Page is loading ...

M968484

Thank you for selecting American-Standard...the benchmark of fine quality for over 100 years.

To ensure that your installation proceeds smoothly--please read these instructions carefully

before you begin.

Installation Instructions

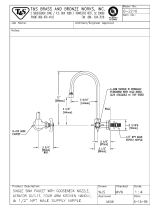

ROUGHING-IN DIMENSIONS

7271.3017271.300

7271.5217271.571

7271.021

7

271.

5

2

1

7

271.

0

21

7271.071

7271.571

7271.071

7271.400

7271.400

LABORATORY FUME HOOD FITTINGS

DIA.

[32mm]

1-1/4"

[89mm]

3-1/2"

DIA.

[54mm]

2-1/8"

[57mm]

2-1/4"

1-3/4"

[45mm]

[24mm]

15/16"

[67mm]

2-5/8"

3/8" NPT FEMALE

THREAD OUTLET

3/8" NPT

FEMALE

THREAD INLET

INDEX A

S

RE

QU

IRE

D

(

AIR, GAS, OR VAC

)

DIA.

[32mm]

1-1/4"

1/16"-

[2mm-32mm]

WARE THICKNESS

1-1/4"

1/16"-

[2mm-32mm]

WARE THICKNESS

1-1/4"

[89mm]

3-1/2"

DIA.

[54mm]

2-1/8"

[57mm]

2-1/4"

[24mm]

15/16"

1-3/4"

[45mm]

[57mm]

2-1/4"

3/8" NPT FEMALE

THREAD OUTLET

3/8" NPT FEMALE

THREAD INLET

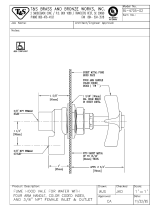

INDEX 'CW'

PANEL THI

C

KNE

SS

N

O

T T

O

EX

C

EE

D

[

3mm

]

1

/

8

"

4

5

˚

3"

[76mm

]

1-

3/

4

"

[

44mm

]

[

44mm

]

1-3

/

4

"

[

51mm

]

I

A. FLAN

GE

2"

[

32mm

]

1-1

/

4

"

[

7mm

]

9

/

32

"

1-5/8" [41mm]

HEX. N

U

L

OC

K D

O

PROVIDE 1-1/2"

[

38mm

]

DIA

.

O

PENIN

G

IN PANEL T

O

A

CC

EP

T

1-7/16"

[

37mm

]

DIA. BOD

Y

IN

OUT

N

O

TE

:

I

NLET ALWAY

S

O

N B

O

TT

OM

3

/

8" NPT FEM

.

INLET THRD.

3

/

8" NPT FEM

.

OU

TLET THRD

.

INDEX A

S

RE

QU

IRE

D

(

AIR, GAS, VAC

)

[

54mm

]

2-1/8"

1

/

16"

-

[

2mm-32mm

]

WARE THICKNESS

1-1

/

4

"

[54mm]

DIA. FLAN

GE

2-1/8

DIA.

[

17mm

]

11/16

"

"

[

102mm

]

4

3/8

" NPT MALE

THREAD INLET

Product names listed herein are trademarks of American Standard Inc.

©American Standard Inc. 2004

HOTLINE FOR HELP

For toll-free information and answers to your questions, call:

1 (800) 442-1902

Weekdays

8:00 to 7:00 p.m. Eastern Time

CANADA

1-800-387-0369 (TORONTO 1-905-306-1093)

M968484

R

OUG

HIN

G

-IN DIMEN

S

I

O

N

S

T

OO

L

S

AND

SU

PPLIE

S

RE

QU

IRE

D

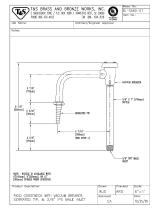

7271.301 7271.300

3

˚

3

˚

[29mm

]

1-1

/

8

"

[

51mm

]

2

"

[

7

3

mm

]

" DIA.

[

51mm

]

2

[

152mm

]

6"

[

273mm

]

10-3

/

4

"

[

114mm

]

4-1/2

"

[

38mm

]

1-1

/

2

"

3

/

8" NPT FEMALE

THREAD INLET

3

/

8" NPT FEMALE

THREAD INLET

[29mm

]

1-1

/

8

"

[

51mm

]

2"

[

7

3

mm

]

2-7

/

8

"

" DIA.

[

51mm

]

2

[

137mm

]

5-3/8"

[114mm

]

4-1

/

2

"

[279mm

]

11"

Adjustable Wrench

Channel Locks

Flat Blade Screwdriver

Phillips Screwdriver

Pipe Wrench

Teflon Tape

Plumbers' Putty or

Caulking

1

2

3

4

FR

O

NT-L

O

ADED VALVE F

O

R AN

G

LED PANEL

S

(

AIR, GAS, VACUUM, WATER

)

FR

O

NT-L

O

ADED VALV

E

F

O

R

S

TRAI

G

HT PANEL

S

(

AIR, GAS, VACUUM OR WATER

)

TYPI

C

AL F

U

ME H

OOD

F

U

ME H

OO

D FITTIN

GS

WALL M

OU

NTED REM

O

T

E

CO

NTR

O

L

OU

TLET FITTIN

G

For installation of

p

roducts refe

r

t

o ste

p

s one to four

.

WALL M

OU

NTED REM

O

T

E

CO

NTR

O

L

OU

TLET FITTIN

G

M

968

4

84

1

2

B

O

D

Y

S

H

OU

LDER WA

S

HE

R

H

O

LD D

O

WN N

UT

CARTRIDGE STEM

HANDLE

SC

RE

W

Im

p

ortant service note

:

T

he Faucet Panel mounted fume hood fittin

g

has been desi

g

ned such that future servicin

g

of th

e

f

ittin

g

's cartrid

g

e can be done from the (user's) side of the fume hood. To do this, insure that th

e

main suppl

y

valve to the fittin

g

has been completel

y

turned off and then pur

g

ed b

y

completel

y

o

penin

g

the fittin

g

and releasin

g

trapped material into the fume hood atmosphere. Then, suppor

t

t

he entire fittin

g

b

y

holdin

g

the hold-down nut in place with a wrench, before loosenin

g

th

e

c

artrid

g

e's cap nut

.

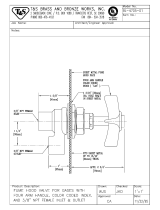

T

his Panel mounted fume hood valve has been shi

pp

ed as shown below to ease installation. It i

s

d

esi

g

ned to be installed in a 4

5

˚

angled fume hood equipped with 1-1/2" (38.1mm) diameter

˚

mountin

g

holes. Before proceedin

g

with the installation, identif

y

and familiarize

y

ourself with al

l

o

f the com

p

onents

.

Important Note: The front load fume hood fittin

g

s described in these installation instruction

s

a

re available in both ri

g

ht hand and left hand models. Ri

g

ht hand models are marked on bot

h

sides of the bod

y

with an "R" and left hand models are similar marked with an "L". Due to th

e

u

se of these fittin

g

s in both ri

g

ht and left hand fume hoods, the bodies are marked on bot

h

sides with directional flow arrows. Re

g

ardless of the model used, the fittin

g

s are desi

g

ned t

o

be

in

sta

ll

ed

suc

h

t

h

at

t

h

e

inl

et

i

s

o

n

t

h

e

botto

m

.

4

5

˚

AN

G

LE

D

F

U

ME H

OOD

L

OC

K N

UT

FLAN

GE

VALVE

H

OO

D M

OU

NTIN

G

H

O

L

E

C

R

OSS

HANDL

E

C

AP N

UT

PACKING NUT (7271.571 and 7271.521 ONLY)

INSTALL FRONT-LOADED ANGLE CONTROL VALVE

,

7271.021/52

1

(

AIR, GAS, VACUUM, WATER

)

INSTALL FRONT-LOADED VALVE FOR STRAIGHT PANELS

,

7271.071/571

(

AIR, GAS, VACUUM, WATER

)

HANDLE SCRE

W

N

DEX B

U

TT

ON

S

TEEL WA

S

HE

R

R

U

BBER WA

S

HE

R

B

O

D

Y

FI

GU

RE

1

S

H

OU

LDE

R

WA

S

HE

R

1-1/2"

(

38.1mm

)

M

OU

NTIN

G

H

O

L

E

H

O

LD D

O

WN N

UT

R

e

m

o

v

e

a

n

d

flan

ge

fr

o

m v

a

lv

e

.

Rubber seal washer

,

steel washe

r

a

n

d

l

oc

k n

ut

v

a

lv

e

Ali

g

n the mounted

a

r

e

in lin

e

a

n

d

t

h

e

v

a

lv

e

a

n

d

v

a

lv

e

bod

y

securel

y.

Wi

t

h v

a

lv

e

now firml

y

secured to the fume hood install the ca

p

nu

t

cro

ss

handl

e

a

n

d

secu

r

e

wi

t

h handle

s

crew

.

in

de

x

button

in

to

h

a

n

d

l

e

cou

n

te

r

bo

r

e.

Complete the inlet and outlet pipin

g

to the v

a

lv

e

a

n

d

c

h

ec

k f

o

r l

ea

k

s.

HANDLE SCREW

INDEX B

U

TT

O

N

S

(

AIR, GAS, VACUUM, WATER

)

HANDLE

S

TE

M

FI

GU

RE

2

4

5

˚

AN

G

LE

D

F

U

ME H

OOD

IMP

O

RTANT: FL

US

H ALL

SU

PPLY LINE

S

PRI

O

R T

O

FITTIN

G

IN

S

TALLATI

O

N

.

IMPORTANT: FLUSH ALL SUPPLY LINES PRIOR TO FITTING INSTALLATION.

R

e

m

o

v

e

t

h

e

h

o

l

d

-

do

wn n

ut

fr

o

m

t

h

e

body

a

n

d

t

h

e

y

handle

s

cre

w

fr

o

m

t

h

e

s

te

m

.

With a

p

air o

f

body

such that the threads on the two components lock together.

y

Pl

ace

t

h

e

fr

o

n

t

e

n

d

o

f

t

h

e

bod

y

(end which contains the operating cartridge) through the 1-1/2"

y

h

o

l

d

-

do

wn n

ut

o

n

to

t

h

e

bod

y

h

o

l

d

-

do

wn n

ut

at

t

hi

s

t

im

e.

Align the mounted fitting from the backside of the fume hood such that the

bod

y

'

s

inl

et

a

n

d

out

l

et

a

r

e

in lin

e

a

n

d

t

h

e

su

pp

ort the valve bod

y

from the backside, tighten the

y

h

o

l

d

-

do

wn n

ut

securel

y.

h

a

n

d

l

e

o

n

to

t

h

e

s

te

m

and ti

g

hten i

t

into

p

lace with the

s

cre

w

r

e

m

o

v

ed

fr

o

m

t

h

e

s

tem

.

in

de

x

button

in

to

h

a

n

d

l

e

Complete the inlet and outlet pipin

g

to the fittin

g

a

n

d

c

h

ec

k f

o

r l

ea

k

s.

7

271.

301

7

271.

300

7271.521

7271.571

7271.071

7271.021

7271.400

M968484

3

S

P

OU

T N

UT

SPOUT BOD

Y

RTRIDGE

96

2

3

2

9

-

00

7

0

A L

H

9

62330-0070A R

H

W Index

M96

2

3

12-

00

7

0A

HANDLE

M

96

2

3

1

0

-

00

2

0A

S

P

OU

T A

SS

EMBL

Y

WALL MOUNTED REMOTE

C

ONTRO

L

4

WALL MOUNTED REMOTE CONTROL OUTLET

FITTING

(

GOOSE NECK SPOUTS

)

, 7271.300/30

1

AVAILABLE REPAIR PART

S

L

OC

K N

UT

S

TEEL WA

S

HE

R

H

OO

D M

OU

NTIN

G

H

O

L

E

1-1/4" DIA.

(

32mm

)

R

e

m

o

v

e

l

oc

k n

ut

a

n

d

s

teel wa

s

he

r

from fittin

g.

Ali

g

n and moun

t

fittin

g

from the front side of the fume hood. Usin

g

fittin

g

bod

y

and install

s

tee

l

wa

s

he

r

a

n

d

l

oc

k n

ut.

ti

g

hten the l

oc

k n

ut

securel

y

.

Wi

t

h fittin

g

now firml

y

secured to the fume hood complete the i

n

pipin

g

to the fittin

g.

(See rou

g

h-in for pipin

g

requirements)

.

Turn suppl

y

to fittin

g

o

n

a

n

d

c

h

ec

k f

o

r l

ea

k

s.

Note: See roughing-in to determine pipe nipple length fro

m

s

i

de

w

a

ll

.

T

u

rn s

p

out nu

t

cou

n

te

r

c

l

oc

k-wi

se

to

l

oose

n

a

n

d

r

e

m

o

v

e

spout assembl

y

from

f

ittin

g

base

.

p

i

pe

ni

pp

l

e

(See rou

g

h-in for pipin

g

requirements)

.

Thr

ead

spout body

o

n

to

y

p

i

p

e ni

pp

l

e

and align so tha

t

s

p

ou

t

assembl

y

i

s

v

e

r

t

i

ca

l

.

Thr

ead

spout assembly

o

n

to

y

spout body

and tighten.

y

Turn suppl

y

t

o

fittin

g

o

n

a

n

d

c

h

ec

k f

o

r l

ea

k

s

.

F

U

ME H

OO

D WAL

L

F

U

ME H

OOD

WALL

VA

CUU

M BREAKE

R

REPAIR KIT

M

96

2

3

22-

00

7

0A

GOOS

ENE

C

K

S

P

OUT

M

96

2

3

1

6

-

00

2

0A

S

ERRATED TIP

S

M

96

2

3

1

8

-

00

2

0A

BREAKER SPOUT

M

96

2

3

17-

00

2

0A

FITTIN

G

3

/

8" NP

T

APPLY

S

EALAN

T

C

W In

dex

M96

2

3

12-

00

7

0A

GAS Index

M

96

2

3

1

3

-

00

AIR

M962314-00

VA

C

M

96

2

3

1

5

-

00

VA

C

In

d

M

96

2

3

1

5

-

00

7

HANDLE

M

96

2

3

1

0

-

00

2

0

G

A

S

In

M

96

2

3

1

3

-

007

AIR In

M

96

2

3

14-

007

C

ARTRID

GE

M

96

2

3

2

9

-

00

7

0A

M

96

2

330

-

00

7

0A

C

ARTRID

GE

M

96

2

336

-

00

7

0A

C

ARTR

I

M

96

2

336

-

007

C

ARE INSTRU

C

TIONS

:

DO: SIMPLY RINSE THE PRODU

C

T

C

LEAN WITH

C

LEA

R

WATER. DRY WITH A SOFT COTTON FLANNEL CLOTH.

DO NOT: CLEAN THE PRODUCT WITH SOAPS, ACID,

POLISH, ABRASIVES, HARSH CLEANERS, OR A CLOTH

WITH A COARSE SURFACE.

/