Best Barns mansfield_1212df Installation guide

- Type

- Installation guide

This manual is also suitable for

Best Barns mansfield_1212df is a DIY shed kit that includes pre-cut lumber, hardware, and instructions for assembly. It features a 12' x 12' footprint, with a sturdy frame constructed from imported framing lumber. The shed includes pre-built barn doors for easy installation, as well as pre-cut siding and roof sheathing for a simplified assembly process. The siding is primed and ready to be painted, allowing you to customize the look of your shed to match your personal style or outdoor décor.

Best Barns mansfield_1212df is a DIY shed kit that includes pre-cut lumber, hardware, and instructions for assembly. It features a 12' x 12' footprint, with a sturdy frame constructed from imported framing lumber. The shed includes pre-built barn doors for easy installation, as well as pre-cut siding and roof sheathing for a simplified assembly process. The siding is primed and ready to be painted, allowing you to customize the look of your shed to match your personal style or outdoor décor.

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

Best Barns mansfield_1212df Installation guide

- Type

- Installation guide

- This manual is also suitable for

Best Barns mansfield_1212df is a DIY shed kit that includes pre-cut lumber, hardware, and instructions for assembly. It features a 12' x 12' footprint, with a sturdy frame constructed from imported framing lumber. The shed includes pre-built barn doors for easy installation, as well as pre-cut siding and roof sheathing for a simplified assembly process. The siding is primed and ready to be painted, allowing you to customize the look of your shed to match your personal style or outdoor décor.

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Best Barns northdakota_1212 Operating instructions

Best Barns northdakota_1212 Operating instructions

-

Best Barns northwood_1010 Installation guide

Best Barns northwood_1010 Installation guide

-

Best Barns cypress_1610 Installation guide

Best Barns cypress_1610 Installation guide

-

Best Barns newcastle_1612df Installation guide

Best Barns newcastle_1612df Installation guide

-

Best Barns brookfield_1612df Installation guide

Best Barns brookfield_1612df Installation guide

-

Best Barns easton1216 Owner's manual

Best Barns easton1216 Owner's manual

-

Best Barns brandon1212 Operating instructions

Best Barns brandon1212 Operating instructions

-

Best Barns northdakota_1220 Installation guide

Best Barns northdakota_1220 Installation guide

-

Best Barns elm_1012df Installation guide

Best Barns elm_1012df Installation guide

-

Best Barns Northwood 14x10 User manual

Best Barns Northwood 14x10 User manual

Other documents

-

Reynolds Building Systems the Easton Assembly Manual

Reynolds Building Systems the Easton Assembly Manual

-

VENTS-US D250X300 Installation guide

-

Sentry Lakewood Assembly Book

-

Air Vent EV16624BR Operating instructions

Air Vent EV16624BR Operating instructions

-

Builders Edge 120033030034 Installation guide

-

POLYWOOD PWS118-1-11TE Operating instructions

-

Glide-Lock GLSH-4 Installation guide

-

Gibraltar Building Products SCV164-1/8 Operating instructions

-

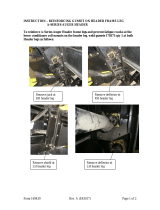

MacDon MD #169439 A A SERIES Installation guide

MacDon MD #169439 A A SERIES Installation guide

-

Quiet Glide QGRTA0036X81PN Operating instructions