Walker PERFAERATORTM PA6685 User manual

- Category

- Lawnmowers

- Type

- User manual

This manual is also suitable for

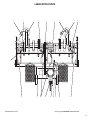

Walker PERFAERATORTM PA6685 is a rugged and versatile machine that is ideal for homeowners and professional landscapers alike. With a working width of 41-1/2 inches and a core spacing of 3.63 x 6 inches, it can quickly and easily aerate large areas of land. The machine's 12 machined, high carbon, heat-treated steel tines work in line as a camshaft to provide up to 2.50 inches of coring depth.

The PA6685 is also very easy to use. It attaches to the PTO of a compatible tractor and is controlled by a single lift lever and foot trigger. The machine's pneumatic 11 x 4.00-5 deck caster wheels and 3-7/8 inch roller wheel provide excellent stability and maneuverability, even on uneven terrain.

Walker PERFAERATORTM PA6685 is a rugged and versatile machine that is ideal for homeowners and professional landscapers alike. With a working width of 41-1/2 inches and a core spacing of 3.63 x 6 inches, it can quickly and easily aerate large areas of land. The machine's 12 machined, high carbon, heat-treated steel tines work in line as a camshaft to provide up to 2.50 inches of coring depth.

The PA6685 is also very easy to use. It attaches to the PTO of a compatible tractor and is controlled by a single lift lever and foot trigger. The machine's pneumatic 11 x 4.00-5 deck caster wheels and 3-7/8 inch roller wheel provide excellent stability and maneuverability, even on uneven terrain.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

Walker PERFAERATORTM PA6685 User manual

- Category

- Lawnmowers

- Type

- User manual

- This manual is also suitable for

Walker PERFAERATORTM PA6685 is a rugged and versatile machine that is ideal for homeowners and professional landscapers alike. With a working width of 41-1/2 inches and a core spacing of 3.63 x 6 inches, it can quickly and easily aerate large areas of land. The machine's 12 machined, high carbon, heat-treated steel tines work in line as a camshaft to provide up to 2.50 inches of coring depth.

The PA6685 is also very easy to use. It attaches to the PTO of a compatible tractor and is controlled by a single lift lever and foot trigger. The machine's pneumatic 11 x 4.00-5 deck caster wheels and 3-7/8 inch roller wheel provide excellent stability and maneuverability, even on uneven terrain.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Walker MTL Detailed Instructions

-

Walker 36" User manual

-

Walker Combined Implements User manual

-

Walker IH6620 User manual

-

Walker H12 42" Snowblower User manual

-

Walker H12 42" Snowblower User manual

-

Walker Rider Lawnmowers SB36 User manual

Walker Rider Lawnmowers SB36 User manual

-

Walker Combined Decks User manual

-

Walker S18 User manual

-

Walker S14i User manual

Other documents

-

Ransomes 58237G01 Owner's manual

-

Ransomes 58236G01 Owner's manual

-

Ransomes 58235G01 Owner's manual

-

Ransomes 88119 Owner's manual

-

Ransomes 544917 Owner's manual

-

Baroness TDA1200/1600 Operating instructions

-

Toro Aerator 686 User manual

-

Ransomes 88120, 88121 Owner's manual

-

Parkside PLV 1500 A1 Translation Of The Original Instructions

-

Toro ProCore SR48 Aerator User manual