Page is loading ...

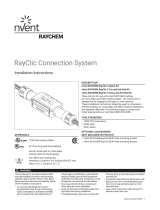

DESCRIPTION

The nVent RAYCHEM HWT-P Power Connection and End Seal Kit

is for use with nVent RAYCHEM HWAT heating cables. Materials

for one power connection and one end seal are included in this kit.

These installation instructions should be used in conjunction with

the HWAT System Installation and Operation Manual (H57548). For

technical support contact your nVent representative or call nVent at

800-545-6258.

TOOLS REQUIRED

• Screw driver • Pen

• Needle-nose pliers • Diagonal cutters

• Utility knife • Heat gun or torch

• Tape measure • Channel lock pliers

ADDITIONAL MATERIALS REQUIRED

(NOT PROVIDED IN THIS KIT)

• UL Listed or CSA Certified junction box suitable for the location,

with a through hole or threaded hub for 3/4-inch NPT.

APPROVALS

Heating Cable

718K Pipe

-G

HWAT heating cables are UL Listed, CSA Certified, and FM

Approved when used with the appropriate agency-approved

nVent components and accessories. The components are

intended for use in dry and accessible locations.

WARNING:

CAUTION:

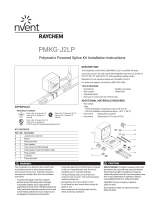

KIT CONTENTS

Item Qty Description

A 1 HWAT water heater tag

B 1 Gel-filled end seal

C 1 Pipe mounting bracket

D 1 #3 pipe strap

G 4 Warning labels

H 2 Wire nuts (red)

I 1 Wire nut (gray)

K 1 Lock nut

L 1 Cable gland

M 1 Black washer

N 1 Plastic cable tie

H

G

K

N

J

I

L

M

F

E

D

A

C

B

© 2014 nVent Thermal LLC

WWW.nVentTHERMA L.COM

PN P000001655 H59088 02/14

For HWAT Systems install this tag on

the hot water heater or temperature control valve

servicing the hot water systems.

ATTENTION

150°F

MAX.

DO NOT heat water above 150°F. Temperatures

above 150°F will permanently reduce the power

output of the HWAT heating cable used on this

hot water system.

HWT-P

HWAT Power Connection Kit with End Seal Installation Instructions

This component is an electrical device that must be

installed correctly to ensure proper operation and to prevent

shock or fire. Read these important warnings and carefully

follow all the installation instructions.

• To minimize the danger of fire from sustained electrical

arcing if the heating cable is damaged or improperly

installed, and to comply with the requirements of nVent,

agency certifications, and national electrical codes,

ground-fault equipment protection must be used. Arcing

may not be stopped by conventional circuit breakers.

• Bus wires will short if they contact each other. Keep bus

wires separated.

• Keep components and heating cable ends dry before

and during installation.

• The black heating cable core is conductive and can short.

It must be properly insulated and kept dry.

• Component approvals and performance are based

on the use of nVent–specified parts only. Do not use

substitute parts or vinyl electrical tape.

• Use fire-resistant insulation materials.

• Do not damage cable jackets or braid. Remove any

damaged cables or connections from service.

• Do not use aluminum feed wires.

• Leave these instructions with end user for reference and

future use.

HEALTH HAZARD: Overheating heat-shrinkable tubes will

produce fumes that may cause irritation. Use adequate

ventilation and avoid charring or burning. Consult MSDS

RAY3122 for further information.

CHEMTREC 24-hour emergency telephone:

(800) 424-9300

Non-emergency health and safety information:

(800) 545-6258.

Nickel-plated copper bus wires

Self-regulating conductive core

Polymer-coated aluminum wrap

Tinned-copper braid

Modified polyolefin inner jacket

HWAT

Modified polyolefin

outer jacket

Nickel-plated copper bus wires

Self-regulating conductive core

Polymer-coated aluminum wrap

Tinned-copper braid

Modified polyolefin inner jacket

HWAT

Modified polyolefin

outer jacket

Black washer

Do not cut

metal braid or

inner jacket.

6 1/2 in

24 in.

(60 cm)

• Unscrew cable gland (Item L).

• Discard white washer and use black washer

(Item M) instead.

• Slide nut, washer and grommet over the cable as

shown.

• Bevel on the washer should face into the nut.

• Lightly score completely around

and then down outer jacket.

• Bend heating cable to break jacket

at score then peel off outer jacket.

Power Connection Installation

• Carefully slide screwdriver

underneath the braid and poke

tip of screwdriver up through

2-3 bundles of the braid wire.

• Straighten out braid wire

• Repeat until entire length of braid is unraveled.

• Slowly pull

back on

screwdriver to

unravel

braid.

1

2

3

4

5

6

7

8

9

0

2 | nVent.com

1

2 3

4

Do not cut

bus wires.

1/2 in

6 in

Do not cut

bus wires.

1/4 in

• Using wire cutters, cut

away aluminum wrap.

• Straighten the braid and

twist braid into a pigtail.

• Do not shorten the braid.

• Notch core at the end

• Twist back and peel bus wires

from core

• Score between

bus wires at base

jacket

• Bend core to break

free at base jacket

• Peel core and any

remaining material

from bus wires

• At the end of each heating cable, lightly score completely

around and down inner jacket

• Bend heating cable to break jacket at score, then peel off

inner jacket

• Slide heat-shrinkable tubes (Item E) over the

bus wires.

• Starting from the center of the tube, move the

heat source continuously from side to side.

• Slide heat-shrinkable tube (Item J)

over the stripped portion of the cable,

until tube butts up against the outer

jacket.

• To prevent the shrink tube

from moving, slightly spread

the bus wires to hold tube in

place while shrinking.

CAUTION: Health

Hazard. Consult

material safety data

sheet RAY3122.

1

2

3

4

5

6

7

8

9

0

IMPORTANT: If using a

torch, be careful not to

overheat, char or

damage the tube.

nVent.com | 3

5

6

7

9 10

8

Lock

nut

Note: For junction

boxes with a

through hole,

use provided lock

nut (Item K).

Note: Ensure junction box is in proper orientation and

tighten to pipe mounting bracket (Item C). In some

cases, it may be required to install the junction box

in the 3 o'clock or 9 o'clock position on the pipe.

• Slip green/yellow tube (item F)

over braid and shrink.

1/2 in

1/2 in

5 1/2 in

• While tube is still hot, pinch with pliers between

bus wires to seal; hold for 10 seconds.

• Starting at center of tube, move heat source

continuously from side to side.

1 1/2"

• Slide grommet until end is 1 1/2"

from end of outer jacket

• Bring cable into

junction box

• Hand tighten nut

• With channel lock

pliers tighten nut, but

do not exceed more

than one (1) turn.

1

2

3

4

5

6

7

8

9

0

CAUTION: Health Hazard. Consult

included material safety data sheet.

CAUTION: Health Hazard. Consult

included material safety data sheet.

CAUTION: To avoid burns allow heated

sections to cool before touching.

4 | nVent.com

11

12

13

15

14

16

Cold

water in

HWAT water

heater tag

Mixing

valve

Tempered

water out

Hot water out

Hot water in

Water

heater

© 2014 nVent LLC

WWW.nVent.COM

PN P000001655 H59088 02/14

For HWAT Systems install this tag on

the hot water heater or temperature control valve

servicing the hot water systems.

ATTENTION

150°F

MAX.

DO NOT heat water above 150°F. Temperatures

above 150°F will permanently reduce the power

output of the HWAT heating cable used on this hot

water system.

Ground wire

Red wire nuts

(Item H)

Gray wire nut

(Item I)

• Apply warning label

(Item G) to junction

box cover.

• Use red wire nuts

(Item H) to connect

the supply with the

heating cable bus

wires.

• Use gray wire nut

(Item I) to connect

the ground braid to

the supply ground.

• Attach HWAT water heater tag

(Item A) to either the water

heater or temperature control

valve servicing the hot water

systems, using the plastic cable

tie (Item N).

1

2

3

4

5

6

7

8

9

0

nVent.com | 5

17

18

19

End Seal Installation for HWAT Heating Cables

1"

• Score down and around outer jacket 1 inch from the end.

• Remove the outer jacket.

• Do not cut or damage inner jacket.

• Using wire cutters, cut away aluminum wrap close to

braid and outer jacket.

• Remove exposed braid.

• Push end seal completely onto heating cable.

• Wipe off excess gel that may ooze out after you insert the

heating cable.

Note: The end seal can be installed only once; it cannot be

removed from the heating cable.

1

2

3

4

5

6

0

North America

Tel +...

Fax +...

Europe, Middle East, Africa

Tel +...

Fax +...

Asia Pacific

Tel +...

Fax +...

Latin America

Tel +1.713.868.4800

Fax +...

©2019 nVent. All nVent marks and logos are owned or licensed by nVent Services GmbH or its affiliates. All other trademarks are the property of their respective owners. nVent reserves the right to change

specifications without notice.

Raychem-IM-H59091-HWTP-EN-1901

1

2

3

4

nVent.com

/