ESSENCE REVERSE OSMOSIS SYSTEM

ROES-PHUV75 INSTALLATION

INSTRUCTION & OWNER’S MANUAL

All Rights Reserved © APEC Water Systems

www.FreeDrinkingWater.com

Ver 1.0

A

ll Ri

g

hts R

es

erv

rv

rv

ededed

©©©

APE

A

A

C W

a

ter S

y

stems

w

ww

.

F

r

e

e

D

D

D

r

r

i

i

i

n

n

n

ki

n

g

W

a

t

e

r

.

c

o

m

r

r

Ve

r

1.

0

Please keep this Owner’s Manual for future reference.

It contains useful information on how to maintain and care for your

APEC Reverse Osmosis water filter system.

TABLE OF CONTENT

1. Installation:

Preparation ................................................................... page 1

Filter housings assembly ................................................. page 4

Feed water connection .................................................... page 5

Drain saddle connection ................................................ page 9

Faucet mounting ........................................................... page 11

Connecting the system .................................................. page 13

2. Maintenance:

Filter change schedule & instructions ............................. page 19

3. Owner’s Manual - RO Basics:

System flow diagram ...................................................... page 25

Input water pressure: most important factor ................... page 26

Tank volume & delivery pressure ..................................... page 26

Misc. topics .................................................................... page 27

4. Trouble-shoot Guide:

RO Head diagram .......................................................... page 29

Slow output .................................................................. page 31

System shut off abnormal ............................................... page 33

Misc. topics .................................................................... page 34

5. Other Information:

AirGap Faucet Installation ............................................. page 37

6. Warranty ........................................................................... page 38

0

Please keep this

O

O

w

w

n

n

er’s Manual

f

or

f

uture re

f

erence.

It contains use

f

ul in

f

ormation on how to maintain and care

f

or your

A

PEC Reverse Osmosis water

f

ilter system.

TA

BLE

OF

OF

C

C

ON

ON

TE

N

T

1

.

I

n

s

t

a

ll

a

ti

o

n

:

Preparat

i

on ...........

.

.

..

..

....

..

.

..

.

..............................................

pa

gege

1

1

Filter housings

as

sese

mb

mb

ly

ly

.................................................

pa

a

gege

44

Feed water c

on

n

nee

ctct

io

io

n .................................................... pa

ge

ge

5

5

Dr

a

in

sadd

l

e

c

on

on

ne

ne

c

ct

i

o

n ................................................ page

9

Fauc

et

t

mm

ouou

nt

nt

in

g

g

........................................................... page

11

C

onn

ec

ec

ti

ti

ngng

t

t

h

he

system .................................................. page 1

3

2

.

M

aintenance:

Filter change schedule & instructions

..

.

..

.

..

.

..

.

..

..

..

.

................. page 1

9

3

.

O

wner’s Manual - RO Basics:

System

f

low diagram ...........

..

.

..

..

.

.

.

..

..

.

.

............................... page

25

I

nput water pressure: most

i

mp

mp

or

or

ta

ta

nt

f

actor ................... page 2

6

T

ank volume & delivery p

re

re

ss

ss

ur

ur

e

e

..................................... page

26

6

M

isc. topics ..............

.

..

.

..

.................................................. page

2727

4

.

T

r

oub

l

e

-

s

h

oo

t

Gu

Gu

idid

e:

e:

RO Head di

ag

ag

ra

ra

m

m

...............................................

....

....

....

..

..

..

.

p

pa

ge

29

Slow

o

o

ut

ut

pu

p

t ....................................................

..

.

..

..

..

..

..

..

.

..

..

..

.

page

31

Sy

st

t

emem

ss

huhu

t

t

of

f

f

abnormal ..................................

..

..

....

.

..

..

.

..

..

..

..

. page

33

M

i

sc

sc

.

.

toto

pipi

cs

cs

.................................................................... page

34

5

.

O

th

e

r In

fo

rm

a

ti

o

n:

A

irGap Faucet Installation ............................................. page 37

6

.

W

arranty

...........................................................................

page

38

0

1

Thank you for choosing APEC reverse osmosis systems.

You now own the finest water filter in America.

Please read and become familiar with instructions and parts needed before proceeding with the

installation.

(This manual is constructed for standard APEC Essence ROES-PHUV75 System.)

BEFORE INSTALLATION:

Inspect the system:

Please take the system and all the components out of the box. Inspect the system and all the connection

fittings carefully, make sure nothing is damaged during shipping. If any part is cracked or broken, please

do not proceed with the installation and contact APEC or your distributor for an exchange or diagnosis.

Recommended tools list:

x Variable speed drill

x Drill bit:1/4”

(for the drain line), 1/8” (as pilot, not mandatory), and 1/2” (for standard faucet

hole, air-gap faucet requires 1”d hole)

x 5/8”, 9/16” open-end wrench, or adjustable wrench, pliers

x Phillips screwdriver

x Utility knife, or scissors

x Teflon tape

Operating Parameter

x Operating pressure: 40 – 85psi maximum

x Feed water temperature: 40 – 100 ºF (4-37 ºC)

x Feed water TDS level: 2000ppm maximum

x Do not connect this unit to hot water source

x Install the RO in a sheltered environment, avoid exposure to hot and cold weather or under direct

sun light.

General Installation/Operation/Maintenance Requirements

x Installation needs to comply with state and local laws and regulations.

x System must be installed indoor away from possible environmental damage

x Do not use with water that is microbiologically unsafe or of unknown quality without adequate

disinfection before or after system. Systems certified for cyst reduction may be used on disinfected

water that may contain filterable cysts.

x This reverse osmosis system contains a replaceable treatment component critical for effective re-

duction of total dissolved solids. The product water shall be tested periodically to verify that system

is performing satisfactorily.

Copyright:

This manual is copyrighted by APEC Inc. Under the copyright laws, this manual may not be reproduced in any form, in whole or

part, without the prior written consent of APEC Inc. Manual print ver. 1.0, 2018 Nov.

1

T

T

h

h

ank you

f

or choosing

A

A

P

P

E

E

CC

r

r

everse osmosis syste

m

m

ss

.

.

Y

ou now own the

f

i

i

nn

ee

s

s

t

t

water

f

ilter in America.

PlPl

ea

ea

se read and become

f

amiliar

wi

i

th

th

i

i

ns

ns

tr

tr

uctions and parts needed be

f

ore

pr

pr

oc

oc

e

ee

ding with the

in

i

s

t

a

ll

a

ti

o

n.

(This manual is constructed

f

or standard APEC Essence ROES-PHUV75 System.)

B

E

FO

RE I

NS

TALLAT

IO

N:

I

nspect the syst

em

m

:

:

P

lease take the

sy

sy

stst

emem

a

a

nd all the components out o

f

t

he

he

bb

oxox

. Inspect the system and all the c

on

n

ne

n

ct

ct

io

io

n

f

ittin

gs

care

f

ul

l

ly

ly

,

,

mama

k

ke

sure nothin

g

is dam

ag

ed dur

in

n

g

g

shsh

ip

i

pi

ng

. I

f

a

ny

p

art is cracked or brok

en

en

,

pl

p

ease

d

o not p

ro

ce

ce

ed

ed

with the installation and contact

A

A

PE

E

C C

or your distributor

f

or an exchange

oror

dd

iaia

gn

g

osis.

R

e

co

o

mmmm

en

en

ded

t

oo

l

s

li

s

t:

x

x

Variable s

pe

ed dril

l

x

D

rill bit:1/4”

(f

or the drain

l

l

in

in

e)

e)

,

,

1/8” (as pilot, not mandatory), and

1/

/

2”

2”

(f

(f

or

o

standard

f

aucet

hole, air-gap

f

aucet r

eq

eq

ui

u

re

s

s

1”

1

d hole

)

x

5/8”, 9/16” open

-e

e

ndnd

ww

rere

nch, or adjustable wrench, pliers

x

P

hilli

ps

screwdrive

r

x

U

tility kni

f

e, or scissors

x

Te

f

lon tap

e

Op

erat

i

ng Parameter

x

Op

Op

er

e

ating pressure: 40 – 85psi maxim

um

m

x

FeFe

ed

ed

water temperature: 40 – 100 ºF

(4

4

-3-3

7 7

º

ºC

)

x

x

FeFe

ed

water TDS level: 2000ppm ma

xi

xi

mu

mu

m

m

x

x

D

o

n

ot

connect this unit to h

ot

w

at

at

er

s

s

ou

o

rc

e

x

I

nstall the RO in a sheltered en

vi

vi

ro

ro

nm

nm

ent, avoid e

xp

osure to hot and

c

c

olol

dd

we

w

ather or under direct

s

un li

gh

t.

Ge

n

e

ra

l Installation/O

pe

pe

ra

ra

ti

t

on

n

/

/M

aintenance Requirement

s

x

I

nstallation nee

ds

t

t

o o

coco

m

mp

ly

with state and local laws and r

eg

ulations.

x

System must be installed indoor away

f

rom possible environmental damag

e

x

D

o not use with water that is microbiologically unsa

f

e or o

f

unknown quality without ade

qu

u

atat

e

e

d

isin

f

ection be

f

ore or a

f

ter system. Systems certi

f

ied

f

or cyst reduction may be used on

d

d

is

is

in

in

fefe

ct

c

ed

water that may contain

f

ilterable cysts.

x

This reverse osmosis s

ys

tem contains a r

epep

la

la

ceable treatment com

po

nent critical

fo

o

r r

efef

fe

fe

ct

ive re-

du

du

ction o

f

total dissolved solids. The

p

p

ro

o

du

du

ct

ct

water shall be tested periodicall

y

y

to

o

v

v

erer

if

i

y that system

is

is

p

p

er

f

orming satis

f

actorily.

Co

Co

pyright

:

This manual is copyrighted by APEC I

nc

nc

.

Un

U

de

de

r the copyright laws, this manual may

no

o

t

t

bebe

rr

e

ep

roduced in any

f

orm, in whole o

r

part, without the prior written cons

en

n

t

t

of

of

A

A

P

PE

C Inc. Manual print ver. 1.0, 2018

N

N

ov

o

.

2

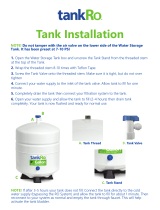

Components included with the ROES-PHUV75 system:

Make sure you have all these parts before starting installation.

1 RO system head

with pre installed membrane

3 Color tubing 1/4”

3 Pre-filters in

3 Housings

UV Transformer

110V

1 Feed water adaptor

3/8” - 1/2”

with needle valve kit

1 Tank ball valve

1 Storage tank

1 Drain Saddle

for waste water

Installation kit includes:

1 Faucet with

washers and nuts

(Faucet color may vary,

depends on the color selected)

2 Wrenches for opening filter

and Membrane housing

Recommended: Please keep both wrenches near

or on the RO unit for future maintenance.

1 Faucet Adapter

2

Compon

e

e

n

n

t

t

s

s

i

i

ncluded with the ROES-

P

P

H

H

UU

VV

7

7

5 system:

p y

M

a

a

k

k

e

e

sure you have all these

p

a

a

rr

t

t

s

s

be

f

ore starting inst

a

a

l

l

l

l

aa

t

t

i

i

oo

n

n

.

1

RORO

s

ys

tem head

wi

th

th

p

p

re

re

installed membran

e

3

3

C

Co

lor tubing 1/4”

3

Pr

e

-

f

ilt

e

r

s

i

n

3

Hous

i

ng

s

UV Tra

ns

ns

fo

fo

rm

rm

er

11

11

0V

0V

1

1

F

Fe

ed water adaptor

3

/8” - 1/2”

wi

th n

ee

dl

e

va

lv

e

ki

t

1 Tank

bb

alal

l

l

valv

e

1

1

S

St

or

ag

e tank

1

Dr

a

in

Sadd

l

e

f

or waste water

I

n

s

t

a

ll

a

ti

o

n kit in

c

l

u

de

s:

s:

1 Faucet wit

h

washers and nut

s

(Faucet color ma

y

va

ry

,

d

e

pe

nds on the color s

el

el

ec

ec

te

te

d)

2 Wrenches for o

pe

ni

ngng

f

f

il

il

te

te

r

s

and Membrane

h

h

ouou

si

si

n

ng

R

ecommended: Please ke

ep

p

b

b

ot

ot

h

h

wrenches nea

r

or on the RO uni

t

fo

o

r

f

u

tu

tu

r

re

maintenance.

1 Faucet Ada

pt

er

3

1) Bracket

2) Membrane and housing (4

th

-stage filter)

3) UV Light (5

th

-stage filter)

4) Inline carbon filter (6

th

-stage filter)

5) Inline pH plus filter(7

th

-stage filter)

6) Sediment pre-filter and housing (1

st

-stage filter)

7) Carbon block pre-filter and housing ( 2

nd

-stage filter)

8) Carbon block pre-filter and housing ( 3

rd

-stage filter)

9) Storage tank

10) Tank ball valve

11) ASO – Automatic Shut Off valve

12) Check valve (Internal check valve encased in plastic fitting)

13) T-fitting

14) Feed water inlet

15) Product (filtered) water outlet

Component Itemization:

3

1)1)

Br

ac

k

et

2

)

Membrane and housing (

4

4

th

h

-s

-s

tata

ge

g

f

ilter)

3)

UV Light (

5

th

-

stage

f

ilte

r)

r)

4) Inline carbon

f

ilter (6

th

h

-s

-s

ta

ta

ge

f

ilter)

5) Inline pH pl

us

s

f

f

ilil

te

te

r(r(

7

7

th

-

stage

f

ilter)

6

) Sediment pre

-f

-f

ilil

tete

r

r

a

an

d housing (

1

st

-

stage

f

ilter)

7)

C

arbon block pre-

f

ilter and housing ( 2

n

d

-

stage

f

ilter)

8

)

C

arbon block pre-

f

ilter and housing (

3

r

d

-

stage

f

ilte

r)

9)

Storage ta

nk

10

)

T

ank ball valv

e

11

1

))

A

SO – Automatic Shut O

ff

valv

e

1212

)

)

C

heck valve (Internal check

v

v

al

al

ve

ve

e

ncased in plastic

f

itting)

1

13

)

T

-

f

itting

14

)

Feed water inle

t

15

)

Product (

f

iltered) w

at

at

er

er

o

o

utle

t

Compon

e

e

n

n

tt

I

I

t

t

emization

:

p

4

THERE ARE TWO PARTS TO INSTALLING THE RO SYSTEM:

Assemble the filters and housings onto the main system

Installing the system

The RO Membrane Element has already been pre-installed.

PART I. ASSEMBLE THE FILTERS AND HOUSINGS ONTO THE MAIN SYSTEM

Remove plastic/paper wrappings on the 3 filters and housings, put filters into the 3 housings, and assemble

the housings onto the main system as follows:

Stand the 3 housings upright. Make sure each housing has a rubber O-ring in its groove.

Put the Essence sediment filter (FI-ES-SED10) into the “1st stage” housing on the right.

Put the Essence carbon filters (FI-ES-CAB10) into the “2nd

and 3rd stage” housing in the

middle and left.

Starting from the 3

rd

stage housing on the left, hand twist the housing onto the main system

turning counterclockwise, one by one, for all 3 housings.

Use the wrench provided to completely tighten the housing starting from 1st-stage. Repeat this

step for the 2

nd

stage housing in the middle, and for the 3

rd

stage housing on the left.

Note: For some people it is easier to use the wrench with the system laid down (face up).

Fig. 1

Fig. 2

Fig. 3

Part I.

Part II.

Note:

3rd

Stage

2nd

Stage

1st

Stage

Fig. 1 Fig. 2 Fig. 3

3rd

Stage

turn counter-clockwise

to tighten

3rd

Stage

2nd

Stage

1st

Stage

Use

Wrench

Use

4

THER

E

E

A

A

RR

E

E

TW

O

PART

S

T

O

IN

S

TALLIN

G

G

TT

H

H

E

E

R

O

S

Y

S

TEM

:

A

ssemble the

f

ilters a

nd

d

h

h

ou

o

si

si

n

ng

s onto the main syste

m

I

nstalling the syste

m

The RO Membrane

EE

ll

ee

mm

e

e

nt has alread

y

been

p

re-installed.

PART I. A

SS

EMBLE THE FILTER

S

AND H

OUS

IN

GS

O

NT

O

THE MAIN

S

Y

S

TE

M

R

emove plastic/paper wrappings on the 3

f

ilters and housin

gs

gs

,

pu

pu

t

f

ilters into the 3 housings, and ass

em

em

bl

bl

e

e

the housings onto

th

th

ee

main system as

f

ollows

:

StSt

anan

d

d

the 3 housings upright. Make s

ur

ur

e

e

ea

ea

ch housing has a rubber O-ring i

n

it

t

s s

grgr

oo

o

ve.

P

ut the Essence sediment

f

ilter

(F

(

I-

I-

ES

ES

-S-S

E

ED

10) into the “1st stage” housing

oo

nn

th

th

e right.

P

ut the Essence carbon

f

il

te

e

rsrs

(

(

FI

FI

E

-E

S-CAB10) into the “2nd and

3

3

rd

rd

ss

ta

ta

ge

e

” housing in the

mi

dd

l

e

a

n

d

l

ef

t.

Starting

f

rom

th

h

e

e

3

3

r

d

s

s

ta

ta

ge housing on the le

f

t, hand twist the housing onto the main system

turning co

un

n

tete

rcrc

lolo

ck

ck

wise, one by one,

f

or all 3 housings.

U

se the wren

ch

h

provided to completely tighten the housing starting

f

rom 1st-stage. Repeat this

s

t

ep

f

or the

2

n

d

sta

ge

housi

ng

in the middle, and

f

or the

3

rd

sta

ge

housi

ng

on the le

f

t.

N

ote

:

For some people it is easier to

us

e

e

th

th

e

e

wr

ench with the system laid do

wn

n

(

(

fafa

ce

ce

u

u

p).

F

i

g.

1

F

i

g.

2

F

i

g. 3

PaPa

rtrt

I.

Pa

Pa

rt II.

Note:

3r

r

dd

St

St

agag

e

e

2

n

d

S

tage

1

st

S

tag

e

F

Fi

g.

1

F

i

g.

2

F

i

g.

3

3

r

d

S

ta

g

g

e

e

t

urn coun

t

er

-

c

l

oc

k

wise

to tig

h

te

n

3

r

d

S

ta

g

e

2n

n

d

d

St

St

ag

ag

e

e

1s

t

S

ta

g

e

Us

e

Wr

W

e

n

ch

Us

e

5

Fig. 4

Step 1: Feed Water Connection

The RO system must be connected to the COLD water supply only!

1. Locate the Cold water supply valve under the kitchen sink (the round or oblong handle on

the right side). Turn off the incoming cold water completely by turning the shut off handle

clockwise.

Note: If the cold water shut off valve can not turn off the water, the main water supply

to the house must be shut off for the installation. Another option is to use a “self

piercing saddle valve” from APEC or from a local hardware store.

2. Feed Water Adaptor (1/2” to 3/8”): See Fig. 4. The Feed Water Adaptor comes with a

separate Needle Valve. The Adaptor goes inline onto your 1/2” or 3/8” cold water pipe. The

Needle Valve portion screws onto the Adaptor as shown in Fig. 4A.

A. 1/2” x 3/8” Female-Male Water Supply Adapter

with O-ring.

B. 1/2” x 3/8” Male-Female Converter with O-ring.

C. 1/4” x 1/8” Male Needle Valve.

PART II. INSTALLING THE SYSTEM

Space: Make sure there is sufficient space under the counter for installation (an area of about 17”L x

6”W x 18”H for the system, 11”D x 18”H for tank).

The RO system is best installed under the kitchen sink. But if that is not feasible you can install the system

anywhere where there is a cold water supply with sufficient water pressure for the chosen RO model, and

an outlet to drain off the drain water from the system.

Mounting: No need to mount the RO system on the wall. The RO system can stand in the sink cabinet

without mounting, this makes future filter change easy and convenient. If you prefer to mount the system

to the wall, please make sure it can be taken down easily for filter replacement.

Feed Water: RO systems are designed to treat both hard and soft water and can handle incoming TDS

levels up to 2,000 ppm.

5

F

i

g.

4

StSt

ep

ep

1: Feed Water Connectio

n

The RO system must be

coco

nnnn

ecec

t

te

d to the COLD water supply only!

y pp y y

1. Locate the

Co

l

d

water

s

s

up

up

plpl

y

y

va

lve under the kitchen sink (the round or oblong handle on

the right side). Turn o

ff

the incoming cold water completely by turning the shut o

ff

handle

c

lockwise.

N

ote: I

f

the cold water shut o

ff

valve can not

tu

u

rnrn

oo

ffff

the water, the main water suppl

y

y

to the house must be shut o

ff

f

or the

in

in

stst

alal

la

la

t

ti

on. Another option is to use a

“s

“s

el

el

f

f

piercing saddle valve”

f

rom APEC

o

o

r

r

frfr

om

om

a local hardware store.

2.

.

FeFe

eded

Water Adaptor (1/2” to 3/8”

):

S

ee

e

F

Fi

g. 4. The Feed Water Adaptor

c

c

om

om

eses

with a

se

se

parate Needle Valve. The Adaptor

g

g

oeoe

s

s

in

i

line onto your 1/2” or 3/8”

co

o

ld

ld

ww

atat

e

er

pipe. The

N

eedle Valve portion screws on

to

o

t

t

hehe

AA

da

d

ptor as shown in Fig. 4

A

.

A

. 1/2” x 3/8” Female-Male Water Supply Adapte

r

with O-ring.

B. 1/2” x 3/8” Male-Female Converter with

O

O

-r-r

inin

g.g.

C.C.

1

1

/4

/

” x

1/

8” Male Needle Valve

.

PART II.

IN

N

STST

AL

AL

LIN

G

THE

S

Y

S

TE

M

Sp

ac

c

e:

e

M

M

a

ak

e sure there is su

ff

icient space u

nd

d

er

er

t

t

h

he

counter

f

or installation (an

ar

ar

ea

ea

o

o

f

ab

ab

out 17”L x

6”

W

W

xx

18”

H

f

or the system, 11”D x

1

1

8”

8

H

ff

o

or

tank).

Th

T

e RO system is best installed under

thth

e e

kiki

tctc

hen sink. But i

f

that is not

f

easible you can install the system

anywhere where there is a cold water sup

pl

y with su

ff

icient water pressure

f

or the chosen RO model, and

an outlet to drain o

ff

the drain water

f

rom the

sy

stem.

M

ounti

ng

:

No need to mount the RO s

ys

tem on the wall. The RO

sy

stem can stand in the sink cabinet

without mounting, this makes future filter change easy and c

on

on

ve

ve

nient. If you prefer to mount the syst

em

m

g

to the wall, please

ma

ma

ke sure it can be taken down easil

y

y

fofo

r

r

fifi

lt

lt

er replacement.

Feed Water

:

:

R

R

O O

sy

sy

stems are designed to treat both

hh

ar

ar

dd

and so

f

t water and can handle in

co

co

mi

mi

ngng

TDS

l

evels u

p

to

o

2

2

,0,0

00

0

p

pm

.

6

Fig. 4A - Needle Valve Installation.

Attach the needle valve (C) to water supply adapter (A). Please apply 4-5 wraps of

teflon tape to needle valve prior to connecting it to the water supply adapter (A).

Fig. 4B - If your pipe has a 1/2” Connection.

By attaching the 1/2” x 3/8” converter (B) to the Male end of the water supply adapter

(A), you now have a 1/2” Male and Female water supply adapter.

Fig. 4C - If your pipe has a 3/8” Connection.

By attaching the 1/2” x 3/8” converter (B) to the Female end of the water supply

adapter (A), you now have a 3/8” Male and Female water supply adapter.

Fig. 4A

Fig. 4B

1/2” Connection 3/8” Connection

Fig. 4C

6

Fig. 4

A

-

Ne

Ne

eded

le

le

Valve Installation.

At

At

tata

ch the needle valve (C) to water s

up

up

plpl

y

y

adad

apter (A). Please apply 4-5 wr

ap

p

s

s

ofof

te

te

f

lon t

ap

e to needle valve

pr

ior to

c

c

on

n

ne

ne

ctin

g

it to the water su

pp

ly

ada

pt

p

er

(

A)

A)

.

FiFi

g.g.

4

4

B

-

I

f

your pipe has a 1/2”

Co

Co

nnnn

ecec

ti

t

on

o

.

B

y attaching the 1/2” x 3/

8”

8”

cc

onon

ve

ve

rter (B) to the Male end o

f

the water

su

s

pp

ly adapte

r

(

A), you now have a 1/2” M

al

al

e

e

a

an

d Female water supply adapter.

Fig. 4

C

-

I

f

your pipe has a 3/8” Connection.

B

y attaching the 1/2” x 3/8” converter (B) to the Female end o

f

the water supply

adapter (A), you now have a 3/8” Male and Fema

le

e

w

w

ater supply adapter.

Fig

.

4A

Fig 4

A

F

i

g. 4

B

1/

2” Connectio

n

3/

8” Connectio

n

Fig. 4

C

7

3. Recommend Connection For Flex Line Riser: See Fig. 5A. & Fig. 5E Loosen nut and separate cold

water riser tube from shut off valve. Gently bend riser tube so that the Feed Water Adapter (Fig. 4) fits

onto the shut off valve. Connect the riser tube, feed water adapter, and shut off valve together and

tighten.

For Solid Copper Riser: See Fig. 5B. Follow the same procedure as for flex line. If the copper riser

cannot bend, this it’s best to replace it with a flex line riser. Fit the feed water adaptor to the shut off valve

the same way as described above.

Option Connection Point: See Fig. 5F. The feed water adapter can also be installed between the riser

tube and faucet shank. Loosen nut and separate cold water riser tube from faucet shank. Gently bend

riser tube so that the Feed Water Adapter fits onto the faucet shank. If your riser tube has no built-in

washer, then fit the cone-shaped washer provided onto the riser tube. Connect the riser tube, feed water

adapter, and faucet shank together and tighten.

Riser

Tube

For Flexible Line

Faucet

Shank

Main Water

Supply

Shut-off

Valve

Riser

Tube

For Solid Line

Faucet

Shank

Needle

Valve

Needle

Valve

Main Water

Supply

Shut-off

Valve

Sink

Sink

Fig. 5A Fig. 5B

7

3

. R

eco

mm

m

enen

d

d

C

Co

nn

ec

ti

o

n F

o

r Fl

e

x Lin

e

Ri

se

r

:

S

S

eeee

Fi

Fi

g

g.

5

A

.

&

F

i

g. 5E Loosen nut an

d

d

se

se

pa

pa

ra

ra

te cold

water

ri

ri

se

se

r

r

t

tu

be

f

rom shut o

ff

valve. Gently b

en

n

d

d

riri

sese

r

r

tube so that the Feed Water Ad

ap

ap

te

te

r

r

(

Fig. 4

)

f

i

ts

on

to

to

t

t

he

he

shut o

ff

valve. Connect the riser t

ub

b

e,e,

f

f

e

ee

d water ad

ap

ter, and shut o

ff

va

va

lve

toto

ge

ther and

ti

i

ghgh

te

te

n.

For Solid Copper Riser

:

See

F

i

g.

5

5

B

B.

F

F

ol

low the same procedure as

f

or

f

lex line. I

f

the copper rise

r

cannot bend, this it’s best to r

ep

lace it with a

f

lex line riser. Fit the

f

eed water ada

pt

or to the shut o

ff

valve

the same way as described above.

Op

tion

C

onne

ct

t

io

io

n Point

:

See

F

i

g. 5F. The

f

eed water

aa

dada

pt

pt

er can also be installed between t

he

he

r

r

is

is

e

er

tube and

f

au

ce

e

t

t

shsh

an

an

k. Loosen nut and se

pa

rate col

d

d

wawa

tete

r r

riser tube

f

rom

f

aucet shank. Gent

ly

y

bb

e

en

d

d

riser tube s

o

o

th

th

atat

t

t

he Feed Water Adapter

f

its onto

t

t

hehe

f

f

au

au

cet shank. I

f

your riser tube has

no

o

b

b

ui

ui

lt

l

-in

washer,

th

h

enen

f

f

it

it

t

t

he cone-shaped washer provid

ed

d

o

o

nt

nt

o

o

the riser tube. Connect the riser

tu

u

bebe

,

,

fefe

ed

wate

r

adap

te

e

r,r,

a

a

nd

nd

f

aucet shank together and ti

gh

te

te

n

n

.

Ri

se

r

Tu

b

e

Fo

r F

l

exi

bl

e Lin

e

FaFa

ucuc

etet

Sh

h

an

an

k

k

Ma

i

n

Wa

t

e

r

Su

pp

l

y

Shut-o

ff

V

a

lv

e

Ri

se

r

T

u

b

e

Fo

r So

l

i

d

Lin

e

Fa

u

ce

t

Sh

an

k

Nee

dle

V

a

l

ve

N

ee

dl

e

V

a

l

v

e

Ma

in

Wa

t

e

r

S

u

pply

Sh

ut-o

ff

V

a

l

v

e

S

ink

Sin

k

Fig. 5

A

F

i

g. 5

B

8

Fig. 5C

5. Needle Valve tubing connection instructions:

Please first slide the metal compression nut, then the plastic sleeve, and push the plastic insert all the

way into the red tubing (See Fig. 5C).

Please push the red tubing all the way into the needle valve connection until you feel a click.

Please push the plastic sleeve all the way up to the needle valve connection.

Please screw the metal compression nut with the red tubing pushed all the way into the needle valve then

use a wrench to fully tighten this connection.

Fig. 5E Fig. 5F

4. Needle Valve: See Fig. 5D. Screw the Needle Valve onto the Adaptor tightly. Apply 6-8 rounds of

Teflon tape onto Needle Valve before attaching it to the Adaptor.

To open needle valve: Turn needle handle counter-clockwise.

To close needle valve: Turn needle handle clockwise.

Fig. 5D

Insert Sleeve Compression Nut

Apply Teflon Tape Here

Push the tubing all the way into the needle valve

while tightening compression nut.

8

Fig. 5

C

5

. Needle Valve tubing connec

ti

ti

onon

i

i

nstructions

:

P

lease

f

irst slide the m

et

t

alal

c

c

om

om

pr

r

ession nut, then the plastic sleeve, and push the plastic insert all the

way into the red tubing

(S(S

ee

ee

F

F

i

ig

. 5C

)

.

P

lease push the red tu

bi

ng

ng

a

a

ll

ll

the way into the needle valve connection until you

f

eel a click.

P

lease push the plastic sleeve all the way up to the needle valve connection.

P

lease screw the metal compression nut with the red tu

bi

bi

ng

ng

pushed all the way into the needle

vava

lvlv

e

e

th

th

en

use a wrench to

f

ully tighten this connection.

F

i

g.

5

5

E

E

F

Fi

g. 5F

4

. Needle

V

V

alal

ve

ve

:

See

F

i

g.

5D. Screw the Needle

V

V

al

al

v

ve

onto the Ad

ap

tor ti

gh

tl

y.

A

pp

ly

6

-8

8

r

r

ouou

nd

nd

s o

f

Te

f

l

on

n

tt

apap

e

e

onto Needle Valve be

f

ore attac

hi

hi

ngng

i

i

t

t

to

to

the Adaptor.

To

T

op

p

en

needle

va

lve

:

Turn nee

dl

d

e

e

ha

ha

nd

n

le counter-

c

l

oc

kwise.

To

To

c

l

ose

needle valve: Turn

n

n

eeee

dldl

e e

h

ha

ndle clockwise.

Fi

Fi

g

g.

5D

Insert S

l

e

e

e

ve Com

pre

pre

ssissi

o

o

n Nut

App

ly

Teflon Ta

pe

Here

l

Tf

lT H

dle valve Push the tubin

g

all t

h

h

e wa

y

into the nee

w

h

i

l

e

tig

h

tenin

g c

om

mp

ression nut.

9

Step 2: Drain Saddle Installation

Important: DO NOT REMOVE the black drain tubing from the RO system system! If you

need to extend the drain tubing please use a union connector to connect

additional length of tubing.

Note: To avoid possible drainage noise, mount drain line as low as possible on the

vertical tailpiece, or on horizontal tailpiece.

There is constant water pressure “packed” inside the RO system which blocks the drain water from back-

ing-up into the system. So the drain water is “forced-drained”, not “gravity-drained”.

1. See Fig. 6. The drain saddle assembly should be installed above the trap and on the vertical or horizon-

tal tailpiece. To reduce the drainage noise, mount the drain line as low as possible above the trap, or on

the horizontal tailpiece.

MOUNT DRAIN

SADDLE AT

EITHER

LOCATION

2. Select the location of the hole and drill a 1/4’’ hole through one side of the drain pipe then put the

self-adhesive black sponge around the hole location (See Fig. 7A and 7B).

Next, align and install the drain saddle clip with the tubing connection port onto the black sponge.

This will cushion any gap between the saddle and the pipe. Make sure the hole on the sponge is

thoroughly punched out, and is aligned to the hole on the saddle to complete the installation (See

Fig. 8)

Fig. 6

Fig. 7A Fig. 8

Test for leaks after the system is completely installed: Close the Needle Valve (turn needle handle clock-

wise all the way in to close). Turn ON the cold water supply to the sink faucet. If the Needle Valve or the

Adaptor leaks, check the connection and try applying more Teflon tape or tighten the brass nut some

more to stop the leak.

Fig. 7B

9

St

S

ep 2: Drain Saddle Installati

on

n

Im

p

ortant

:

DO NOT REMOVE the black drain tubing from the RO system system! If you

need to extend the drain tubing please use a union connector to conne

ct

additional length o

f

tubing.

N

ote

:

To avo

id

d

p

p

ossible drainage noise, mount

dr

dr

aiai

n

n

line as low as possible on t

he

e

p

p

g

,

p

vertic

al

al

tt

ai

ai

lp

l

iece, or on horizontal tai

lp

p

ieie

cece

.

.

p,

p

p

There

is

s

c

c

on

on

stst

ant water pressure “packed” in

si

dede

tt

he

he

R

O system which blocks the drai

n

wawa

tete

r r

f

fr

om back-

i

n

g-

upup

i

i

ntnt

o

th

e system. So the drain water i

s

s

“f“f

oror

ce

ce

d-

d

rained”, not “gravity-drained

”.

.

1.

.

Se

S

e

Fi

Fi

g.

6

. The drain saddle assembl

y

y

sh

sh

ouou

ld

ld

be installed above the trap

a

nd

nd

o

o

n

n

th

h

e

e

vertical or horizon-

tata

l

l

tailpiece. To reduce the drain

ag

g

e e

nono

isis

e

e,

mount the drain line as low a

s

po

po

ss

s

ibib

le

l

above the trap, or on

the horizontal tailpiece.

MOU

NT

DR

DR

AI

AI

N

N

S

A

DD

DD

LE

LE

AT

AT

EI

EI

TH

TH

ER

ER

LO

LO

CA

CA

TI

ON

A

A

2

2.

Select the location o

f

the hole

an

n

d

d

drdr

il

il

l

l

a

1/4’’ hole through one side o

f

t

t

hehe

d

d

rain pipe then put the

s

el

f

-adhesive black sponge a

ro

o

unun

d

d

the hole location

(S

ee

Fig. 7A

and

A

7B

7B

)

).

N

ext, align and install the dr

ai

ai

n

n

sa

sa

ddle clip with the tubing co

nn

n

ecec

titi

onon

p

p

o

or

t onto the black sponge.

This will cushion any

gaga

p p

be

be

tw

w

een the saddle and the pipe. M

ak

ak

e e

su

su

re

re

the hole on the sponge is

thorou

gh

ly

punched

oo

ut

ut

,,

an

an

d

d

is aligned to the hole on the sadd

le

le

t

t

o

o

c

co

mplete the installation

(S

ee

F

i

g. 8

)

Fig.

6

F

i

g

.

7

A

F

i

g.

8

Test for

l

l

eaea

ks

ks

a

a

fter the system is completely inst

al

l

le

le

d:

d:

C

C

lo

lo

se the Needle Valve (turn ne

ed

d

le

le

hh

an

an

dl

d

e clock-

y

p

y

(

wise

a

a

ll

ll

tt

he

he

way in to close). Turn ON the col

d

d

wa

wa

te

te

r

r

supply to the sink faucet. If the

NeNe

eded

l

le

Valve or the

y ) pp y

Ad

d

ap

ap

to

to

r

r

leaks, check the connection and tr

y

y

apap

pl

yi

ng

more Teflon t

ap

e or t

ig

ht

en

e

t

he

e

b

b

rass nut some

p,

y

y

p

py g p g

mo

m

re

re

to stop the leak.

p

F

i

g. 7

B

10

3. See Fig. 8, 8A. Make sure to align the drain saddle hole to the drilled hole perfectly.

Mis-aligning these two holes will block the drain water and cause membrane damage.

Attach the drain saddle to the drain pipe and tighten the two screws evenly.

4. Once the drain saddle is secured, push 1/4” black drain tubing into the Quick Connect fitting on the

saddle. DO NOT use a “Insert” on the drain tubing.

Fig. 8A

Step 3: Drill A Hole For The RO Faucet

Drill 1/2” diameter hole for standard RO faucet. (Air-Gap faucet: drill 1”D hole.)

For best results use a 1/2” carbide-tipped masonry drill bit.

Wear safety glasses to protect your eyes while drilling the faucet hole.

Note: No need to drill a hole if an existing hole is available:

a) Spare hole: If there is a spare hole in the sink covered by a chrome cover, simply remove the chrome

cover and install the RO faucet there.

b) Spray hose: If the spray hose is not in use, remove the hose, and mount the RO faucet there. Remember

to plug up the outlet under the main faucet. If the spray hose uses a diverter at the base of the spout, be sure

to remove it to avoid trouble later on.

c) Hanging faucet: If drilling a hole is not feasible (i.e. rental home, drill tool not available etc.), the faucet

can just hang on the cabinet door or wherever that is convenient. Be creative!

When drilling a hole for the RO faucet, choose a location that looks good, works well, and is most con-

venient for dispensing pure water. An ample flat area is required for the faucet base so that the faucet

can be drawn down tightly.

1. Faucet location: Make sure the faucet stem will be accessible from below when the hole is drilled.

If space is not available on the upper sink area, the faucet can be located on the counter top by the

edge of the sink. If the counter top is ceramic tile, the method for drilling the hole will be the same as

for porcelain sinks.

2. For Stainless Steel Sink: Before using a 1/2” carbide drill bit, an indent should be made with a

center punch to keep the drill bit from walking. A small pilot hole will also aid the drill bit.

1

0

3

.

See Fi

g.

.

8

8

, ,

8A

8A

. Make sure to align the drai

n

n

sasa

dd

dd

le

le

hole to the drilled hole pe

rf

rf

ec

ec

tltl

y.

y.

g p

y

M

is-

al

l

ig

ig

nini

n

ng

these two holes will block the

dr

ai

ai

n

n

wawa

t

te

r and cause membrane dam

ag

g

e.

e.

At

t

ta

ta

ch

ch

t

t

he

h

drain saddle to the drain pipe

an

an

dd

titi

g

gh

ten the two screws evenly.

4.4.

OnOn

ce the drain saddle is secured,

pupu

shsh

11

/4/4

”

black drain tubing into the Qu

ic

ic

k k

CoCo

n

nn

ect

f

itting on the

sadd

l

e

. DO

N

O

T

use a “Insert”

on

n

tt

hehe

dd

r

ra

in tubing.

Fig. 8

A

St

t

epep

3

3

: Drill A Hole For The RO

Fa

Fa

ucuc

etet

Drill 1/2” diameter ho

le

e

f

f

oror

s

s

ta

ndard RO

f

aucet.

(

Air-Gap

f

aucet: dri

ll

ll

1

1

”D

”D

hole.

)

For best results

uu

se

se

aa

11

/2

/

” carbide-tipped masonry drill bit.

Wear sa

f

ety glasses to protect your eyes while drilling the

f

aucet hole.

No

te

:

No need to drill a hole if an existing hole

is

s

a

a

vava

il

i

able:

g

a

)

Spare hole

:

I

f

there is a spare hole in the sink

co

o

ve

ve

re

re

d

d

by

by

a chrome cover, simply remove t

he

he

cc

hrhr

o

om

e

c

over

an

a

d install the RO

f

aucet there.

b

b

)

)

SpSp

ray hose:

If

the spray hose is not in

us

s

e,

e,

r

r

em

em

o

ov

e the hose, and mount the RO

f

au

au

c

ce

t

th

ere. Remembe

r

to

o

p

p

lu

lu

g up the outlet under the main

f

au

ce

e

t.t.

I

f

th

h

e spray hose uses a diverter at the

ba

ba

se

se

oo

f

f

th

th

e spout, be sure

to

to

remove it to avoid trouble later on.

c

)

Ha

ng

in

g

f

aucet:

If

drillin

g

a

hoho

lele

is not

f

easible (i.e. rental home, drill

to

o

ol

ol

n

n

ot

ot

available etc.), the

f

aucet

c

an just hang on the cabinet d

oo

oo

r

r

or

or

wherever that is convenient. Be

cc

rere

atat

iviv

e!

e

When drilling a hole

f

or

tt

hehe

RR

O

O

f

aucet, choose a location that loo

ks

ks

g

g

oo

oo

d

d,

works well, and is most con-

venient

f

or dispensing p

ur

r

e

e

wawa

te

te

r. An ample

f

lat area is required

f

or the

f

aucet base so that the

f

aucet

c

an be drawn down tightly.

1

. Fa

uce

t l

oc

ati

o

n:

M

ake sure the

f

aucet stem will be accessible

f

rom below when the hole

is

is

d

d

riri

llll

e

ed

.

If

space is not available on the upper sink area, the

f

aucet can be located

on

the co

un

tete

r

r

toto

p

p

b

by

the

e

dge o

f

the sink. I

f

the counter top is cera

mi

mi

c

c

titi

le

e

, the method

f

or drilling the hole will

bebe

t

t

h

he

same as

fo

o

r r

popo

rcelain sinks.

2.2.

FoFo

r

S

tainl

ess

S

t

ee

l

S

ink

:

Be

f

ore

us

s

in

n

g

g

a

a

1/2” carbide drill bit, an indent

sh

h

ouou

ld

ld

b

b

e

e

made with a

c

enter punch to keep the drill b

it

f

f

ro

ro

m

m

walking. A small pilot hole will a

ls

s

o

o

aiai

d

d

th

th

e drill bit.

11

3. For Porcelain Sink: Porcelain enameled sinks can readily be chipped if care is not exercised when

drilling the hole. Before starting the drill motor, apply firm downward pressure on the bit until a

crunching occurs. This will help keep the drill bit from walking when starting the hole. A small pilot

hole will also aid the drill bit.

Note: Immediately after the hole drilling is done, clean up all metal chips, for metal chips will

stain the porcelain!!

Step 4: Mounting The Faucet

Step 5: Positioning The System

1. Main System: The main system can stand in the sink cabinet. No need to mount the system to the

wall. If you prefer to mount the system to the wall, please make sure it can be taken down easily for

filter replacement.

2. Tank: The storage tank can lay on its side if needed. The tank works fine in this position. If the tank

cannot fit under the kitchen sink, it can be placed elsewhere up to 20 feet away from the RO system

without much pressure loss.

1. Mount the faucet as shown in Fig. 9A

or Fig. 9B.

2. Attach threaded end of faucet adapter to the

faucet metal stem. No teflon tape needed here.

3. Connect the Clear line to the faucet.

4. The faucet handle controls the flow of purified

water exiting the faucet. Turn the handle to

horizontal position to release the water and

vertically to shut off.

Black Locating Washer

Lock Washer

Lock Nut

Faucet Adapter

Tubing

Counter Top

Counter Top

Opening

Faucet Base

Fig. 9A

11

3

. F

o

r P

o

rc

c

el

el

ai

ai

n

n

S

ink

:

Porcelain enameled sinks

ca

a

n

n

rere

adad

il

y be chipped i

f

care is not ex

er

r

cici

sese

d

d

wh

w

en

d

rilli

ng

g

t

t

hehe

hole. Be

f

ore starting the drill mot

or

or

,

,

apap

pl

pl

y

y

f

irm downward pressure on th

e

e

bibi

t

t

u

un

til a

cr

r

un

u

ch

ch

in

in

g

occurs. This will he

lp

kee

p

the

dr

d

il

l

l

bibi

t

t

f

rom walki

ng

when starti

ng

t

he

hol

e.

.

A

A

small

p

ilot

ho

ho

le

e

w

w

ill also aid the drill bit

.

N

No

te

:

Immediately a

f

ter the hole

dd

riri

ll

ll

inin

gg

is done, clean up all metal chips,

f

o

r

m

me

tal chips will

stain the porcelain!

!

Step 4: Mounting The Fauc

et

Step 5: Positioning The Syste

m

1

.

M

ain System

:

The main system can stand in the sink cabinet. No need to mount the s

ys

te

te

m

m

toto

t

t

he

wall. I

f

y

ou

p

re

f

er to mount the s

ys

tem to the

w

w

all,

p

lease make sure it can be taken

do

o

wn

wn

e

e

asil

y

f

o

r

f

ilt

er

replacement.

2.

.

TaTa

n

nk

: The storage tank can lay on it

s

s

sisi

de

de

i

i

f

f

needed. The tank works

f

ine in t

hi

hi

s

s

po

po

sition. I

f

the tank

ca

ca

nnot

f

it under the kitchen sink, i

t

t

caca

n

n

be

b

placed elsewhere up to 20

f

eet

awaw

ayay

f

f

rom the RO system

without much

p

ressure loss.

1. Mount the

f

a

uc

c

et

et

a

a

s

s

shown in Fig. 9

A

or

F

i

g. 9

B

B

.

2

. Atta

ch

h

tt

hr

hr

ea

ea

d

de

d end o

f

f

aucet adapter to t

he

e

f

au

au

ce

ce

t

t

me

me

tal stem. No te

f

lon tape neede

d

d

he

h

re.

3.

.

Co

Co

nnect the

C

l

ea

r

l

ine to the

f

auc

et

et

.

4.

4

The

f

aucet handle controls the

f

f

lo

o

w

w

o

of

p

uri

f

ied

water exiting the

f

aucet

..

TuTu

rnrn

t

t

he

e

handle

to

horizontal position to r

elel

ea

ea

sese

t

t

he water and

vertically to shut o

ff

.

B

l

a

ck

L

o

catin

g

Washer

Lo

ck

Wa

a

sh

sh

er

er

Lo

c

k

Nut

LkN

t

FaFa

ucuc

etet

Ad

Ad

ap

te

r

Tubin

g

C

ou

nter T

o

p

Co

Co

unter To

p

Openin

g

Fa

uc

c

et

B

ase

Fig. 9

A

12

Option: Mounting The Faucet (Metal Compression Fitting)

1. Make sure the tube insert is pushed all the way into the tubing. Fig. 9C

2. Make sure the tubing is inserted inside the faucet stem at least 1/4” deep while screwing the nut.

Fig. 9D

Faucet Base

Black Locating Washer

Lock Washer

Lock Nut

Insert

Sleeve

C

ompression Nut

Counter Top

Counter Top

Opening

Tube insert

Sleeve

Compression nut

Tubing

Faucet stem

Sleeve

&

Tube insert

Compression nut

Fig.9D

Fig. 9B

Fig.9C

1

2

O

ption:

Mo

Mo

un

un

ti

ti

n

ng

The Faucet

(

Metal Compr

es

s

sisi

onon

F

F

itting

)

1. M

ak

ak

e

e

su

su

re

r

the tube insert is

pushed all the

w

w

ay

ay

into the tubing.

y

Fig. 9

C

2

.

M

M

a

ak

e

e

sure the tubing is

i

n

se

rt

ed

inside the

fa

fa

uc

uc

et stem at least 1/4” deep w

hi

hi

lele

s

s

crcr

ewew

i

in

g the nut.

FiFi

g.g.

9D

Faucet

B

as

e

BlaBla

c

k

Loc

a

a

ti

ng

Was

h

er

Loc

k

Was

h

er

Loc

oc

k Nk N

utut

In

se

r

t

Sle

Sle

eve

e

C

N

u

t

omp

ress

i

on

N

C

ou

nter

T

o

p

C

o

unter

T

op

O

penin

g

Tube

in

se

r

t

Sl

l

ee

ee

veve

Co

mp

mp

rere

ss

sisi

o

on

n

ut

T

ub

in

g

Fa

u

ce

t s

tem

S

le

eve

&

Tube

in

se

rt

Comp

res

si

o

n

nut

ut

F

i

g.

9D

9D

F

i

g.

9

B

Fig.9

C

13

P

G

IMPORTANT INSTALLATION NOTICE!

The Quick connect fittings come with an

end plug that needs to be removed be-

fore the tubing can be connected. Please

disconnect the end plugs at Points G and

H from the Quick connect fittings before

connecting tubing. See Fig.10A and

Fig.10B.

Fig.10A

Fig.10B

Step 6: Connecting The System

Fig.10C

Fig.10D

To Disconnect the End Plugs:

Push In and Hold Down on the collet ring square against the

fitting. While holding down the collet ring, pull out the end

plug with your other hand. Only the plug will slide out from the

connection. See Fig.10C.

Depending on your system model, there will be 2 types of protective end

plugs. Both types of end plugs are disconnected the same way. After

disconnecting the end plugs, please discard them as they are not needed for

installation.

Soft Plug Hard Plug

2 Types of End Plugs

To Connect the Tubing:

Push the tubing all the way into the Quick-

Connect fitting, then gently pull back on the tubing to make sure

the connection is completely secure. See Fig.10D.

- No inserts, sleeve, or nuts are needed to secure the connection.

- No Teflon tape!

1

3

P

G

I

M

M

PP

OO

R

R

T

T

ANT IN

S

TALLATI

O

N

N

N

OO

T

T

ICE

!

ThTh

e

e

Q

Qu

ick connect

f

ittings come with

aa

nn

en

e

d plug that needs to be removed

b

b

e-

e-

f

ore the tubing can be connected. Please

d

isconnect the end plugs at Points G and

H

f

rom the Quick connect

f

itti

ng

s be

f

ore

c

onnecting tubing. See Fig.10

A

an

d

F

i

g.10B.

Fi

F

g.g.

1010

A

A

F

i

g.10

B

Step 6:

CoCo

nnnn

e

ec

ting The Syste

m

FiFi

g.

g

10

C

F

i

g.

g.

1010

D

D

To Disconnect the End

Pl

Pl

ugug

s:s:

g

g

P

ush In and Hold Down on the collet ring square against the

f

itting. While holding down the collet ring, pull out the end

plug with your other hand. Only the plug will slide out

f

r

om

m

t

t

h

he

c

onnection. See Fig.10C.

D

e

pe

ndin

g

on

on

y

y

ouou

r

r

sy

stem model, there will be 2

ty

y

pepe

s

s

of

of

p

rotective end

plugs. B

ot

h

h

ty

ty

pe

pe

s o

f

end plugs are disconnected

th

h

e

e

sa

sa

me way. A

f

te

r

d

iscon

ne

ne

ctct

inin

g the end plugs, please discard

th

em

em

a

a

s

th

ey are not needed

f

o

r

i

n

s

t

a

l

la

la

ti

ti

o

on

.

So

So

ft

ft

P

lu

u

g

gH

ard Plug

2

Types o

f

End

P

P

lulu

gs

To Connect the Tubin

g:

g

P

ush the tubing all the

wa

a

y y

in

in

to

to

t

t

he Quick-

Connect

f

itting, then ge

nt

ly

ly

p

p

ul

ul

l

l

back on the tubing to make sure

the connection is complete

ly

secure. See F

i

g.10

D.

-

No inserts

,

sleeve

,

or nuts are needed to secure the connection.

-

No Te

f

lon tape

!

14

Summary of Tubing Connections:

There are 4 connections: See Fig. 11. & Fig. 11A.

Point A to X: Connect RO to COLD water supply — Red tubing.

Point G to Y: Connect product water from 5

th

-stage UV Light to tank — Yellow tubing. This tubing is a

2-way line, Product water enters and leaves the tank via this line.

Point P to Z: Connect product water from 6th-stage pH filter output to RO faucet — Clear tubing.

Drain line to W: Connect waste water from 4

th

-stage membrane to drain outlet — Black tubing.

Fig. 11

Fig.10E

To Disconnect the Tubing:

See Fig.10B. Push in and hold down on the collet ring square

against the fitting. With the collet held in this position the tube can

be removed. See Fig.10E.

Important! Insert and sleeve Must be installed to prevent water leaking. Metal compression nut must be

fully tightened! (See Page 8)

1

4

Summary o

f

Tubing Connections:

There are 4 connections: See Fig. 11. & Fig. 11A.

Po

int

A

to

A

X

:

Co

o

nnnn

ec

ec

t

t

RO

to COLD water supply

—

Re

e

dd

t

t

ub

ub

in

in

g.

Po

int

G

t

o

YY

:

:

Co

Co

nnect

pr

oduct water

f

rom 5

th

-

sta

ge

ge

U

U

V

V

Li

gh

t to tank

—

Yellow

tubin

g.

T

hi

i

s

s

tutu

bibi

n

ng

is a

w

2

-wa

y

li

i

ne

ne

,

,

Pr

Pr

od

uct water enters and leaves th

e

ta

ta

nknk

via this line.

Po

o

in

in

t

t

P

t

t

o

Z

:

Connect product water

f

r

om

m

6

6

th

th

-s

-s

ta

ta

ge pH

f

ilter output to RO

f

a

uc

c

et

et

—

—

Cl

Cl

e

ea

r

tubing.

r

DrDr

ai

a

n lin

e

t

o

W

:

Connect waste wate

r

r

frfr

o

om

4

th

-

stage membrane to drain out

le

e

t t

——

BlBl

a

ac

k

tubing.

k

F

i

g. 1

1

F

i

g.10E

To Disco

nnnn

ec

ec

t the Tubing:

g

See

FiFi

g.

10

1

B

. Push in and hold down on the

c

ol

ol

lele

t

t

ri

r

ng square

ag

ag

ai

ai

nsns

t

t

t

th

e

f

itting. With the collet held

in

in

t

t

hi

hi

s

s

po

o

si

tion the tube can

bebe

rr

e

em

oved. See F

i

g.

10

E.

I

m

po

rtant!

I

nsert and sle

ev

v

ee

MuMu

st

st

b

b

e installed to

p

revent water leaki

ng

. Metal co

mp

ression nut must be

f

ully tightened! (See Page

8

8

))

15

Stage

6

th

Stag

e

4

t

h

Stage

1

st

Stage

2

nd

Stage

3

rd

Stage

5

th

Stage

7

th

DRAIN

LINE

1

st

Stage - Sediment pre- r

2

nd

Stage - Carbon block pre- r

3

rd

Stage - Carbon block pre- r

4

th

Stage - Membrane

5

th

Stage - UV light

6

th

Stage -

7

th

Stage - Inline pH plus filter

Inline carbon

r

WASTE WATER

INPUT WATER

DRINKING

WATER

TO ICEMAKER OPTION

W

G

P

A

Z

Y

DRINKING WATER FAUCET

SINK

Option 1 Diagram

Fig. 11A

Details on Tubing Connections:

To ensure a smooth and correct installation, please connect the water lines following the sequence and

order outlined below. Refer to Fig.11 & 11A for proper point locations.

1. Point Z - Faucet connection:

Tubing color: Clear tubing. Connect the CLEAR tubing to the base of the RO faucet.

Fitting type: Quick Connect Fitting: Simply push Clear Tubing into Quick Connect Fitting. No Insert,

Sleeve or Nut needed here. (Attach threaded and of faucet adapter to the faucet metal

stem. No teflon tape needed here). See Fig.9A (Page 11)

2. Point X - Feed water connection:

Important: Insert and sleeve Must be installed to prevent water leaking. Metal compression nut must be

fully tightened! (See Page 8)

Tubing color: Red tubing. Connect the RED tubing to the Feed Water Needle Valve.

Fitting type: See Fig. 5C (Page 8). Metal compression nut fitting. Use plastic sleeve.

Add “insert” to tubing. No teflon tape here. Tighten nut with wrench.

15

Stage

6

6

t

th

Stag

e

4

t

h

S

ta

ge

1

st

S

ta

g

e

2

n

d

S

ta

g

e

3

r

d

Stag

e

5

5

th

th

StagStag

e

e

g

7

7

th

th

DR

AI

N

L

IN

E

1

st

St

ag

ag

e

e -

S

S

edi

edi

m

men

t

p

r

e-

r