Page

CONTENTS

1. PRODUCT NAME...........................................................................................................................1

2. MARKETING OBJECTIVE .............................................................................................................1

3. APPLICATIONS..............................................................................................................................1

4. SELLING POINTS ..........................................................................................................................1

4-1. Selling Point Descriptions .............................................................................................................. 2

5. SPECIFICATIONS ..........................................................................................................................3

6. COMPARISONS WITH SIMILAR PRODUCTS ..............................................................................5

7. ORBITAL MECHANISM .................................................................................................................6

7-1. Blade Movement............................................................................................................................ 6

7-2. Orbital Position Selection............................................................................................................... 6

8. BLADES .........................................................................................................................................7

9. PRECAUTIONS IN SALES PROMOTION .....................................................................................8

9-1. Handling Instructions ..................................................................................................................... 8

9-2. Name Plate .................................................................................................................................... 8

10. PRECAUTIONS IN DISASSEMBLY AND REASSEMBLY ..........................................................9

10-1. Disassembly ................................................................................................................................ 9

10-2. Reassembly ............................................................................................................................... 14

10-3. Wiring Diagrams ........................................................................................................................ 16

10-4. Insulation Tests .......................................................................................................................... 17

10-5. No-Load Current Value .............................................................................................................. 17

11. STANDARD REPAIR TIME (UNIT) SCHEDULES......................................................................18

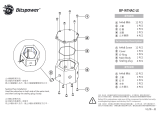

Assembly Diagram for CJ 120V

Assembly Diagram for CJ 120VA