Page is loading ...

© COPYRIGHT 2000, MULTIQUIP INC.

PARTS AND OPERATION MANUAL

VR- 36HA

VIBRATORY ROLLER

MULTIQUIP INC

..

..

. PARTS DEPARTMENT:

18910 WILMINGTON AVE. 800-427-1244

CARSON, CALIFORNIA 90746 FAX: 800-672-7877

310-537-3700

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE:

800-421-1244 800-478-1244

FAX: 310-537-3927 FAX: 310-631-5032

E-mail:[email protected] • www:multiquip.com

Atlanta • Boise • Dallas • Houston • Newark

Montreal, Canada • Manchester, UK

Rio De Janiero, Brazil • Guadalajara, Mexico

Revision #6 (06/13/06)

VR-36HA - VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 3

HERE'S HOW TO GET HELP

PLEASE HAVE THE MODEL AND SERIAL NUMBER

ON-HAND WHEN CALLING

PARTS DEPARTMENT

800-427-1244 or 310-537-3700

FAX: 800-672-7877 or 310-637-3284

SERVICE DEPARTMENT/TECHNICAL ASSISTANCE

800-478-1244 or 310-537-3700

FAX: 310- 537-4259

WARRANTY DEPARTMENT

888-661-4279, or 310-661-4279

FAX: 310- 537-1173

MAIN

800-421-1244 or 310-537-3700

FAX: 310-537-3927

PAGE 4 — VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06)

TABLE OF CONTENTS

NOTE: Specification and part number

are subject to change without notice.

Here's How To Get Help .......................................... 2

Table Of Contents ................................................... 3

Parts Ordering Procedures ..................................... 4

Rules For Safe Operation ................................... 5-6

Operations .......................................................... 7-8

MULTIQUIP — VR36HA

VIBRATORY ROLLER

Explanation Of Codes In Remarks Column .......... 10

Suggested Spare Parts ......................................... 11

Engine Cover & Articulated Joint ..................... 12-13

Hydraulic Oil Filters .......................................... 14-15

Engine Coupler ................................................ 16-17

Hydraulic Drive Pumps..................................... 18-19

Hydraulic fitting & Exhaust Systems ................ 20-21

Adapters, Steel Lines & Hoses ........................ 22-23

Adapters, Steel Lines & Hoses ........................ 24-25

Front Drum & Exciter ........................................ 26-27

Rear Drum ....................................................... 28-29

Sheet Metal, Fuel & Water Tanks & Seat ......... 30-31

Steering Cylinder, Rear Frame Components &

Throttle Control ................................................ 32-33

Steering Column & Switches ............................ 34-35

Scrapers ........................................................... 36-37

Battery, Rear Water Pipes ................................ 38-39

Transmission & Brake Control.......................... 40-41

Brake Control Compnents ............................... 42-43

Water System ................................................... 44-45

Hydraulic Manifold ........................................... 46-47

Hoses & Electrical System ............................... 48-49

Drive Motor, Tubes, Hoses, Fuel Pump ........... 50-51

Hydraulic System (1.5).......................................... 53

Changing Hydraulic Oil & Filters (1.6) .................. 53

Scraper Bars & Cocoa Mats (1.7) ......................... 53

Towing Valve (1.8) ................................................. 53

Hydraulic System (2.0).......................................... 53

General — Hydraulic Flow Diagram (2.1) ............. 53

Drum Drives (2.2) ................................................. 54

Vibration & Streering (2.3) .................................... 54

Back Pressure Valve (2.4) ..................................... 54

Towing Valve (2.5) ................................................. 54

Testing Hydraulic Pressure (2.6)........................... 54

Hydraulic Diagram ................................................ 55

A. Drive Circuit Pressure ....................................... 56

B. Adjusting Drive Relief Valves............................. 57

C. Vibration Circuit Pressure ................................. 57

D. Steering Circuit Pressure .................................. 57

Removing & Replacing Hydraulic

Pump Assembly (2.7)............................................ 57

Removing & Replacing Vibration/Steering Pumps &

Hydraulic Schematic (2.8) ..................................... 58

Drum & Main Frame (3.0) ..................................... 59

Removing Front Drum (3.1) .................................. 59

Front Drum Disassembly (3.2) .............................. 59

Front Drum Assembly (3.3) ................................... 59

Vibrator Assembly Removal (3.4) ......................... 60

Vibrator Assembly Installation (3.5) ...................... 60

Vibrator Disassembly (3.6) ................................... 60

Vibrator Assembly (3.7) ........................................ 60

Installation Front Drum (3.8) ................................. 61

Drive Motor Removal (3.9) ................................... 61

Drive Motor Installation (3.10) .............................. 61

Rear Drum Removal (3.11) .................................. 61

Rear Drum Installation (3.12) ............................... 62

Alternator/Regulator (4.0) ..................................... 62

Neutral Safety Switch (4.1) ................................... 62

Vibration Solenoid (4.2) ........................................ 62

Ignition Switch (4.3) .............................................. 63

Starter Solenoid (4.4) ........................................... 63

Fuses (4.5) ............................................................ 63

Electrical Schematic (4.6) ..................................... 63

Terms and Conditions Of Sale — Parts ................ 64

SERVICE INFORMATION

Maintenance (1.0) ................................................. 52

Engine Lubrication (1.1)........................................ 52

Center Joint (articulation) (1.2) ............................. 52

Rear Drum (1.3) .................................................... 52

Vibrator Oil (1.4) ................................................... 52

VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 5

PARTS ORDERING PROCEDURES

Get special freight allowances

when you order 10 or more

line items via FAX!**

■■

■■

■

UPS Ground Service at no charge for freight

■■

■■

■

PS Third Day Service at one-half of actual freight cost

No other allowances on freight shipped by any other carrier.

**Common nuts, bolts and washers (all items under $1.00 list price)

do not count towards the 10+ line items.

*DISCOUNTS ARE SUBJECT TO CHANGE*

Fax order discount and UPS special programs revised June 1, 1995

Earn Extra Discounts when

you order by FAX!

All parts orders which include complete part numbers

and are received by fax qualify for the following extra

discounts:

Number of

line items ordered Additional Discount

1-9 items 3%

10+ items** 5%

Now! Direct TOLL-FREE access

to our Parts Department!

Toll-free nationwide:

800-421-1244

Toll-free FAX:

800/6-PARTS-7 • 800-672-7877

■■

■■

■ Dealer account number

■■

■■

■ Dealer name and address

■■

■■

■ Shipping address (if different than billing address)

■■

■■

■ Return fax number

■■

■■

■ Applicable model number

■■

■■

■ Quantity, part number and description of each part

■■

■■

■ Specify preferred method of shipment:

•

UPS Ground

•

UPS Second Day or Third Day*

•

UPS Next Day*

•

Federal Express Priority One (please provide us with your Federal

Express account number)*

•

Airborne Express*

•

Truck or parcel post

*Normally shipped the same day the order is received, if prior to 2PM west coast time.

Extra Fax DiscountExtra Fax Discount

Extra Fax DiscountExtra Fax Discount

Extra Fax Discount

for Domestic USAfor Domestic USA

for Domestic USAfor Domestic USA

for Domestic USA

Dealers OnlyDealers Only

Dealers OnlyDealers Only

Dealers Only

PAGE 6 — VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06)

Read and understand this manual before attempting to operate

the machine.

The VR-36H roller has been designed for asphalt application

and compaction of granular soils used in site preparation. Use

the machine only for the purpose intended and by experienced

personnel who understand this operating manual and all safety

decals.

Keep this manual with the machine and refer to it frequently.

DANGER!

Indicates extreme care should be

taken to prevent personal injury during

operation, inspection, maintenance and

service.

CAUTION!

Indicates when special observation is needed during

operation and maintenance of this machine.

SAFETY RULES

■

Completely familiarize yourself with the operation and safety

of this machine

BEFORE USE.

■

DO NOT remove or modify any parts of the machine. Doing

so may result in the warranty becoming invalid.

■

DO NOT use the machine for any purpose other than that

which it is intended.

■

Always wear proper safety equipment:

hard hat

safety glasses

work clothes

safety shoes

protective gloves

respirator in dusty environments

DANGER!

Stay Clear of turning points of

machine. This is a pinch point. Never place

yourself or allow anyone else to stand near the

unit while the engine is running.

■

Start the unit only when seated in the operator’s position.

(see starting instructions)

■

Whenever possible, always stop the unit on a stable, level

and hard surface. If the machine must be stopped on an

incline; before leaving the operator’s seat, secure the

parking brake and stop the engine; then chock both the

front and rear drums securely. Always remove the

ignition key to prevent unauthorized personnel from

operating the machine.

DANGER!

Exhaust gasses are extremely

dangerous and cause death. Operate the

machine only in well ventilated areas.

■

If malfunction occurs in the travel lever mechanism, speed

and direction will be impossible to control. Immediately stop

the

■

In the event of hydraulic hose or pipe failure, promptly return

the travel lever to the “neutral” position, stop the engine

and set the parking brake.

■

If the steering system operates improperly, immediately stop

the engine and apply the parking brake.

■

When malfunctions occur, always remove the ignition key

and place a “DO NOT OPERATE” sign in the operator’s

seat.

INSPECTION PRIOR TO STARTING

DANGER!

Perform inspections only with the

machine parked on a stable, level and hard

surface. Never inspect the unit with the engine

running. Inspections should only be performed

by trained and qualified personnel.

CAUTION!

Perform the following checks before each operation

of the machine and only with the engine STOPPED!

■

Check hydraulic oil, engine oil, and fuel levels and for

leakage.

■

Check all hydraulic components and fittings for wear.

■

Insure smooth movement of the travel lever, throttle and

parking brake.

■

Check all fasteners (bolts & nuts) for tightness.

RULES FOR SAFETY OPERATION

VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 7

RULES FOR SAFETY OPERATION

STARTING THE ENGINE

DANGER!

Always keep the operator’s area

clean and free from debris, dirt, oil, grease, mud,

asphalt or anything else that may become a

hazard to free movement of the operator.

■

Make sure no unauthorized personnel are near the machine

before attempting to start the unit.

DANGER!

Start and operate the unit only

from the operator’s position.

■

Always use seat belts when provided.

■

Adjust the seat to obtain the most comfortable position.

■

Place the travel lever in the “neutral” position

BEFORE

attempting to start the unit.

■

Make sure that the “vibrator” switch is in the “OFF” position.

■

Pull the “choke” knob to full choke (see engine operating

manual).

■

Turn the key to the start position to the right of the “ON”

position. (The ignition switch is spring loaded to prevent

the starter from being constantly engaged.)

■

As soon as the engine has started, release the ignition key.

■

Adjust the choke as required until the engine runs smoothly.

CAUTION!

Do not operate the starter switch when the engine

running.

INSPECTION (After Start-Up)

■

Run the engine at an idle 3 to 5 minutes. In colder climates,

longer warm periods may be necessary. Sufficiently

warming the engine allows all lubricants to reach the proper

operating temperature.

CAUTION!

Do not leave the operator’s position while the engine

is running.

Test the steering for proper operation - left to right.

DANGER!

Do not attempt to check the

steering function if anyone is near the unit

or in the way of the front or rear drums.

■

While seated in the operator’s seat and with the engine

running, check that the hydraulic oil level indicator registers

in the “operation” zone.

■

Check for abnormal noise, odor, exhaust color or other

sign that may be out of the ordinary.

ROPS — Roll Over Protection System

It is strongly suggested that ROPS and seat

belts be installed on this machine to protect the

operator against the unlikely event of a roll-

over.

The ROPS are sold as a optional accessory item and may be

ordered by calling:

Multiquip Sales • 800-421-1244 - P/N VR36ROPS

The following is a few examples of hazardous conditions of

when ROPS must be used:

1) When working on slopes or near open trenches

2) Hollow spaces or rocks that might be below the surface.

3) Sharp steering movements.

4) Surfaces that may be slippery or objects in the roller path.

PAGE 8 — VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06)

VR-36HA — OPERATIONS

OPERATION

By moving the travel lever forward or backward, the machine will

travel in either forward or reverse. The speed in which movement

of this lever is made is directly related to the amount of pressure

that is applied to the travel lever in each direction. Travel speed

is infinitely variable from 0 to 4.8 mph.

DANGER!

Before operating the roller, make sure that personnel

and obstacles are free from the roller’s path. Serious injury or

death can result!

CAUTION!

Allow the roller to come to a complete stop before

changing the direction of travel. Changing directions before the

roller comes to a complete stop will result in excessive force

being applied to the transmission and drive system which will

reduce overall service life.

COMPACTION

In order to apply vibration to the surface, the vibrator switch must

be in the “ON” position. If the vibration appears to be weak or

slow, allow the machine to warm-up thoroughly, and check the

hydraulic oil level. Add hydraulic oil if necessary.

CAUTION!

Do not allow the roller to operate on cured concrete

or other hard surface while the vibrator is “ON”.

WATER SYSTEM

The built-in water sprinkling system is designed to apply sufficient

quantities of water to the surface of the rollers. This method

prevents fresh asphalt from sticking to the drums while the rolling

operation is taking place.

The water system is fully adjustable from the operator’s position

by adjusting the two water valves. The front valve controls the

water supply to the front drum, and the rear valve controls water

to the rear drum.

Each roller is equipped with drum scrapers that are lined with

cocoa mats. These mats must be wetted before operation either

by the water supply system or other water source.

REFUELING

DANGER!

Do not attempt to refuel the engine while running!

Spilled gasoline can cause fire or explosion and can cause

serious injury or even death! Do not smoke or allow sparks or

open flame near the machine at any time - especially when

refueling. Clean the engine of any spilled fuel BEFORE re-

starting.

PARKING BRAKE

CAUTION!

Always apply the parking brake when the roller is

stopped. Do not operate the machine with the parking brake in

the “SET” position. Severe brake wear can result.

ENGINE SHUT-DOWN

DANGER!

Do not leave the operator’s seat while the engine is

running.

CAUTION!

Should stopping the unit be unavoidable on a slope

or grade, stop the engine, set the parking brake and place chocks

in the front and rear of each drum.

■

Place the travel lever in the “neutral” position.

■

Return the throttle lever to the idle position.

■

Turn the vibration switch to the “OFF” position.

■

Set the parking brake

■

Allow the engine to idle for 3 to 5 minutes prior to stopping

to allow proper cool-down period.

■

Stop the engine and remove the ignition key.

LOADING AND TRANSPORTING

DANGER!

ALWAYS LOAD AND UNLOAD THE ROLLER ON

LEVEL, HARD GROUND OR PAVEMENT. Serious injury or

death can result from improper loading, lifting or unloading. Use

caution!

■

When driving the roller onto a transporting vehicle or trailer

■

Use ramps or other suitable material of sufficient strength

to support the roller.

■

Remove mud, oil, ice, snow or any other slippery materials

from the ramps and bed of the vehicle to avoid accidents.

■

After loading, apply the parking brake, lock the frame with

the locking bar that is provided.

■

Use chain and binders or other suitable means to firmly

secure the load before attempting to move the vehicle.

■

Lifting the roller onto a transporting vehicle or trailer

■

Only use the lifting points for the roller that are clearly

marked as “lifting point”.

DANGER!

Do not allow personnel under or near any suspended

machine. Serious injury or death may result.

VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 9

■

Remove mud, oil, ice, snow or any other slippery materials

from the ramps and bed of the vehicle to avoid accidents.

■

After loading, apply the parking brake, lock the frame with

the locking bar that is provided.

■

Use chain and binders or other suitable means to firmly

secure the load before attempting to move the vehicle.

BATTERY INFORMATION

DANGER!

Lead acid batteries contain sulfuric acid which will

damage eyes, skin and clothing upon contact. Always wear proper

safety eye protection, rubber gloves and other safety clothing.

Should acid contact the eyes, flush immediately with clean water

and get prompt medical attention. If acid comes in contact with

skin, wash immediately with clean water and get prompt medical

attention.

DANGER!

Avoid fire and open flame near batteries. Battery acids

are extremely flammable and explosion can result.

■

Clean and inspect battery terminals regularly.

■

Non-use of machine will result in reduced battery charge

level and will damage the plates which reduces the battery

life.

■

Keep battery caps tightly fastened at all times.

■

Add distilled water as needed

■

Proper sequence must be observed during installation and

removal of batteries:

■

Removal - Disconnect the negative (ground) terminal first,

then the positive terminal.

■

Installation - Install the Positive terminal first, then the

negative (ground) terminal.

DANGER!

Never allow the negative and positive cables to come

in contact with each other. Serious injury could result.

VR-36HA — OPERATIONS

SERVICE AND INSPECTION

Performing all periodic inspections and service work on a timely

basis will result in increased performance, productivity and

reduced maintenance costs.

When the roller is used in severe, unusually dusty or dirty, or

extremely humid or hot environments, it will be necessary to

perform routine service and inspections more frequently.

DANGER!

Always operate the machine in a well ventilated area.

Exhaust gasses are dangerous and cause injury or death. Never

operate this or any other machine within an enclosed space.

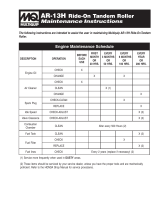

SERVICE INSTRUCTIONS CHART

Engine Speed 3500 RPM

Exciter Speed 3900 VPM

Exciter Lubrication Type SAE 30

16 oz. (475 ml)

Every 1100 hours

Grease Type Alvania #2 or equiv.

Articulated joint (4 fittings)

Static drum bearing (1 fitting)

Every 75 hours

Hydraulic Oil Type ISO46 (Anti-Wear)

5.7 gallons (21.6 liters)

Every 1100 hours

Hydraulic Filter Change every 500 hours

Engine Lubrication/ Refer to Engine Owners Manual

Service

CAUTION!

Running the machine without sufficient hydraulic oil

will result in extreme damage to the unit’s hydraulic system.

PAGE 10 — VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06)

How to read the marks and remarks used in this parts book.

Section 1: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial

number range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model

number or model number variant.

Section 2: Items Found In the “Remarks” Column

Serial Numbers-Where indicated, this indicates a serial number

range (inclusive) where a particular part is used.

Model Number-Where indicated, this shows that the

corresponding part is utilized only with this specific model number

or model number variant.

Section 3: Items Found In the “Items Number” Column

All parts with same symbol in the number column,

*

, #, +, %, or

■

, belong to the same assembly or kit.

Note: If more than one of the same reference number is listed,

the last one listed indicates newest (or latest) part available.

NOTE

If more than one of the same reference number is

listed, the last one listed indicates newest (or latest)

part available.

NOTE

The contents of this catalog are

subject to change without notice

.

VR-36HA — EXPLANATION OF CODE IN REMARKS COLUMN

VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 11

NOTE

Part numbers on this Suggested

Spare Parts List may supercede/

replace the P/N shown in the text

pages of this book.

VR36HA

1 Unit

Qty. . P/N ................... Description

2 ..... 508667 ............. HYDRAULIC FILTER CART.

3 ..... 506141 ............. RUBBER SHOCK MOUNTS

6 ..... 508433 ............. RUBBER SHOCK MOUNTS

1 ..... 506097 ............. FWD./REV. CABLE

1 ..... 510229 ............. ENG THROTTLE CABLE

1 ..... 506239 ............. ENGINE CHOKE CABLE

2 ..... 503735 ............. FLANGE BEARING

4 ..... 352431090 ....... INLINE FUEL FILTER

1 ..... 9807956846 ..... SPARK PLUG

1 ..... 17010ZJ1000 ... ELEMENT SET

1 ..... 506267K ........... KEY

VR-36HA — SUGGESTED SPARE PARTS

PAGE 12 — VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06)

VR-36HA — ENGINE COVER & ARTICULATED JOINT

30

31

VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 13

MODEL VR-36H

ENGINE COVER & ARTICULATED JOINT

NO PART NO PART NAME QTY. SERIAL NO.

1 506100 COVER ........................................................................ 1 ........................... S/N 960601 TO 970630

1 510074 COVER ........................................................................ 1 ........................... S/N 970701 & UP

2 506103 ARTICULATED SHAFT 1

3 506095 CABLE 1

4 506101 FRONT COVER 1

5 504544 LATCH ASSEMBLY 2

7 491687 KING PIN 2

9 506158 HEX. HEAD SCREWS 5/16" NC x ¾" G5 7

10 490937 RUBBER BUMPER 2

11 492582 LOCK NUT 5/16" NC 2

12 492597 FLAT WASHER 5/16" 2

13 506176 FLAT HEAD SOCKET S. 5/16 NC x 1" G5 2

14 506102 ARTICULATED BODY 1

15 506164 BEARING 1

16 506165 BEARING 3

17 506104 RETAINER 1

18 492269 SOCKET HEAD SCREW 5/16" NF x ¾" G5 3

19 506105 PIVOT 1

20 506172 HEX. HEAD SCREW ½" NC x 1, 3/8" G5 4

21 506124 BUSHING 2

22 506107 PILLOW BLOCK 2

23 491705 GREASE FITTING ¼" NF 4

24 506109 FLAT WASHER 4

25 503982 HEX. HEAD SCREW 5/8" NC x 2" G5 4

26 506160 SHAFT SEAL 2

27 506110 PLUG 2

28 506166 SHIM 3

29 506110 DUST CAP 2

30 510292 ACCESS COVER ......................................................... 1 ........................... S/N 970701 & UP

31 506176 BOLTS ......................................................................... 4 ........................... S/N 970701 & UP

WHEN ORDERING PARTS, ALWAYS GIVE MODEL NUMBER AND SERIAL NUMBER OF UNIT.

VR-36HA — ENGINE COVER & ARTICULATED JOINT

PAGE 14 — VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06)

VR-36HA — HYDRAULIC OIL FILTERS

51

VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 15

MODEL VR-36H

HYDRAULIC OIL FILTER

NO PART NO PART NAME QTY. SERIAL NO.

35 508814 HEX. HEAD SCREW 5/16" NC x 3, ¼" G5 2

36 506218 FITTING INLET 1

37 506221 SUCTION FILTER 1

38 507278 CAP 1

39 508287 SEAL - AIR INTAKE 1

40 506205 PLUG W/O-RING 1

41 492356 HEX. HEAD SCREW ¼" NC x ¾" G5 5

42 492622 LOCK WASHER 3

43 508667 OIL FILTER, HYDRAULIC 1

44 506199 FITTING ELBOW 1

45 506204 FITTING 1

46 506244 MANIFOLD BLOCK 1

47 506193 ADAPTER 2

48 508670 CHECK VALVE 1

49 508664 FILTER ADAPTOR 1

50 508287 SEAL INSIDE BODY 1

51 490181 SIGHT GLASS 1

WHEN ORDERING PARTS, ALWAYS GIVE MODEL NUMBER AND SERIAL NUMBER OF UNIT.

VR-36HA — HYDRAULIC OIL FILTERS

PAGE 16 — VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06)

VR-36HA — ENGINE COUPLER

PAGE 16

PAGE 12

NOTE: ENGINE FUEL

PUMP, REF. TO PAGE 48

VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 17

VR-36HA — ENGINE COUPLER

MODEL VR-36H

ENGINE COUPLER

NO PART NO PART NAME QTY. SERIAL NO.

55 492371 HEX. HEAD SCREW 5/16" NC x 3" G5 1

56 492583 LOCK NUT 3/8" NC 4

57 492379 HEX. HEAD SCREW 3/8" NC x 2" G5 4

58 505891 FRONT FRAME 1

59 492598 FLAT WASHER 8

60 506159 SOCKET HEAD SCREWS ½" NC x 1-3/8" G 8

61 505976 HOSE RETAINER 2

62 506185 SUPPORT PLATE 1

63 508350 ENGINE HONDA 18 HP. GX610 QZB 1

64 506234 SPACER 1

65 506235 COUPLING 1

66 506236 ADAPTER 1

67 492376 HEX. HEAD SCREW 3/8" NC x 1-1/4" G5 6

68 500569 SQUARE KEY ¼" x 1 ¼" 1

69 506240 FUEL HOSE 3

70 508346 LOCK WASHER SPECIAL 2

WHEN ORDERING PARTS, ALWAYS GIVE MODEL NUMBER AND SERIAL NUMBER OF UNIT.

PAGE 18 — VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06)

VR-36HA — HYDRAULIC DRIVE PUMPS

VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06) — PAGE 19

VR-36HA — HYDRAULIC DRIVE PUMPS

MODEL VR-36H

HYDRAULIC DRIVE PUMPS

NO PART NO PART NAME QTY. SERIAL NO.

78 507845 GEAR PUMP (INCL. A, B, C, D, E, F, G, H.) 1

79 506187 PISTON PUMP (INCL. I, J.) 1

80 507860 FLANGE SUNDSTRAND 1

81 492582 LOCK NUT 5/16" NC 2

82 506158 HEX. HEAD SCREW 5/16" NC x ¾" G5 2

83 506225 PUMP SUPPORT 1

84 506243 LEVER – FORWARD/REVERSE 1

85 506098 BALL JOINT 1

86 508451 LOCK NUT ¼" – 28 NF 1

87 506227 HEX. HEAD SCREW 3/16" 24 NS x 1 ½" 1

88 508343 FITTING 3

89 508427 FLAT WASHER 21/30 (COPPER) 3

90 506217 FITTING 1

91 506219 FITTING 1

92 508428 FLAT WASHER SPECIAL (COPPER) 1

93 506203 FITTING 1

94 492367 HEX. HEAD SCREW 5/16" NC x 1 ¾" G5 1

95 492582 LOCK NUT 5/16" NC 1

96 503119 LOCK NUT 3/16" 24 NS 1

WHEN ORDERING PARTS, ALWAYS GIVE MODEL NUMBER AND SERIAL NUMBER OF UNIT.

PAGE 20 — VR-36HA • VIBRATORY ROLLER — PARTS & OPERATION MANUAL — REV. 6 (06/13/06)

VR-36HA — HYDRAULIC FITTING & EXHAUST SYSTEMS

/