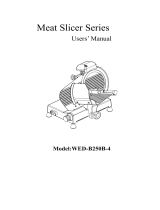

GGM Gastro AMH220N is a semi-automatic meat slicer designed for food use. It can cut ham, frozen meat without bone, fresh meat, and vegetables. The machine features a blade with a diameter of 220mm and a slicing thickness adjustment from 0 to 12mm. It has a 120W motor and operates on a single-phase AC and 50HZ power frequency. The AMH220N is suitable for use in restaurants, hotels, supermarkets, and food processing plants.

GGM Gastro AMH220N is a semi-automatic meat slicer designed for food use. It can cut ham, frozen meat without bone, fresh meat, and vegetables. The machine features a blade with a diameter of 220mm and a slicing thickness adjustment from 0 to 12mm. It has a 120W motor and operates on a single-phase AC and 50HZ power frequency. The AMH220N is suitable for use in restaurants, hotels, supermarkets, and food processing plants.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

GGM Gastro AMH220N is a semi-automatic meat slicer designed for food use. It can cut ham, frozen meat without bone, fresh meat, and vegetables. The machine features a blade with a diameter of 220mm and a slicing thickness adjustment from 0 to 12mm. It has a 120W motor and operates on a single-phase AC and 50HZ power frequency. The AMH220N is suitable for use in restaurants, hotels, supermarkets, and food processing plants.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

Other documents

-

Sentinel PA0185 Operating instructions

-

Brice CX35E Operation And Safety Manual

Brice CX35E Operation And Safety Manual

-

Pantheon MS300 Operating instructions

-

American Eagle AE-MS12 Operating instructions

American Eagle AE-MS12 Operating instructions

-

SUPER DEAL T61 User manual

SUPER DEAL T61 User manual

-

Univex 1000s Operating instructions

-

Avantco SL310 User manual

-

BestEquip Commercial Food Slicer 10 inch Blade 530 RPM Commercial Electric Meat Slicer 240W for Commercial and Home Use User manual

BestEquip Commercial Food Slicer 10 inch Blade 530 RPM Commercial Electric Meat Slicer 240W for Commercial and Home Use User manual

-

Univex 1000M Operating instructions

-

Cecilware HDPS-12 User manual