Page is loading ...

SERVICE

& INSTALLATION

MANUAL

General Specifications

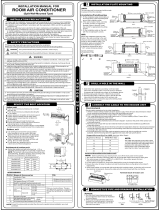

Dimensions of Indoor Units

Dimensions of Outdoor Units

General

Location of the Indoor Unit

Location of the Indoor Unit

Refrigerant Line

Scheduled Maintenance

Electrical Connections

Servicing

.............. 4-5

................. 6

................. 7

................. 8

.............. 8-9

............... 10

.......... 10-11

.......... 12-14

............... 15

............... 16

CONTENTS

SPLIT DUCTED UNITS

For information on control options and

P.C. Board refer to Electronic Controls and Control Options

for KRS Controllers Manual.

Part No. TH 3451 A - 3990038A

Uncontrolled Document for Information Purposes

August 2003

A fresh approach to air conditioning

INDOOR MODEL OUTDOOR MODEL

HEATPUMP

K 30 RCF GC30RCFA & GC30RCC

K 45 RCF GC 45 RCFX

K INST. MENU

22

22

2

.

EC STATEMENT OF

COMPLIANCE

Manufacturer: A.C.E.

Address: 1bis, Av du 8 mai 1945

St-Quentin-en-Yvelines

78284 Guyancourt Cedex

Hereby states that: the evaporation units in

the CASSETTES type comfort range,

models:

K 30 RCF - K 45 RCF

under the code:

7 SP 04

Are in compliance with the provisions of

the EEC directives mentioned hereunder

and with the national legislation

transposing them:

Machines Directive 98 / 37/ECC

Low tension Directive (DBT) 73/23/EEC

Electromagnetic compatibility Directive 89/

336/EEC

Pressurised Equipment Directive (DESP)

97/23/ CEE : sub-module A, category I

and that

- the following paragraphs of the

harmonized standards have been applied:

NF EN 60 204-1 / 1998

NF EN 60 335-1 / 1995

NF EN 60 335-2-40 / 1994

NF EN 55 022 / 1998

NF EN 61 000-3-2 / 1998

NF EN 50 082-1 / 1998

NF EN 814 / 1997

NF EN 378 / 99

NF EN 255 / 1997

At Tillières sur Avre

27570 - FRANCE

On: 17/03/99

Richard FALCO

Quality Director

K INST. MENU

33

33

3

.

GENERAL RECOMMENDATIONS

- Congratulations for having selected an

Airwell Airwell

Airwell Airwell

Airwell air conditioner.

SAFETY DIRECTIONS

- Follow the safety rules in force when you are working on your

appliance.

- Installation and maintenance of the equipment should be

performed by qualified specialists.

- Make sure that the power supply and its frequency are

adapted to the required electric current of operation, taking

into account specific conditions of the location and the current

required for any other appliance connected with the same

circuit.

WARNING

- Cutoff power supply before starting to work on the appliance.

- The manufacturer declines any responsibility and the warranty

becomes void if these instructions are not respected.

- If you meet a problem, please call the Technical Department

of your area.

- If possible, assemble the mandatory or optional accessories

before placing the appliance on its final location.(see instruc-

tions provided with each accessory)

- The information contained in these Instructions are subject to

modification without advance notice.

IT IS MANDATYORY TO CUTOFF

POWER SUPPLY BEFORE STARTING

TO WORK IN THE ELECTRIC CASING

BOXES.

K INST. MENU

44

44

4

.

ELECTRIC SPECIFICATIONS

IMPORTANT

CABLE SIZES ARE GIVEN FOR INFORMATION ONLY

(MINIMUM SIZE REQUIRED BY THE SYSTEM) :

USE CABLE SIZES PER LOCAL REGULATION

* THESE VALUES ARE GIVEN FOR GUIDANCE. THEY

MUST BE CHECKED AND ADJUSTED ACCORDING TO

PREVAILING STANDARDS. THEY DEPEND ON THE SYSTEM

INSTALLED AND THE CABLES USED.

COOLING SPECIFICATIONS

Flare coupling 3/4" pipe 3/4"

** Compressor SCROLL power supply by ST

*** power supply by GC

COOLING + VENTILATION

(OR HEATPUMP HEATING)

Nominal current

Heatpump. heating 17.4 10.5

Cooling + ventilation A

Maximum current

Fuse rating aM

Fuse rating ASE/VDE*

Cable section* (minimum) MAINS

Linking pipes

Maximum current INTERCONECT

Cable section*(minimum)INTERCONECT

A

A

A

mm

2

A

mm

2

24.8

25

25

3Core 4

2

6Core 1.5

12.4

25

25

5Core 1.5

2

6Core 1.5

A

11.217.4

POWER SUPPLY V / PH / Hz

13.45

18.75

25

25

3Core 4

2

6Core 1.5

13.94

GC30RCFA GC45RCFXGC30RCC OUTDOOR

K30RCF K45 RCFK30RCF INDOOR

240 / 1 / 50 240 / 1 / 50 315 / 3 / 50

CHARACTERISTIC

GAS PIPE

LIQUID PIPE

K30RCF

5/8”

3/8”

K45RCF

GC30RCFA GC45RCFXGC30RCC

R22 charge in the

outdoor unit factory

charged.

2380 g

R22 charge to add

on site.

17 g / m

Pipe O

Pipe O

5/8”

3/8”

2710 g

20 g / m

7/8”

3/8”

4200 g

58 g / m

K INST. MENU

55

55

5

.

LENGTH OF THE LINKINGS PIPES

COOLING SPECIFICATIONS

- The R22 charge depends on the length of the cooling linking

pipes.

Example:

- Installation of a réversible K 30 RCF with cooling pipes 10 m long:

- Add + 282 g + 102 g = 384 g of R22 on site.

Maximum height of the cooling link

- The maximum permissible difference in height between the outdoor unit and the indoor unit is indicated in page11.

K 30 RCF K 45 RCF 0 grs : 1 -> 25m

1 m - 51 grs 58 grs 26 m

2 m - 34 grs 116 grs 27 m

3 m - 17 grs 174 grs 28 m

4 m

232 grs 29 m

5 m 17 grs 290 grs 30 m

6 m 34 grs 348 grs 31 m

7 m 51 grs 406 grs 32 m

8 m 68 grs 464 grs 33 m

9 m 85 grs 522 grs 34 m

10 m 102 grs 580 grs 35 m

11 m 119 grs 638 grs 36 m

12 m 136 grs 696 grs 37 m

13 m 153 grs 754 grs 38 m

14 m 170 grs 812 grs 39 m

15 m 187 grs 870 grs 40 m

16 m 204 grs 928 grs 41 m

17 m 221 grs 986 grs 42 m

18 m 238 grs 1044 grs 43 m

19 m 255 grs 1102 grs 44 m

20 m 272 grs 1160 grs 45 m

21 m 289 grs 1218 grs 46 m

22 m 306 grs 1276 grs 47 m

23 m 323 grs 1334 grs 48 m

24 m 340 grs 1392 grs 49 m

25 m 357 grs 1450 grs 50 m

NOTE

:

fo

r

K

30

RCF

to

ma

tch

with

GC

30

RCC

NOTE: see RESTRICTOR INSTALLATION on page 18 when K30RCF to match with GC30RCC

HEATING PERFORMANCE

K INST. MENU

66

66

6

.

DIMENSIONS OF INDOOR UNITS

K 30 RCF - 45 RCFA

1271

1221

1171

50

17

40

287

571 120

277

460

230

5 maxi

600

1225

20,5

20,5

530

625

1

25

6

7

8

9

Ø 1/2"

3

3

4

4

Ø 200

Ø 100

10 10

11

585,5

150

120

140

369 430

118,5

1 False ceiling

2 T-shaped rod (false ceiling)

3 Evaporator

4 Fan

5 Return air grille

6 Electrical box (removable)

7 Draining of condensates

8 "GAS" pipe

9 "LIQUID" pipe

10 Supply air pop. (prepunched)

11 fresh air pop. (prepunched)

510 30,530,5

K INST. MENU

337

362

380

WIRING

CONNECTIONS

LIQUID TUBE

(FLARED)

SUCTION TUBE

(FLARED)

AIR INTAKE

AIR OUTLET

357

50

695

340

97

900

706

55

225

293

.

DIMENSIONS OF OUTDOOR UNIT GC30RCFA

7

K INST. MENU

TOP VIEW

378

340

950

527

AIR INTAKE

AIR OUTLET

200

100 MIN

WALL

WALL

500 MIN

WALL

MIN

800

WALL

MIN

MINIMUM CLEARANCE

500 MIN FROM TOP

835

865

FRONT VIEW

WIRING

CONNECTIONS

SUCTION

PIPE (FLARED)

LIQUID

PIPE (FLARED)

RIGHT VIEW

25

100

DIMENSIONS OF OUTDOOR UNIT GC45RCFX

340

380

WIRING

CONNECTIONS

90

50

130

230

290

AIR INTAKE

AIR OUTLET

356.5

50

705 100

1255

900

WALL

200

MIN

300 MIN

WALL

600

MIN

WALL

MINIMUM CLEARANCE

800 MIN

WALL

500 MIN FROM TOP

15

.

DIMENSIONS OF OUTDOOR UNIT GC30RCC

8

K INST. MENU

.

INSTALLATION OF THE INDOOR UNIT

- Mark the position of each supporting rod, cooling pipes,

drainpipe of condensates, wires of power supply and cable of

remote control .

The supporting rods can be fixed, depending on the type of

ceiling.

Various models to fix

- Fix the angle brackets provided with the unit, on the threaded

rods , we recommend Ø 6, max.Ø 8,

and keep them away from the ceiling at a distance of 270mm or

107mm .

GENERAL POINTS

BEFORE INSTALLATION

- It is recommended to place the indoor unit as close as possible

to its final location before unpacking.

- Avoid to lay heavy tools or weights on the packed unit.

Check as soon as the packing is opened, that no accessories

required for the installation, are missing. The grilled panel is

provided separately for better protection.

DO NOT LIFT THE UNIT BY GRASPING THE

DRAINPIPE OF CONDENSATES OR THE

COOLING CONNECTIONS, BUT ONLY THE

FOUR CORNERS.

CHOICE OF LOCATION

- Do not install the un it in rooms where inflammable gas or acid

or alkaline substances are present. Aluminium and copper

evaporators and/or plastic components inside could be

damaged.

- Do no install the unit in workshops or kitchens; oil vapours

attracted by treated air could settle on the evaporators of the

unit and change its performance or damage plastic parts inside.

- The indoor unit is flush mounted into a false ceiling, size of the

tiles 600x600 and multiple.

- Installation of the unit is made easier when using a fork-lift truck

and the base of the packing by placing the base between the

unit and the forks of the truck .

- It is recommended during installation to choose the location of

the unit as much as possible in the middle of the room, so as to

obtain the best distribution of treated air.

- Check that you can remove the discharge grilles and that the

clearance is large enough to allow maintenace and repairs.

-

The cassettes must not be positioned above electricalThe cassettes must not be positioned above electrical

The cassettes must not be positioned above electricalThe cassettes must not be positioned above electrical

The cassettes must not be positioned above electrical

equipment in order to avoid exposure to running waterequipment in order to avoid exposure to running water

equipment in order to avoid exposure to running waterequipment in order to avoid exposure to running water

equipment in order to avoid exposure to running water

which could appear that may occur under extremewhich could appear that may occur under extreme

which could appear that may occur under extremewhich could appear that may occur under extreme

which could appear that may occur under extreme

conditions.conditions.

conditions.conditions.

conditions.

HOLDER TO FIX THE REMOTE

CONTROL ON THE WALL

- Use the holder when the remote control is not in operation. The

control can be easily removed and placed back on the holder.

2

1

Nut

Rubber mount

Large washer

Counter-nut

Angle bracket

to hang

9

K INST. MENU

.

600 mm

MAXI

1cm/m

50 mini

Ø

16max

OK

NO

Nut

- In case the brackets are assembled at the lower part, remove

the insulating foam around the fixing nuts .

The possibility to adjust the bracket at different heights leaves

the brackets free to fix them at the upper or lower part of the

cassette.

- Fixing the brackets at the lower part offers an easier assembly.

Do not tighten the nuts, nor the counter-nuts, this should only be

done after having made all connections and placed the unit in its

final horizontal position.

- Lift the unit (without the frame) carefully by picking it up at the

four corners.

- Place the unit in the false ceiling.

- To make the assembly easier the electrical box can be

disassembled by removing 2 screws, and disconnect the

multipoints connector (15 pts connector for the main connection)

and small connector for the infra-red.

- Fix the cassette, connect the multipoints connectors, place the

cassette into is final position and reset the electrical box with 2

screws

- Fix the screws to fix the corner irons .

- In case the false ceiling is 300 mm distant from the ceiling (mini-

mum height admitted) it may be necessary to remove

temporarily a few T-shaped rods from the false ceiling.

- Position the unit with a level and keep 10mm between the sheet

metal body and the false ceiling .

Angle bracket

to hang

Electrical box

T-shaped rod

- Position the unit on the supporting rods of the false ceiling by

first tightening the bolts on the side , then the nuts and counter-

nuts of the threaded rods . Finally place the rubber mount.

- Check once more that the unit is in a horizontal position after

connection of the condensate drain and the refrigeration

pipework.

DRAINING CONDENSATES

- To obtain correct condensate drainage , the slope downwards

should be 1 cm per meter without any bottleneck nor passage

upwards . Furthermore a trap of at least 50 mm high should be

mounted to avoid bad smells in the room.

- Install an auxiliary pump to drain condensates and a levelcontroller

if the condensates are to be drained at a higher level than the

unit. It is recommended to install an appliance equipped with a

safety floater to stop the compressor in case the auxiliary pump

is damaged.

- The drainpipe of condensates should be heat insulated with

insulating material 5 to 10 mm thick, such as polyurethane,

propylane or neoprene, avoiding condensation.

- If several units are placed in the room , the draining system can

be made as indicated above.

Connection on the top of the pipe

Heat insulated drainpipe

Slope of 1cm/m

Trap

THE CASTHE CAS

THE CASTHE CAS

THE CAS

SETSET

SETSET

SET

TE MUST ALTE MUST AL

TE MUST ALTE MUST AL

TE MUST AL

WW

WW

W

AA

AA

A

YS REMAIN CONNECTEDYS REMAIN CONNECTED

YS REMAIN CONNECTEDYS REMAIN CONNECTED

YS REMAIN CONNECTED

WITH ELECTRICAL SUPPLWITH ELECTRICAL SUPPL

WITH ELECTRICAL SUPPLWITH ELECTRICAL SUPPL

WITH ELECTRICAL SUPPL

Y TO ALLY TO ALL

Y TO ALLY TO ALL

Y TO ALL

OW THE DRAI-OW THE DRAI-

OW THE DRAI-OW THE DRAI-

OW THE DRAI-

NAGE OF WATER CONDENSATS.NAGE OF WATER CONDENSATS.

NAGE OF WATER CONDENSATS.NAGE OF WATER CONDENSATS.

NAGE OF WATER CONDENSATS.

10

K INST. MENU

.

REFRIGERANT LINES AND

CONNECTIONS

CAUTION

- On K 45 RCFA, the expansion kit is installed, to the indoor unit,

on the liquid line.

- The cassettes are designed to be connected to the outdoor

units using flare lines (refrigerant grade copper pipe fitted at

both ends with flare nuts and insulated over the full length).

PIPE PREPARATION

- Use refrigerant grade copper pipe with a diameter suited to

each model (see page 4).

- The gas pipe and liquid pipe must mandatorily be covered with

insulating material at least 6 mm thick.

- Fit the flare nuts on the ends of the pipes before flaring the

pipes.

- The separately insulated pipes and their fittings can then be

attached to the condensate drain and power cables with a clamp.

INSTALLATION OF REFRIGERANT

LINES

- Drill an 80 mm diameter hole through the wall for the crossing of

the lines between the outdoor unit and indoor unit .

INSTALLATION OF THE OUTDOOR

UNIT

- Minimum clearance to respect (in mm).

- Avoid recycling the air, even partially, between the air inlet and

discharge.

INSTALLATION ON THE FLOOR

- The outdoor unit is supposed to be fixed directly on the floor: 4

holes Ø 10 (see dimensional drawing).

- Waffle pad can also be placed under the feet to absorb vibra-

tion.

A

C

D

B

E

F

expansion kit

liquid line

A Outside

B Inside

1 Drill Ø 80 mm

2 Wall

5°

B

A

2

1

K 45 RCFX

Distance in mm

GC 30 RCFA GC 45 RCFX

A rear 150 300

B front 500 800

C left 150 200

D right 400 600

E on top 500 500

F bottom 150 150

11

K INST. MENU

.

ROUTING OF THE PIPES

- The pipe bending radius must be greater than or equal to 3.5

times the pipe diameter.

- Do not bend the pipes more than three times in a row and do

not make more than 12 bends in the total length of the line.

- If the suction pipe has a vertical section more than 8 meters in

length, it is MANDATORY to provide a trap every 3 meters when

the outdoor unit is installed above K 30 RCF .

EVACUATION OF REFRIGER-

ANT LINES AND INDOOR UNIT

- The R22 charge is contained only in the outdoor unit. The indoor

unit contains a small amount of neutral gas. That is why it is

necessary to evacuate the lines and indoor unit after installing

the lines.The outdoor unit has a valve used for evacuating the

system (large valve).

INSTALLATION PROCEDURE

- The outdoor unit a valve (large valve) used for evacuating the

complete system.

1 Connect the pipes of the line to the outdoor unit and indoor unit.

- Cover the surface with refrigerant oil to tighten the fittings

correctly.

- Always use a counterwrench to tighten the valves .

- The table below shows the tightening torques.

A "GAS" line

B "LIQUID" line

H max.

A

B

* WITHOUT trap

ehtfoØ

sepip

euqroT

epip"4/1

epip"8/3

epip"2/1

epip"8/5

epip"4/3

epip"8/7

mN02-51

mN53-03

mN45-05

mN57-07

mN58-08

mN59-09

2 Connect the vacuum pump to the flare coupling of the outdoor

unit fitted with the large service valve (large coupling).

3 Turn on the vacuum pump and check that the dial pointer drops

to -0.1 MPa (-76 cm Hg).

The pump should remain in operation for at least 15 minutes.

4 Before removing the vacuum pump, check that the vacuum dial

remains stable for five minutes.

5 Disconnect the vacuum pump and reclose the service valve.

6 Remove the caps from the GAS and LIQUID valves and open

them with a socket wrench to release the R22 contained in the

outdoor unit.

7 It may be necessary to adjust the charge according to the

length of the line and the processing unit (see pages 5 and 6 to

calculate the charge to be added). Put the caps back.

8 Check the lines for leaks using an electronic leak tester or a

sponge soaked with sudsy water.

CHARGE ADJUSTMENT

- This operation must only be carried out by qualified personnel

in accordance with the rules of good workmanship in

refrigeration. The extra charge is added through the service

valve of the outdoor unit flare coupling (large coupling).

FINAL TASKS

- Check that the valve caps are correctly tightened.

- Attach the cables and lines to the wall with clamps if necessary.

- The additional capillary (identified by a red tag) should only be

used above 8 meters.

- Below 8 meters, it can adversely affect the heating power (winter

mode) and compressor oil temperature and should not be left

in service. Pinch it as shown on the red tag.

- Capillary before pinching:

(loop made in the factory)

- Capillary after pinching:

- Run the air conditioner in presence of the user and explain all the

functions.

- Show the user how to remove, clean and reinstall the filters.

K

12

K30RCF / GC30RCFA

K30RCF / GC30RCC

K45RCF / GC45RCFX

10

20

50*

H. Max (m)

K INST. MENU

.

- On models K 30 RCF and K 45 RCFA, there are two parts to

install .

- Connect the infrared receiver ribbon cable.

- Install the filter.

- Place the hinges of the return air in openings A , then fasten the

grille with the locks on both sides .

- On models K 30 RCF and K 45 RCFA install the central grille by

twisting.

- Avoid distorsions of the frame caused by excessive traction;

the frame should be correctly centered in relation to the false

ceiling and it should especially ensure an airtight separation

between return air and supply air .

- The figure indicates the airtight packings, avoiding

A : the by-pass of air

B : discharge of treated air inside the false

ceiling.

- Check after installation that the space between frame and false

ceiling is less than 5 mm.

Latch of the grille

Packings

AIR INLET AND OUTLET

Return / Supply air grille

- Unpack the assembly with care. Fit the location snaps on the

corners of the frame.

- Position the frame on the unit and press on it to snap it in place.

This facilitates installation of the frame in its final position on the

unit. Then attach it with screws.

AA

AA

A

13

K INST. MENU

.

CHECKING BEFORE START-UP

VOLTAGE OF POWER SUPPLY

- Voltage and frequency of power supply of the appliance should

comply with the values indicated on the identification plates of

the indoor and outdoor units.

ELECTRICAL CONNECTIONS

- Electrical installations must comply with local codes and

regulations.

- Sensor cables (Low voltage) from UA (indoor) units to CDS

condensing units must be run separately to power supply wiring.

CONDENSATES DRAIN

CAUTION: Do not weld the condensate drain pipe to the cas-

sette condensate drain outlet.

- Check that the drain works perfectly by pouring water into the

condensing tray of the indoor unit. Check that connections are

sealed and, if needed, heat insulate the drain pipe in case of

freezing or condensation risk .

REFRIGERATION PIPEWORK

- Check with an appropriate detector that the refrigeration lines

are sealed, particularly at the connecting couplings of the outdoor

unit. Check that the heat insulation of the pipes is perfect.

CROSSING A WALL

- Check that the passage of the refrigeration lines are sealed, in

case they go across an outside wall. Check that there is no

direct contact between the pipework and the wall.

FIXING

- Check that the indoor and outdoor units are firmly fixed. Install

the elements previouly removed.

MAINTENANCE

- Before servicing, switch the power supply OFF.

RENEWAL OF AIR

- Lateral openings allow to install separate ducts for fresh air from

outside and supply air towards an adjoining room .

- Remove the anti-condensation insulation and the prepunched

sheet metal of the openings by using a punching die : BE

CAREFUL not to damage the heat exchanger in the rear.

- Fill the space between the ducts and the border of the openings

with anti-condensation insulating material.

Use material resisting to a temperature of 60°C when operating

continuously.

- The ducts may be of the flexible type with a spring core or of

corrugated aluminium insulated at the outside (with fibreglass

12 to 25 mm thick).

- When the installation is finished, all ductsurfaces which are not

heat insulated should be covered with anti-condensation insulating

material (expanded polystyrene, expanded neoprene 6 mm

thick).

IF THESE INSTRUCTIONS ARE NOT FOLLOWED CONDEN-

SATES WILL FLOW DOWN. AND THE MANUFACTURER DE-

CLINES ANY RESPONSIBILITY

CAUTION

Comply with the indications for air discharge

Relief grille

14

K INST. MENU

.

CHECK THE AIR FILTER FOR FOULING REGULARLY AND

BEFORE THE START OF THE SEASON

LONG PERIODS NON OPERATION OF

THE APPLIANCE

Before restarting to operate the appliance:

- Check and clean the outdoor unit and in particular the heat

exchanger.

- Clean or replace the air filter of the indoor unit

- Check and clean the condensing tray of the indoor unit as well

as the outdoor units of the heatpump

- Check that the electrical contacts are tight.

REMARK

- If the outdoor unit is equipped with a casing resistor on the

compressor, it must be turned on 12 hours before turning on

the system.

TURN OFF THE UNIT REMOTE CONTROL SYSTEM AND TURN

ON THE LINE SWITCH

REPLACEMENT OF FAN-MOTOR

UNIT

- Open the return air grille by releasing the locks.

- Remove the air filter

- Remove the front panel by removing the four screws.

- Remove the four polystyrene tray attaching brackets

- Remove the probe from its plastic clip and disconnect the infrared

remote control unit cable

- Pull the polystyrene tray out as straight as possible toward the

bottom.

- Unscrew the central fan attaching screw

- Remove the fan

- Disconnect the motor wires (marking on the wires and the

connector)

- Remove the four motor support screws

- Replace the motor

- Reconnect the new motor, carefully checking the marking on

each wire

- Install the motor support

- Install the fan

- Install the polystyrene tray, being careful to insert the probe

through the hole in the tray

- Attach the tray with the four metal brackets

- Install the front panel, infrared remote control unit cable, air filter

and return air grille

- The air filter is made of acrylic fiber and can be washed with

water. To remove the filter, simply open the return air grille by

releasing the two locks.

Latch of the grille

ELECTRICAL CONNECTIONS

GENERAL POWER SUPPLY

- Make the connection on the outdoor unit

- This unit is designed to be permanently wired to a

fixed power line.

- Refer to the circuit diagrams on the units.

GC 30 RCF -> 45 RCFA

- Make the connection on the side of the outdoor

unit after removing access panel .

A

A = Hatch for connection

15

K INST. MENU

.

POWER SUPPLY

K30RCF

POWER SUPPLY ~ 240 V / 50 Hz

GC30RCFA & GC30RCC

K45RCF

GC45RCFX

POWER SUPPLY 3N ~ 415 V

16

K INST. MENU

17

.

SERVICING

ROUTINE SERVICINGROUTINE SERVICING

ROUTINE SERVICINGROUTINE SERVICING

ROUTINE SERVICING

To ensure the correct operation of the installation, it is necessary

to have preventive maintenance of the indoor and outdoor units

carried out by qualified personnel.

GENERAL INSTALLATIONGENERAL INSTALLATION

GENERAL INSTALLATIONGENERAL INSTALLATION

GENERAL INSTALLATION

Carry out a visual inspection of the complete installation in ser-

vice.

Check the general cleanness of the installation, and check that

the condensate evacuations are not blocked, particularly on the

indoor unit, before the summer season.

Check the condition of the tray.

OUTDOOR UNITOUTDOOR UNIT

OUTDOOR UNITOUTDOOR UNIT

OUTDOOR UNIT

COOLANT SYSTEMCOOLANT SYSTEM

COOLANT SYSTEMCOOLANT SYSTEM

COOLANT SYSTEM

Clean the heat exchanger using a special product for alumi-

nium-copper heat exchangers, and rinse with water. Do not use

hot water or steam, as this could cause the pressure of the

coolant to increase.

Check that the surface of the aluminium fins of the heat exchanger

is not damaged by impacts or scratches, and clean with an

appropriate tool if necessary.

ELECTRICAL SECTIONELECTRICAL SECTION

ELECTRICAL SECTIONELECTRICAL SECTION

ELECTRICAL SECTION

Check that the main power supply cable is not damaged or altered

in such a way as to affect the insulation

Check that the interconnecting cables between the two units are

not damaged or altered, and that they are correctly connected.

Check the earth connection.

INDOOR UNITINDOOR UNIT

INDOOR UNITINDOOR UNIT

INDOOR UNIT

In order for the installation to operate correctly, it is essential to

regularly clean the air filter located in the intake of the indoor unit.

When clogged, the filter reduces the air flow through the heat

exchanger of the indoor unit, which in turn reduces the efficiency

of the installation and inhibits the cooling of the fan motor.

Check the cleanness of the indoor heat exchanger.

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

BEFORE CARRYING OUT ANY OPERATION

ON THE EQUIPMENT, CHECK THAT THE

ELECTRICAL POWER SUPPLY IS

SWITCHED OFF AND THAT IT CANNOT BE

SWITCHED ON INADVERTENTLY.

K INST. MENU

Cassette K30RCF / GC30RCC

ATTENTION:

THE INDOOR UNIT IS SUPPLIED WITH AN EXTRA RESTRICTOR

KIT FOR CONNECTION TO THE INDOOR LIQUID VALVE DURING

INSTALLATION AS THE ABOVE ILLUSTRATION.

WARNING:

WITHOUT THIS KIT, THE UNIT WILL NOT OPERATE PROPERLY

IN THE HEATING MODE.

FOR CONNECTION TO INDOOR UNIT

RESTRICTOR KIT INSTALLATIONRESTRICTOR KIT INSTALLATION

SUCTION VALVE

RESTRICTOR

LIQUID VALVE

18

K INST. MENU

TECHNICAL ENQUIRIES

SERVICE / WARRANTY

1800 1800 04 1300 553 000

MELBOURNE

745 Springvale Road

Mulgrave VIC 3170

TEL: (03) 9271 3505 FAX: (03) 9271 3540

SYDNEY

CNR Marion St & Airport Ave

(P.O. Box. VQ)Banktown

Airport NSW 2200

TEL: (02) 9793 3644 FAX: (02) 9793 3688

BRISBANE

Unit 9, 123 Muriel Ave

Moorooka QLD 4105

TEL: (07) 3392 8113 FAX: (07) 3392 8115

ADELAIDE

Offices on the parkSuite 27, 8

Greenhill Road

Wayville SA 5034

TEL: (08) 8372 7866 FAX: (08) 8372 7816

PERTH

Suite 23, 350 Cambridge St

Wembley WA 6014

TEL: (08) 9284 0800 FAX: (08) 9284 0600

NEWCASTLE

Suite 3, 19 Darby Street

Newcastle NSW 2300

TEL: (02) 4940 4652 FAX: (02) 4940 4653

NEW ZEALAND

517A Rosebank Road

Avondale, Auckland NZ

TEL: (09) 820 0333 FAX: (09) 820 0332

www.airwell.com.au

NZ Tech Support Freecall

TEL: 0800 180 094

WITH A CONCERN FOR A CONSTANT IMPROVEMENT, OUR PRODUCTS CAN BE MODIFIED WITHOUT NOTICE. PHOTOS NON CONTRACTUAL. © Copyright 2003

K INST. MENU

/