Page is loading ...

Page 1

(SEE HOMEOWNER MANUAL FOR OPERATING INSTRUCTIONS)

INSTALLER:

Leave this manual with the appliance.

CONSUMER:

Retain this manual for future reference.

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

— Do not store or use gasoline or other

ammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch;

do not use any phone in your building.

• Leave the building immediately.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

• If you cannot reach your gas

supplier, call the re department.

— Installation and service must be

performed by a qualied installer,

service agency or the gas supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless

a certied kit is used.

This replace is design

certied in accordance

with American National

Standard/CSA Standard

ANSI Z21.88/CSA 2.33

and by Underwriters

Laboratories as a Direct

Vent Gas Fireplace

Heater and shall be

installed according to

these instructions.

GAS-FIRED

UL FILE NO. MH30033

HOT GLASS

DO NOT TOUCH

NEVER

WILL

CAUSE BURNS.

GLASS

UNTIL COOLED.

ALLOW CHILDREN

TO TOUCH GLASS.

DANGER

A barrier designed to reduce the risk of burns from the

hot viewing glass is provided with this appliance and shall

be installed for the protection of children and other at-risk

individuals.

DIRECT

-

VENT

ZERO CLEARANCE GAS

FIREPLACE HEATER SERIES:

DVCT40CSP95(N,P)-1

INSTALLATION INSTRUCTIONS

40651-3-0520Page 2

TABLE OF CONTENTS

Standard Work Checklist .............................................................................................................................................3

Before You Start .......................................................................................................................................................4-5

Carton Contents And Hardware ..................................................................................................................................6

Introduction ..................................................................................................................................................................7

Homeowner Reference Information ............................................................................................................................7

Specications ..............................................................................................................................................................8

Accessories .................................................................................................................................................................8

Fireplace Dimensions ..................................................................................................................................................9

Clearances ................................................................................................................................................................10

Vent Termination Clearances ...............................................................................................................................11-12

Gas Supply ................................................................................................................................................................13

Locating Fireplace .....................................................................................................................................................14

Electrical Considerations ...........................................................................................................................................14

Component Wiring Diagram ......................................................................................................................................15

Installation ............................................................................................................................................................16-19

Vent Framing ........................................................................................................................................................20-21

Vent System Identication .........................................................................................................................................22

Special Vent Systems ................................................................................................................................................22

Venting Fireplace ..................................................................................................................................................23-25

Horizontal Termination ...............................................................................................................................................26

Vertical Termination ..............................................................................................................................................27-29

Air Shutter Adjustment ...............................................................................................................................................30

Multifunction Remote Operating Instructions .......................................................................................................31-37

Control System Troubleshooting ..........................................................................................................................38-39

Accessing Valve Compartment .................................................................................................................................40

Testing Gas Supply ...................................................................................................................................................41

Parts List ...................................................................................................................................................................42

Exploded View ...........................................................................................................................................................43

Maintenance And Service .....................................................................................................................................44-45

Important Safety Information .....................................................................................................................................46

Requirements For Massachusetts .............................................................................................................................47

Master Parts Distributor List ......................................................................................................................................48

How To Order Repair Parts .......................................................................................................................................48

Appliance Service History ....................................................................................................................................49-50

Warranty ....................................................................................................................................................................51

SECTION PAGE

40651-3-0520 Page 3

ATTENTION INSTALLER:

Follow This Standard Work Checklist

This standard work checklist is to be used by the installer in conjunction with, not instead of, the instruction manual.

Customer: _____________________________________

Lot/Address: ___________________________________

_______________________________________________

Model: ________________________________________

Serial # ________________________________________

Date Installed: _________________________________

Fireplace Location: _____________________________

Installer: ______________________________________

Dealer Phone #: ________________________________

______________________________________________

Empire recommends the following:

• Photograph the installation and copying this checklist for your le.

• Keep this checklist visible on the replace until the installation is complete.

Comments: Further description of the issues, who is responsible (Installer/Builder/Other, etc) and corrective action needed:

___________________________________________________________________________________________________________

Comments communicated to party responsible _____________________by _____________________ on ______________________

DVCT40CSP95(N,P)-1

FIREPLACE INSTALLATION COMMENTS

Veried clearances to combustibles. (pg. 10) ...................................................................... o ____________________

Fireplace is leveled and secured. ........................................................................................ o ____________________

VENTING / CHIMNEY

Venting conguration complies to vent diagrams. (pg. 25) .................................................. o ____________________

Venting installed, locked, secured in place with correct clearance. ..................................... o ____________________

Firestops installed. ............................................................................................................... o ____________________

Exterior wall/roof ashing installed and sealed. ................................................................... o ____________________

Terminations installed and sealed. (pgs. 27-29) .................................................................. o ____________________

Light unit and test venting before enclosing the replace. ................................................... o ____________________

ELECTRICAL (pgs. 14-15)

Unswitched power (110-120 VAC) provided to the appliance. ............................................ o

____________________

GAS (pg. 13)

Proper appliance for fuel type. ............................................................................................. o

____________________

Was a conversion performed? .............................................................................................. oYes oNo

Leak check performed and inlet pressure veried ................................................................ o ____________________

FINISHING ( pg. 17)

Non-combustible board used as required............................................................................. o ____________________

Veried all clearances meet installation manual requirements. ........................................... o ____________________

Mantels and wall projections comply with installation manual requirements. ...................... o ____________________

Granite or Clean Face nishing complete and complies with clearance

requirements in installation manual. ....................................................................................

o ____________________

Barrier screen for glass properly installed. .......................................................................... o ____________________

FIREPLACE SETUP

All packaging and protective materials removed (inside & outside of appliance) . ............... o ____________________

Media installed correctly. ..................................................................................................... o ____________________

Firebox glass assembly cleaned, installed, and secured. ................................................... o ____________________

Accessories installed properly. ............................................................................................ o ____________________

Manual envelope and all of its contents are removed from inside/outside the

appliance and given to party responsible for use and operation. ........................................

o ____________________

Started Appliance and veried no gas leaks exist. .............................................................. o ____________________

40651-3-0520Page 4

BEFORE YOU START

Television Considerations

Installing a television above a replace has become increasingly

popular; however, the area above any replace gets hot and most

TV manufacturers recommend against placing their products near

a heat source.

If you install a television above this replace, Empire Comfort

Systems accepts no responsibility for damage or injuries. Follow

the television manufacturer’s installation instructions, including any

recommendations regarding proximity to heat sources.

If you have a TV above your replace, turn off the replace and let it

cool completely before servicing or touching any buttons on the TV.

Samples, Warnings, and Denitions:

DANGER

Indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE: Addresses practices not related to personal injury.

Read all instructions before starting installation and

follow them carefully to ensure safety. Failure to follow

the instructions will void the warranty and may cause

a re hazard.

The warranty will be voided by, and the warranter disclaims

any responsibility for the following actions:

• Installation by anyone other than the dealer or his agent.

• Installation of any damaged replace or component.

• Modication of the replace or direct vent system.

•

Installation other than as instructed by Empire Comfort Systems.

• Improper positioning of logs, glass door, or accessories.

• Installation and/or use of any component part not

manufactured or approved by Empire Comfort Systems.

All correspondence should refer to complete Model Number,

Serial Number and type of gas. Fill out the Homeowner

Reference Section on (Page 7).

Unpacking The Fireplace

1. Remove the outer boards/crate by removing screws.

2. Cut away shrink-wrap material around the unit. Retain

instruction manual and instruction sheets.

3. Remove (2) screws securing unit to pallet.

4. Get help to lift unit off of the pallet using the handles.

5. Remove non-combustible board from the pallet and place in

a safe location. It will be needed for installation.

6. Logs may remain in unit until installation in wall. Instruction

sheet from step #2 shows how to remove barrier screen and

glass door.

40651-3-0520 Page 5

BEFORE YOU START (CONT’D)

Accessories

Most accessories install much more easily before tting the replace

to the opening.

For example, it takes just 10-15 minutes to install the blower through

the back of the unit. Once the replace is framed in, it takes up

to an hour.

TrueFlame Technology

This replace is equipped with TrueFlame Technology for maximum

ames and ember glow with minimum emissions. The system

includes independently controlled front and rear burners set into a

large ember bed plus a ceramic catalyst and externally adjustable

bafe mounted at the top. Once adjusted by the dealer/technician at

installation, the TrueFlame system requires no scheduled service.

Preparation

This fireplace and its components are safe when installed in

accordance with this Manual. Report any parts damaged in shipment

to your dealer. Do not install the replace with damaged, incomplete

or substitute parts.

Installation Considerations

• Gas supply piping – right side entrance

• Electrical supply and connections

• 120V, 60Hz, 1 Amp

• Right side entrance

• Allowable replace mounting surfaces:

• A at, hard, combustible or non-combustible surface

• A raised platform of combustible or non-combustible material.

• The four corners of the replace onto non-combustible material

so that contact is made on all four perimeter edges on the

bottom of the replace – such as on cinder blocks

(where allowed by local codes).

• If the replace is installed directly on carpeting, tile or other

combustible material other than wood ooring, it should be

installed on a metal or wood panel extending the full width and

depth of the replace.

• This replace is designed to be installed in a zero-clearance

enclosure. Combustible material can come in contact with the

side standoff spacers, and the replace can be secured to

combustible framing with the framing brackets provided with

the replace.

Planning the installation

First determine where the fireplace will be located and what

accessories will be installed.

Your location must allow for:

• Venting – either vertical or horizontal. Choose a vent conguration,

(See Pages 26 - 29) and make sure the required access through

attics and walls is not blocked by other utilities such as water

lines, sewer vents, gas lines, etc. If access is blocked, you will

need to move the utilities or relocate the replace.

• Gas supply piping (right side entrance) – see pipe size and

specs on (Page 13).

• Electrical supply requirements

(120V, 60Hz, 1 Amp) (right side entrance)

• Proper framing required for installation of the replace.

See framing dimensions on (See Page 16).

• Finishing the fireplace – drywall thickness, tile or stone

thickness, and the desired decorative accessories can affect

how you frame the opening and how you attach the nailing

anges to set the proper depth. (See Page 17) for nishing

details, before you begin.

40651-3-0520Page 6

CARTON CONTENTS

Index

Number

Description

Quantity

Supplied

1 Unit 1

3 AAA Batteries 3

4 AA Batteries 4

5 Rockwool 2 Bags

6 Drywall Screws 10

7

Non-Combustible Board (on pallet)

2

8 Remote 1

9 Battery Holder & Switch 1

10 Ember Chunk Assembly 1

See Parts Lists on page 61 for ordering replacement parts. Do not order batteries, bolts, screws, washers or nuts.

They are standard hardware items and can be purchased at your local hardware store.

CARTON CONTENTS AND HARDWARE

IMAGE NOT TO SCALE

NOTICE: Re-Install Screws After Unpack (Outer Bottom)

Rock

wool

Rock

wool

1

3

4

5

6

10

7

8

9

EMBER CHUNK

ASSEMBLY

Under Pallet

40651-3-0520 Page 7

INTRODUCTION

The information in this manual pertains to all models and gas

control systems unless otherwise noted.

Instructions to Installer

1. Leave this manual with Homeowner.

2. Have the homeowner complete the Product Registration

Card or register online at www.empirecomfort.com

3. Show the homeowner how to start and operate the replace.

Notes to Installer

• This replace is designed to:

- Operate with combustion air siphoned from outside of

the building.

- Expel all exhaust gases to the outside of the building.

• The installation must conform with local codes or, in the

absence of local codes, with the National Fuel Gas Code

ANSI Z223.1/NFPA 54* Natural Gas and Propane Installation

Code, or CSA B149.1 in Canada. * Available from the

American National Standards Institute, Inc. 11 West 42nd

St., New York, N.Y. 10036

• Any alteration of the original design, installation other than

as shown in these instructions, or use with a type of gas not

shown on the rating plate is the responsibility of the person

and company making the change.

• This replace is not for use with solid fuels.

• These replace models may be installed in a bedroom or

bed-sitting room in the U.S.A. and Canada.

WARNING

Any change to this replace can be dangerous. Improper

installation or use can cause serious injury or death from re,

burns, explosion or carbon monoxide poisoning.

Fireplace Certication

This replace is design certied in accordance with American

National Standard/CSA Standard ANSI Z21.88/CSA 2.33 and by

Underwriters Laboratories as a Direct Vent Gas Fireplace Heater

and shall be installed according to these instructions.

Consult your local building code agency, prior to installation,

to ensure compliance with local codes-including permits and

inspections.

The replace, when installed, must be electrically grounded in

accordance with local codes or, in absence of local codes, with

the National Electric Code ANSI/NFPA 70 or Canadian Electric

code, CSA C22.1, if an external electrical source is utilized.

Qualied Installing Agency

Installation and replacement of gas piping, gas utilization

equipment or accessories and repair and servicing of equipment

shall be performed only by a qualied agency. The term “qualied

agency” means any individual, rm, corporation or company

which either in person or through a representative is engaged

in and is responsible for (a) the installation or replacement of

gas piping or (b) the connection, installation, repair or servicing

of equipment, who is experienced in such work, familiar with all

precautions required and has complied with all the requirements

of the authority having jurisdiction.

Commonwealth of Massachusetts: The installation must be

made by a licensed plumber or gas tter in the Commonwealth

of Massachusetts.

High Altitude (USA)

When installing this replace at an elevation above 2000 feet

(in the United States) it may be necessary to decrease the input

rating by changing the existing burner orice to a smaller size.

Generally, input should be reduced 4 percent for each 1000

feet above sea level. However, if the heating value of the gas

has been reduced, this general rule may not apply. Check with

Empire Comfort System’s local gas utility for proper orice size

identication.

High Altitude (CANADA)

Altitude: 0-4500 feet (0-1370 m)

When installing this replace at an elevation above 4500 feet

(in Canada), check with local authorities.

Consult your local gas utility for assistance in determining the

proper orice for your location.

HOMEOWNER REFERENCE INFORMATION

We recommend that you record the following information about your replace.

Model Number: _____________________________ Date purchased: ________________________

Serial Number: _____________________________ Location of replace: _____________________

Dealer Name: ______________________________ Dealer Phone: _________________________

Notes: ______________________________________________________________________________

40651-3-0520Page 8

SPECIFICATIONS

Model Number DVCT40NAT DVCT40LP

Input BTU/Hr Maximum (w/ both burners on) 60,500 55,000

Input BTU/Hr Minimum (w/ both burners on) 40,000 43,000

Input BTU/Hr Minimum (front burner on only) 16,500 26,000

KWH (Maximum) 17.73 16.12

KWH (Minimum) 11.73 12.60

Orice - Front #35 #52

Orice - Rear #37 1.55 mm

Air Shutter Opening Front Full Closed Full Opened

Air Shutter Opening Rear Full Closed Full Opened

Height without standoff (inches) 47-1/2 47-1/2

Width (inches) 57-1/4 57-1/4

Depth (inches) 24-3/16 24-3/16

Gas Inlet Shutoff Valve (pipe) 1/2 NPT 1/2 NPT

NOTE: Air shutter is at factory-minimum settings. Some vent congurations may require minor air shutter adjustments for optimum performance.

GAS SUPPLY PRESSURES (Inches Water Column)

Gas Type Maximum Minimum Manifold

Natural 14 4.5 3.5

Propane 14 10.8 10

VENTING LIGHT BULB REPLACEMENT

5 x 8 Direct Vent System 35w Clear Halogen, Bi-Pin 6.35mm base,120vac, UL

ACCESSORIES

The following accessory parts can be obtained from your Empire Comfort Systems dealer. For additional information beyond what your dealer can furnish,

contact Empire Comfort Systems Inc., 918 Freeburg Ave., Belleville, Illinois 62220-2623.

Model Number

ACCESSORIES

Description

DFF40FPD Decorative Front, Forged Iron Frame, Distressed Pewter

DFF40RPD Decorative Arch Insert, Forged Iron, Distressed Pewter

DFF40CPD

Decorative Rectangle Insert, Forged Iron, Distressed Pewter (Requires DFF40FPD)

DCA1ABL Andirons, Black

Model Number

CONVERSION KITS

Description

40636 Conversion Kit, IP System Natural to Propane Gas

40637 Conversion Kit, IP System Propane to Natural Gas

Model Number

OUTDOOR KIT

Description

DFED409SS Frame, Stainless Steel

Model Number

LOG SETS

Description

LS40STB Log Set for TruFlame Insert, Fiber - Traditional - Charred

Model Number LINER KITS

DVP40PS... A liner is required. Contact your Empire Comfort Systems Dealer for available liners.

NOTE: A liner kit and log set must be purchased and installed in order to operate the unit. The liner must be installed before installing the logs.

40651-3-0520 Page 9

R

R

B

B

C

C

E

E

F

F

I

I

J

J

A

A

K

K

L

L

M

M

N

N

O

O

P

P

D

D

Q

Q

FIREPLACE DIMENSIONS

INDEX LETTER DIMENSION DESCRIPTION DIMENSION (In Inches)

A The maximum height of replace face 47-1/2

B The maximum width of the replace face 57-1/4

C The maximum depth of the replace 24-3/16

D The height of the replace opening 35

E The width of the replace opening 40-7/8

F The interior depth of the replace

20

G The rear exterior width of the replace N/A

H The height to the replace standoffs N/A

I Width from the left side to the centerline of vent 28-5/8

J Depth from back to centerline of top vent 12-3/8

K Height from the bottom to the gas line opening 6-13/16

L Depth from the front to gas line opening 20

M Depth from rear to gas line opening 4-3/4

N Glass height 31-1/2

O Glass width 37-3/8

P Depth from front to centerline of vent 12-3/8

Q Distance from oor to replace opening 2

R Height from oor to vent collar 47-1/2

N/A - Not applicable for this unit.

Figure 1

40651-3-0520Page 10

Mantel Chart

COMBUSTIBLES

ALLOWED

WALL

STUD

FIREBOX FACE

72” MINIMUM

(CEILING TO FLOOR)

CEILING

FLOOR

OPENING OF

FIREPLACE

35”

MIN.

24”

MIN.

14”

MIN.

10”

A

B

C

D

E

F

WALL

FACING

Index

Letter

DISTANCE FROM

WALL FACING

DISTANCE FROM

TOP OF OPENING

Dimensions (In Inches)

A 2 14

B 4 15-5/8

C 6 17-5/16

D 8 19

E 10 20-5/8

F 12 24

Figure 4

Clearances

Clearance from top opening of replace to ceiling is 35 inches.

Clearance from opening to adjacent sidewall is 9 inches.

9” (228 mm)

TO

FIREPLACE

OPENING

35” (889mm)

TO

FIREPLACE

OPENING

Figure 5

CLEARANCES

CLEARANCE TO COMBUSTIBLES

Dimension (In Inches)

Back N/A

Side 3

Floor 0

Top of Unit 24

Top Framing Edge 0

FINISHED WALL

(COMBUSTIBLE)

NONCOMBUSTIBLE

BOARD INSTALLED

OVER APPLIANCE

SEE MANTEL CHART

FOR MAXIMUM

MANTEL DEPTH

FRAMING HEADER

FINISHED WITH

NONCOMBUSTIBLE

MATERIAL AS

DESIRED

REFER TO

MANTEL CHART

BARRIER SCREEN

AND GLASS FRONT

NAILING

FLANGES

Figure 2

NOTICE: Use only non-combustible materials to nish the face of

the replace.

9

PERPENDICULAR

SIDE WALL

3

MAX.

45

o

3

FRONT

FACE

(SIDE

Figure 3

40651-3-0520 Page 11

Figure 6

Vertical Sidewall Installations

Important! Minimum clearance between vent pipes and combustible

materials is 3 inch (76 mm) on top, and 1 inch (25 mm) on bottom

and sides.

Important! When vent termination exits through foundation less

than 20 inch (508 mm) below siding outcrop, the vent pipe must

extend outward so that the horizontal vent termination is located

ush to, or beyond the outcrop siding.

Information on Various Venting Routes and Components

Important: Locate the replace in such a way that minimizes the

number of offsets and horizontal vent length.

Since it is very important that the venting system maintain its balance

between the combustion air intake and the ue gas exhaust, certain

limitations as to vent congurations apply and must be strictly

adhered to.

The graph showing the relationship between vertical and horizontal

side wall venting will help to determine the various vent lengths

allowable.

The horizontal vent run refers to the total length of vent pipe from

the ue collar of the replace to the face of the outer wall.

Venting termination shall not be recessed into wall or siding.

ATTENTION: Vinyl Soft, Vinyl Ceiling, Vinyl Overhang

Disclaimer

Clearances are to heat resistant material (i.e. wood, metal). This

does not include vinyl. Empire Comfort Systems Inc. will not be held

responsible for heat damage caused from terminating under vinyl

overhangs, vinyl ceilings or vinyl ventilated/unventilated softs.

Termination clearance for buildings with combustible and noncombustible exteriors.

VENT TERMINATION CLEARANCES

40651-3-0520Page 12

VENT TERMINATION CLEARANCES (CONT’D)

Canadian Installations1 US Installations2 Canadian Installations1 US Installations2

A= Clearance above grade,

veranda, porch, deck, or

balcony

12-in (30cm) 12-in (30cm)

I= Clearance to service

regulator vent outlet

3ft (91cm) 61-in

B= Clearance to window or

door that may be open

12-in (30cm) for

appliances >

10,000Btuh (3kW) and

≤ 100,000 Btuh (30kW)

9-in (23cm) for

appliances >

10,000Btuh

(3kW) and ≤ 50,000

Btuh (15kW)

J= Clearance to non-me-

chanical air supply

inlet to building or the

combustion air inlet to

any other appliance

12-in (30cm) for

appliances > 10,000

Btuh (3kW) and ≤

100,000 Btuh (30kW)

9-in (23cm) for

appliances > 10,000Btuh

(3kW) and ≤ 50,000Btuh

(15kW)

C= Clearance to permanent-

ly closed window

12-in (30cm) 12in (30cm)

K= Clearance to a me-

chanical air supply inlet

6ft (1.83m)

3ft (91cm) above if within

10ft (3m) horizontally

D= Vertical clearance venti-

lated soft located above

the terminal within a hor-

izontal distance of 2 feet

(61cm) from the center

line of the terminal

18-in 18-in

L= Clearance above

paved sidewalk or

paved driveway

located on public

property

7ft (2.13m) † 7ft (2.13m)

E= Clearance to unventilat-

ed soft

18-in 18-in

M= Clearance under

veranda, porch

deck, or balcony

12-in (30cm) ‡ 12-in (30cm)

F= Clearance to outside

corner

See previous page. 1

In accordance with the current CSA B149.1, Natural Gas and Propane

Installation Code

G= Clearance inside corner See previous page. 2

In Accordance with the current ANSI Z223.1/NFPA 54, National Fuel Gas Code

H= Clearance to each side

of center line extended

above meter/regulator

assembly

3ft (91cm) within a

height 15ft (4.5m)

above the meter/regula-

tor assembly

3ft (91cm) †

A vent shall not terminate directly above a sidewalk or paved driveway that

is located between two single family dwellings and serves both dwellings

ATTENTION: Vinyl Soft, Vinyl Ceiling, Vinyl Overhang

Disclaimer

Clearances are to heat resistant material (i.e. wood, metal). This

does not include vinyl. Empire Comfort Systems Inc. will not be

held responsible for heat damage caused from terminating under

vinyl overhangs, vinyl ceilings or vinyl ventilated/unventilated softs.

‡

Permitted only if veranda,, porch, deck, or balcony is fully open on a mini-

mum of two sides beneath the oor.

*

For clearances not specied in ANSI Z223.1/NFPA 54 or CSA B149.1, one

of the following shall be indicated:

Clearance in accordance with local installation codes and the requirements of the

gas supplier.

40651-3-0520 Page 13

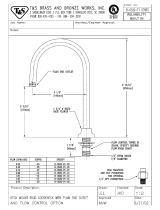

GAS SUPPLY

The gas pipeline can be brought in through the right side of the

replace. The replace has a Flexline with shut-off valve located

on the right side when facing the replace. See Figures 7.

Consult the current National Fuel Gas Code, ANSI Z223.1 CAN/

CGA-B149 (.1 or .2) installation code.

CAUTION

Never use plastic pipe. Check to conrm whether your local

codes allow copper or galvanized tubing.

NOTICE: Some municipalities have additional local codes.

Consult your local authority and installation code.

The use of the following gas connectors is recommended:

— ANSI Z21.24 Fireplace Connectors of Corrugated Metal

Tubing and Fittings.

— ANSI Z21.45 Assembled Flexible Fireplace Connectors of

Other Than All-Metal Construction

The above connectors may be used if acceptable by the authority

having jurisdiction. The Commonwealth of Massachusetts requires

that a exible replace connector cannot exceed three feet in length.

Figure 7

Installing the Main Gas Shut-Off

Each replace should have its own manual gas shut-off.

A manual main gas shut-off should be located in the vicinity of the

replace and can be easily accessed. Where none exists, or where

its size or location is not adequate, contact your local authorized

installer for installation or relocation.

Compounds used on threaded joints of gas piping shall be resistant

to the action of liqueed petroleum gases. The gas lines must be

checked for leaks by the installer. Testing for leaks on all exposed

connections should be done with leak test solution or a soap

solution. After testing is complete, all solution should be cleaned off.

On unexposed connections, a pressure test should be made.

WARNING

Never use an exposed ame to check for leaks. Fireplace

must be disconnected from piping at inlet of control valve and

pipe capped or plugged for pressure test. Never pressure test

with replace connected; control valve will sustain damage.

NOTICE: The gas controls are equipped with a captured screw-

type pressure test point. It is not necessary to provide a 1/8-inch

test point up stream of the control.

When using copper or ex connector use only approved ttings.

The replace and its individual shut-off valve must be

disconnected from supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig

(3.5kPa).

The replace must be isolated from the gas supply piping

system by closing its individual manual shut-off valve during any

pressure testing of the gas supply piping system at test pressures

equal to or less than 1/2 psig (3.5kPa).

WARNING

If one of the procedures results in pressures in excess of

1/2 psig (14 inches w.c.) (3.5 kPa) on the replace gas valve,

it will result in a hazardous condition.

LEFT SIDE OF FIREPLACE

FRONT

OF FIREPLACE

GAS FLEX

LINE WITH

SHUT-OFF VALVE

(PROVIDED)

11 3/4”

19 3/8”

Figure 8

A gas valve and ground joint union should be installed in the gas

line upstream of the gas control to aid in servicing. The National

Fuel Gas Code requires that a drip leg be installed near the gas

inlet. See Figure 9. This should consist of a vertical length of

pipe tee connected into the gas line that is capped on the bottom

in which condensation and foreign particles may collect.

GAS SUPPLY PLUMBING

MANUAL

SHUT-OFF VALVE

GAS SUPPL

Y

INLET

DRIP LEG

3” MINIMUM

TO

CONTROL

VALVE

Figure 9

6 13/16"

20"

40651-3-0520Page 14

NOTICE: When installing this appliance against an exterior wall,

insulate to applicable insulation codes.

NOTICE: Island and Room Divider installation is possible as long

as the horizontal portion of the vent system does not exceed 18 feet

with a minimum vertical run of 8 feet. See details in Venting Section.

When you install your Direct Vent Fireplace in room divider or at

on wall corner positions, maintain a minimum of 6 inches between

the perpendicular wall and the opening of the appliance.

LOCATING FIREPLACE

ROOM DIVIDER

INSTALLATION

FLUSH WALL

INSTALLATION

ISLAND

INSTALLATION

CABINET

INSTALLATION

CORNER

INSTALLATION

Figure 10

ELECTRICAL CONSIDERATIONS

Junction Box

A factory-installed junction box is located on the lower right side of

the replace. Wiring must be fed to the junction box and attached

with wire nuts to the control module power leads already fed into

the junction box.

Attach black to black and white to white. The ground wire should be

attached to the ground on the junction box. See Figure 11.

Interface/Battery Holder

The user interface/battery holder must be mounted within a distance

allowed by the attached 12 foot harness. As shipped, this harness is

already fed through a strain relief on the bottom of the component

access box and is attached to the User Interface/Battery Holder.

NOTICE: If an auxiliary device is to be used, its wiring may be fed

through the junction box strain relief. Auxiliary device amperage

limit is 5 amps.

NOTICE: A one inch diameter hole should be use to pass wiring

through studs.

BLACK (HOT)

JUNCTION BOX

WHITE (NEUTRAL)

GROUND TO JUNCTION BOX

120 VOLT POWER SUPPLY

JUNCTION BOX CONNECTIONS

Figure 11

CAUTION

All wiring should be done by a qualied electrician and shall be in compliance with all local, city and state building codes.

Before making the electrical connection, make sure that the main power supply is disconnected. The appliance, when installed,

must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical

Code ANSI/NFPA 70 (Latest Edition).

VERTICAL

FRAMING

MEMBER

USER INTERFACE

HARNESS

USER INTERFACE/

BATTERY HOLDER

MUST BE INSTALLED

INTO WALL JUNCTION

BOX. (ORANGE LOW-

VOLTAGE BOX

RECOMMENDED.)

ELECTRICAL POWER TO UNIT

JUNCTION BOX / CONTROL MODULE

Figure 12

40651-3-0520 Page 15

Figure 13

COMPONENT WIRING DIAGRAM

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED

WITH THIS UNIT MUST BE REPLACED, IT MUST

BE REPLACED WITH EQUI

V

ALENT GAUGE AND

TEMPERATURE RATED WIRE.

SI LE FIL ORIGINAL L'UN DES COMME FOURNI

AVEC CETTE UNITÉ DOI

T

ÊTRE REMPLACÉ, IL

DOIT REPLCED AVEC LA MESURE ÉQUI

V

ALENTE

ET LE FIL ÉVALUÉ PAR TEMPÉRATURE.

ORANGE

PILOT

GAS CONTROL VALVE

ORANGE

GREEN

YELLOW

WHITE

FUSE

BLACK

WHITE

GREEN

TO JUNCTION

BOX

LOOP

TO LIGHTS

SPLIT FLOW SOLENOID

SLEEVE

USER INTERFACE/

BATTERY HOLDER

A

D

B

C

INDEX NUMBER DESCRIPTION PART NUMBER

A WIRE HARNESS, ACCENT LIGHT TERMINATION R12269

B WIRE ASSEMBLY, MODULE TO INTERFACE R11552

C WIRE HARNESS, PROFLAME2 R11551

D WIRE HARNESS, MODULE TO JUNCTION BOX R11730

Top of Receiver Module

Figure 14

Bottom of Receiver Module

Figure 15

40651-3-0520Page 16

INSTALLATION

A1

C

A2

B

DIMENSIONS (In Inches)

Unit Only With Outdoor Kit

A1 59 59

A2 59 62

B 57-3/4 58

C 23-1/2 25-1/2

Figure 16

The replace can be mounted on any of the following surfaces:

1. A at, hard combustible or non-combustible surface.

2. A raised wooden platform.

3. Four corner supports. (Example: Four concrete masonry

blocks.) These supports must be positioned so they contact

all four perimeter edges on the bottom of the replace, if

allowed by local codes.

NOTICE: Verify the gas supply and electrical considerations

before beginning the framing.

Framing Information

Fireplace framing can be built before or after the replace is set

in place. Position framing to accommodate wall covering and

replace facing material. Construct the replace framing with

2 x 4 lumber or heavier. If outdoor kit is installed, header

must be metal studs. Refer to the INSTALLATION TABLE for

minimum framing dimensions.

CAUTION

Before construction begins, measure replace dimensions

and verify framing methods and wall covering details.

40651-3-0520 Page 17

INSTALLATION (CONT’D)

NAILING FLANGES

FLUSH WALL INSTALLATION

NONCOMBUSTIBLE

BOARD INSTALLED

OVER APPLIANCE

FINISHED

WALL

NAILING

FLANGES

SECURED

IN PLACE

FOR 1/2”DRYWALL

FOR 5/8”DRYWALL

FINISHED

WALL

NONCOMBUSTIBLE

BOARD INSTALLED

OVER APPLIANCE

FRAMING

HEADER

13”

HEAT

SHIELD

SECURE TO

HEADER

Figure 17 Figure 18

Figure 19 Figure 20

WARNING

When nishing the replace never obstruct or modify the

gap around the glass frame in any manner. Provide adequate

clearances around air openings into the combustion chamber.

CAUTION

If the joints between the nished wall and the replace surround

(top and sides) are sealed, a 300°F minimum sealant material

must be used. These joints are not required to be sealed. Only

non-combustible material (using 300°F minimum adhesive if

needed) can be applied as facing to the replace surround.

40651-3-0520Page 18

INSTALLATION (CONT’D)

ON TOP AND SIDES AND

BETWEEN 1/2”TO 3/4”AT BOTT

OM

Figure 21

Horizontal Vent Clearance

For horizontal vent, maintain 1 inch of clearance to the bottom

and sides of vent, and 6 inches of clearance to combustibles

above the vent pipe. See Figure 223.

Vertical Vent Clearance

For vertical vent, maintain a minimum 1 of inch clearance to

combustibles.

NOTICE: Maintain 1 of inch of clearance to combustibles around

vertical vent pipe. See Figure 22. For horizontal vent systems,

maintain a minimum 1 inch of clearance from the bottom and sides

of the vent to combustibles and a 3 inches of clearance above the

vent pipe to combustibles. See Figures 22 and 23.

VENT PIPE

1” MINIMUM CLEARANCE

AROUND VENT PIPE

Figure 22

TOP OF VENT

COMBUSTIBLES NOT

ALLOWED IN SHADED

AREA

6” (152 mm)

8” DIAMETER

INTAKE VENT

1” (25 mm)

5” DIAMETER FLUE

1” (25 mm)

Horizontal Vent Clearances - Figure 23

NOTE: Top clearance through outside wall is 3 inches.

ATTENTION: Cold climate installation recommendation: When

installing this unit against an exterior wall, the exterior wall must

be insulated to conform to applicable insulation codes. The

replace outer wrapper is not considered a thermal barrier and

can allow air inltration. Care should be taken to properly seal

the chase area so air inltration is kept to a minimum and drafts

do not occur through the replace.

Vent Runs

In planning the installation, you must install certain components

before the replace is secured in position. These include the

direct-vent system, gas piping, and the electrical wiring.

The appliance can be mounted on any of the following surfaces:

1. A at, hard combustible or non-combustible surface.

2. A raised wooden platform.

3. Four corner supports(such as masonry blocks). These supports

must be positioned so they contact all four perimeter edges on

the bottom of the unit.

OVERLAP TOP EDGE OF

NON-COMBUSTIBLE

BOARD WITH EXTERIOR

WEATHER BARRIER

SEAL THE PERIMETER OF

THE OUTDOOR KIT WITH

(300°F (149°C) SEALANT

FACING MATERIAL MUST

OVERLAP THE OUTDOOR

KIT PERIMETER BY AT

LEAST 1" ON TOP AND

SIDES AND BETWEEN 1/2"

TO 3/4" AT BOTTOM

FACING MATERIAL MAY

OVERLAP THE OUTDOOR

KIT UP TO 1/2" AWAY FROM

THE KIT OPENING

SEAL THE INTERFACE

BETWEEN THE OUTDOOR

KIT AND THE FACING

MATERIAL WITH AN

EXTERIOR CAULK

40651-3-0520 Page 19

VERTICAL, 90-DEGREE ELBOW TO HORIZONTAL

OUT THE WALL

(24 inch minimum rise before elbow)

VENT CAP

WALL FIRESTOP/

THIMBLE/SPACER

90 ELBOW

◦

A

C

B

DIMENSION (in Inches)

A B C

24 36 4-3/4

Figure 24

VERTICAL, 90-DEGREE ELBOW WITH

HORIZONTAL TERMINATION

VENT CAP

WALL FIRESTOP/

THIMBLE

90° ELBOW

24” MINIMUM

VERTICAL VENT

REQUIRED

A”

DISTANCE

TO BOTTOM

OF UNIT

NO COMBUSTIBLES ALLOWED

IN SHADED AREA

Figure 25

DVCT40 - DIMENSION (in Inches)

A 82

INSTALLATION (CONT’D)

40651-3-0520Page 20

VENT FRAMING

Installing Support Brackets

Install a horizontal pipe support used for each 3 feet of horizontal run

to framing members. Allow 6 inches of clearance to combustibles

above 5x8 inch diameter pipe and elbows and 1 inch of clearance

on both sides and bottom.

Support vertical runs of this vent systems every 4 feet using wall

brackets attached to the vent pipe and secured with nails or screws

to structural framing.

48”

PIPE

STRAP

Installing Firestops - Figure 26

Firestops are required for safety whenever the vent system passes

through an interior wall, an exterior wall, or a ceiling. These restops

act as a rebreak heat shield and as a means to insure that minimum

clearances are maintained to the vent system.

Horizontal Firestops

Horizontal runs in the vent system which pass through either interior

or exterior walls, require the use of wall restops on both sides of

the wall through which the vent passes.

Position the restops on both sides of the framed hole, previously

cut. Secure restop with nails or screws. The heat shields of the

restops MUST BE placed towards the top of the hole. Continue

the vent run through the restops.

WALL THIMBLE

Figure 27

NOTICE: Use the wall thimble (SD58DVAWTEC) to maintain the

required three inches of clearance to combustibles above the vent.

NON-COMBUSTIBLE AREA

EXTERIOR WALL

STANDARD

VENT PIPE

A

B

WALL FRAMING

NON-COMBUSTIBLE AREA

FIRESTOP

THIMBLE

SPACER

WALL THIMBLE

DIMENSIONS (in inches)

A 3

B 1

Figure 28

/