Page is loading ...

Service Manual

SPEED OVEN

Please read this manual completely before attempting

to install, operate or service this equipment

This document is prepared for trained Duke service technicians. It is not to be used by anyone not

properly qualied to perform these procedures.

This Service Manual is not all encompassing. If you have not been trained on servicing this product,

be sure to read the manual completely before attempting servicing. Be sure all necessary tools,

test equipment, and skills are available. Those procedures for which you do not have the proper

skills and test equipment must be performed only by a qualied Duke trained service technician.

This manual is Copyright © 2011 Duke Manufacturing Co. All rights reserved.

Reproduction without written permission is prohibited. Duke is a registered

trademark of the Duke Manufacturing Co.

Duke Manufacturing Co.

2305 N. Broadway

St. Louis, MO 63102

Phone: 314-231-1130

Toll Free: 1-800-735-3853

Fax: 314-231-5074

www.dukemfg.com

P/N 168939B

MODEL

RCO

SELECT

TIME

1

2

3

4

5

6

7

8

9

10

HEAT

MICROWAVE

TEMP

FAN

MICRO

WAVE

Service Manual for RCO Speed Oven

2

IMPORTANT WARNING AND SAFETY INFORMATION

THIS MANUAL HAS BEEN PREPARED FOR PERSONNEL QUALIFIED TO INSTALL

ELECTRICAL EQUIPMENT, WHO SHOULD PERFORM THE INITIAL FIELD STARTUP AND

ADJUSTMENTS OF THE EQUIPMENT COVERED BY THIS MANUAL.

READ THIS MANUAL THOROUGHLY BEFORE OPERATING, INSTALLING OR

PERFORMING MAINTENANCE ON THE EQUIPMENT.

Failure to follow all the instructions

in this manual can cause property damage, injury

or death.

Improper installation, adjustment,

alteration, service or maintenance can cause property

damage, injury or death.

Electrical connections should be

performed only by a certied professional.

Electrical and grounding connections

must comply with the applicable portions of the

National Electric Code and/or all local electric

codes. Failure to comply with this procedure can

cause property damage, injury or death.

Before connecting the unit to the

electrical supply, verify that the electrical and grounding

connections comply with the applicable portions of

the National Electric Code and/or other local electrical

codes. Failure to comply with this procedure can

cause property damage, injury or death.

Before connecting the unit to the

electrical supply, verify that the electrical connection

agrees with the specications on the data plate.

Failure to comply with this procedure can cause

property damage, injury or death.

UL73 grounding instructions: This

appliance must be connected to a grounded, metal,

permanent wiring system. Or an equipment-grounding

conductor must be run with the circuit conductors

and connected to the equipment-grounding terminal

or lead on the appliance. Failure to comply with

this procedure can cause property damage, injury

or death.

Appliances equipped with a exible

electric supply cord, are provided with a three-prong

grounding plug. It is imperative that this plug be

connected into a properly grounded three-prong

receptacle. Failure to comply with this procedure

can cause property damage, injury or death.

If the receptacle is not the proper

grounding type, contact an electrician. Do not

remove the grounding prong from the plug. Failure

to comply with this procedure can cause property

damage, injury or death.

Before performing any service that

involves electrical connection or disconnection and/or

exposure to electrical components, always perform the

Electrical LOCKOUT/TAGOUT Procedure. Disconnect

all circuits. Failure to comply with this procedure

can cause property damage, injury or death.

Before removing any sheet metal

panels or servicing this equipment, always perform

the Electrical LOCKOUT/TAGOUT Procedure. Be sure

all circuits are disconnected. Failure to comply

with this procedure can cause property damage,

injury or death.

Do not operate this equipment

without properly placing and securing all covers and

access panels. Failure to comply with this procedure

can cause property damage, injury or death.

Do not use or store gasoline or

other ammable vapors or liquids in the vicinity

of this or any other appliance. Failure to comply

can cause property damage, injury or death.

In the event of a power failure,

do not attempt to operate this appliance. Failure to

comply can cause property damage, injury or death.

The High Voltage Capacitor retains

a 2.5kV DC charge after the oven has been

disconnected from its power source. The capacitor

must be properly discharged prior to beginning

work on any components in the high voltage area.

Failure to comply can cause property damage,

injury or death.

If Oven is operative before servicing,

a microwave leakage test should be performed

prior to servicing the oven.

3

Service Manual for RCO Speed Oven

FDA CODE OF FEDERAL REGULATIONS

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING: TO AVOID POSSIBLE

EXPOSURE TO EXCESSIVE MICROWAVE ENERGY:

A. Do not operate or allow the oven to be operated with the door open.

B. Make the following safety checks on all ovens to be serviced before activating the magnetron or other microwave

source, and make repairs as necessary:

1. Interlock operation,

2. Proper door closing,

3. Seal and sealing surfaces (arcing, wear, and other damage),

4. Damage to or loosening of hinges and latches,

5. Evidence of dropping or abuse.

C. Before turning on microwave power for any service test or inspection within the microwave generating compartments,

check the magnetron, wave guide or transmission line, and cavity for proper alignment, integrity, and connections.

D. Any defective or misadjusted components in the interlock, door seal, and microwave generation and transmission

systems shall be repaired, replaced, or adjusted by procedures described in this manual before the oven is

released to the owner.

E. A microwave leakage check to verify compliance with the Federal performance standard should be performed

on each oven prior to release to the owner.

Service Manual for RCO Speed Oven

4

TABLE OF CONTENTS

INSTALLATION .................................................................................................................6

UNPACKING...............................................................................................................6

RADIO INTERFERENCE ...........................................................................................6

OVEN PLACEMENT...................................................................................................6

ELECTRICAL REQUIREMENTS ................................................................................6

GROUNDING INSTRUCTIONS .................................................................................6

TOOLS .......................................................................................................................7

SPECIFICATIONS ...................................................................................................... 7

REMOVAL AND REPLACEMENT OF COMPONENTS ....................................................8

Electrical LOCKOUT/TAGOUT Procedure .................................................................8

COVERS AND PANELS .............................................................................................8

Top Panel ............................................................................................................. 8

Side Panels ..........................................................................................................8

Rear Panel Exhaust Vent Covers ........................................................................8

Rear Heater Cover ...............................................................................................9

Louvered Rear Service Panel .............................................................................. 9

EXHAUST FANS ........................................................................................................9

Exhaust Fan Replacement ................................................................................10

Left Side Tangential Blower ...............................................................................10

Tangential Blower Replacement ........................................................................10

Right Side Cooling Fan ...................................................................................... 11

SOLID STATE RELAYS ............................................................................................ 11

MONITOR RELAY ....................................................................................................12

VOLTAGE RELAY ..................................................................................................... 12

LINE FUSE ...............................................................................................................13

CONTROL BOX ASSEMBLY .................................................................................... 14

SIGNAL TRANSFORMER ........................................................................................15

DOOR SWITCHES ................................................................................................... 15

THERMAL CUTOUTS ..............................................................................................16

HEATING ELEMENTS..............................................................................................17

DOOR REPLACEMENT ...........................................................................................18

INVERTER................................................................................................................19

CONVECTION BLOWER MOTOR ASSEMBLIES ...................................................19

MAGNETRON COOLING FAN .................................................................................20

MAGNETRON COOLING FAN REPLACEMENT .....................................................20

MAGNETRON THERMAL SWITCHES ....................................................................21

MAGNETRON ..........................................................................................................22

HIGH VOLTAGE (HV) TRANSFORMERS ................................................................23

HIGH VOLTAGE (HV) CAPACITORS ....................................................................... 25

HIGH VOLTAGE (HV) DIODES ................................................................................27

WAVEGUIDES ..........................................................................................................28

5

Service Manual for RCO Speed Oven

SYSTEM AND COMPONENT TESTING ........................................................................30

GENERAL SYSTEM TEST ....................................................................................... 30

Introduction .......................................................................................................30

Oven Operating Statistics ..................................................................................30

Screen Displays ................................................................................................. 30

FAN TEST .................................................................................................................31

CLEAR COUNTS .....................................................................................................32

MICROWAVE LEAKAGE TEST ................................................................................32

COMPONENT TESTING .................................................................................................33

DISCHARGING THE HIGH VOLTAGE SYSTEM ..................................................... 33

Function .............................................................................................................33

Location and Access .......................................................................................... 33

Safety Issues .....................................................................................................33

Tools Required ................................................................................................... 33

HIGH VOLTAGE CAPACITOR DISCHARGE PROCEDURE ...................................33

POWER TRANSFORMER TEST .............................................................................34

HIGH VOLTAGE DIODE TEST .................................................................................34

MONITOR RELAY ....................................................................................................35

Monitor Circuit Test ............................................................................................36

ADJUSTMENTS ..............................................................................................................38

DOOR INTERLOCK ADJUSTMENT ........................................................................38

INVERTER PROGRAMMING ...................................................................................39

Programming Procedure ....................................................................................39

Inverter Settings .................................................................................................40

MAINTENANCE ..............................................................................................................49

STAINLESS STEEL CARE .......................................................................................49

CARE AND CLEANING ............................................................................................ 49

TROUBLESHOOTING .............................................................................................51

ELECTRICAL SCHEMATIC .............................................................................................54

CUSTOMER ASSISTANCE .............................................................................................55

Service Manual for RCO Speed Oven

6

INSTALLATION

ELECTRICAL REQUIREMENTS

TO AVOID RISK OF ELECTRICAL

SHOCK OR DEATH, THIS OVEN MUST BE

GROUNDED AND ITS PLUG MUST NOT BE

ALTERED.

The operation of this microwave oven can cause

voltage fluctuations on the supply line. The

operation of this oven under unfavorable voltage

supply conditions can have adverse effects.

• This device is intended for the connection to a

power supply system with maximum permissible

systemimpedanceZmaxof1.1Ωattheinterface

point of the user’s supply.

• TheuserMUSTensurethatthisdeviceisconnectedonly

toapowersupplysystemwhichfulllsthisrequirement.

• The public power supply company can provide

system impedance at the interface point.

• The fuse used in this oven is Ferraz Shawmut

OTM30 Fuse (Duke PN: 168120, 250 VAC, 30 A).

GROUNDING INSTRUCTIONS

IMPROPER INSTALLATION

OR GROUNDING CAN RESULT IN RISK

OF ELECTRICAL SHOCK. CONSULT A

QUALIFIED ELECTRICIAN OR SERVICEMAN

IF THE GROUNDING INSTRUCTIONS ARE NOT

COMPLETELY UNDERSTOOD, OR IF DOUBT

EXISTS AS TO WHETHER THE APPLIANCE

IS PROPERLY GROUNDED. DO NOT USE AN

EXTENSION CORD. IF THE POWER SUPPLY

CORD IS TOO SHORT, HAVE A QUALIFIED

ELECTRICIAN OR SERVICEMAN INSTALL AN

OUTLET NEAR THE APPLIANCE.

Grounding reduces risk of electric shock by providing

a conductor for the electric current if an electrical

short occurs.

• This oven is equipped with a cord and plug

containing a properly wired ground.

UNPACKING

Inspect oven for physical damage to the cabinet. Also

check the oven cavity for damage. Report any damage

to the source of purchase immediately. Do not attempt

to install or use the oven if damaged.

Remove all materials from oven interior.

If oven has been stored in an extremely cold area, wait

a few hours before connecting power.

RADIO INTERFERENCE

Microwave operation may cause interference to radio,

television, or a similar oven. Reduce or eliminate

interference by performing the following:

• Keeptheovendoorandsealingsurfacesofthe

oven clean according to instructions in Care and

Cleaning instruction in the OPERATORS MANUAL

(Duke PN:168913).

• Placeradio,television,etc.asfaraspossiblefrom

the oven

• Use a properly installed antenna (radio/TV) will

help to eliminate interference caused by the oven.

OVEN PLACEMENT

• Do not install the oven next to or above source of

heat,suchaspizzaovenordeepfatfryer.

• Install the oven on a level countertop surface.

• ProvideclearanceasdescribedintheSpecications

section.

WARNING

RISK OF APPLIANCE FALLING.

RISK OF PERSONAL INJURY

ONLY operate appliance if its legs are in direct

contact with the countertop or supporting

surface. If the legs are not in direct contact with

the supporting surface, the appliance can creep

slowly during repeated use, eventually falling

off the surface when the door is opened. Such

a fall could possibly injure anyone nearby. The

appliance is often installed using sliding pads

which are inserted between its legs and

supporting surface. These sliding pads MUST

be removed before operating the oven. Nothing

else should be inserted between the legs and the

supporting surface.

7

Service Manual for RCO Speed Oven

SPECIFICATIONS

MODEL RCO (SINGLE PHASE – 208 – 240VAC 60Hz)

Input Power

Operating Voltage 208VACto240VAC,60Hz

(Plug & Play)

Current 30A max

Phase Single

Fuse FerrazShawmutOTM30

(250VAC, 30A)

Plug NEMA L6-30P twist lock

Output Power

Microwave 2000W nominal

Heating Elements 4400W nominal @ 208VAC

Dimensions

Height 24" (60.96cm)

Width 26" (66.04cm)

Depth 32" (81.28cm)

Internal Cook Cavity Dimensions

Height 10.5" (26.67cm)

Width 16.75" (42.55cm)

Depth 14.75" (37.47cm)

Weight

Unpacked 250lbs (113kg)

Packed 325lbs (147kg)

Clearances

Top 6” (15.2cm)

Sides 3" (7.62cm) when next to other

heat sources

.5” (1.3cm) when next to wall

Back 0

• Theplugmustbeconnectedtoaproperlyinstalled

and grounded outlet.

• DONOTchangetheunit’scord.Ifthecordistoo

short an additional grounded outlet must be installed.

• Thisovenmustbeconnectedtoaseparatecircuit

with the electrical rating as provided in product

specications.

TOOLS

• Astandardsetoftoolsisrequired

• Adigitalmultimeter

• MicrowaveLeakageSurveymeter

• 1LiterPyrexBeaker

• ThermocoupleforTemperatureMeasurement

• TooltoDischargeHVCapacitor(DukePN:168775)

• NeedleNosePlierswithInsulatedGrips.

Service Manual for RCO Speed Oven

8

ELECTRICAL LOCKOUT/TAGOUT

PROCEDURE

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

The Electrical LOCKOUT/TAGOUT Procedure is used

to protect personnel working on an electrical appliance.

Before performing any maintenance or service that

requires exposure to electrical components, follow

these steps:

1. In electrical box, place appliance circuit breaker

into OFF position.

2. Place a lock or other device on electrical box

cover to prevent someone from placing circuit

breaker ON.

3. Place a tag on electrical box cover to indicate

that appliance has been disconnected for service

and power should not be restored until tag is

removed by maintenance personnel.

4. Disconnect appliance power cord from electrical

outlet.

5. Place a tag on the cord to indicate that unit

has been disconnected for service and power

should not be restored until tag is removed by

maintenance personnel.

COVERS AND PANELS

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

CAUTION: Interior components and surfaces may

be hot if the unit has been in recent use.

Top Panel

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove all of the sheet metal screws that secure

the Top Panel to the unit. Set aside for reuse.

3. Remove the Top Panel to gain access to the control

components.

Side Panels

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the Top Panel as described in the Top

Panel removal section.

3. Remove the screws securing the Side Panels.

Retain for reuse.

4. Removing the Side Panels provides access to

components not accessible from the rear of the unit.

Rear Panel Exhaust Vent Covers

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

REMOVAL AND REPLACEMENT OF COMPONENTS

9

Service Manual for RCO Speed Oven

The oven is equipped with two circulating fans mounted

on the rear panel. An exhaust vent cover is mounted

over each fan. These must be removed to gain access

to the fans.

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the four screws securing each Exhaust

Vent Cover. Retain for reuse.

Rear Heater Cover

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

The Rear Heater Cover provides access to the heat

elements.

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the screws securing the Rear Heater

Element Cover.

Louvered Rear Service Panel

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

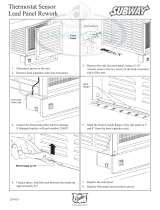

Louvered

Rear

Service Panel

Location of Louvered Rear Service Panel

Removing the Louvered Rear Service Panel provides

access to the High Voltage components.

1. Remove the unit from its power source and

follow the proper Lockout/Tagout procedures.

2. Remove the screws securing the Louvered Rear

Panel to the back of the oven. Set aside for reuse.

EXHAUST FANS

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

The exhaust fans are mounted on the rear panel of

the unit.

Rear Exhaust Fans

Location of Rear Exhaust Fans

Testing

Exhaust Fans operate constantly when the oven is

connected to its power source. They provide cooling

for the electrical compartment. If both fans do not

operate, the line fuse should be checked. Inspect

all wiring between the fuse holder and the fans. If a

single exhaust fan does not operate, there is a greater

likelihood a fan has failed. Test the motor winding leads

for a short, open, or grounded condition.

Service Manual for RCO Speed Oven

10

Exhaust Fan Replacement

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the Top Cover.

3. Remove the Exhaust Vent Cover/s.

4. Tag and disconnect the exhaust fan wires.

5. Remove the screws and nuts securing the fan to

the panel. Retain these for reuse.

6. Remove the fan.

7. Reverse procedure to install the replacement fan.

8. Restore the unit to service and check for proper

fan operation.

9. Reattach Exhaust Vent Covers and Top Panel.

LEFT SIDE TANGENTIAL BLOWER

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The Tangential Blower is located on the left side of

the oven.

Tangential

Blower

Location of Tangential Blower

Testing

The Left Side Tangential Fan operates constantly when

the oven is connected to its power source. It provides

cooling for the electrical compartment. If not operating,

the line fuse should be checked. Inspect all wiring

between the fuse holder and the fan. Test the motor

winding leads for a short, open, or grounded condition.

Tangential Blower Replacement

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the Top Panel.

3. Remove the Left Side Panel.

4. Tag and disconnect the blower wires.

5. Remove the two screws securing duct to the

blower assembly. Set aside for reuse.

Remove

screws

6. Remove the duct to gain access to the Tangential

Blower assembly mounting screws.

7. Remove the two nuts securing the Tangential

Blower assembly to the bracket and remove the

blower assembly.

Remove

nuts

11

Service Manual for RCO Speed Oven

8. Reverse this procedure to install a new Tangential

Blower assembly.

9. Restore the unit to service and check for proper

operation.

10. Reattach all panels and covers.

RIGHT SIDE COOLING FAN

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

Right Side

Cooling Fan

Location of Right Side Cooling Fan

Testing

The Right Side Cooling Fan operates constantly when

the oven is connected to its power source. It provides

cooling for the electrical compartment. If not operating,

the line fuse should be checked. Inspect all wiring

between the fuse holder and the fan. Test the motor

winding leads for a short, open, or grounded condition.

Right Side Cooling Fan Replacement

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the Top Panel.

3. Tag and disconnect the Cooling Fan wires.

4. Remove the screws and nuts that secure the

Cooling Fan to the right side panel. Retain for

use later.

5. Remove the Cooling Fan.

6. Reverse procedure to install the replacement fan.

7. Restore the unit to service and check for proper

operation.

8. Reattached all panels and covers.

SOLID STATE RELAYS

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

Solid State

Relays

Location of Solid State Relays

The Solid State Relays are located on the Electrical

Mounting Panel in the top front of the unit. There are

two Solid State Relays. The left side SSR controls the

power supply to the High Voltage Transformers and the

right side SSR controls the Heat Elements.

Operational Testing

The Solid State Relays are equipped with an LED that

illuminates when input voltage is provided to the relay.

Input voltage will only occur if the oven is turned ON

and the door is closed. If the LED does not illuminate,

test the inputs to the relay using a volt meter. 12 VDC

should be present when switched on by the control. If

voltage is not present check the door switches.

Solid State Relay Replacement

Service Manual for RCO Speed Oven

12

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the Top Panel.

3. Tag and disconnect the wires to the defective Solid

State Relay.

4. Remove the defective relay.

5. Install the replacement Solid State Relay.

6. Refer to the tags or the schematic and reconnect

all of the wires.

7. Attach all covers and panels.

8. Restore power to the unit and test for proper relay

operation.

MONITOR RELAY

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The Monitor Relay is located on the electrical panel in

the top front of the unit.

Monitor

Relay

Location of Monitor Relay

Operational Testing

The Monitor circuit protects against hazardous

microwave leakage by disabling the oven if a fault exist

in the microwave system with the oven's door open

or ajar. The Monitor circuit trips the internal 30A Fast

Blow Fuse with a door open / microwave fault state

through the output contacts of the Monitor Relay. The

MonitorRelaycoilisenergizedbyfeedbackfromthe

Mag SSR output through the normally closed contacts

of the Monitor Door Switch.

Failure of the Mag SSR, failure of components in the

magnetron system, or a combination of failures of the

controller PCB, the Primary Door Switch, and the Secondary

Door Switch are sources of Monitor circuit activation and

the resultant fuse trip. The Monitor Relay output contacts

experience excessive current loads when activated

preventing future operation of this safety circuit.

The Monitor Relay must be replaced if the 30A fuse

in the oven trips. Do not attempt to reuse a Monitor

Relay after a fuse trip event.

The Primary and Secondary Door Switch interrupt the

function of the microwave and heating circuits when the

oven door is open or ajar. Improper function of either or

both the Primary and Secondary Door Switches will prevent

the oven from heating and prevent microwave functions.

Monitor Relay Replacement

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the top panel

3. Tag and disconnect the defective relay’s wires.

4. Remove the defective relay.

5. Install the new Monitor Relay.

6. Restore power to the unit and test for proper

operation.

7. Remove power and reattach all covers and panels.

8. Restore Power to the unit.

VOLTAGE RELAY

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The Voltage Relay is located on the electrical panel in

the top front of the unit.

13

Service Manual for RCO Speed Oven

Voltage

Relay

Location of Voltage Relay

Operation and Testing

The Voltage Relay is connected to the output of the DC

power supply. The power supply provides a 24 VDC

signal from the control board for the 208VAC supply

condition. For 240VAC, the mechanical relay is not

triggered. After plugging the unit into a rated power

source, the control board determines if the supply

source holds a voltage of either above or below 220VAC.

Voltages above 220VAC are considered the default

condition (no relay switching occurs). The 240VAC tap

wire remains active on the high voltage transformer.

Voltages below 220V cause the mechanical relay to

switch to the tap wire to 208VAC on the high voltage

transformer tap.

To test, disconnect the oven from power. It must be

disconnected each time it is tested so the Voltage

Relay returns to its default state. When connected to

a 240VAC supply, the Voltage Relay should remain in

the default state. When tested with a 208VAC supply

the Voltage Relay should switch to the 208VAC within

three seconds of the oven being turned on.

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the top panel.

3. Tag and disconnect the Voltage Relay wires.

4. Remove the faulty relay.

5. Install the replacement relay.

6. Temporarily power up unit and ensure relay is

working as designed.

7. Remove unit from its power source and reattach

all panels and covers.

8. Restore unit to its power source.

LINE FUSE

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The line fuse is a component of the supply circuit for

all components, including all of the cooling fans. It is

located in the fuse clip on the upper right side of the

electrical component panel.

A fuse trip is a function of an over voltage / current

condition or a Monitor circuit activation. The Monitor

circuitprotectsagainsthazardousmicrowaveleakage

by disabling the oven if a fault exist in the microwave

system with the oven’s door open or ajar. The Monitor

circuit trips the internal 30A Fast Blow Fuse with a door

open / microwave fault state through the output contacts

oftheMonitorRelay.TheMonitorRelaycoilisenergized

by feedback from the Mag SSR output through the

normally closed contacts of the Monitor Door Switch.

Failure of the Mag SSR, failure of components in the

magnetron system, or a combination of failures of

the controller PCB, the Primary Door Switch, and the

Secondary Door Switch are sources of Monitor circuit

activation and the resultant fuse trip. The Monitor

Relay output contacts experience excessive current

loads when activated preventing future operation of

this safety circuit.

The Monitor Relay must be replaced if the 30A fuse

in the oven trips. Do not attempt to reuse a Monitor

Relay after a fuse trip event.

Line Fuse

Location of Line Fuse

Line Fuse Replacement

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the top panel.

Service Manual for RCO Speed Oven

14

3. Remove the fuse.

4. Perform a continuity test on the fuse.

5. Replace the faulty fuse.

6. Restore the unit to its power source.

7. Ensure the unit is operating correctly.

8. Remove power from unit and reattach top panel.

9. Restore power to the unit.

Note: Check the Primary and Secondary interlock

switches for proper operations. Any damaged or non-

functional switches must be replaced.

CONTROL BOX ASSEMBLY

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The Control Board is mounted on the front of the unit.

Control Board

Speed Oven Control Board

System Testing

See the section on General Systems Testing in the

System Testing Section of the Manual for full details

on testing Control Board.

Control Box Replacement

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Tag and disconnect wires to the Control Board.

3. Remove the Control Box Assembly mounting

screws.

Mounting

Screws

Control Box Assembly Mounting Screws

4. Remove the faulty Control Box Assembly.

5. Install the replacement Control Box Assembly.

6. Referring to the tags, reconnect all of the Control

Board wires.

7. Temporarily restore power to the unit and verify

the Control Board is operating correctly.

8. Remove the unit from its power source and reattach

the top panel.

9. Restore the unit to its power source.

10. Perform a Microwave Leakage Test (as described

on page 32) to validate proper functionality.

Control Box Adjustment

1. Allow the oven to cool below 150 °F (66 °C). Unplug

the oven and remove the top and side panels.

2. Heat the oven to 500 °F (260 °C)

3. Loosen the 2 screws holding the controller box in

place.

4. Pull the door so that the prong above the primary

switch contacts the roller.

Oven

Door

Primary

Switch

Prong

Roller

Prong Touching Roller

15

Service Manual for RCO Speed Oven

5. Adjust the controller forward and backwards so that

the trailing edge of the EMI shield contacts the back

edge of the door.

EMI

Shield

Controller

Box

Screw

Door

Controller

Door Touching EMI Shield

6. Tighten the 2 controller box screws.

7. Allow the oven to cool below 150 °F (66 °C), unplug

the oven and replace the top and side panels.

8. Heat the oven to 500 °F (260 °C)

9. Perform a Microwave Leakage Test (as described

on page 32) to validate proper functionality.

SIGNAL TRANSFORMER

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The Signal Transformer is located on the upper left side

of the oven just behind the Control Panel.

The Signal Transformer provides low voltage to the

Control Panel.

Signal

Transformer

Location of Signal Transformer

Operational Testing

With a 208 / 240 VAC on the Primary winding (input),

the measured voltage across the entire Secondary

winding (output) should be approximately 24 VAC.

The voltage across either outer terminal and middle

terminal should be approximately 12 VAC.

A short to ground can be measured by testing for

continuity between each individual terminal and ground.

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the top panel.

3. Tag and disconnect Signal Transformer wires.

4. Remove the Signal Transformer.

5. Install the replacement Signal Transformer.

6. Brieyrestorepowerto the unitandensurethe

Control Panel is operating.

7. Remove the unit from its power source and reattach

the top panel.

8. Restore the unit to its power source and ensure it

is operating properly.

DOOR SWITCHES

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The Monitor Switch and Primary Interlock switches are

located on the upper right side of the unit.

Service Manual for RCO Speed Oven

16

OVEN FRONT

Monitor

Switch

Primary

Interlock

Switch

Location of the Monitor and Primary

Interlock Switches

The Secondary Interlock switch is located on the upper

left side of the unit.

OVEN FRONT

Secondary

Interlock

Switch

Location of the Secondary Interlock Switch

Operational Testing

The Primary Interlock and Secondary Interlock switches

are normally closed when the door is closed. The Monitor

Switch is normally open when the door is closed.

Switch Replacement

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the top and both side panels.

3. Test for proper switch operation.

4. Tag and disconnect the faulty switch’s wires.

5. Remove the faulty switch.

6. Install the replacement switch.

7. Restore power to the unit, and test for proper switch

operation.

8. Remove power from the unit and reattach all covers

and panels.

9. Restore power to the unit.

10. Perform a Microwave Leakage Test (as described

on page 32) to validate proper functionality.

THERMAL CUTOUTS

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The Thermal Cutout Switch (Hi Limit) and Auxiliary

Cutout Switch are located on the rear of the unit just

above the power cord strain relief.

Auxiliary

Thermal

Cutout

Switch

Thermal

Cutout

Switch

Location of Thermal Cutout Switches

Operational Testing

The main Thermal Cutout Switch remains closed until

the oven reaches 572°F (300°C) The Auxiliary Switch

opens when the oven cavity reaches 525°F (274°C). The

main Thermal Cutout Switch must be manually reset.

The temperature must drop below 500°F (260°C) before

a reset can be attempted. Test the Thermal Cutouts for

continuity in ambient temperature. The Thermal Cutout

must be reset before attempting the test. If the test fails

the unit is faulty.

17

Service Manual for RCO Speed Oven

Thermal Cutout Replacement

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the top and right side panels.

3. Tag and disconnect the faulty Thermal Cutout

switch wires.

4. Remove the faulty Thermal Cutout switch.

5. Reverse this procedure to install the new Thermal

Cutout switch.

6. Restore the unit to its power source and check for

proper operation.

7. Remove the unit from its power source and reattach

all covers and panels

8. Restore power to the unit.

HEATING ELEMENTS

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

Discharge the HV Capacitors.

Refer to the Discharging the High Voltage

System section of the manual for proper

instructions for this procedure.

Heating Elements

Location of Heating Elements

Testing Procedures

Disconnect the wires from the Heating Elements. Test

both elements using an Ohm meter. Each element

shouldreadfrom18.14to21.01Ω.

Heating Element Replacement

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the top and side panels.

3. Tag and disconnect the Exhaust Fans and Thermal

Cutout wires.

4. Remove the rear panels.

5. Tag and disconnect the Heating Element wires.

6. Remove the Insulation Panel and Insulation.

Insulation

Panel

Insulation Panel Removed

7. Remove the Diverter Heater Box Assembly.

Diverter Heat Box Assembly

Diverter Heat Assembly Removed

Service Manual for RCO Speed Oven

18

8. Remove the defective Heating Element.

Heating

Elements

Screws

Heating Elements Removed

9. Install the replacement element onto the Diverter

Heat Assembly.

10. Add RTV silicone to reseal.

11. Install the Diverter Heat Assembly.

12. Dress the insulation around the diverter assembly.

13. Reconnect the Heating Element wires.

14. Dress insulation around heating element

connections.

15. Attach the insulation panel.

16. Attach the rear panel.

17. Reconnect the wires to the exhaust fans and

Thermal Cutout Switch.

18. Reattach the remaining panels.

Restore unit to power and check for proper operation.

DOOR REPLACEMENT

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The door assembly should be replaced if the door seal,

choke or door face plate is damaged. A damaged door

maycauseapotentialhazardtotheoperator.Theoven

must not be used until the door is replaced.

CAUTION: If the oven has been in use, the oven door

may be hot. Allow door and oven cavity to

cool before beginning this procedure.

Arrestor

Closed

Door

Left Side Hinge with Door Open –

Arrestor Arm in Locked Down Position

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Open the oven door and release the Arrestor Arms

on both sides by moving them up to the open

position.Aatbladescrewdrivermayberequired

for this operation.

Screwdriver

Opening Door Arrestors

Arrestor

Open

Door

Door Arrestors Open

19

Service Manual for RCO Speed Oven

3. Lift and pull the door gently out of the hinge receiver

brackets. Be careful not to bend the brackets.

4. Insert new door into the Hinge Receiver brackets.

5. Once the door is correctly inserted, lock the arrestor

arms in the down position.

Locking Arrestor Arms

6. Restore power to the unit and perform a Microwave

Emissions Test. See the Microwave Leakage Test

section of the manual for more information on the

microwave emissions test.

INVERTER

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The Inverter is located on the top left side of the

oven. The inverter provides signaling functions for the

convection blowers.

Inverter

Location of Inverter

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the top and left side panels.

3. Tag and disconnect the Inverter wires.

4. Remove the mounting screws securing the Inverter

to the unit and remove the inverter.

5. Install the replacement Inverter. Ensure the inverter

is oriented correctly.

6. Referring to the tags, reconnect all of the wires.

7. Refer to Inverter Programming Instructions in this

manual to continue.

CONVECTION BLOWER MOTOR

ASSEMBLIES

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components, always

follow the Electrical LOCKOUT/TAGOUT Procedure.

Disconnect all circuits. Failure to comply can

cause property damage, injury or death.

The Convection Blower Motor Assemblies are located

at the rear of the oven directly behind the rear panel.

Convection

Blower Motors

Remove

nuts

Location of the Convection Blower Motors

CAUTION: The blower motor assemblies are not

the same. Motor directionality must be

conrmedwhenreplacingablowermo-

tor assembly. Observe Blower Wheel

orientation after replacement installa-

tion. Motors need to spin in opposite

directions. The motor on the right side of

the unit should have the Blower Wheel

blades curved to the left and the mo-

tor on the left side must of the Blower

Wheel blades curved to the right.

Service Manual for RCO Speed Oven

20

FAILURE TO INSTALL THE

BLOWER MOTORS PROPERLY WILL CAUSE

THE OVEN TO OVERHEAT AND BECOME A

FIRE HAZARD.

1. Remove the unit from its power source and follow

the proper Lockout/Tagout procedures.

2. Remove the top panel and the side panel of the

defective Blower Motor Assembly. Note: the

right side panel is equipped with a cooling fan.

Disconnect the wires to the cooling pan before

removing the right side panel.

3. Tag and disconnect the Blower Motor Assembly

wires.

4. Remove the Blower Motor Assembly by removing

the nuts that secure the assembly to the inside

chassis of the oven.

5. Compare the blower wheel orientation of the

faulty blower assembly to the replacement blower

assembly. Ensure that they match!

6. Install the replacement Blower Motor Assembly.

7. Referring to the tags or wiring diagram, reconnect

the Blower Motor Assembly wires

BLOWER SPEED MOTOR

E: Emerson motor

R: Regal-Beloit Motor

Convection

Blower Ð Right

L1 Ð E: 1, R: Blue

L2 Ð E: 2, R: White

L3 Ð E: 3, R: Orange

Convection

Blower Ð Left

L1 Ð E: 1, R: Blue

L2 Ð E: 2, R: White

L3 Ð E: 3, R: Orange

T1

ORANGE

ORANGE

YELLOW

YELLOW

BLUE BLUE

T2 T3

L1 L2 L3L1 L2 L3

Blower Motor Assembly Wiring Diagram

8. Brieyrestorepowerto the unitandensurethe

Blower Motor Assembly is operating correctly.

9. Remove the unit from its power source and reattach

all covers and panels. Note: If the right side panel

was removed reconnect the cooling fan wires before

attaching the top cover.

10. Restore the unit to its power source and ensure

that it is operating correctly.

MAGNETRON COOLING FAN

Before performing any service that

involves electrical connection or disconnection

and/or exposure to electrical components,

always follow the Electrical LOCKOUT/TAGOUT

Procedure. Disconnect all circuits. Failure to

comply can cause property damage, injury

or death.

The High Voltage Capacitor

retains a 2.5kV DC charge after the oven has

been disconnected from its power source. The

capacitor must be properly discharged prior

to beginning work on any components in

the high voltage area. Failure to comply can

cause property damage, injury or death. Refer

to the Discharging the High Voltage System

section of the manual for proper instructions

for this procedure.

The Magnetron Cooling Fan is located behind the rear

access panel.

Magnetron

Cooling Fan

Location of Magnetron Cooling Fan

/