Page is loading ...

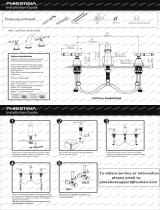

INSTRUCTIONS FOR MODELS

92-SEF-18100-01

For additional assistance or service please contact:

SPEAKMAN

®

800-537-2107

customerser[email protected]

www.speakman.com

SEF-18100

SEF-18200

SEF-18100-8

SEF-18200-8

EYESAVER

®

Sensor Faucet

* YOUR FAUCET MAY DIFFER IN APPEARANCE

TO ITEM SHOWN, IT WILL INSTALL WITH IN

THE SAME MANNER.

TOOLS AND SUPPLIES

Phillips

Screwdriver

Adjustable

Wrench

Aerator

Wrench

(Included)

Supply

Hoses

IMPORTANT

• This installation manual covers several models.

While the appearance of your faucet may vary, the

installation steps required are the same as shown in

this manual.

• This faucet has an operating range of 20-80 psi.

• Be sure to read instructions thoroughly before

beginning installation.

• Do not over-tighten any connections or damage may

occur.

• The supply line for the eyewash shall provide an

uninterruptible supply of flushing fluid at a minimum of

30 psi flowing pressure. If shut off valves are installed in

the supply line of the eyewash, provisions shall be

made to prevent unauthorized shut off. ANSI Z358.1

requires that all emergency equipment shall be tested

weekly to verify proper operation and inspected

annually to assure conformance with ANSI Z358.1

requirements.

Cover your drain to prevent loss of parts. Be sure to

wear eye protection while cutting pipe.

SAFETY TIPS

Warranty information can be found at:

www.speakman.com

WARRANTY

5 Gallon

Bucket

Pencil

Drill & Drill Bit

Mounting Hardware

1

Ensure water supplies are shut OFF. Remove existing faucet spout and clean mounting surface. Verify that the

Rubber Gasket (1) is in position and aligned to the base of the Faucet Spout. Place Hoses and Sensor Wires

carefully, one at a time, through hole in mounting surface. Lower Faucet Spout into position.

NOTE:

If installing with an

optional deck plate,

please place hoses and

wires through deck plate

first.

2

From below, install Rubber Mounting Washer (1), Metal Mounting Washer (2), and Mounting Nut (3).

3

This Faucet has a integral swivel feature. Verify sweep of Faucet Spout and align properly before securing

Faucet Spout into final position.

NOTE: The SPEAKMAN logo at the base of the faucet should be facing front when installed properly.

4

Align Mounting Nut (1) so the Mounting Nut

Screws (2) are aligned towards the front and

rear of faucet as shown below. Final tighten

Mounting Nut Screws (2) using a Phillips

Screwdriver.

FRONT

REAR

5

IMPORTANT

Dry Connection Only!

Do not use any

sealant on this

connection

Install one end of the Included Flex Hose (1) to

the Female Inlet (2) of the faucet. Install the

remaining end of the Included Flex Hose to the

OUTLET of the Solenoid (3). Wrench tighten.

6

Place the Solenoid Assembly against the desired mounting surface while ensuring adequate clearance for

servicing of all connections. If using the optional A/C Adapter, consider the distance to the nearest electrical

outlet. Solenoid Assembly should be mounted so the inlet and outlet ports are aligned vertically. Mark location

of Solenoid Assembly on the mounting surface using a pencil.

10-7/8”

(275mm)

MAX

LEFT OR RIGHT

OF CENTER

9-7/16”

(240mm)

MAX

7

Remove Mounting Bracket (1) from Solenoid Assembly. Using the previously marked location on mounting

surface, align Mounting Bracket (1) horizontally to approximate position and mark the mounting locations with a

pencil. If mounting on drywall and not to stud, use the appropriate anchors and fasteners for application.

Recommend screw in easy anchor or equal for drywall.

8

After securing the Bracket to the mounting surface, align and slide Solenoid Assembly over Mounting Bracket.

9

Make electrical connections from the Sensor Eye to the Solenoid Assembly. Connect the Blue Male Ended Wire

to the Blue Female Connection. Connect the Green Male Ended Wire to the Green Female Connection. To

further aid proper alignment, there are white alignment lines on the connector ends. These alignment lines

should face forward when properly installed.

GREEN

BLUE

10 FOR BATTERY MODELS (SEF-18100 SERIES)

Access the interior Battery Enclosure by pressing down on the tab to release the tray holding the batteries (1). Pull out

Battery Tray (2). Insert or replace the batteries with six (6) new standard 1.5v AA batteries. Ensure the position of the

new batteries are aligned to the plus (+) and minus (-) symbols within the battery holder.

11 FOR A/C MODELS (SEF-18200 SERIES)

Verify that no batteries are present within the battery enclosure (1). Connect the A/C Adapter to the BLACK connector

on the Solenoid Body (2). Plug the A/C Adapter into the wall outlet. The A/C light (3) should illuminate.

12

Reinstall the Battery Tray (1). Make sure to press

the indicated location until the battery door is

fully seated and locks into position (2).

13

Make TEPID WATER connection to the inlet of the Eyewash supply. A Speakman STW Series Thermostatic Mixing Valve is recommended (not included). Make WATER

connection to the inlet of the Solenoid. A Speakman A-TMV Thermostatic Mixing Valve is recommended (not included). Inlet supplies are not included. Wrench tighten

connections.

EYEWASH

TEPID

WATER SUPPLY

IMPORTANT

If shut off valves are

installed in the supply

line of the eyewash,

provisions shall be

made to prevent

unauthorized shut off.

IMPORTANT

Flush Tepid Water Supply

Lines into a Bucket for 1

Minute prior to making

connection.

FAUCET

TEPID

WATER SUPPLY

IMPORTANT

Dry Connections

Only! Do not use any

sealant on these

connections

14

After the assembly is complete, turn the Faucet and Eyewash water

supplies on. Activate Sensor and allow Faucet to run for 1 minute to

flush out any debris. Check all connections for leaks.

15

Install Aerator (1) into the Faucet Outlet. Secure with included Aerator

Wrench.

IMPORTANT

If installing optional

Outlets for either the

Eyewash or Faucet,

please do so at this

time.

16

Activate Faucet and test for proper operation. NOTE: Before

testing, you must remove tape from Eyewash Dust Cap. Lift

Eyewash Handle to activate Eyewash and test for proper operation.

See “EYEWASH FLOW DATA” chart. Check all connections for leaks.

CARE AND CLEANING

1) Your EYESAVER

®

Faucet is designed and engineered in accordance with the highest quality and performance standards. With proper care, it will provide years of hygienic and

trouble-free service.

2) Periodically, the Faucet will require some minor maintenance to keep it at peak performance. There are 2 low battery indicator lights. One located on the Sensor on the Faucet body

and the other located on the Solenoid Box. When the low battery light on the Sensor blinks, it indicates that the battery is low. However, the Solenoid can still function at this point.

When the low battery light on the Solenoid blinks, the Solenoid will stop functioning at this point and the batteries need to be replaced immediately. To replace the batteries, follow the

installation instructions in the electrical connections section of this document.

3) Periodically clean the In-Line Filter.

4) The polished chrome finish of your Faucet should be cleaned using mild soap and warm water.

5) Dry immediately with a soft, clean cloth for best results.

6) NEVER use abrasive cleaners, chemicals, alcohol or other solvents. They may damage the surfaces of the non-chrome plated finishes.

TROUBLESHOOTING

If water flow from the Faucet decreases:

1) Make sure the supply stops are open.

2) Check that the In-line Filter located in the hose connecting the solenoid and the mixer is

not blocked with debris. Remove filter from the Solenoid Inlet and rinse filter screen with

clean water. Reassemble the filter, open stops, and check water flow. Stops must be

turned off when filter is removed.

3) Remove the Aerator from the spout using the outlet wrench. Operate the Faucet with

outlet device removed. If water flow is acceptable, disassemble the outlet device and rinse

components with clean water.

If no water flows from the Faucet, and

If you can hear a clicking sound of Solenoid opening, but no water flows:

1) Verify that the HOT and COLD wall stops are completely open.

2) If the Battery Light within the Sensor Eye or Solenoid blinks continuously, even when

the Faucet is not in use, the batteries within the Solenoid have low voltage and need

replacement.

3) Verify that the In-Line Filter in the Solenoid is not blocked by debris. Clean filter if

needed.

If you do not hear a clicking sound of Solenoid opening and no water flows:

1) If the Battery Light within the Sensor Eye blinks continuously, even when the Faucet is

not in use, the batteries within the Solenoid have low voltage and need replacement.

2) Unplug connections to Solenoid for 2 minutes. Plug connections back in. The red light

on the Sensor should turn on for several seconds before becoming operational. If not,

check power supplies and connections.

3) Disconnect the existing Solenoid Assembly and connect a new Solenoid Assembly.

Activate the Sensor and check for water flow. If the water flows, the existing Solenoid

Assembly should be replaced.

If the batteries have been replaced, but the Faucet still does not operate:

1) Check the battery polarity and electrical connections. Make sure all electrical

connections are fully inserted.

2) If the Faucet does not operate, replace the existing Solenoid Assembly with one you

know to be functioning.

If the Faucet activates, but the water will not shut off:

1) Hold a hand in front of the Sensor at up to 7" away for more than 1 minute until the

water flow stops. Once the water stops, remove your hand and wait 15 seconds. Then

place your hand in front of the Sensor and verify that it is operating properly.

2) If the Faucet still does not shut off, cover the front of the sink with a towel. This will

eliminate the potential of reflections activating the Sensor.

3) If it is a new installation and still not working, replace the Solenoid Assembly.

QUESTIONS & ANSWERS

Q. How does the Sensor Faucet work?

A. It uses laser technology. The Sensor emits a non-visible beam of light. When an object

enters the detection area, the Sensor signals the Solenoid Valve to open for water to flow.

When an object leaves the detection area, the Sensor signals the valve to close.

Q. Is the Sensor Faucet sensor beam adjustable?

A. No, the Sensor Faucet sensor beam is not adjustable. It has been factory set to factory

specifications for these Faucets.

Q. What about water conservation?

A. The Sensorf faucet design directly addresses water conservation. Water savings of up

to 85% are not unusual. Additional energy savings are realized by conserving hot water.

Q. Can the water temperature of the Sensorflo

®

Faucet be adjusted?

A. No, If you need to meet ASSE 1070, you must use our TMV (Thermostatic Mixing

Valve) option.

Q. Does Sensorflo

®

reduce maintenance?

A. By elimination of on/off handles, control components are reduced and fittings stay

cleaner longer. Only a light rinsing and wiping is required to restore the beauty of the

Eyesaver

®

Faucets. Drip stains are eliminated. Fingerprints and soap spots on sinks and

fittings are avoided. Finishes last longer and wash areas stay cleaner. Germs and

bacteria are not transferred as easily making for a healthier environment.

Q. The chrome finish on my Faucet seems to be deteriorating. What can I

do to prevent this from happening?

A. Many commercial cleaning products contain harsh chemicals and abrasives. These

products should not be used on any chrome-plated plumbing products. Please use only

mild soap and water to clean the Faucet. Dry immediately with a soft cloth.

Q. Does the Sensor system shut off immediately when an object leaves the

sensing area?

A. A very short delay of approximately 0 to 1.5 seconds occurs before water is shut off.

Q. Is my Faucet protected from power surges?

A. Yes, this Sensor Faucet has been designed to have built-in power surge protection.

Q. If we lose power, do I have to do something to get the Faucet to

operate again?

A. After a power outage, the Sensor Faucet is automatically ready for operation as soon

as the power comes back on.

Q. If I call a plumber to come and install this Faucet, will they know

enough to hook it up?

A. Our installation diagrams are very easy to follow.

SEF-18100 / SEF-18100-8 REPAIR PARTS

SPEAKMAN

®

RPG05-111352 1.2GPM SLIM AIR AERATOR REPAIR GROUP

RPG38-110458 SPRAY HEAD REPAIR GROUP

RPG76-108060 SOLENOID BOX WITHOUT BATTERIES

ITEM NO. PART NO. DESCRIPTION

EYEWASH FLOW DATA

SPEAKMAN

®

NOTE: If plume heights are low, check to ensure that your supply valves are fully open. If there is a noticeable height difference

between the two plumes, remove the aerators and flow controls and remove any debris that would inhibit the flow of water.

"A"

psi bar gpm L/min in. cm

30 2.07 1.9 7.2 9.5 24.13

40 2.76 2.1 7.9 10.5 26.67

50 3.45 2.2 8.3 10.65 27.31

60 4.14 2.1 7.9 10.5 26.67

70 4.83 2.2 8.3 11 27.94

80 5.52 2.3 8.7 11.5 29.21

SEF-18100

FLOWING

PRESSURE

FLOW RA TE

PL UME

DISTANCE "A"

psi bar gpm L/min in. cm

30 2.07 1.9 7.2 9.5 24.13

40 2.76 2.1 7.9 10.5 26.67

50 3.45 2.2 8.3 10.65 27.31

60 4.14 2.1 7.9 10.5 26.67

70 4.83 2.2 8.3 11 27.94

80 5.52 2.3 8.7 11.5 29.21

SEF-18100-NA

FLOWING

PRESS URE

FLOW RA TE

PL UME

DISTANCE "A"

psi bar gpm L/min in. cm

30 2.07 1.76 6.7 11.5 29.21

40 2.76 2.03 7.7 13 33.02

50 3.45 2.18 8.3 14 35.56

60 4.14 2.1 7.9 13 33.02

70 4.83 2.1 7.9 13.5 34.29

80 5.52 2.2 8.3 13.75 34.93

SEF-18100-8

FLOWING

PRESS URE

FLOW RA TE

PL UME

DISTA NCE " A "

psi bar gpm L/min in. cm

30 2.07 1.76 6.7 11.5 29.21

40 2.76 2.03 7.7 13 33.02

50 3.45 2.18 8.3 14 35.56

60 4.14 2.1 7.9 13 33.02

70 4.83 2.1 7.9 13.5 34.29

34.93 34.93 34.93 34.93 34.93 34.93

SEF-18100-8-NA

FLOWING

PRESS URE

FLOW RA TE

PL UME

DISTA NCE " A "

ROUGH-IN DIAGRAM

SPEAKMAN

®

NOTE: UNLESS OTHERWISE SPECIFIED, ALL INLETS ARE 3/8” COMPRESSION WITH MALE THREADS. UNLESS OTHERWISE SPECIFIED,

ALL DIMENSIONS ARE IN INCHES AND ARE SUBJECT TO CHANGE WITHOUT NOTICE.

SEF-18100 SEF-18100-8

2"

MIN. TO LEDGE

51mm

2"

MIN. TO WALL

51mm

LAVATORY ROUGH-IN

32mm

1

1

4

"

MIN

NOTES:

COMPLIANCE:

CONNECTIONS:

• ANSI/ISEA Z358.1 certified

• ASME A112.18.1/CSA B125.1 certified

• IGC 272 certified

• NSF/ANSI 61 certified

• NSF 372 certified

• Faucet Inlet: 3/8” compression

• Eyewash Inlet: 3/8" compression

Contractor to supply necessary inlet

connections.

2"

51mm

MAX DECK THICKNESS

9

7

16

"

240mm

MAX

10

7

8

"

275mm

MAX

LEFT OR RIGHT

OF CENTER

MIXED WATER INLET

3/8" COMPRESSION

12°

6

5

8

"

168mm

70°

5

1

2

"

140mm

5

1

4

"

133mm

2

1

4

"

57mm

5

7

16

"

137mm

TEPID WATER INLET

3/8" COMPRESSION

12°

8

5

8

"

[219mm]

70°

7

1

4

"

184mm

8"

203mm

9

9

16

"

242mm

2

1

4

"

57mm

7

7

8

"

200mm

TEPID WATER INLET

3/8" COMPRESSION

INSTRUCTIONS FOR MODELS

92-A-TMV-02

For additional assistance or service please contact:

SPEAKMAN

®

800-537-2107

customerser[email protected]

www.speakman.com

A-TMV

Thermostatic Mixing Valve

HELPFUL TOOLS & SUPPLIES:

TOOLS AND SUPPLIES

Thermometer Measuring

Tape

Safety

Glasses

Pencil

Flat Tip

Screwdriver

Phillips

Screwdriver

Adjustable

Wrench

Phillips

Drive Bit

Drill

Drill Bit

Ø

5

/16”

Tile Drill Bit

Ø

5

/16”

IMPORTANT

• Compliance and conformity to local codes and

ordinances is the responsibility of the installer.

• Valve should be accessible for testing, adjustment

and maintenance in the installed position.

• Make sure that all water supply lines have been

flushed and then completely turned off before

beginning installation. Debris in supply lines can

cause valves to malfunction.

• Ensure the mounting structure and mounting

hardware can safely support the product in use.

• Do not over-tighten any connections or damage

may occur.

• Be sure to read instructions thoroughly before

beginning installation.

Be sure to wear eye protection.

SAFETY TIPS

Warranty information can be found at:

www.speakman.com

WARRANTY

See section “Testing the Mixing Valve”.

MAINTENANCE

IMPORTANT

1

Determine desired mounting position of the

A-TMV with Plastic Wall Bracket. Ensure

mounting location is capable of supporting the

product in use. Using a pencil, mark the hole

location.

2

If mounting to drywall or tile, select appropriate

5/16" drill bit and drill guide hole at marked

location. Install the Plastic Wall Bracket into the

drilled hole and press/tap into place until the

bracket is flush to the wall surface. Secure the

Plastic Wall Bracket to the wall with the proper

Mounting Screw (included).

Ø

5

/16”

OR OR

3

Ensure the A-TMV is vertical and the body rests

on the top face of the Plastic Wall Bracket.

4

Connect Supply Lines and Fixtures.

• Ensure incoming water supplies are turned OFF.

• Install Inlet and Outlet connections to the valve.

Wrench Tighten.

HOT

INLET

COLD

INLET

TEPID WATER

OUTLET

5

• Check for leaks by pressurizing the unit SLOWLY.

• Check the temperature and adjust if necessary.

HOT

INLET

COLD

INLET

TEPID WATER

OUTLET

CAUTION

When maintaining and

adjusting the Mixing Valve, all

fixtures should be isolated from

use. Speakman recommends

that appropriate personnel

shall work safely at all times.

6 SETTING THE MIXING VALVE

Should the Valve require adjustment, or an

application require a different set temperature,

proceed as follows:

Adjust Temperature with Water Running

• Check the temperature with a stick thermometer.

• Contact proper medical and safety authorities

to determine the correct water temperature for

the specific application.

• Remove the Plastic Cap (White) from the Valve

using a flat tip screwdriver.

REMOVE THE CAP WITH

FLAT TIP SCREWDRIVER

FROM THE NOTCH

ON THE CAP

7 SETTING THE MIXING VALVE

• Create a draw on the Mixing Valve by opening

the faucet.

• Loosen, but do not remove the Locking Nut (2)

using adjustable wrench. Invert Plastic Cap and

align triangular recess in cap to the Adjuster

Screw (1).

• Set the outlet temperature by turning the Adjuster

Screw clockwise to reduce temperature,

counterclockwise to increase temperature.

Use a stick Thermometer to check the outlet

temperature.

• Tighten the Locking Nut to avoid inadvertent

adjustment of outlet temperature.

WARMER

COLDER

8 TESTING THE MIXING VALVE

After installation, test the Mixing Valve and the faucet it

serves for proper operation by following the steps below.

Valve temperature test procedure is as follows:

1. Activate faucet to observe and record the temperature with a stick

Thermometer. If the temperature of the Thermometer is not correct,

readjust the Mixing Valve according to the section “Setting the Mixing

Valve”.

9 REPLACING THE THERMOSTATIC ELEMENT

The Thermostatic Element’s replacement procedure is

as follows:

1. Shut off the hot water supply and cold water supply to the Mixing Valve.

2. Remove the Plastic Cap and disassemble the Valve Cap.

3. Remove Thermostatic Element in conjunction with the Shuttle from the

Valve Body. No special tools are required.

4. Inspect the Thermostatic Element. If it feels slippery to the touch,

then the Element has lost its wax and requires replacement. If the

Thermostatic Element feels normal to the touch, then it is in good

condition and operable.

5. Verify that the stainless steel Piston moves freely up and down within

the Element’s body.

Note:

Gallon per minute ratings may

vary depending upon incoming

water temperatures and

pressures. Hot and cold water

inlet pressures must be equal.

Provisions shall be made to

thermally isolate the valve.

A-TMV REPAIR PARTS

SPEAKMAN

®

RPG05-109269 THERMOSTATIC & O-RING REPAIR KIT

ITEM NO. PART NO. DESCRIPTION

A-TMV ROUGH-IN DIAGRAM

SPEAKMAN

®

NOTES:

COMPLIANCE:

ASSE 1070 & cUPC Certified

• Inlets: 3/8” Compression Male Threads

• Outlet: 3/8” Compression Male Threads

• Maximum Working Pressure: 125 psi (861.9 kPa)

• Rated flow at 30 psi (206.9 kPa) differential

pressure: 2.16 GPM (8.2 L/min)

• Minimum flow rate: 0.35 GPM (1.3 L/min)

• Hot Water Inlet Temperature Range: 120° – 180° F

• Cold Water Inlet Temperature Range: 37° – 80° F

• Outlet Water Temperature Range: 80° – 120° F

• Minimum Temperature Differential (Hot to Mix):

18° F (10° C)

Contractor to supply necessary inlet

connections.

FLOW CAPACITY OF A-TMV

PRESSURE DROP,

psi (bar)

5

(0.4)

10

(0.7)

15

(1.0)

20

(1.4)

30

(2.1)

40

(2.8)

45

(3.1)

TEMPERED FLOW,

GPM (L/min)

0.66

(2.5)

1.2

(4.5)

1.5

(5.7)

1.74

(6.6)

2.16

(8.2)

2.51

(9.5)

2.66

(10.1)

50

(3.4)

2.8

(10.6)

2

9

16

"

66mm

1

5

16

"

33mm

2

3

16

"

55mm

9/16"-24 THREAD FOR

3/8" COMPRESSION FITTINGS

(3 PLACES)

1"

26mm

NOTES:

ALL DIMENSIONS ARE IN INCHES [MILLIMETERS] UNLESS OTHERWISE

1.

SPECIFIED AND ARE SUBJECT TO CHANGE.

/