2

SUSSEX

INFO & INSTALL GUIDES

CONCEPTS

sussextaps.com.au

5.0 litres per

minute

Licence No. 0124

In accordance with AS/NZS 6400

Sussex Taps Pty Ltd

WATER RATING

www.waterrating.gov.au

The more

stars the more

water efcient

AS/NZS 3718:2005

LIC. 20081

Calibre

INFORMATION SHEET

Calibre Basin Mixer

Product code: CBM

160

80

100

40

35

48

sussextaps.com.au

5.0 litres per

minute

Licence No. 0124

In accordance with AS/NZS 6400

Sussex Taps Pty Ltd

WATER RATING

www.waterrating.gov.au

The more

stars the more

water efcient

AS/NZS 3718:2005

LIC. 20081

Calibre

Calibre Basin Mixer

Product code: Available options:

CBM Basin Mixer

CEBM Extended Basin Mixer

INSTALLATION GUIDE

PLUMBER NOTE

- On-site testing using higher water pressures must be

conducted with the Mixer in the closed position.

(STATIC TEST )

- Under no circumstances is the Mixer to be opened

when exceeding the maximum stated water pressure.

- At the completion of testing, do not relieve any high

water pressure by operating the Mixer.

- Exposing the internals of the Mixer Cartridge to higher

than specified water pressures will void the

manufacturers warranty.

INSTALLATION GUIDELINES

- The Mixer is supplied assembled, only the Fixing nut

and the Clamp need to be removed.

- After removing the mentioned parts, lower the Mixer

on to the mounting surface and fit the Flexible Hoses.

- In some cases the Flexible Hoses may need to be fed

through from under the mounting surface and then

attached. (Tighten using appropriate spanner)

- After securing the Flexible Hoses, fit Clamp and attach

the Fixing Nut from underneath.

- Before fully securing the Mixer ensure that the Base O

Ring is intact and the Mixer is properly centered over

the mounting surface hole.

- The Mixer mounting surface must be completely sealed

and water-tight.

- The 1/2” Fittings of the Flexible Hoses have a conical

seal, ensure that the matching threads are cut square

and burr free.

- Prior to connecting the Flexible Hoses, ensure all

pipework is thoroughly flushed and ensure pipework is

free of any dirt or debri.

- Isolating Stop Valves are recommended with all

installations. (not supplied)

- Connect the Flexible Hoses to Hot and Cold pipework

fittings, ensure the Hoses do not kink or become

twisted when tightening.

- Check all fittings and connections are secure and

water-tight.

BASE

O-RING

CLAMP

Hole Size

32-35mm

50mm Max.

Bench thickness

1/2" BSP Fittings

with conical Seals

FLEXIBLE HOSES

FIXING

NUT

Product code

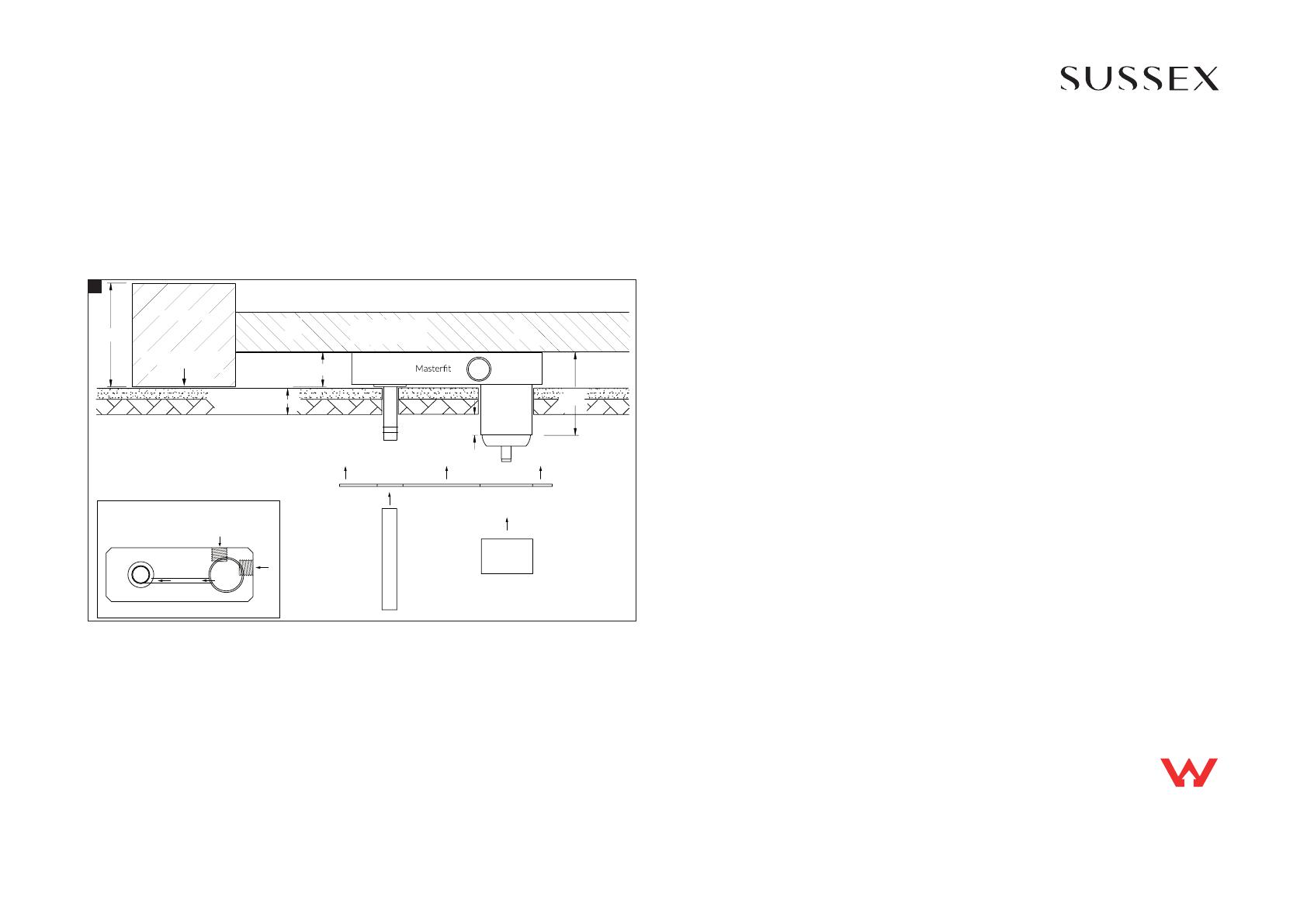

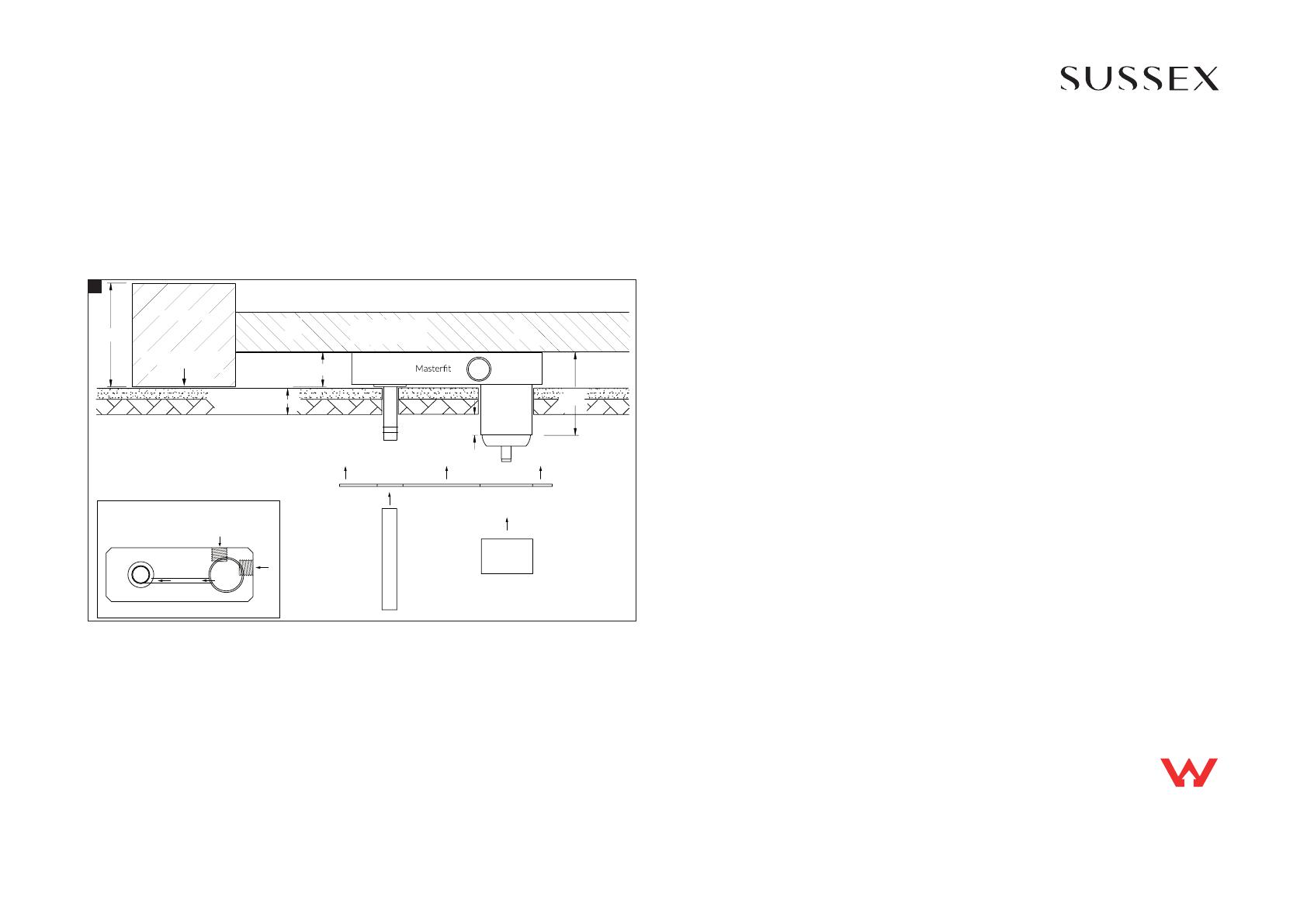

Calibre

CWBMS150RH Wall basin mixer outlet system 150mm RH

CWBMS200RH Wall basin mixer outlet system 200mm RH

Wall basin mixer outlet system RH Rough-in

Plumber note

Pipe connections

Rough in plumbing

- Prior to installing, calculate the finished wall thickness, maximum is 30mm thick, contact manufacturer for

further options.

- If Wall thickness is greater than 30mm, contact manufacturer for further options.

- Prepare a Nogging to be fixed parallel between the Wall Studs.

- The Nogging must be fitted to enable the base of the Masterfit to be 30-32mm back from the Stud Face.

- The Masterfit will be marked “This side Up” to indicate orientation.

- Using the screws (x4) provided, mount the Masterfit to the Nogging. Ensure the Masterfit is level and square.

- On-site high pressure line testing must be conducted with the Mixer in the closed position. (STATIC TEST ONLY)

- Under no circumstances is the Mixer to be opened when exceeding the maximum stated water pressure.

- At the completion of the testing, do not relieve any high pressure by opening the Mixer.

- Exposing the internals of the Mixer Cartridge to higher than specified water pressures, will void the

manufacturer’s warranty.

- The Hot and Cold ports are marked on the Masterfit. (Mixers have individual Hot/Cold inlet ports).

- Flush all water feed lines. All lines must be free from any dirt and debris before connecting to the Masterfit.

- Connect Hot and Cold lines to the corresponding 1/2” BSP ports of the Masterfit. (see Drawing)

- Do not remove any factory fitted pressure plugs or Fixings.

- Once all water connections are made, check Hot/Cold water flow by operating the Mixer Cartridge.

- Check all fittings and fixtures for leaks.

- Leave the Mixer(s) in the closed position and replace the Mixer protective cover.

- Store the Dress Kit in a safe place until required (see Dress Finishing Guide)

1

Vi ew f ro m ab ov e

NOGGING

Back Plate

Handle

Body

30-32mm

Wall Covering

Max. 30mm

90

70

Mixer

Stud face

Min.

8mm

This

side

UP

Outlet

Hot

Cold

Mixer Outlet

Pipe Connections

Outlet

Fitting

Tapware is to be installed by a Licensed Plumber in accordance with AS/NZS 3500:2003

Recommended working water pressure 300-500 kpa. Maximum water temperature is 65 deg.c

Copyright © Sussex Taps.sussextaps.com.au