ESAB Precision PLASMARC® Cutting and High Speed Marking System with Integrated Flow Control Installation guide

- Category

- Welding System

- Type

- Installation guide

This manual is also suitable for

F-15-650

December, 2001

Rev B

Installation, Operation and Maintenance Manual for the

Precision PLASMARC

Cutting

and High Speed Marking SYSTEM

with Integrated Flow Control

411 s. Ebenezer Road

Florence, SC 29501-0545

The equipment described in this manual is

potentially hazardous. Use caution when installing,

operating and maintaining this equipment.

Purchaser is solely responsible for the safe

operation and use of all products purchased,

including compliance with OSHA and other

government standards. ESAB Cutting

Systems has no liability for personal injury or

other damage arising out of the use of any

product manufactured or sold by ESAB. See

standard ESAB terms and conditions of sale

for a specific statement of ESAB’s

responsibilities and limitations on its liability.

ESAB Cutting Systems first priority is total customer

ESAB Cutting Systems first priority is total customer ESAB Cutting Systems first priority is total customer

ESAB Cutting Systems first priority is total customer

satisfaction. We constantly look for ways to

satisfaction. We constantly look for ways to satisfaction. We constantly look for ways to

satisfaction. We constantly look for ways to

improve our products, service and documentation.

improve our products, service and documentation. improve our products, service and documentation.

improve our products, service and documentation.

As a result, we make e

As a result, we make eAs a result, we make e

As a result, we make en

nn

nhancements and/or de

hancements and/or dehancements and/or de

hancements and/or design

sign sign

sign

changes as r

changes as rchanges as r

changes as re

ee

equired. ESAB makes every possible

quired. ESAB makes every possible quired. ESAB makes every possible

quired. ESAB makes every possible

effort to ensure our documentation is current. We

effort to ensure our documentation is current. We effort to ensure our documentation is current. We

effort to ensure our documentation is current. We

cannot guarantee that each piece of docume

cannot guarantee that each piece of documecannot guarantee that each piece of docume

cannot guarantee that each piece of documen

nn

ntation

tation tation

tation

received by our customers reflects the latest design

received by our customers reflects the latest design received by our customers reflects the latest design

received by our customers reflects the latest design

enhancements. Therefore, the information

enhancements. Therefore, the information enhancements. Therefore, the information

enhancements. Therefore, the information

contain

containcontain

contained in this document is subject to change

ed in this document is subject to change ed in this document is subject to change

ed in this document is subject to change

without n

without nwithout n

without no

oo

otice.

tice.tice.

tice.

This manual is ESAB Part Number F15650

This manual is ESAB Part Number F15650This manual is ESAB Part Number F15650

This manual is ESAB Part Number F15650

Revision A was made to include CE parts and

Revision A was made to include CE parts and Revision A was made to include CE parts and

Revision A was made to include CE parts and

Drawings

DrawingsDrawings

Drawings

Rev B new IFC Schematic, install Instructions

Rev B new IFC Schematic, install Instructions Rev B new IFC Schematic, install Instructions

Rev B new IFC Schematic, install Instructions

(p13,14)

(p13,14)(p13,14)

(p13,14)

Rev B December 2001, Added parts Section 7,

Rev B December 2001, Added parts Section 7, Rev B December 2001, Added parts Section 7,

Rev B December 2001, Added parts Section 7,

p34,

p34,p34,

p34,35; updated wiring to solenoid section 6 &7

35; updated wiring to solenoid section 6 &735; updated wiring to solenoid section 6 &7

35; updated wiring to solenoid section 6 &7

This manual is for the convenience and use of the

cutting machine purchaser. It is not a contract or

other obligation on the part of ESAB Cutting

Systems.

©

©©

© ESAB Cutting Systems, 2001

Printed in U.S.A.

Precision Plasma Integrated Flow Control Table of Contents

i

Page

Section 1 Safety

1.1 Introduction.......................................................................................... 1

1.2 Safety Notations And Symbols.............................................................. 1

1.3 General Safety Information.................................................................... 2

1.4 Installation Precautions......................................................................... 3

1.5 Electrical Grounding ............................................................................. 4

1.6 Operating A Plasma Cutting Machine.................................................... 4-9

1.7 Service Precautions.............................................................................. 9

1.8 Safety References ................................................................................ 10

Section 2 Description

2.1 General................................................................................................ 1

2.2 Scope.................................................................................................. 1

2.3 Package Options Available ................................................................... 1

2.4 Technical Specifications

2.4.1 Precision Plasma System.............................................................. 2

2.4.2 Plasma Gas.................................................................................. 3

2.4.3 Start Gas...................................................................................... 3

2.4.4 Secondary Gas............................................................................. 3

2.4.5 Cut Gas........................................................................................ 3

2.4.5 PT-24 Torch................................................................................. 4

Section 3 Installation

3.1 General................................................................................................ 1

3.2 Equipment Required............................................................................. 1

3.3 Location............................................................................................... 1

3.4 Primary Electrical Input Connections..................................................... 2-3

3.5 Alternate Connection Locations for IFC ................................................. 4

3.6 IFC Basic Component Identification ...................................................... 4

3.7 Interconnecting Lines ........................................................................... 5-10

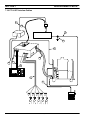

3.8 Precision Plasmarc Component Interconnecting Diagram...................... 7

3.9 Torch Mounting.................................................................................... 11

3.10 Torch Coolant ..................................................................................... 12

3.11 Inspection Of Gas And Coolant Lines................................................... 12

Precision Plasma Integrated Flow Control Table of Contents

ii

Section 4 Operation

4.1 Power Supply Controls ........................................................................

.

4.1.1 Main Power Switch ......................................................................

.

1

4.1.2 Pilot Arc Switch............................................................................

.

1

4.1.3 Fault Indicator Lights....................................................................

.

2

4.1.4 Meters .........................................................................................

.

2

4.1.5 Current Control Switch.................................................................

.

2

4.2 Cut Quality

4.2.1 Introduction .................................................................................

.

3

4.2.2 Cut Angle.....................................................................................

.

3

4.2.3 Cut Flatness.................................................................................

.

4

4.2.4 Surface Finish ..............................................................................

.

5

4.2.5 Dross...........................................................................................

.

6-7

4.2.6 Dimensional Accuracy..................................................................

.

8

4.3 Influence of Gas Options on Cut Quality

4.3.1 Introduction .................................................................................

.

9

4.3.2 Aluminum.....................................................................................

.

9

4.3.3 Carbon Steel................................................................................

.

10

4.3.4 Stainless Steel..............................................................................

.

11

4.4 Process Data

4.4.1 Introduction .................................................................................

.

13

4.4.2 Process Data Settings..................................................................

.

14-55

Aluminum..............................................................................

.

14-21

Carbon Steel.........................................................................

.

22-31

Stainless Steel.......................................................................

.

32-55

4.4.3 Relationship of Kerf Width to Amperes and Material Thickness......

.

56

4.4.3.1 Aluminum Kerf Values...........................................................

.

56

4.4.3.2 Carbon Steel Kerf Values......................................................

.

58

4.4.3.3 Stainless Steel Kerf Values O

2

/N

2

/O

2

.....................................

.

61

4.4.3.4 Stainless Steel Kerf Values Air/Air/CH

4

.................................

.

62

4.4.3.5 Stainless Steel Kerf Values N

2

/N

2

/CH

4

..................................

.

63

4.4.3.6 Stainless Steel Kerf Values N

2

/N

2

..........................................

.

64

4.4.3.7 Stainless Steel Kerf Values Air/Air ........................................

.

66

Plasma Marking Data ...........................................................

.

68

Precision Plasma Integrated Flow Control Table of Contents

iii

Section 5 Maintenance

5.1 General................................................................................................ 1

5.2 Inspection and Cleaning ....................................................................... 1

5.3 PT-24 Torch Description....................................................................... 2-4

5.4 IFC Fluid Schematic.............................................................................. 3

5.4 Torch Maintenance............................................................................... 5-6

5.5 PT-24 Consumable Disassembly and Inspection................................... 7-10

5.6 PT-24 Torch Re-Assembly.................................................................... 10-11

5.7 Flow Control......................................................................................... 12

5.8 Proportional Valve Removal .................................................................. 13

Section 6 Troubleshooting

6.1 General Safety...................................................................................... 1

6.2 Troubleshooting Guide ......................................................................... 1

6.2.1 Reduced Consumable Life............................................................ 2

6.2.2 Poor Cut Quality ........................................................................... 2

6.2.3 No Pilot Arc..................................................................................

6.2.4 No Arc Transfer ............................................................................ 3

6.2.5 No Preflow ................................................................................... 4

6.2.6 Torch Fails to Fire ......................................................................... 4

6.2.7 Nozzle Life Extremely Short........................................................... 4

6.2.8 Short Electrode Life ...................................................................... 4

6.2.9 Short Electrode AND Nozzle Life................................................... 4

6.3 IFC Fluid Schematic.............................................................................. 5

IFC Manifold Valve Identification.................................................... 5

6.4 IFC Electrical Schematic ....................................................................... 6-7

6.5 Precision Plasma Power Source Electrical Schematic............................ 8-9

6.6 Precision Plasma Power Module Wiring Diagram................................... 10-11

6.7 Power Module Schematic..................................................................... 12

6.8 Power Module Schematic – CE Version ................................................ 13

6.9 Power Module Wiring Diagram – CE Version ......................................... 14-15

6.8 Precision Plasma Power Source Wiring Diagram (includes CE Version) 16-20

6.9 Torch Manifold ..................................................................................... 21

Precision Plasma Integrated Flow Control Table of Contents

iv

Section 7 Replacement Parts

7.1 General................................................................................................

.

1

7.2 Ordering ..............................................................................................

.

1

7.3 Plasmarc Power Source – Exterior Components...................................

.

2-7

7.4 Plasmarc Power Source – Internal Components ...................................

.

8-17

7.5 Power Source Module..........................................................................

.

18-25

7.6 IFC ......................................................................................................

.

26-27

7.7 IFC Manifold ........................................................................................

.

28-29

7.8 PT-24 Torch Assembly IFC Series with Marking...................................

.

30-31

7.9 Torch Manifold with marking.................................................................

.

32-33

7.10 System interfacing..............................................................................

.

34-35

Customer/Technical Information Back Manual Cover

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-1

DANGER

!

WARNING

!

CAUTION

!

CAUTION

NOTICE

1.1 Introduction

The process of cutting metals with plasma equipment

provides industry with a valuable and versatile tool.

ESAB cutting machines are designed to provide both

operation safety and efficiency. However, as with any

machine tool, sensible attention to operating

procedures, precautions, and safe practices is

necessary to achieve a full measure of usefulness.

Whether an individual is involved with operation,

servicing, or as an observer, compliance with

established precautions and safe practices must be

accomplished. Failure to observe certain precautions

could result in serious personnel injury or severe

equipment damage. The following precautions are

general guidelines applicable when working with

cutting machines. More explicit precautions pertaining

to the basic machine and accessories are found in the

instruction literature. For a wide scope of safety

information on the field of cutting and welding

apparatus, obtain and read the publications listed in

the Recommended References.

1.2 Safety Notations And Symbols

The following words and symbols are used throughout

this manual. They indicate different levels of required

safety involvement.

!

ALERT or ATTENTION. Your safety is involved

or potential equipment failure exists. Used with

other symbols and information.

Used to call attention to immediate hazards

which, if not avoided, will result in serious

personal injury or loss of life.

Used to call attention to potential hazards

that could result in personal injury or loss of

life.

Used to call attention to hazards that could

result in minor personal injury or equipment

damage.

Used to call attention to minor hazards to

equipment.

Used to call attention to important

installation, operation or maintenance

information not directly related to safety

hazards.

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-2

1.3 General Safety Information

WARNING

!

Machine starts automatically.

This equipment moves in various directions and

This equipment moves in various directions andThis equipment moves in various directions and

This equipment moves in various directions and

speeds.

speeds.speeds.

speeds.

• Moving machinery can crush.

Moving machinery can crush.Moving machinery can crush.

Moving machinery can crush.

• Only qualified personnel should operate or service

Only qualified personnel should operate or serviceOnly qualified personnel should operate or service

Only qualified personnel should operate or service

equipment.

equipment.equipment.

equipment.

• Keep all personnel, materials, and equipment not

Keep all personnel, materials, and equipment notKeep all personnel, materials, and equipment not

Keep all personnel, materials, and equipment not

involved in production process clear of entire

involved in production process clear of entireinvolved in production process clear of entire

involved in production process clear of entire

system area.

system area.system area.

system area.

• Keep gear racks and rails clear of debris or

Keep gear racks and rails clear of debris orKeep gear racks and rails clear of debris or

Keep gear racks and rails clear of debris or

obstructions, such as tools or clothing.

obstructions, such as tools or clothing.obstructions, such as tools or clothing.

obstructions, such as tools or clothing.

• Fence off entire work cell to prevent personnel

Fence off entire work cell to prevent personnelFence off entire work cell to prevent personnel

Fence off entire work cell to prevent personnel

from passing through area or standing in the

from passing through area or standing in thefrom passing through area or standing in the

from passing through area or standing in the

working envelope of the equipment.

working envelope of the equipment.working envelope of the equipment.

working envelope of the equipment.

• Post appropriate WARNING signs at every work

Post appropriate WARNING signs at every workPost appropriate WARNING signs at every work

Post appropriate WARNING signs at every work

cell entrance.

cell entrance.cell entrance.

cell entrance.

• Follow lockout procedure before servicing.

Follow lockout procedure before servicing.Follow lockout procedure before servicing.

Follow lockout procedure before servicing.

WARNING

!

Failure to follow operating instructions

could result in death or serious injury.

Read and understand this operator’s manual before

Read and understand this operator’s manual beforeRead and understand this operator’s manual before

Read and understand this operator’s manual before

using machine.

using machine.using machine.

using machine.

• Read entire procedure before operating or

Read entire procedure before operating orRead entire procedure before operating or

Read entire procedure before operating or

performing any system maintenance.

performing any system maintenance.performing any system maintenance.

performing any system maintenance.

• Special attention must be given to all hazard

Special attention must be given to all hazardSpecial attention must be given to all hazard

Special attention must be given to all hazard

warnings that provide essential information

warnings that provide essential informationwarnings that provide essential information

warnings that provide essential information

regarding personnel safety and/or possible

regarding personnel safety and/or possibleregarding personnel safety and/or possible

regarding personnel safety and/or possible

equipment damage.

equipment damage.equipment damage.

equipment damage.

• All safety precautions relevant to electrical

All safety precautions relevant to electricalAll safety precautions relevant to electrical

All safety precautions relevant to electrical

equipment and process operations must be

equipment and process operations must beequipment and process operations must be

equipment and process operations must be

strictly observed by all having system

strictly observed by all having systemstrictly observed by all having system

strictly observed by all having system

responsibility or access.

responsibility or access.responsibility or access.

responsibility or access.

• Read all safety publications made available by

Read all safety publications made available byRead all safety publications made available by

Read all safety publications made available by

your company.

your company.your company.

your company.

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-3

WARNING

!

Failure to follow safety warning label

instructions could result in death or

serious injury.

Read and understand all safety warning labels on

Read and understand all safety warning labels onRead and understand all safety warning labels on

Read and understand all safety warning labels on

machine.

machine.machine.

machine.

Refer to operator’s manual for additional safety

Refer to operator’s manual for additional safetyRefer to operator’s manual for additional safety

Refer to operator’s manual for additional safety

information.

information.information.

information.

1.4 Installation Precautions

WARNING

!

Improperly Installed Equipment Can Cause

Injury Or Death.

Follow these guidelines while installing machine:

Follow these guidelines while installing machine:Follow these guidelines while installing machine:

Follow these guidelines while installing machine:

• Do not connect a cylinder directly to machine inlet.

Do not connect a cylinder directly to machine inlet.Do not connect a cylinder directly to machine inlet.

Do not connect a cylinder directly to machine inlet.

An appropriate cylinder regulator must be installed

An appropriate cylinder regulator must be installedAn appropriate cylinder regulator must be installed

An appropriate cylinder regulator must be installed

on a fuel gas cylinder to reduce pressure to a

on a fuel gas cylinder to reduce pressure to aon a fuel gas cylinder to reduce pressure to a

on a fuel gas cylinder to reduce pressure to a

reasonable inlet supply pressure. Machine

reasonable inlet supply pressure. Machinereasonable inlet supply pressure. Machine

reasonable inlet supply pressure. Machine

regulator is then used to obtain pressure required

regulator is then used to obtain pressure requiredregulator is then used to obtain pressure required

regulator is then used to obtain pressure required

by torches.

by torches.by torches.

by torches.

• Contact your ESAB representative before

Contact your ESAB representative beforeContact your ESAB representative before

Contact your ESAB representative before

installation. He can suggest certain precautions

installation. He can suggest certain precautionsinstallation. He can suggest certain precautions

installation. He can suggest certain precautions

regarding piping installation and machine lifting,

regarding piping installation and machine lifting,regarding piping installation and machine lifting,

regarding piping installation and machine lifting,

etc. to ensure maximum security.

etc. to ensure maximum security.etc. to ensure maximum security.

etc. to ensure maximum security.

• Never attempt any machine modifications or

Never attempt any machine modifications orNever attempt any machine modifications or

Never attempt any machine modifications or

apparatus additions without first consulting a

apparatus additions without first consulting aapparatus additions without first consulting a

apparatus additions without first consulting a

qualified ESAB representative.

qualified ESAB representative.qualified ESAB representative.

qualified ESAB representative.

• Observe machine clearance requirements for

Observe machine clearance requirements forObserve machine clearance requirements for

Observe machine clearance requirements for

proper operation and personnel safety.

proper operation and personnel safety.proper operation and personnel safety.

proper operation and personnel safety.

• Always have qualified personnel

Always have qualified personnel Always have qualified personnel

Always have qualified personnel perform

performperform

perform

installation, troubleshooting and maintenance of

installation, troubleshooting and maintenance ofinstallation, troubleshooting and maintenance of

installation, troubleshooting and maintenance of

this equipment.

this equipment.this equipment.

this equipment.

• Provide a wall mounted disconnect switch with

Provide a wall mounted disconnect switch withProvide a wall mounted disconnect switch with

Provide a wall mounted disconnect switch with

proper fuse sizes close to the power supply.

proper fuse sizes close to the power supply.proper fuse sizes close to the power supply.

proper fuse sizes close to the power supply.

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-4

1.5 Electrical Grounding

Electrical grounding is imperative for proper machine

operation and SAFETY. Refer to this manual’s

Installation section for detailed grounding instructions.

WARNING

!

Electric shock hazard.

Improper grounding can cause severe injury or death.

Improper grounding can cause severe injury or death.Improper grounding can cause severe injury or death.

Improper grounding can cause severe injury or death.

Machine must be properly grounded before put into

Machine must be properly grounded before put intoMachine must be properly grounded before put into

Machine must be properly grounded before put into

service.

service.service.

service.

WARNING

!

Improper Grounding Can Damage

Machine And Electrical Components.

• Machine must be properly grounded before put

Machine must be properly grounded before putMachine must be properly grounded before put

Machine must be properly grounded before put

into service.

into service.into service.

into service.

• Cutting table must be properly grounded to

Cutting table must be properly grounded toCutting table must be properly grounded to

Cutting table must be properly grounded to a good

a gooda good

a good

Earth ground rod.

Earth ground rod.Earth ground rod.

Earth ground rod.

1.6 Operating A Plasma Cutting Machine

WARNING

!

Flying debris and loud noise hazards.

• Hot spatter can burn and injure eyes. Wear

Hot spatter can burn and injure eyes. WearHot spatter can burn and injure eyes. Wear

Hot spatter can burn and injure eyes. Wear

goggles to protect eyes from burns and flying

goggles to protect eyes from burns and flyinggoggles to protect eyes from burns and flying

goggles to protect eyes from burns and flying

debris generated during operation.

debris generated during operation.debris generated during operation.

debris generated during operation.

• Chipped slag may be hot and fly far. Bystanders

Chipped slag may be hot and fly far. BystandersChipped slag may be hot and fly far. Bystanders

Chipped slag may be hot and fly far. Bystanders

should also wear goggles and safety glasses.

should also wear goggles and safety glasses.should also wear goggles and safety glasses.

should also wear goggles and safety glasses.

• Noise from plasma arc can damage hearing. Wear

Noise from plasma arc can damage hearing. WearNoise from plasma arc can damage hearing. Wear

Noise from plasma arc can damage hearing. Wear

correct ear protection when cutting above water.

correct ear protection when cutting above water.correct ear protection when cutting above water.

correct ear protection when cutting above water.

WARNING

!

Burn hazard.

Hot metal can burn.

Hot metal can burn.Hot metal can burn.

Hot metal can burn.

• Do not touch metal plate or parts immediately after

Do not touch metal plate or parts immediately afterDo not touch metal plate or parts immediately after

Do not touch metal plate or parts immediately after

cutting. Allow metal time to cool, or douse with

cutting. Allow metal time to cool, or douse withcutting. Allow metal time to cool, or douse with

cutting. Allow metal time to cool, or douse with

water.

water.water.

water.

• Do not touch plasma torch immediately after

Do not touch plasma torch immediately afterDo not touch plasma torch immediately after

Do not touch plasma torch immediately after

cutting. Allow torch time to cool.

cutting. Allow torch time to cool.cutting. Allow torch time to cool.

cutting. Allow torch time to cool.

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-5

WARNING

!

Hazardous voltages. Electric shock

can kill.

• Do NOT touch plasma torch, cutting table or cable

Do NOT touch plasma torch, cutting table or cableDo NOT touch plasma torch, cutting table or cable

Do NOT touch plasma torch, cutting table or cable

connections during plasma cutting process.

connections during plasma cutting process.connections during plasma cutting process.

connections during plasma cutting process.

• Always turn power off to plasma power supplies

Always turn power off to plasma power suppliesAlways turn power off to plasma power supplies

Always turn power off to plasma power supplies

before touching or servicing plasma torch.

before touching or servicing plasma torch.before touching or servicing plasma torch.

before touching or servicing plasma torch.

• Always turn power off to plasma power supplies

Always turn power off to plasma power suppliesAlways turn power off to plasma power supplies

Always turn power off to plasma power supplies

before servicing any system component.

before servicing any system component.before servicing any system component.

before servicing any system component.

• Do not touch live electrical parts.

Do not touch live electrical parts.Do not touch live electrical parts.

Do not touch live electrical parts.

• Keep all panels and covers in place when machine

Keep all panels and covers in place when machineKeep all panels and covers in place when machine

Keep all panels and covers in place when machine

is connected to power source.

is connected to power source.is connected to power source.

is connected to power source.

• Wear insulating gloves, shoes and clothing to

Wear insulating gloves, shoes and clothing toWear insulating gloves, shoes and clothing to

Wear insulating gloves, shoes and clothing to

insulate yourself from

insulate yourself from insulate yourself from

insulate yourself from workpiece and electrical

workpiece and electricalworkpiece and electrical

workpiece and electrical

ground.

ground.ground.

ground.

• Keep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, andKeep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, and

equipment dry.

equipment dry.equipment dry.

equipment dry.

• Replace worn or damaged cables.

Replace worn or damaged cables.Replace worn or damaged cables.

Replace worn or damaged cables.

WARNING

!

Fume hazard.

Fumes and gases generated by the plasma cutting

Fumes and gases generated by the plasma cuttingFumes and gases generated by the plasma cutting

Fumes and gases generated by the plasma cutting

process can be hazardous to your health.

process can be hazardous to your health.process can be hazardous to your health.

process can be hazardous to your health.

• Do NOT breathe fumes.

Do NOT breathe fumes.Do NOT breathe fumes.

Do NOT breathe fumes.

• Do not operate plasma torch without fume removal

Do not operate plasma torch without fume removalDo not operate plasma torch without fume removal

Do not operate plasma torch without fume removal

system operating properly.

system operating properly.system operating properly.

system operating properly.

• Use additional ventilation to remove fumes if

Use additional ventilation to remove fumes ifUse additional ventilation to remove fumes if

Use additional ventilation to remove fumes if

necessary.

necessary.necessary.

necessary.

• Use approved respirator if ventilation is not

Use approved respirator if ventilation is notUse approved respirator if ventilation is not

Use approved respirator if ventilation is not

adequate.

adequate.adequate.

adequate.

• Provide positive mechanical ventilation when

Provide positive mechanical ventilation whenProvide positive mechanical ventilation when

Provide positive mechanical ventilation when

cutting galvanized steel, stainless steel, copper,

cutting galvanized steel, stainless steel, copper,cutting galvanized steel, stainless steel, copper,

cutting galvanized steel, stainless steel, copper,

zinc, beryllium, or cadmium. Do not breathe these

zinc, beryllium, or cadmium. Do not breathe thesezinc, beryllium, or cadmium. Do not breathe these

zinc, beryllium, or cadmium. Do not breathe these

fumes.

fumes.fumes.

fumes.

• Do not operate near degreasing and spraying

Do not operate near degreasing and sprayingDo not operate near degreasing and spraying

Do not operate near degreasing and spraying

operations. Heat or arc rays can react with

operations. Heat or arc rays can react withoperations. Heat or arc rays can react with

operations. Heat or arc rays can react with

chlorinated hydrocarbon vapors to form phosgene,

chlorinated hydrocarbon vapors to form phosgene,chlorinated hydrocarbon vapors to form phosgene,

chlorinated hydrocarbon vapors to form phosgene,

a highly toxic gas and other irritant gases.

a highly toxic gas and other irritant gases.a highly toxic gas and other irritant gases.

a highly toxic gas and other irritant gases.

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-6

WARNING

!

WARNING

!

Radiation hazard.

Arc rays can injure eyes and burn

Arc rays can injure eyes and burn Arc rays can injure eyes and burn

Arc rays can injure eyes and burn skin.

skin.skin.

skin.

• Wear correct eye and body protection.

Wear correct eye and body protection.Wear correct eye and body protection.

Wear correct eye and body protection.

• Wear dark safety glasses or goggles with

Wear dark safety glasses or goggles with Wear dark safety glasses or goggles with

Wear dark safety glasses or goggles with side

sideside

side

shields. Refer to following chart for recommended

shields. Refer to following chart for recommendedshields. Refer to following chart for recommended

shields. Refer to following chart for recommended

lens shades for plasma cutting:

lens shades for plasma cutting:lens shades for plasma cutting:

lens shades for plasma cutting:

Arc Current

Arc CurrentArc Current

Arc Current

Lens Shade

Lens Shade Lens Shade

Lens Shade

Up to 100 Amps

Up to 100 AmpsUp to 100 Amps

Up to 100 Amps Shade No. 8

Shade No. 8Shade No. 8

Shade No. 8

100-200 Amps

100-200 Amps100-200 Amps

100-200 AmpsShade No. 10

Shade No. 10Shade No. 10

Shade No. 10

200-400 Amps

200-400 Amps200-400 Amps

200-400 AmpsShade No. 12

Shade No. 12Shade No. 12

Shade No. 12

Over 400 Amps

Over 400 AmpsOver 400 Amps

Over 400 Amps Shade No. 14

Shade No. 14Shade No. 14

Shade No. 14

• Replace glasses/goggles when lenses are pitted or

Replace glasses/goggles when lenses are pitted orReplace glasses/goggles when lenses are pitted or

Replace glasses/goggles when lenses are pitted or

broken

brokenbroken

broken

• Warn others in area not to look directly at the arc

Warn others in area not to look directly at the arcWarn others in area not to look directly at the arc

Warn others in area not to look directly at the arc

unless wearing appropriate safety glasses.

unless wearing appropriate safety glasses.unless wearing appropriate safety glasses.

unless wearing appropriate safety glasses.

• Prepare cutting area to reduce reflection and

Prepare cutting area to reduce reflection andPrepare cutting area to reduce reflection and

Prepare cutting area to reduce reflection and

transmission of ultraviolet light.

transmission of ultraviolet light.transmission of ultraviolet light.

transmission of ultraviolet light.

§ Paint walls and other surfaces with dark

Paint walls and other surfaces with darkPaint walls and other surfaces with dark

Paint walls and other surfaces with dark

colors to reduce reflections.

colors to reduce reflections.colors to reduce reflections.

colors to reduce reflections.

§ Install protective screens or curtains to

Install protective screens or curtains toInstall protective screens or curtains to

Install protective screens or curtains to

reduce ultraviolet transmission.

reduce ultraviolet transmission.reduce ultraviolet transmission.

reduce ultraviolet transmission.

Ruptured Gas Cylinders Can Kill

Mishandling gas cylinders can rupture and violently

Mishandling gas cylinders can rupture and violentlyMishandling gas cylinders can rupture and violently

Mishandling gas cylinders can rupture and violently

release gas.

release gas.release gas.

release gas.

• Avoid rough handling of cylinders.

Avoid rough handling of cylinders.Avoid rough handling of cylinders.

Avoid rough handling of cylinders.

• Keep cylinder valves closed when not in use.

Keep cylinder valves closed when not in use.Keep cylinder valves closed when not in use.

Keep cylinder valves closed when not in use.

• Maintain hoses and fittings in good condition.

Maintain hoses and fittings in good condition.Maintain hoses and fittings in good condition.

Maintain hoses and fittings in good condition.

• Always secure cylinders in an upright position by

Always secure cylinders in an upright position byAlways secure cylinders in an upright position by

Always secure cylinders in an upright position by

chain or strap to a suitable stable object not part of

chain or strap to a suitable stable object not part ofchain or strap to a suitable stable object not part of

chain or strap to a suitable stable object not part of

an electrical circuit.

an electrical circuit.an electrical circuit.

an electrical circuit.

• Locate cylinders away from heat, sparks and

Locate cylinders away from heat, sparks andLocate cylinders away from heat, sparks and

Locate cylinders away from heat, sparks and

flames. Never strike an arc on a cylinder.

flames. Never strike an arc on a cylinder.flames. Never strike an arc on a cylinder.

flames. Never strike an arc on a cylinder.

• Use approved

Use approved Use approved

Use approved pressure reducing regulator for the

pressure reducing regulator for thepressure reducing regulator for the

pressure reducing regulator for the

specific gas.

specific gas.specific gas.

specific gas.

• Refer to CGA Standard P-1, “Precautions for Safe

Refer to CGA Standard P-1, “Precautions for SafeRefer to CGA Standard P-1, “Precautions for Safe

Refer to CGA Standard P-1, “Precautions for Safe

Handling of Compressed Gases in Cylinders”,

Handling of Compressed Gases in Cylinders”,Handling of Compressed Gases in Cylinders”,

Handling of Compressed Gases in Cylinders”,

available from Compressed Gas Association.

available from Compressed Gas Association.available from Compressed Gas Association.

available from Compressed Gas Association.

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-7

CAUTION

WARNING

!

Burn Hazard.

Heat, spatter, and sparks cause fire and burns.

Heat, spatter, and sparks cause fire and burns.Heat, spatter, and sparks cause fire and burns.

Heat, spatter, and sparks cause fire and burns.

• Do not cut near combustible material.

Do not cut near combustible material.Do not cut near combustible material.

Do not cut near combustible material.

• Do not have on your person any combustibles (e.g.

Do not have on your person any combustibles (e.g.Do not have on your person any combustibles (e.g.

Do not have on your person any combustibles (e.g.

butane lighter).

butane lighter).butane lighter).

butane lighter).

• Pilot arc can cause burns. Keep torch nozzle

Pilot arc can cause burns. Keep torch nozzlePilot arc can cause burns. Keep torch nozzle

Pilot arc can cause burns. Keep torch nozzle

away from yourself and others when activating

away from yourself and others when activatingaway from yourself and others when activating

away from yourself and others when activating

plasma process.

plasma process.plasma process.

plasma process.

• Wear correct eye and body protection.

Wear correct eye and body protection.Wear correct eye and body protection.

Wear correct eye and body protection.

• Wear gauntlet gloves, safety shoes and hat.

Wear gauntlet gloves, safety shoes and hat.Wear gauntlet gloves, safety shoes and hat.

Wear gauntlet gloves, safety shoes and hat.

• Wear flame-retardant clothing covering all exposed

Wear flame-retardant clothing covering all exposedWear flame-retardant clothing covering all exposed

Wear flame-retardant clothing covering all exposed

areas.

areas.areas.

areas.

• Wear cuff-less trousers to prevent entry of sparks

Wear cuff-less trousers to prevent entry of sparksWear cuff-less trousers to prevent entry of sparks

Wear cuff-less trousers to prevent entry of sparks

and slag.

and slag.and slag.

and slag.

• Have

Have Have

Have fire extinguishing equipment available for use.

fire extinguishing equipment available for use.fire extinguishing equipment available for use.

fire extinguishing equipment available for use.

Poor Performance Will Result When

Cutting Above Water.

The PT-24 is designed to be a dry cutting

process.

Cutting above water may result in:

Cutting above water may result in:Cutting above water may result in:

Cutting above water may result in:

• reduced consumable life

reduced consumable lifereduced consumable life

reduced consumable life

• degradation of cut quality

degradation of cut qualitydegradation of cut quality

degradation of cut quality

Cutting above water may result in poor cutting

Cutting above water may result in poor cuttingCutting above water may result in poor cutting

Cutting above water may result in poor cutting

performance. Water vapor created when hot material

performance. Water vapor created when hot materialperformance. Water vapor created when hot material

performance. Water vapor created when hot material

or sparks contact liquid may cause arcing inside torch.

or sparks contact liquid may cause arcing inside torch.or sparks contact liquid may cause arcing inside torch.

or sparks contact liquid may cause arcing inside torch.

When cutting on a water table, reduce the water level

When cutting on a water table, reduce the water levelWhen cutting on a water table, reduce the water level

When cutting on a water table, reduce the water level

to provide maximum clearance between water and

to provide maximum clearance between water andto provide maximum clearance between water and

to provide maximum clearance between water and

material.

material.material.

material.

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-8

WARNING

!

Explosion hazard.

• Certain molten aluminum-lithium (Al-

Certain molten aluminum-lithium (Al-Certain molten aluminum-lithium (Al-

Certain molten aluminum-lithium (Al-Li) alloys can

Li) alloys canLi) alloys can

Li) alloys can

cause explosions when plasma cut OVER water.

cause explosions when plasma cut OVER water.cause explosions when plasma cut OVER water.

cause explosions when plasma cut OVER water.

§ These alloys should only be dry cut on a dry

These alloys should only be dry cut on a dryThese alloys should only be dry cut on a dry

These alloys should only be dry cut on a dry

table.

table.table.

table.

§ DO NOT dry cut over water.

DO NOT dry cut over water.DO NOT dry cut over water.

DO NOT dry cut over water.

§ Contact your aluminum supplier for

Contact your aluminum supplier forContact your aluminum supplier for

Contact your aluminum supplier for

additional safety information regarding

additional safety information regardingadditional safety information regarding

additional safety information regarding

hazards associated with these alloys

hazards associated with these alloyshazards associated with these alloys

hazards associated with these alloys

.

• Do not cut in atmospheres containing explosive

Do not cut in atmospheres containing explosiveDo not cut in atmospheres containing explosive

Do not cut in atmospheres containing explosive

dust or vapors.

dust or vapors.dust or vapors.

dust or vapors.

• Do not carry any combustibles on your person

Do not carry any combustibles on your personDo not carry any combustibles on your person

Do not carry any combustibles on your person

(e.g. butane lighter)

(e.g. butane lighter)(e.g. butane lighter)

(e.g. butane lighter)

• Do not cut containers that have held combustibles.

Do not cut containers that have held combustibles.Do not cut containers that have held combustibles.

Do not cut containers that have held combustibles.

WARNING

!

Pinch hazard.

Moving vertical slides can crush or pinch.

Moving vertical slides can crush or pinch.Moving vertical slides can crush or pinch.

Moving vertical slides can crush or pinch.

Keep hands clear of torch and slide during operation.

Keep hands clear of torch and slide during operation.Keep hands clear of torch and slide during operation.

Keep hands clear of torch and slide during operation.

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-9

1.7 Service Precautions

WARNING

!

Hazardous voltages. Electric shock

can kill.

• Do NOT touch plasma torch, cutting table or cable

Do NOT touch plasma torch, cutting table or cableDo NOT touch plasma torch, cutting table or cable

Do NOT touch plasma torch, cutting table or cable

connections during plasma cutting process.

connections during plasma cutting process.connections during plasma cutting process.

connections during plasma cutting process.

• Always turn power off to plasma power supplies

Always turn power off to plasma power suppliesAlways turn power off to plasma power supplies

Always turn power off to plasma power supplies

before touching or servicing plasma torch.

before touching or servicing plasma torch.before touching or servicing plasma torch.

before touching or servicing plasma torch.

• Always turn power off to plasma power supplies

Always turn power off to plasma power suppliesAlways turn power off to plasma power supplies

Always turn power off to plasma power supplies

before removing covers or panels to service any

before removing covers or panels to service anybefore removing covers or panels to service any

before removing covers or panels to service any

system component.

system component.system component.

system component.

• Do not touch live electrical parts.

Do not touch live electrical parts.Do not touch live electrical parts.

Do not touch live electrical parts.

• Keep all panels and covers in place when machine

Keep all panels and covers in place when machineKeep all panels and covers in place when machine

Keep all panels and covers in place when machine

is connected to power source.

is connected to power source.is connected to power source.

is connected to power source.

• Keep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, andKeep gloves, shoes, clothing, work area, and

Keep gloves, shoes, clothing, work area, and

equipment dry.

equipment dry.equipment dry.

equipment dry.

• Inspect power and ground leads cables for wear or

Inspect power and ground leads cables for wear orInspect power and ground leads cables for wear or

Inspect power and ground leads cables for wear or

cracking. Replace worn or damaged cables. Do

cracking. Replace worn or damaged cables. Docracking. Replace worn or damaged cables. Do

cracking. Replace worn or damaged cables. Do

not use if damaged.

not use if damaged.not use if damaged.

not use if damaged.

• Never bypass safety interlocks.

Never bypass safety interlocks.Never bypass safety interlocks.

Never bypass safety interlocks.

• Follow

Follow Follow

Follow lock-out procedures.

lock-out procedures.lock-out procedures.

lock-out procedures.

CAUTION

Establish and adhere to preventive maintenance. A

Establish and adhere to preventive maintenance. AEstablish and adhere to preventive maintenance. A

Establish and adhere to preventive maintenance. A

composite program can be established from

composite program can be established fromcomposite program can be established from

composite program can be established from

recommended schedules.

recommended schedules.recommended schedules.

recommended schedules.

Avoid leaving test equipment or hand tools on

Avoid leaving test equipment or hand tools onAvoid leaving test equipment or hand tools on

Avoid leaving test equipment or hand tools on

machine. Severe electrical or mechanical damage

machine. Severe electrical or mechanical damagemachine. Severe electrical or mechanical damage

machine. Severe electrical or mechanical damage

could occur to equipment or machine.

could occur to equipment or machine.could occur to equipment or machine.

could occur to equipment or machine.

CAUTION

!

Extreme caution should be used when probing

Extreme caution should be used when probingExtreme caution should be used when probing

Extreme caution should be used when probing

circuitry with an oscilloscope or voltmeter. Integrated

circuitry with an oscilloscope or voltmeter. Integratedcircuitry with an oscilloscope or voltmeter. Integrated

circuitry with an oscilloscope or voltmeter. Integrated

circuits are susceptible to over voltage damage.

circuits are susceptible to over voltage damage.circuits are susceptible to over voltage damage.

circuits are susceptible to over voltage damage.

Power off before using test probes to prevent

Power off before using test probes to preventPower off before using test probes to prevent

Power off before using test probes to prevent

accidental shorting of components.

accidental shorting of components.accidental shorting of components.

accidental shorting of components.

All circuit boards securely seated in sockets, all cables

All circuit boards securely seated in sockets, all cablesAll circuit boards securely seated in sockets, all cables

All circuit boards securely seated in sockets, all cables

properly connected, all cabinets closed and locked, all

properly connected, all cabinets closed and locked, allproperly connected, all cabinets closed and locked, all

properly connected, all cabinets closed and locked, all

guards and covers replaced before power is turned

guards and covers replaced before power is turnedguards and covers replaced before power is turned

guards and covers replaced before power is turned

on.

on.on.

on.

SECTION 1 SAFETY

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

1-10

1.8 Safety References

The following nationally recognized publications on safety in welding

and cutting operations are recommended. These publications have

been prepared to protect persons from injury or illness and to protect

property from damage, which could result from unsafe practices.

Although some of these publications are not related specifically to this

type of industrial cutting apparatus, the principles of safety apply

equally.

• “Precautions and Safe Practices in Welding and Cutting with

Oxygen-Fuel Gas Equipment,” Form 2035. ESAB Cutting

Systems.

• “Precautions and Safe Practices for Electric Welding and Cutting,”

Form 52-529. ESAB Cutting Systems.

• “Safety in Welding and Cutting” - ANSI Z 49.1, American Welding

Society, 2501 NW 7th Street, Miami, Florida, 33125.

• “Recommended Safe Practices for Shielded Gases for Welding and

Plasma Arc Cutting” - AWS C5.10-94, American Welding Society.

• “Recommended Practices for Plasma Arc Welding” - AWS C5.1,

American Welding Society.

• “Recommended Practices for Arc Cutting” - AWS C5.2, American

Welding Society.

• “Safe Practices” - AWS SP, American Welding Society.

• “Standard for Fire Protection in Use of Cutting and Welding

Procedures” - NFPA 51B, National Fire Protection Association, 60

Batterymarch Street, Boston, Massachusetts, 02110.

• “Standard for Installation and Operation of Oxygen - Fuel Gas

Systems for Welding and Cutting” - NFPA 51, National Fire

Protection Association.

• “Safety Precautions for Oxygen, Nitrogen, Argon, Helium, Carbon

Dioxide, Hydrogen, and Acetylene,” Form 3499. ESAB Cutting

Systems. Obtainable through your ESAB representative or local

distributor.

• "Design and Installation of Oxygen Piping Systems," Form 5110.

ESAB Cutting Systems.

• “Precautions for Safe Handling of Compressed Gases in

Cylinders”, CGA Standard P-1, Compressed Gas Association.

Literature applicable to safe practices in welding and cutting with

gaseous materials is also available from the Compressed Gas

Association, Inc., 500 Fifth Ave., New York, NY 10036.

SECTION 2 DESCRIPTION

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

2-1

2.1 General

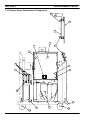

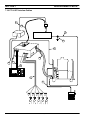

The PT-24 Precision Plasmarc Integrated Flow

Control System provides programmable gas

switching and pressure control. The IFC is the next

generation electronic flow control combining

junction and flow control box components for:

a reduced combined footprint,

fewer parts,

improved reliability,

and improved high speed marking option.

The gas pressure and switching is controlled

through the cutting machine CNC eliminating the

need for other programmable controls.

2.2 Scope

The purpose of this manual is to provide the

operator with all the information required to install

and operate the Precision Plasmarc System.

Technical reference material is also provided to

assist in troubleshooting the cutting package.

2.3 Package Options Available

Precision Plasmarc® Integrated Flow Control package options available through your ESAB dealer

Precision Plasmarc® Power Source (200/230/380/415/460/575) 3-phase 50/60 Hz

(required) CNC Controllable/Without PLC

Without PLCWithout PLC

Without PLC

CE Version (not covered in this manual)

P/N 0558002077

P/N 0558002263

Integrated Flow Control Box P/N 0558002069

4.5 ft. (1.4 m) P/N 0558002337

12 ft. (3.7 m) P/N 0558002338

PT-24 Torch with high speed marking

20 ft. (6.1 m) P/N 0558002339

12 ft. (3.7 m) P/N 22428

25 ft. (7.6 m) P/N 21905

40 ft. (12.2 m) P/N 22504

60 ft. (18 m) P/N 21906

80 ft. (24.4 m) P/N 22505

Power Bundle (one required)

100 ft. (30 m) P/N 21907

10 ft. (3 m) P/N 0560987422

20 ft. (6.1 m) P/N 0560987423

30 ft. (9 m) P/N 0560987424

60 ft. (18 m) P/N 0560987425

Control Lead, CNC to Power Supply (one required)

100 ft. (30 m) P/N 0560987426

Torch Coolant (one gallon (3.8 liters) containers. four gallons (15 liters) required) P/N 156F05

NOTES:

• Control lead from the power source to customer CNC is supplied based on customer order.

• Gas supply, hoses, work lead and input primary cable are all supplied by the customer.

• See Process Data Sheets for a list of torch consumable parts.

SECTION 2 DESCRIPTION

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

2-2

R

E

C

I

S

I

O

N

P

L

A

S

M

A

R

C

P

O

W

E

R

C

O

N

T

R

O

L

C

U

R

R

E

N

T

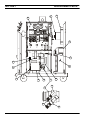

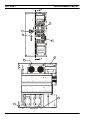

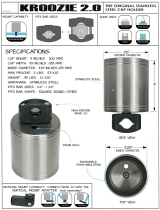

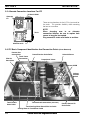

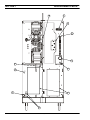

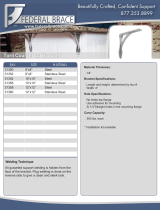

22" (559mm)

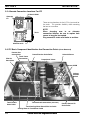

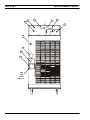

42" (1067mm)

44" (1118mm)

WEIGHT = 560 lbs. (254 kg)

WEIGHT = 560 lbs. (254 kg)WEIGHT = 560 lbs. (254 kg)

WEIGHT = 560 lbs. (254 kg)

Power Supply

Power SupplyPower Supply

Power Supply

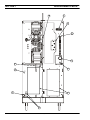

14.5 " (36.8 mm)

20 " (50.8 mm)

7.5 " (19.0 mm)

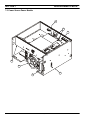

Integrated Flow Control

Integrated Flow ControlIntegrated Flow Control

Integrated Flow Control

WEIGHT = 59 lbs. (130 kg)

WEIGHT = 59 lbs. (130 kg)WEIGHT = 59 lbs. (130 kg)

WEIGHT = 59 lbs. (130 kg)

2.4 Precision Plasma Technical Specifications

2.4.1 System

Input Voltage 200/230/380/415/460/575 V 3 phase 50/60 Hz

Input Current 65/60/50/40/30/25 amps per phase

Power Factor 0.95

Output Current Range 15-100 amps dc

Output Load Voltage 120 V dc

Duty Cycle 100%

Open Circuit Voltage 315 V dc

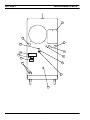

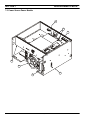

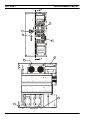

PT-24 Torch and Torch Bundle

PT-24 Torch and Torch BundlePT-24 Torch and Torch Bundle

PT-24 Torch and Torch Bundle

SECTION 2 DESCRIPTION

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

2-3

2.4.2 Plasma Gas Technical Specifications

Type O

2

, N

2

, Ar, Air

Pressure 150 psig (10.4 bars)

Flow

100 cfh (47 l/min) max. (varies with

application)

Purity Required*

O

2

-99.8 to 99.995%

N

2

, Ar-99.995%

Air-clean, dry and oil free

Recommended Liquid Cylinder Service

Regulators

Oxygen: R-76-150-540LC (P/N 19777)

Inert gas: R-76-150-580LC (P/N 19977)

Recommended Cylinder 2-Stage

Regulators

Oxygen: R-77-150-540 (P/N 998337

Hydrogen/Methane:R-77-150-350 (P/N

998342)

Nitrogen: R-77-150-580 (P/N 998344)

Industrial Air: R-77150=590 (P/N

998348)

Recommended Heavy –Duty Hi-flow

Station or Pipeline Regulators

Oxygen: R-76-150-024 (P/N 19151)

Recommended High-capacity Station

or Pipeline Regulators

R-6703 (P/N 22236)

Gas Filter Required 25 micron w/bowl guard (P/N 56998133)

2.4.3 Start Gas Technical Specifications

Type N

2

, Ar, Air

Pressure 150 psig (10.4 bar)

Flow

60 cfh (28 l/min) max (varies with

application)

Minimum Purity Required N2, Ar - 99.995% Air –Clean, Dry

2.4.4 Secondary Gas Technical Specifications

Type N

2

, O

2

, Methane, Air

Pressure

100 psig (6.6 bar) H-35, Methane;

150 psig (10.4 bar) N

2

, O

2

, Air

Flow

60 cfh (28 l/min) max

(varies with application)

Minimum Purity Required N

2

, O

2

, CH

4

- 99.995% Air –Clean, Dry

2.4.5 Cut Gas Technical Specifications

Type N

2

, O

2

, Air

Pressure 150 psig (10.4 bar) N

2

, O

2

, Air

Flow

60 cfh (28 l/min) max

(varies with application)

Minimum Purity Required 99.995% N

2

, 99.8% O

2

and Air

SECTION 2 DESCRIPTION

Precision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow ControlPrecision Plasma with Integrated Flow Control

Precision Plasma with Integrated Flow Control

2-4

2.4.5 Pt-24 Torch Technical Specifications

Type Water-Cooled, Dual Gas

Rating 100 amps @ 100 % duty cycle

Dimensions See Package Options (2.3)

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

-

53

53

-

54

54

-

55

55

-

56

56

-

57

57

-

58

58

-

59

59

-

60

60

-

61

61

-

62

62

-

63

63

-

64

64

-

65

65

-

66

66

-

67

67

-

68

68

-

69

69

-

70

70

-

71

71

-

72

72

-

73

73

-

74

74

-

75

75

-

76

76

-

77

77

-

78

78

-

79

79

-

80

80

-

81

81

-

82

82

-

83

83

-

84

84

-

85

85

-

86

86

-

87

87

-

88

88

-

89

89

-

90

90

-

91

91

-

92

92

-

93

93

-

94

94

-

95

95

-

96

96

-

97

97

-

98

98

-

99

99

-

100

100

-

101

101

-

102

102

-

103

103

-

104

104

-

105

105

-

106

106

-

107

107

-

108

108

-

109

109

-

110

110

-

111

111

-

112

112

-

113

113

-

114

114

-

115

115

-

116

116

-

117

117

-

118

118

-

119

119

-

120

120

-

121

121

-

122

122

-

123

123

-

124

124

-

125

125

-

126

126

-

127

127

-

128

128

-

129

129

-

130

130

-

131

131

-

132

132

-

133

133

-

134

134

-

135

135

-

136

136

-

137

137

-

138

138

-

139

139

-

140

140

-

141

141

-

142

142

-

143

143

-

144

144

-

145

145

-

146

146

-

147

147

-

148

148

-

149

149

-

150

150

-

151

151

-

152

152

-

153

153

-

154

154

-

155

155

-

156

156

-

157

157

-

158

158

-

159

159

-

160

160

-

161

161

-

162

162

-

163

163

-

164

164

-

165

165

-

166

166

-

167

167

-

168

168

-

169

169

-

170

170

-

171

171

-

172

172

-

173

173

-

174

174

-

175

175

-

176

176

-

177

177

-

178

178

-

179

179

-

180

180

-

181

181

-

182

182

-

183

183

-

184

184

-

185

185

-

186

186

-

187

187

-

188

188

-

189

189

-

190

190

-

191

191

-

192

192

-

193

193

-

194

194

-

195

195

-

196

196

-

197

197

-

198

198

ESAB Precision PLASMARC® Cutting and High Speed Marking System with Integrated Flow Control Installation guide

- Category

- Welding System

- Type

- Installation guide

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

ESAB Precision PLASMARC® Cutting and High Speed Marking System Installation guide

-

ESAB Precision Plasmarc System with Electronic Flow Control Installation guide

-

ESAB Precision PLASMARC® Cutting and High Speed Marking System Installation guide

-

ESAB Precision Plasmarc System with Electronic Flow Control Installation guide

-

ESAB Precision Plasmarc System with Electronic Flow Control Installation guide

-

ESAB PT-15XL Plasmarc Water Injection Cutting Torch Installation guide

-

ESAB Precision Plasmarc System Series "A" User manual

-