

ovided in case you need to connect your

ow

ow

n

n

me

me

t

ta

l

tubing. Use Te

f

lon ta

pe

pe

i

i

f

f

c

co

nnecting metal tubing.

)

1.

Q

uick

-

Connect (QC)

f

itting

:

(n

(n

(

o

o

inin

s

se

rt, sleeve, or nut

)

Most o

f

the

f

ittings on the RO unit are this

type.

Ho

Ho

w to Connect:

-

See

F

i

g.

1.

P

us

s

h

h

t

th

e tubing into the Quick-Connect

f

itting,

t

t

hehe

n

n

gently

pull back o

n

n

th

h

e

e

tu

tu

b

bi

ng to make sure connection w

as

as

s

s

ec

ec

ur

r

e

e.

- No ins

er

r

tsts

,

,

s

sl

eeve

,

or nuts are needed to secure t

he

e

cc

onon

ne

ne

ction.

-

N

o

T

ef

ef

lo

lo

n

n

ta

ta

pe is needed!

TT

To Disconnect:

-

SeSe

e

e

e

Fig.1

A

.

Pus

h in

a

n

d

hold down

on the collet ring square against

th

th

e

e

f

fi

tting. With the collet held in this position the tube can be removed.

F

i

g.

1

Fig. 1

A

5

THERE ARE TWO PARTS TO INSTALLING THE RO SYSTEM:

Part I. Assemble the filters and housings onto the main system

Part II. Installing the system

Note: The RO Membrane Element has already been pre-installed.

PART I. ASSEMBLE THE FILTERS AND HOUSINGS ONTO THE MAIN SYSTEM

Remove plastic/paper wrappings on the 3 filters, put them into the 3 housings, and assemble the

housings onto the main system as follow:

1. See

Fig. 2 Stand the 3 housings upright. Make sure each housing has a rubber O-ring in its

groove.

Put the APEC Sediment filter (1-SED10) into the “1

st

stage” housing on the right.

Put the APEC Carbon filter (23-CAB10) into the “2

nd

stage” housing in the middle.

Put the APEC Carbon filter (23-CAB10) into the “3

rd

stage” housing on the left.

2. See

Fig. 3 Starting from the 3

rd

stage housing on the left, hand twist the housing onto the main

system turning counterclockwise, one by one, for all 3 housings.

3. See

Fig. 4 Use the wrench provided to completely tighten the housing starting from 1st-stage.

Repeat this step for the 2

nd

stage housing in the middle, and for the 3

rd

stage housing

on left.

Note: For some people it is easier to use the wrench with the system laid down

(face up).

4. See Pg. 3 Remove 2 end plugs (white color) from Point 10 & 12

Fig. 2

Fig. 3

Fig. 4

turn counter-clockwise

to tighten

3rd

Stage

3rd

Stage

2nd

Stage

1st

Stage

Use

Wrench

Use

5

T

T

H

E

E

R

R

E ARE TW

O

PART

S

T

O

IN

S

T

A

A

L

L

L

L

I

I

N

N

G

THE R

O

S

Y

S

TEM

:

P

a

rt I.

A

ssemble the

f

il

te

e

rsrs

a

a

ndnd

d

h

ousings onto the main syste

m

Part II.

I

nstalling the sys

te

e

e

mm

N

ote: The RO Membrane Element has already been pre-installe

d.

PART I. A

SS

EMBLE THE FILTER

S

AND H

OUS

IN

GS

O

NT

O

THE MAIN

S

Y

S

TE

M

R

emove pla

st

t

icic

/p/p

ap

a

a

er wrappings on the 3

f

ilters, put

t

he

he

h

m

m

in

in

to the 3 housings, and assemble th

e

e

housings

o

o

nt

nt

oo

th

th

e main system as

f

ollow

:

1

.

S

eeee

Fi

Fi

g

g.

2 Stand the 3 housings upright.

Ma

Ma

ke

ke

k

sure each housing has a rubber O-

ri

ri

i

ngng

i

i

n

n

it

it

s

groo

v

e

.

P

ut the APEC Sediment

f

i

lt

lt

e

er

(

(

1-

1

SED10) into the “

1

st

stage” housing

on

n

t

t

he

he

right.

P

ut the APEC Carbon

fi

fi

lt

lt

er

er

(

(

(

23

2

-CAB10) into the “

2

n

d

stage”

ho

o

usus

in

in

gg

in

n

the middle.

P

ut the APEC Car

bo

bo

n

n

fifi

lt

lt

er

e

(23-CAB10) into the “

3

rd

stage”

ho

ho

us

us

us

inin

g

g

on

o

the le

f

t.

2

.

See

Fig. 3 Starting

f

ro

o

m

m

th

e

e

3

3

d

rd

stage housing on the le

f

t, hand twist the housing onto the main

s

ystem

t

t

urur

u

ni

ni

ngng

c

c

ounterclockwise, one by one,

f

or all 3 housings.

3

.

See

Fig. 4

U

se the

wr

wr

en

en

ch

provided to completely tighten the housing starting

f

rom 1st-stage.

R

epeat this step

f

or the

2

n

d

stage housing in the middle, and

f

or the 3

r

d

stage housi

ng

g

o

n l

ef

t.

N

ote

:

For some people it is easi

er

t

t

o o

usus

e e

t

th

e wrench with the system laid

do

o

wn

wn

(f

ace

up

).

4.

4.

S

S

ee

Pg. 3

R

emove 2 end plugs (whit

e

e

coco

lo

lo

r)

r)

f

rom Point 10 & 12

F

i

g.

2

FiFi

g.

3

FiFi

g.

4

4

4

t

urn coun

t

er

-

cl

oc

k

wi

se

to t

ig

hte

n

3

r

d

Stag

e

3

r

d

S

ta

g

e

2n

d

S

tage

1s1s

t

t

St

St

ag

ag

e

Us

Us

e

e

WrWr

W

W

W

en

en

c

h

UU

U

Us

s

ee

6

PART II. INSTALLING THE SYSTEM

Space: Make sure there is sufficient space under the counter for installation (an area of about

17”L x 6”W x 18”H for the system, 11”D x 18”H for tank).

The RO system is best installed under the kitchen sink. But if that is not feasible you

can install the system anywhere where there is a cold water supply with sufficient

water pressure for the chosen RO model, and an outlet to drain off the waste water

from the system.

Mounting: No need to mount the RO system on the wall. The RO system can stand in the sink

cabinet without mounting, this makes future filter change easy and convenient. If

you prefer to mount the system to the wall, please make sure it can be taken down

easily for filter replacement.

Feed Water: RO systems are designed to treat both hard and soft water and can handle incoming

TDS levels up to 2000ppm.

Step 1: Feed Water Connection

The RO system must be connected to the COLD water supply only!

1. Locate the Cold water supply valve under the kitchen sink (the round or oblong handle on

the right side). Turn off the incoming cold water completely by turning the shut off handle

clockwise.

Note: If the cold water shut off valve can not turn off the water, the main water supply

to the house must be shut off for the installation. Another option is to use a “self

piercing saddle valve” from APEC or from a local hardware store.

2. Feed Water Adaptor (1/2” or 3/8”): See Fig. 5. The Feed Water Adaptor comes with a

separate Needle Valve. The Adaptor goes inline onto your 1/2” or 3/8” cold water pipe. The

Needle Valve portion screws onto the Adaptor as shown in Fig. 5A.

Fig. 5

A. 1/2” x 3/8” Male-Female Water Supply Adapter

with O-ring.

B. 1/2” x 3/8” Male-Female Converter with O-ring.

C. 1/4” x 1/8” Male Needle Valve.

6

PA

P

RT

RT

II. IN

S

TALLIN

G

THE

S

Y

S

TE

M

Sp

ace

:

Make sure there is

su

su

ffff

ic

ic

ieie

nt

nt

s

pa

ce under the counter

f

or installat

io

o

n

n

(a(a

n

n

a

ar

ea o

f

about

17”L x 6”W x 1

8”

”

HH

H

ff

or

or

tt

h

he

h

system, 11

”D

x 1

8”

H

f

or tank).

The RO system is best installed under the kitchen sink. But i

f

that is not

f

easible you

c

an install the system anywhere where there is a cold water supply with su

ff

icient

water pressure

f

or the chosen RO model, and an outlet to drain o

ff

the waste wate

r

f

rom the system.

M

ounti

ng

g

:

:

NoNo

need to mount the RO system on

th

e e

e

wawa

ll

ll

. The RO system can stand in the sin

k

k

c

ca

binet

without mounting

g

, this mak

es

es

f

f

utut

ur

ur

e

e

f

ilter change easy and convenien

t.

I

I

I

f

f

f

y

ou pre

f

er to mount the system t

o

o

th

th

e

e

wa

wa

ll, please make sure it can be tak

en

n

d

d

owow

n

n

e

asily

f

or

f

ilter replacement.

Fe

Fe

ed

ed

Water:

R

O systems are designed

to

to

t

re

re

at both hard and so

f

t water and can

ha

ha

ndnd

le

le

incoming

TDS levels up to 200

0p

0p

pm

pm

.

.

Step 1: Feed Water Conne

ct

ct

ioio

nn

The RO s

ys

tem

mu

stst

st

bb

e e

co

co

nnected to the COLD water su

pp

ly

onl

y!

yppyy

1. Locate the

C

old water supply valve under the kitchen sink (the round or oblong handle on

the right side). Turn o

ff

the incoming cold water completely by turning the shut o

ff

handle

cl

oc

kw

is

e.

N

ote: I

f

the cold water shut o

ff

valve can

nono

n

t

t

t

tu

tu

r

rn

o

ff

the water, the main water s

up

p

pl

pl

y y

to the house must be shut o

ff

f

o

r

r

thth

e

e

in

in

stallation. Another o

pt

ion is to us

e

e

a

a

“s“s

el

f

piercing saddle valve”

f

rom

AP

AP

EC

EC

C

or

f

rom a local hardware store.

2

2.

Feed Water Ada

pt

or

(

1/2” or

3/

/

8”

8”

8

):

See F

i

g.

5.

T

he Feed Water Ada

pt

pt

oror

cc

om

om

o

es with a

s

eparate Needle Valve. The A

da

da

pt

pt

or

or

r

g

g

oes inline onto your 1/2” or 3/8”

coco

o

ld

ld

w

w

ater pipe. The

N

eedle Valve portion screw

s

s

onon

toto

t

t

h

he

Adaptor as shown in

F

ig. 5

A

.

Fig.

5

A

. 1/2” x 3/8” M

al

l

e-

e-

Fe

Fe

ma

m

le Water Supply Adapter

with O-ring.

B. 1/2” x 3/8” Male-Female Converter with O-rin

g.

g.

C.

1/4” x 1/8” Male Needle Valve

.

7

Fig. 5A - Needle Valve Installation.

Attach the needle valve (C) to water supply adapter (A). Please apply 5-6 wraps of

teflon tape to needle valve prior to connecting it to the water supply adapter (A).

Fig. 5B - If your pipe has a 1/2” Connection.

By attaching the 1/2” x 3/8” converter (B) to the Male end of the water supply adapter

(A), you now have a 1/2” Male and Female water supply adapter.

Fig. 5C - If your pipe has a 3/8” Connection.

By attaching the 1/2” x 3/8” converter (B) to the Female end of the water supply

adapter (A), you now have a 3/8” Male and Female water supply adapter.

Fig. 5A

Fig. 5B

Fig. 5C

1/2” Connection 3/8” Connection

7

Fi

F

g.

5

5

A

-

Needle Valve Installation.

Attach the needle valve

(C

(C

)

)

to

to

w

w

atat

er supply adapter (A). Please ap

pl

pl

y

y

5-5-

6 6

6

w

wr

aps o

f

te

f

lon tape to needle

va

a

lvlv

e

e

pr

pr

io

io

r

to

connecting it to the water supp

ly

y

aa

da

da

ptpt

e

er

(A).

F

i

g. 5

B

-

I

f

your pipe has a 1/2

”

”

”

Co

Co

nnection.

B

y attaching the 1/2” x 3/8” converter (B) to the Male end o

f

the water supply adapte

r

(

A), you now have a 1/2” Male and Female water supply adapter.

Fig. 5

C

-

I

f

your pipe has a 3/8” Connection.

B

y attaching the 1/2” x 3/8” converter (B) to

th

th

ee

FeFe

F

ma

m

le end o

f

the water supply

ad

d

apap

tete

r

r

r

(A), you now have a 3/8” Male an

d

d

d

FeFe

ma

m

le water supply adapter.

Fig

.

5A

Fi

g

5

A

F

i

g. 5

B

Fig. 5

C

Connectio

n

1/2”

o

nnectio

n

3

/8” C

o

8

Riser

Tube

For Flexible Line

Faucet

Shank

Main Water

Supply

Shut-off

Valve

Riser

Tube

For Solid Line

Faucet

Shank

Needle

Valve

Needle

Valve

Main Water

Supply

Shut-off

Valve

Sink

Sink

3. Recommend Connection For Flex Line Riser: See Fig.6A. & Fig. 6D. Loosen nut and

separate cold water riser tube from faucet shank. Gently bend riser tube so that the Feed

Water Adapter (Fig 5) fits onto the faucet shank. Connect the riser tube, the feed water

adapter, and faucet shank together and tighten.

For Solid Copper Riser: See Fig.6B. Follow the same procedure as for flex line. If the copper

riser cannot bend, then it’s best to replace it with a flex line riser. Then fit the feed water adaptor

the same way as described above.

Fig. 6A Fig. 6B

Option Connection Point: See Fig. 6E. The feed water adapter can also be installed between the

riser tube and faucet shank. Loosen nut and separate cold water riser tube from faucet shank.

Gently bend riser tube so that the Feed Water Adapter fits onto the faucet shank. Connect the

riser tube, feed water adapter, and faucet shank together and tighten.

8

Ri

i

i

i

se

s

s

s

r

r

r

r

Tu

Tu

Tu

Tu

be

e

e

e

Fo

r

Flexible Lin

e

Fa

uce

t

S

h

an

k

M

ai

n

Wa

te

r

S

u

pply

S

h

u

t-

off

Va

l

v

e

Riser

Tu

be

F

o

r

S

o

li

d

Line

F

a

u

ce

t

S

ha

n

k

Nee

dle

Va

l

v

e

Nee

dle

Va

l

v

e

M

ai

n

Wa

te

r

Su

pply

Sh

ut

-o

ff

V

a

l

v

e

Sin

k

S

in

k

3.

3

Re

Re

co

mm

e

n

d

Co

nn

ec

ti

o

n F

o

r Fl

e

x

Li

i

ne

ne

RR

i

se

r:

See

Fig.

6

A. & Fig.

6

D.

Lo

o

os

os

en

en

n

ut

ut

a

n

d

s

eparate cold water riser tube

f

ro

ro

m

m

f

a

uc

uc

et

shank. Gently bend riser tube

s

s

o

o

thth

atat

a

t

t

he

h

Feed

Water Adapter (Fig 5)

f

its ont

o

o

thth

e

e

fafa

uc

u

et shank. Connect the riser tube,

th

h

e e

fe

fe

eded

wate

r

adapter, and

f

aucet shank to

ge

ge

g

thth

er

er

a

a

nd tighte

n

.

For Solid Copper Riser:

Se

e

Fig.6B. Follow the same procedure as

f

or

f

lex line. I

f

the coppe

r

riser cannot bend, then it’s best to replace it with a

f

lex line riser. Then

f

it the

f

eed water adapto

r

the same way as described above.

Fig. 6A Fig. 6

B

O

pti

on

n

C

C

C

onon

o

ne

n

ction Point

:

See Fig.

6

E. The

fe

e

eded

w

w

at

at

er adapter can also be installed b

et

we

we

enen

t

t

he

h

ri

i

se

se

r

r

tutu

be and

f

aucet shank. Loosen nut

an

n

d

d

se

se

parate cold water riser tube

f

rom

f

a

uc

uc

etet

ss

haha

nk

.

GeGe

nt

ly bend riser tube so that the Feed

W

W

a

at

er Ada

pt

er

f

its onto the

f

aucet shank.

CC

C

on

on

nect the

i

ri

ser tube,

f

eed water adapter, and

fa

fa

uc

et

e

shank together and tighte

n

.

9

Fig. 6C

4. Needle Valve: See Fig. 6C. Screw the Needle Valve onto the Adaptor tightly. Apply 6-8 rounds

of Teflon tape onto Needle Valve before attaching it to the Adaptor.

To open needle valve: Turn needle handle counter-clockwise.

To close needle valve: Turn needle handle clockwise.

Test for leaks at this point: Close the Needle Valve (turn needle handle clockwise all the

way in to close) Turn ON the cold water supply to the sink faucet. If the Needle Valve or the

Adaptor leaks, check the connection and try applying more Teflon tape or tighten the brass

nut some more to stop the leak.

Fig. 6D Fig. 6E

9

Fi

Fi

g.

6

C

4

. Needle Valve

:

S

S

ee

ee

Fi

Fi

g.

6

C

. Screw the Needle Valve onto the Adaptor tightly. Apply 6-8 rounds

of T

eflon tape onto Needle Valve before attaching it to the Adaptor.

T

T

T

o

ope

n

needle valve

:

T

urn needle handle counter-clockwis

e.

TT

T

o

c

l

ose

needle valve:

T

urn needle handle clockwise.

TT

Test for leaks at this

p

oint:

p

Close t

he

he

N

N

ee

ee

e

d

dl

e Valve

(

turn needle handle

cloc

kw

w

is

is

e

e

al

al

l the

wa

y

in to clos

e)

Turn ON the co

ld

d

w

w

atat

er

er

s

up

pl

y

to the sink

f

aucet. I

f

the N

ee

e

dl

d

e

Va

Va

lve or the

Adaptor leaks, check the con

ne

e

ctct

ioio

nn

and try applying more Te

f

lon tape

or

t

t

igig

ht

ht

en

e

the brass

nut some more to sto

p

the

le

e

akak

.

.

Fi

g.

g.

6

D

FiFi

g

g.

6E

10

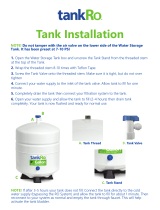

MOUNT DRAIN

SADDLE AT

EITHER

LOCATION

Step 2: Drain Saddle Installation

Note: To avoid annoying drainage noise, mount drain line as low as possible

on the vertical tailpiece, or on horizontal tailpiece.

There is constant water pressure “packed” inside the RO system which blocks the waste water

from backing-up into the system. So the waste water is “forced-drained”, not “gravity-drained”.

1. See Fig.7. The drain saddle assembly should be installed above the trap and on the vertical

or horizontal tailpiece . To reduce the drainage noise, mount the drain line as low as possible

above the trap, or on the horizontal tailpiece.

2. See Fig.8. Mark the position of the hole on the drain pipe and drill a 1/4’’ hole through one

side of the drain pipe . There is a piece of self-adhesive sponge provided. Glue this sponge

to the inside of the saddle, this will cushion any gap between the saddle and the pipe. Make

sure the hole on the sponge is thoroughly punched out, and is aligned to the hole on the

saddle.

Fig. 7

Fig. 8 Fig. 9

1

0

MO

UNT DRAI

N

S

ADDLE A

T

EITHER

LO

CA

TION

A

A

St

S

ep

p

2

: Drain Saddle Installatio

n

N

ote

:

To avoid annoy

in

n

gg

drdr

ai

ai

nage noise, mount drain line a

s

s

lolo

l

w w

as

a

possible

y

g

g

g, p

on the vertical

ta

a

a

ilil

pipi

ecec

e,

e

or on horizontal tailpiece.

p

p

,p

There is constant water pressure “packed” inside the RO system which blocks the waste wate

r

f

rom backing-up into the system. So the waste water is “

f

orced-drained”, not “gravity-drained”.

1.

See Fig.7. The drain saddle assembly should be in

st

t

alal

le

le

d

d

d

ab

ove the trap and on the vertical

o

r horiz

on

on

tata

l

l

ta

ta

a

ilpiece . To reduce the drainage n

oi

oi

i

sese

,

,

m

mo

unt the drain line as low as possibl

e

e

abov

e

e

th

th

t

ee

tr

tr

ap, or on the horizontal tailpiece.

2

.

See

F

i

g.8. Mark the position o

f

th

h

e

e

ho

ho

o

le on the drain pipe and drill a 1

/4

/4

’’

’’

h

h

olol

l

e

through one

s

ide o

f

the drain pipe . There

i

ss

a

a

pipi

ec

e o

f

sel

f

-adhesive sponge prov

id

eded

.

Gl

Gl

G

ue this sponge

to the inside o

f

the saddle,

t

t

t

hihi

h

ss

s

wi

wi

ll

ll

cushion any gap between the s

ad

d

dl

dl

e

e

an

a

d the pipe. Make

s

ure the hole on the s

po

ng

ng

e

e

is

is

thoroughly punched out, and

i

i

s

s

al

al

ig

ig

ne

e

d

d

d

to the hole on the

sadd

l

e

.

F

i

g.

7

7

F

i

g. 8

Fi

g.

9

Fi

9

11

Step 3: Drill A Hole For The RO Faucet

Drill 1/2” diameter hole for standard RO faucet. (Air-Gap faucet: drill 1&1/4” hole.)

For best results use a 1/2” carbide-tipped masonry drill bit.

Wear safety glasses to protect your eyes while drilling the faucet hole.

Note: No need to drill a hole if an existing hole is available:

a) Spare hole: If there is a spare hole in the sink covered by a chrome cover, simply remove the chrome

cover and install the RO faucet there.

b) Spray hose: If the spray hose is not in use, remove the hose, and mount the RO faucet there. Remember

to plug up the outlet under the main faucet. If the spray hose uses a diverter at the base of the spout, be sure

to remove it to avoid trouble later on.

c) Hanging faucet: If drilling a hole is not feasible (i.e. rental home, drill tool not available etc.), the faucet

can just hang on the cabinet door or wherever that is convenient. Be creative!

When drilling a hole for the RO faucet, choose a location that looks good, works well, and is most con-

venient for dispensing pure water. An ample flat area is required for the faucet base so that the faucet

can be drawn down tightly.

1. Faucet location: Make sure the faucet stud will be accessible from below when the hole is drilled.

If space is not available on the upper sink area, the faucet can be located on the counter top by the

edge of the sink. If the counter top is ceramic tile, the method for drilling the hole will be the same as

for porcelain sinks.

2. For Stainless Steel Sink: Before using a 1/2” carbide drill bit, an indent should be made with a

center punch to keep the drill bit from walking. A small pilot hole will also aid the drill bit.

3. See Fig.9, 9A. Make sure to align the drain saddle hole to the drilled hole perfectly.

Mis-aligning these two holes will block the drain water and cause membrane damage. Attach the

drain saddle to the drain pipe and tighten the two screws evenly.

4. Once the drain saddle is secured, push 1/4” black drain tubing into the Quick Connect fitting on the

saddle. DO NOT use a “Insert” on the drain tubing.

Fig. 9A

11

St

ep

ep

3

3

: Drill A Hole For The RO Fa

uc

c

et

et

Drill 1/2” diameter hole

f

or

or

s

s

ta

ta

nd

nd

ard RO

f

aucet.

(

Air-Gap

f

aucet: d

ri

i

ll

ll

11

&1

&1

/4/4

” hole.

)

For best results use a 1

/2

/2

”

c

ca

rbide-tipped masonry drill bit.

Wear sa

f

ety gl

as

as

s

sese

s s

s

to

to

protect your eyes while drilling the

f

aucet hole.

N

ote

:

No need to drill a hole if an existing hole is available:

g

a)

Sp

are hole: I

f

there is a

sp

are hole in the sink cov

er

er

r

eded

bb

y

y

a chrome cover, si

mp

ly

remove the

ch

h

ro

ro

me

me

c

over and install the RO

f

aucet there.

b

b

)

)

Sp

Sp

p

ra

r

y hose: I

f

the spray hose is not in use

,

,

re

e

mo

mo

ve the hose, and mount the RO

f

aucet

t

t

hehe

re

re

.

R

Re

membe

r

to

o

pp

p

lu

lu

g up the outlet under the main

f

aucet.

I

I

f

f

thth

e

e

sp

sp

ray hose uses a diverter at the base

o

o

f

f

t

th

e spout, be sure

toto

r

emove it to avoid trouble later on.

c

)

Hanging

f

aucet:

If

drilling a

ho

le

le

i

i

s

s

no

n

t

f

easible (i.e. rental home, drill tool

nn

otot

a

a

va

il

able etc.), the

f

aucet

c

an just hang on the cabinet d

oo

o

r

r

r

oror

r

w

w

he

he

rever that is convenient. Be creative

!

When drilling a hole

f

or

r

tt

hehe

RR

O

O

f

aucet, choose a location that loo

ks

ks

gg

oooo

d,

d,

works well, and is most con

-

venient

f

or dispensing

p

p

urur

e

e

wawa

wa

te

t

r. An ample

f

lat area is required

f

or the

f

aucet base so that the

f

auc

et

c

an be drawn down tightly.

1

. Fa

uce

t l

oc

ati

o

n:

M

ake sure the

f

aucet stud will be accessible

f

rom below when the hole

is

is

dd

ri

ri

i

ll

ll

ed

ed

.

If

space is not available on the upper sink

ar

ea

ea

, the

f

aucet can be located on the coun

te

te

r

r

to

to

p

p

by the

ed

ed

ge

g

o

f

the sink. I

f

the counter top is cera

mi

mi

c

c

titi

le

le

, the method

f

or drilling the hole wil

l

l

bebe

t

t

h

he

same as

fofo

r

r

po

p

rcelain sinks.

2

2.

Fo

r

S

tainl

ess

S

t

ee

l

S

ink

:

Be

f

ore

us

us

in

in

g

g

a

a

1/2” carbide drill bit, an indent sh

ou

ou

ldld

b

b

e

e

made with a

c

enter punch to keep the drill b

it

it

f

f

roro

o

m

m

walking. A small pilot hole will als

o

o

aiai

d

d

d

th

th

e drill bit.

3

. Se

e

e

Fi

Fi

g.

g.

9,

9

9

A

.

Make sure to align the d

ra

a

inin

ss

adad

d

dl

e hole to the drilled hole p

er

r

fe

fe

ct

ct

ly

ly

gp

y

y

.

y

y

MM

is

is

-a

-a

li

l

gning these two holes will block t

he

d

ra

ra

in

in

water and cause membrane da

ma

ge

.

AtAt

tach th

e

d

rara

a

in saddle to the drain pipe and ti

gh

g

ten

th

th

h

e

e

t

tw

o screws evenl

y.

4

4.

Once the drain saddle is secured

,

,

pupu

sh

sh

1

1

/4

” black drain tubing into the Quic

k

k

Co

Co

n

nn

ect

f

itting on the

sadd

l

e

.

D

O

N

OT use a “Insert”

on

n

t

t

he

he

d

d

rain tubing.

Fig. 9

A

12

Black Locating Washer

Lock Washer

Lock Nut

Faucet Adapter

Tubing

Counter Top

Counter Top

Opening

Please hand tighten only!

Faucet Base

Step 4: Mounting The Faucet

1. Mount the faucet as shown in Fig.10.

Fig. 10

2.

Attach threaded end of faucet adapter to the

faucet metal stem. No teflon tape needed here.

3. Connect the Clear line to the faucet.

4. The faucet has a solid metal handle

that controls the flow of purified water

exiting the faucet. Turn the handle to

horizontal position to release the water

and vertically to shut off.

3. For Porcelain Sink: Porcelain enameled sinks can readily be chipped if care is not exercised

when drilling the hole. Before starting the drill motor, apply firm downward pressure on the bit

until a crunching occurs. This will help keep the drill bit from walking when starting the hole.

A small pilot hole will also aid the drill bit.

Note: Immediately after the hole drilling is done, clean up all metal chips, as metal chips

will stain the porcelain!!

Step 5: Positioning The System

1. Main System: The main system can stand in the sink cabinet. No need

to mount the system to the wall. If you prefer to mount the system to the

wall, please make sure it can be taken down easily for filter replacement.

2. Tank: The storage tank can also lay on its side if needed. The tank works fine in this

position. If the tank cannot fit under the kitchen sink, it can be placed elsewhere up to 20 feet

away from the RO system without much pressure loss.

1

2

B

l

a

ck

L

ocatin

g W

W

ash

ash

er

er

Loc

c

k

k

Wa

Wa

W

she

she

r

r

Lo

c

k

Nut

LkNt

Fa

u

cet A

d

a

p

t

e

r

T

u

b

in

g

Cou

nte

nte

r

r

ToTo

p

p

C

ounter Top

Ope

nin

g

P

lease hand tighten o

nly

!

F

auc

c

et B

a

se

Step 4: Mounting The Fauce

t

1. Mount t

he

e

f

f

f

au

a

cet as shown in

Fi

g.10.

Fig. 1

0

2.

At

ta

ta

ch

ch

t

t

hr

hr

h

e

ea

ded end o

f

f

aucet adapter to the

fa

fa

uc

uc

et

et

m

m

etal stem. No te

f

lon tape needed h

er

r

e.e.

3.

3.

Connect the

C

l

ea

r

l

ine to the

f

auc

et

et

.

4.

The

f

aucet has a solid metal

h

h

anan

dl

dl

e

e

that controls the

f

low o

f

pu

u

ri

ri

fi

fi

ed

ed

wate

r

e

xiting the

f

aucet.

Tu

Tu

rn

rn

r

t

t

he

h

h

andle to

horizontal positio

n

n

n

toto

r

r

elel

e

ea

se the wate

r

and vertically to

sh

h

utut

oo

ffff

..

3.

F

F

or

or

P

P

o

r

ce

lain

S

ink

:

Porcelain enameled

si

si

nknk

s

s

ca

ca

n readily be chipped i

f

care is

no

t

t

exex

er

er

ci

sed

wh

wh

en drilling the hole. Be

f

ore starting

th

th

e

e

drdr

il

l motor, apply

f

irm downward

p

p

re

ss

ur

e

e

o

on

the bit

until a crunching occurs. This will he

lp

k

k

k

e

ee

e

p

the drill bit

f

rom walking whe

n

n

stst

arar

titi

ng

n

t

t

he hole.

A small pilot hole will also a

id

d

tt

hehe

dd

ri

ri

r

ll

b

b

it

.

N

ote

:

Immediately a

f

ter the

ho

o

o

le

le

d

d

ri

r

lling is done, clean up all metal chips, as metal chips

will stain the porcelain!!

Step 5: Positioning The Syste

m

1.

M

ain System

:

The main system can stand in the sink cabinet. No need

to mount the system to the wall. I

f

you

pr

ef

e

er to mount the system to the

wall, please make sure it can be taken

dd

ow

ow

n

n

easily

f

or

f

ilter replacement.

2.

2.

2

Ta

nk: The storage tank can als

o

o

la

la

y

y

on

on

its side i

f

needed. The tank works

fi

fi

ne

ne

in

h

th

is

position. I

f

the tank cannot

f

it

uu

ndnd

er

er

t

t

he kitchen sink, it can be placed el

se

se

wh

wh

erer

e

e

up to 20

f

eet

away

f

rom the RO system

wi

wi

w

th

th

ou

ou

o

t much pressure loss.

13

Step 6: Connecting The System

Summary of Tubing Connections:

There are 4 connections: See Fig. 11 and 11A

Point A to X: Connect RO to COLD water supply — Red tubing.

Point G to Y: Connect product water from 5

th

-stage filter to tank — Yellow tubing. This tubing

is a 2-way line, Product water enters and leaves the tank via this line.

Point H to Z: Connect product water from 5

th

-stage output to RO faucet — Clear tubing.

Drain line to W: Connect waste water from 4

th

-stage membrane to drain outlet — Black tubing.

Please Note: The diagram below is for our Non Pump RO-90 and RO-PH90. If you are install

ing the RO-Pump, please refer to the diagram in the addendum.

Fig. 11

1

3

St

S

ep

6

6

: Connecting The Syste

m

Su

mmary o

f

Tubing Connecti

on

on

s:s:

T

h

e

r

e

a

r

e

4

co

nn

ec

ti

o

n

s:

See Fig. 11 and 11A

Po

int

A

to

A

X

:

Connect RO to COLD water supply

—

Re

Re

d

tubing.

Po

int

G

t

o

Y

:

:

Connect product water

f

rom 5

th

-

s

ta

a

gege

g

f

f

il

il

te

te

r to tank

—

Yellow

tubing. This tub

in

in

gg

w

i

s a 2-way line, Product water e

nt

nt

er

er

s

an

an

d

leaves the tank via this line.

Po

in

n

t

t

H

H

t

t

o o

Z

:

Connect product water

f

r

om

m

5

5

5

th

th

-

-s

tage output to RO

f

aucet

—

Clear

t

t

t

ub

ub

inin

g.

g.

r

Dr

Dr

a

ai

n lin

e

t

o

W

:

Connect waste water

fr

fr

om

m

4

th

-

stage membrane to drain outlet

—

Bl

Bl

ac

ac

k

k

tubing.

k

Please Not

e:

The diagr

am

m

b

b

elel

ow

o

is

f

or our Non Pump RO-90 and R

O-

O

PH

PH

90

90

. I

f

you are install

ing t

he

he

e

R

R

O-

Pu

Pu

mp, please re

f

er to the diagram in the addendum.

Fi

g.

1

1

14

Fig. 11A

Details on Tubing Connections:

To ensure a smooth and correct installation, please connect the water lines following the se-

quence and order outlined below. Refer to Fig.11 & 11A for proper point locations.

1. Point Z Faucet connection:

Tubing color: Clear tubing. Connect the CLEAR tubing to the base of the RO faucet.

Fitting type: Quick Connect Fitting. Simply push Clear tubing into Quick Connect fitting. No Insert,

Sleeve or Nut needed here. (Attach threaded end of faucet adapter to the faucet metal

stem. No teflon tape needed here)

2. Point X Feed water connection:

Tubing color: Red tubing. Connect the RED tubing to the Feed Water Needle Valve.

Fitting type: Metal compression nut fitting.

See Fig.1B on page 4. Use plastic sleeve.

Add “insert” to tubing. No teflon tape here. Tighten nut with wrench.

Tips!

If Point X leaks after you have tightened the brass nut, check to make sure you did put the

plastic “insert and sleeve” onto the tubing. If the insert is already in place, then try

applying Teflon tape from the threaded metal stud all the way to the plastic tubing, wrap

the whole connection with 8-10 rounds of Teflon tape. Smooth out the tape on the

threaded part with your fingers. Tighten brass nut again. This should stop the leak.

If the plastic sleeve is damaged, you can use the metal sleeve, but you need to apply

Teflon tape as described above, this should stop the leak.

1

4

Fig. 11

A

Details on Tubing

Co

Co

nnnn

n

ec

ec

tions:

To ensure a smooth and correct installation, please connect the water lines

f

ollowing the s

e

-

quence and order

outlined below. Refer to

r

Fig.11

&

&

&

&

1

1

1A

1A

for proper point locations.

A

1.

P

P

oi

o

nt

Z

Fa

uc

et

c

on

ne

ct

io

n:

TuTu

bibi

b

n

ng

color: Clear tubi

ng

. Connect the

CL

L

EA

EA

R

R

tu

t

bi

ng

to the base o

f

the RO

f

aucet.

Fi

Fi

t

tt

ing type:

Q

uick Connect

F

i

tting.

Si

mp

mp

m

ly

y

push Clear tubing into Quick Connect

fi

fi

tt

tt

inin

g.g.

g

N

N

o Insert,

Sleeve or Nut needed

h

h

er

er

e.e.

.

(

(

At

A

tach threaded end o

f

f

aucet adap

te

e

r

r

toto

t

t

he

he

f

f

aucet metal

s

tem. No te

f

lon ta

pe

pe

nn

eeee

de

de

d here

)

2

.

P

o

int X Feed water

c

c

on

on

ne

ction

:

Tubing color

:

R

ed t

ub

ub

in

in

g.

g.

C

C

o

on

nect the RED tubing to the Feed Water

Ne

Ne

ed

ed

le Valve.

F

itting type:

M

etal

co

co

mp

mp

r

re

ssion nut

f

itting.

See

Fig.1B

on

page

4

.

Use

plastic sleeve.

Ad

d

“i

ns

er

t”

to tubing. No te

f

lon tape here. Tighten nut with wrench.

T

i

ps!

If

Point X leak

s

a

f

ter you have tightened the brass nut, check to make sure you did

pupu

t t

thth

e

e

pl

astic “insert and sleeve” onto the tubi

ng

. I

f

the insert is alrea

dy

in

pl

ace, then

tr

tr

y

y

applying

T

eflon tape from the th

re

re

ad

ad

a

ed metal stud all the way to the plastic tub

in

in

g,

g,

w

w

ra

ra

p

T

T

the whole connection with 8-

10

0

r

r

ouou

nd

n

s o

f

Te

f

lon tape. Smooth out the tape

on

on

t

t

hehe

threaded part with your

f

i

ng

ng

er

er

s.s.

TT

T

ig

ig

hten brass nut again. This should st

op

p

t

t

he

he

l

l

e

ea

k

k.

If

the plastic sleeve

is

dd

am

am

ag

ag

ed, you can use the metal sleeve, but

yo

yo

u

u

nene

ed

ed

to apply

Te

f

lon tape as des

cr

cr

c

ibib

eded

e

above, this should stop the leak.

15

3. Point W Waste water connection:

Tubing color: Black tubing. Connect the BLACK tubing from the RO to the Drain Saddle.

Fitting type: Quick-Connect fitting on drain saddle. No teflon tape.

Do Not add ”insert” into Black tubing. Simply push tubing into port.

4. Point A System water inlet (to Stage 1 prefilter) connection:

Tubing color: Red tubing. Connect the RED tubing from the Feed Water Valve to the RO’s stage -1

pre-filter.

Fitting type: Quick Connect fitting

See Fig.1 on page 4. Simply push the Red tubing into the Quick

Connect fitting. No Inserts, Sleeves or Nuts are needed to secure the connection. No

teflon tape is needed here.

5. Point H Stage-5 filtered water to faucet connection:

Tubing color: Clear tubing. Connect the CLEAR tubing from the faucet base stud to the Stage-5 filter’s

outflow end at point H. (See “Flow -->” arrow on the filter for flow direction.)

Fitting type: Quick Connect fitting

See Fig.1 on page 4. Simply push the Clear tubing into outlet

on the 5th stage filter. No Inserts, Sleeves or Nuts are needed to secure the

connection. No Teflon tape is needed here.

Please Note: There are two end plugs on the stage-5 filter that has to be removed before

inserting the tubing. Please refer to Fig. 1A on page 4 for removal instruction.

6. Point G Stage-5 filter’s T-fitting connection:

Tubing color: Yellow tubing. Connect the YELLOW tubing to Stage-5 filter’s T-fitting.

Fitting type: Quick Connect fitting

See Fig.1. Simply push the Yellow tubing into the 5th stage filter’s

T Fitting. No Inserts, Sleeves or Nuts are needed to secure the connection. No Teflon tape

needed here.

(Note: If the unit comes with a UV Light, connect the Yellow tubing to the T- fitting on the

UV, as the Stage 5 filter will not have a T-fitting).

15

3.

3

P

P

o

oi

nt

W

W

aste water connection:

W

W

T

Tu

bing color

:

B

lack tubing. Conn

ec

c

t t

thth

e e

BL

BL

AC

AC

K tubing

f

r

om

th

e

R

O

t

o

th

e

Dr

a

in

S

ad

ad

dldl

d

e.e.

F

itting type:

Q

uic

k

-

Connect

f

itti

ng

g

g

oo

nn

drdr

ai

ai

a

n saddle. No te

f

lon tape.

Do

N

ot add ”inser

t”

”

i

i

i

nt

nt

o

o

B

Bl

ack tubing. Simply push tubing into port.

4.

P

oi

nt

A

System water inlet (to Stage 1 pre

f

ilter) connection

:

Tubi

ng

color

:

R

ed tubin

g.

Connect the RED tubin

g

f

r

om

the

F

F

eeee

d

d

d

Water Valve to the RO’s st

ag

e -1

pr

pr

p

e-

e

f

ilter.

F

itting type:

QuQu

ic

ic

i

k Connect