OPERATING INSTRUCTIONS for

F-11-273-N

September, 1997

R-502, R-5007, R-5008

REGULATOR/FLOWMETERS

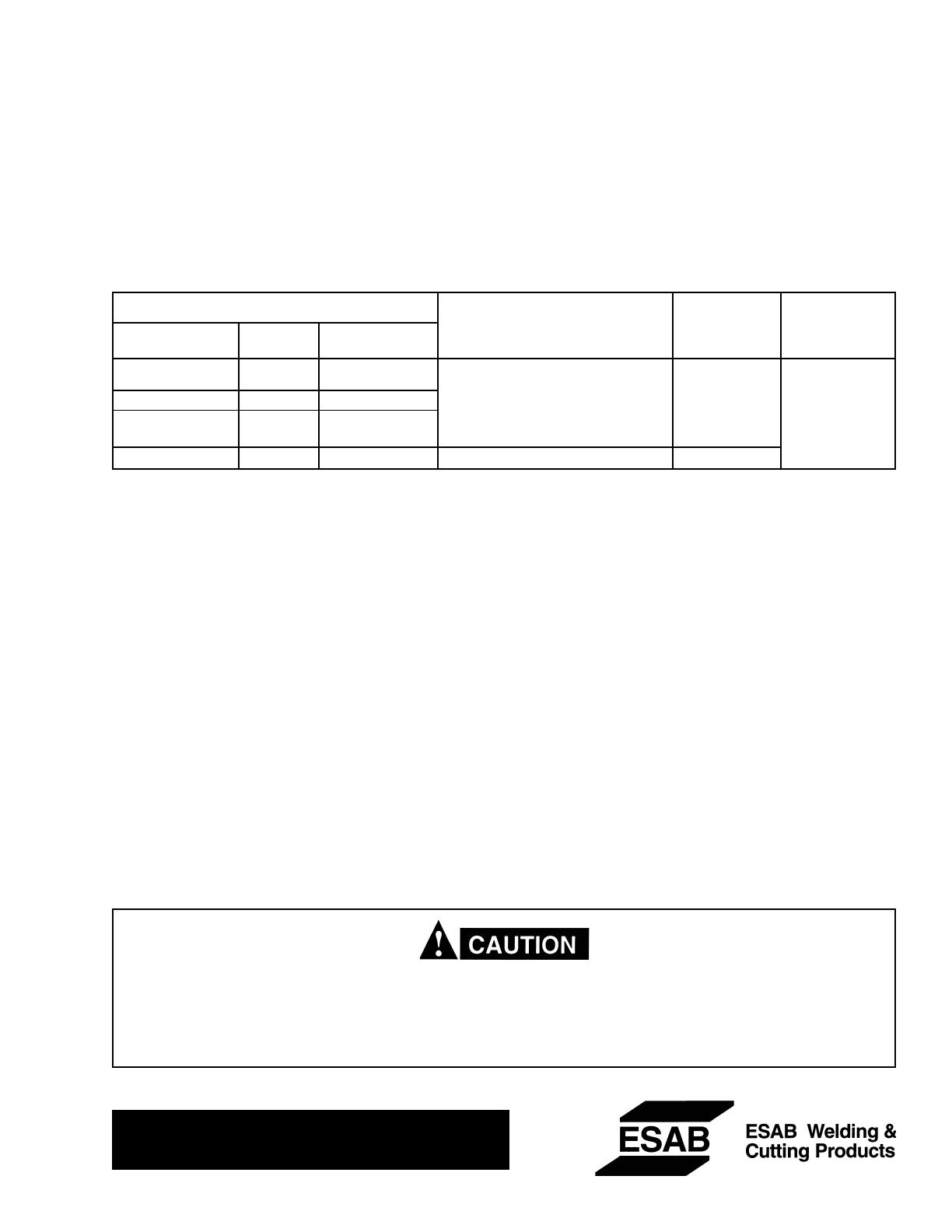

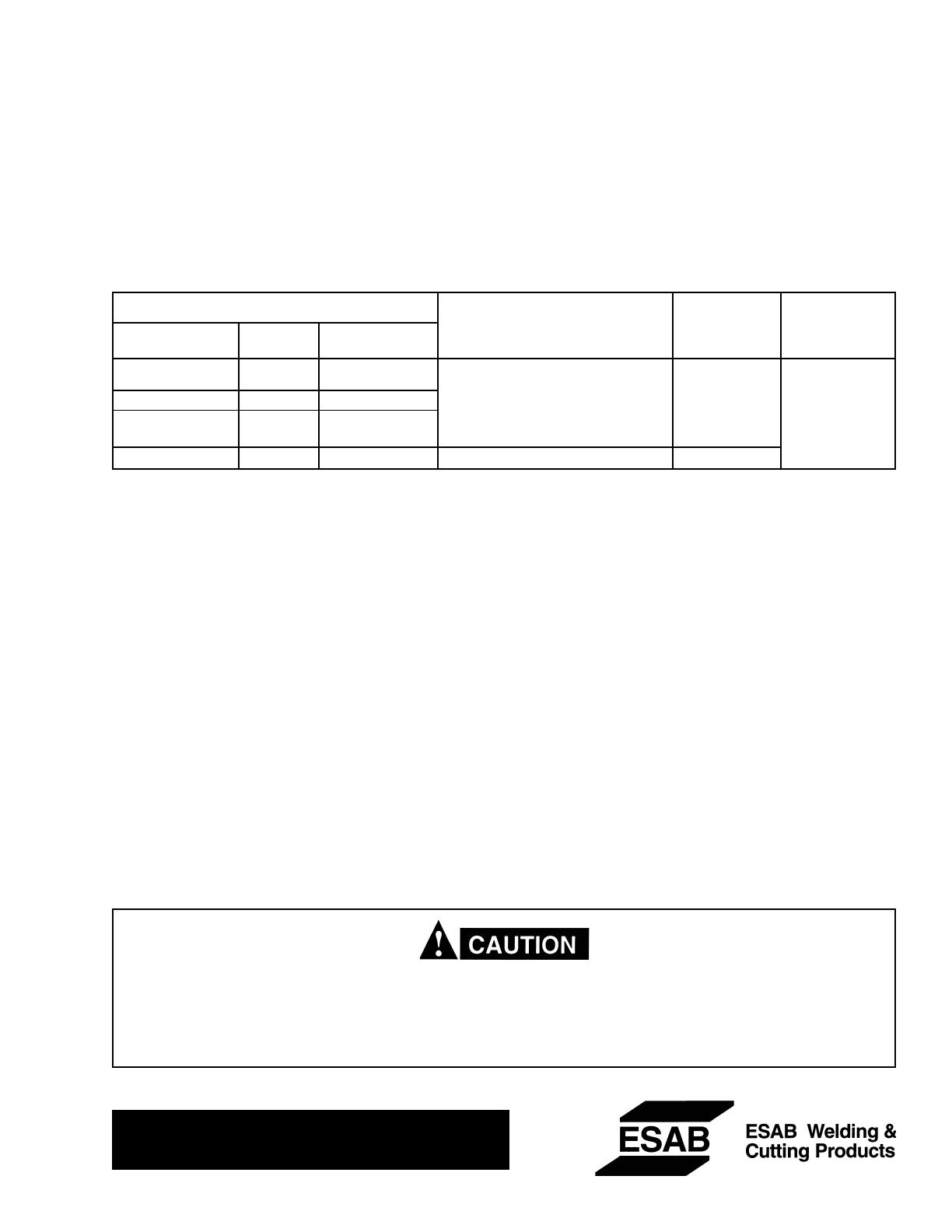

Regulator Gas Service & Inlet Outlet

Calibrated Flow Range, Connection, Connection

Model Part No. Construction cfh (L/min) CGA No. CGA No.

R-502 998846 Two-Stage Argon: 10 - 70 (5 - 33) 580

R-502-FM-680 19018 Two-Stage Helium 20 - 220 (0 - 103) 680 032

C-25*: 10 - 65 (5 - 31) (5/8 ¾18),

R-5007 998124 Single-Stage Nitrogen: 10 - 80 (5 - 38) 580 R.H. Fem.)

R-5008 998125 Single-Stage Carbon Dioxide: 10 - 85 (5 - 40) 320

*75% Argon - 25% CO

2

Mixture

TO CONNECT

1. Open the cylinder valve slightly, for an instant, to

blow out any dust or dirt that may have collected in

the valve outlet. Be sure to keep your face away

from the valve outlet to protect your eyes.

2. Attach the regulator to the cylinder valve, and

tighten the connection nut with a wrench. (Do not

use the flowmeter tube as a handle attaching the

regulator.)

3. Make sure that the flow control valve on the flow-

meter is closed.

4. Open the cylinder valve SLOWLY.

5. Attach hose to the flowmeter outlet and to the equip-

ment with which the gas is to be used. Tighten the

connecting nuts with a wrench.

TO REGULATE FLOW

Flow is controlled by adjusting the flowmeter valve un-

til the desired flow is indicated by the ball float in the

flowmeter tube. Always take the reading across the TOP

of the ball. The outer flowmeter tube (square) can be

rotated by hand to bring the desired scale into position

for convenient reading. Scales for argon, helium, car-

bon dioxide, nitrogen, and C-25 mixture (75 per cent

argon, 25 per cent carbon dioxide) are provided. For

other gas mixtures, consult your gas supplier for the

conversion factor to apply to the reading indicated on

one of the scales. All scales indicate flow in terms of

cubic feet per hour (cfh). The flow readings are accu-

rate within +/- 5% of the maximum calibrated scale

reading for each gas. To convert to liters per minute

(L/min) multiply scale reading by 0.47.

Be sure this information reaches the operator.

You can get extra copies through your supplier.

These INSTRUCTIONS are for experienced operators. If you are not fully familiar with the principles of operation

and safe practices for arc welding equipment, we urge you to read our booklet, Precautions and Safe Practices

for Arc Welding, Cutting, and Gouging, Form 52-529. Do NOT permit untrained persons to install, operate, or

maintain this equipment. Do NOT attempt to install or operate this equipment until you have read and fully under-

stand these instructions. If you do not fully understand these instructions, contact your supplier.