Page is loading ...

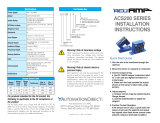

Effective September 2013 Series NRX

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

1600 NRX SUB-TITLE IMAGE (12/15/2010)

Series NRX, Type NF Frame

ANSI, UL1066, UL489 / IEC, IZMX16, IZM91

Series NRX, Type RF Frame

IEC, IZMX40

4000 NRX RF DRAWOUT SUBTITLE IMAGE (12/15/2010)

Instructions apply to:

Effective September 2013

2

EATON www.eaton.com

Instructional Leaet IL01301064E Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

TABLE OF TABLES

Description page

Table 1. Digitrip 1150/1150i Trip Units Functions ...............................6

Table 2. Current Protection Functions .....................................6

Table 3. Protective Relay Functions ........................................7

Table 4. Alarms .......................................................8

Table 5. Current Voltage Frequency Metering Data ............................9

Table 6. Power and Energy Metering Data ...................................9

Table 7. Metered Power Quality System Data ...............................10

Table 8. Event Recording ...............................................11

Table 9. Event Recording continued .......................................12

Table 10. Series NRX/Digitrip Ground Fault Sensing Modes ....................18

Table 11. Series NRX NF Frames and Rating Plugs ...........................34

Table 12. Series NRX RF Frames and Rating Plugs ...........................35

TABLE OF CONTENTS

Description page

Section 1: Introduction ..................................................5

Section 2: Specification Tables ............................................6

Section 3: General description ...........................................13

Section 4: Principles of operation .........................................16

Section 5: Display Module Interface .......................................20

Section 6: Programming Settings .........................................24

Section 7: Test procedures ..............................................28

Section 8: Record keeping ..............................................31

Section 9: Trip unit battery ...............................................33

Section 10: Frame ratings and rating plugs ..................................34

Section 11: Maintenance Mode feature ....................................35

Section 12: References .................................................36

Section 13: Time-current curves ..........................................36

Section 14: Communications .............................................37

Appendix A: Zone Selective Interlocking Examples ...........................38

Appendix B: Troubleshooting .............................................40

Appendix C: Electrical Specifications ......................................42

Appendix D: Display, Indicators and Menus .................................43

Appendix E: Power and Power Factor Sign Conventions .......................92

Appendix F: Setpoint Defaults and Worksheet ...............................94

3

EATON www.eaton.com

Effective September 2013

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

TABLE OF FIGURES

Description page

Figure 1. Digitrip 1150 Trip Unit With Rating Plug and Frame Module ...............5

Figure 2. NRX NF Circuit Breaker with Digitrip 1150 ............................5

Figure 3. Series NRX NF Frame Phase Current Sensor ........................13

Figure 4. Trip Unit Installation on a Frame Module ...........................14

Figure 5. Installation of the Rating Plug into the Trip Unit .......................14

Figure 6. Trip Unit Locking Tabs ...........................................15

Figure 7. Frame Module With Trip Unit Removed .............................15

Figure 8. Block Diagram With Breaker Interface ..............................16

Figure 9. Series NRX RF Frame Neutral Sensor ..............................18

Figure 10. Series NRX NF Frame Neutral Sensor .............................18

Figure 11. Trip Unit and Display Module .....................................20

Figure 12. Trip Unit Indicators (LSIG style with Maintenance Mode) ..............20

Figure 13. Display Module Push Buttons ...................................21

Figure 14. Long Delay Time Setting Bands for I

2

t settings ......................24

Figure 15. Short Delay Time Setting Bands - Flat and I

2

t .......................25

Figure 16. Functional Test Kit .............................................28

Figure 17. Connections for Single-Pole, Single-Phase Current Tests ...............30

Figure 18. Connections for Single-Phase Current Tests With Two Poles in Series ....30

Figure 19. Typical Trip Function Record Nameplate ............................31

Figure 20. Automatic Trip Operation Record .................................31

Figure 21. Typical Performance Test Record Form .............................32

Figure 22. Digitrip Battery Installation ......................................33

Figure 23. CAM Module ................................................37

Figure 24. Example of Interlocking with Three Zones ..........................39

Figure 25. ZSI Example With Mains (M1, M2) and Tie (T) Circuit Breakers .........39

Figure 26. IEC Sign Convention Phasor Diagram .............................92

Figure 27. IEEE Sign Convention Phasor Diagram .............................93

Figure 28. IEEE Direct Mathematical Sign Convention Phasor Diagram ...........93

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

4

EATON www.eaton.com

Effective September 2013

Instructional Leaet IL01301064E

• WARNING

DANGEROUS ELECTRICAL VOLTAGE!

DO NOT ATTEMPT TO INSTALL OR PERFORM MAINTENANCE ON

EQUIPMENT WHILE IT IS ENERGIZED. DEATH OR SEVERE INJURY CAN

RESULT FROM CONTACT WITH ENERGIZED EQUIPMENT. ALWAYS

VERIFY THAT NO VOLTAGE IS PRESENT BEFORE PROCEEDING.

ALWAYS FOLLOW SAFETY PROCEDURES. EATON IS NOT LIABLE FOR

MISAPPLICATION OR MISINSTALLATION OF ITS PRODUCTS.

Before commencing any installation

• Disconnect the power supply of the device

• Ensure that devices cannot be accidentally closed or

powered up

• Verify isolation from the supply, Earth, and short circuit

• Cover or enclose neighboring units that are live

• Danger if circuit breaker mechanism spring is charged!

• Discharge spring

• Follow the engineering instructions of the device concerned

• Only suitably qualified personnel in accordance with

applicable national work safety regulations may work on this

device/system

• Before installation and before touching the device ensure

that you are free of electrostatic charge

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference do not impair the

automation functions

• Suitable safety hardware and software measures should

be implemented for the I/O interface so that a line or wire

breakage on the signal side does not result in undefined

states in the automation devices and create an unwanted

action in the circuit breaker

• WARNING

OBSERVE ALL RECOMMENDATIONS, NOTES, CAUTIONS, AND

WARNINGS RELATED TO THE SAFETY OF PERSONNEL AND

EQUIPMENT. OBSERVE AND COMPLY WITH ALL GENERAL AND

LOCAL HEALTH AND SAFETY LAWS, CODES, AND PROCEDURES.

• Deviation of the mains voltage from the rated value

must not exceed the tolerance limits given in the

specifications, otherwise this may cause malfunction and

dangerous operation

• Emergency stop devices complying with IEC 60204-

1, EN 60204-1 must be in all operating modes of the

automation devices. Unlatching the emergency-stop

devices must not cause restart

• The electrical installation must be carried out in

accordance with the relevant regulations (e.g. with

regard to cable cross section size, fuses, and earthing

(PE)

• All work relating to transport, installation, commissioning

and maintenance must be carried out by qualified

personnel in accordance with applicable national work

safety regulations

Note: The recommendations and information contained herein are

based on experience and judgement, but should not be considered to

be all inclusive or to cover every application or circumstance that may

arise.

If you have any questions or need further information or

instructions, please contact your local Eaton representative or

visit www.Eaton.com.

5

EATON www.eaton.com

Section 1: Introduction

Figure 1. Digitrip 1150 Trip Unit With Rating Plug and Frame

Module

This instruction book specifically covers the application of

Digitrip 1150 and 1150i trip units installed in the Series NRX-NF

frame or Series NRX-RF frame circuit breakers.

The styles of trip units consists of the Digitrip 1150 for

compliance with UL/ANSI standards and the 1150i for the IEC

standards applications.

The Digitrip 1150 and 1150i trip units may be applied on either

50 and 60 Hz systems.

The Digitrip 1150/1150i trip unit system consists of 3 parts, the

frame, the trip unit and the display. The frame module is fixed

to the circuit breaker. This module is matched to the frame

interruption rating and sensors of the circuit breaker and should

not be changed. The trip unit module contains the Digital

Signal Processor (DSP) that performs the measurements and

calculations for protection and metering. The display module

is the user interface and requires external control power to

operate.

The Digitrip 1150/1150i trip units work with either the current

sensors of the NF or RF frame Series NRX circuit breakers. The

appropriate rating plug must be matched to the frame and style

of circuit breaker that the trip unit is applied to.

Effective September 2013

Instructional Leaet IL01301064EOperating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Figure 2. NRX NF Circuit Breaker with Digitrip 1150

6

EATON www.eaton.com

Table 1. Digitrip 1150/1150i Trip Units Functions

Trip Unit Type Digitrip 1150 Digitrip 1150i

Ampere range NF Frame 400 –1200A

RF Frame 800 – 3200A

NF Frame 400 – 1600A

RF Frame 800 – 4000A

Ordering catalog number N11RLSIG, N11RLSI, N11RLSIA, N11LSIG,

N11LSI, N11LSIA

N11IEC, N11IECEF, N11RIEC, N11RIECEF

Available styles LSI, LSIA, LSIG LSI, LSIG

System frequency 50 or 60 Hz 50 or 60 Hz

RMS sensing

•

•

Relays - Programmable for alarms or trips 2 2

Communications

• •

Display - LCD Color Graphic

• •

Table 2. Current Protection Functions

Current Protection and Coordination Digitrip 1150/1150i Step Size

Protection

Fixed rating plug (I

n

)

Overtemperature trip

•

•

Long delay protection Slope

Long delay pickup

I

2

t, I

4

t

IEEE - MI, IEEE - VI, IEEE - EI l

IEC-A, IEC-B, IEC-C k

50 – 100% x (I

n

) 5%

Long delay time @6 x (I

r

) I

2

t

Long delay time @6 x (I

r

) I

4

t

Time Dial Multiplier IEC slope

Time Dial Multiplier IEEE slope

Long delay thermal memory (only on I

2

t and I

4

t slopes)

2 – 24 seconds

1

–

5 seconds

0.05 – 1

0.1 – 5

Enable / Disable

500 ms

500 ms

0.05

0.01

Short delay protection Short delay slope

Short delay pickup

Short delay time at 8 x (I

r

) I

2

t

Short delay time flat

Short delay zone interlock

Flat, I

2

t

200 – 1000% x (I

r

)

0.10 – 0.50 seconds

0.10 – 0.50 seconds

•

(option)

50%

5 ms

5 ms

Instantaneous protection Instantaneous pickup

OFF setting

Making current release

200 – 1200% x (I

n

)

•

•

50%

Neutral protection

4th pole or external neutral trip

50, 100, 150, 200%

Ground (earth) fault

protection (option)

Ground fault pickup

OFF position

Ground fault delay at 0.625 x

(I

r

) I

2

t

Ground fault delay flat

Ground fault zone interlock

Ground fault thermal memory

24 – 100% x

(I

n

)

j

• k

0.10 – 0.50 seconds

0.10 – 0.50 seconds

•

(option)

Enable / Disable

1%

50 ms

50 ms

Maintenance mode

protection (ARMS)

(option)

Setting

Contact for remote Indication of mode

Maintenance mode pickup

On, Off / remote enable

•

NF Frame: 1000A

– 5000A = Pickup

RF Frame: 4000A – 20000A = Pickup

1000A

4000A

Current unbalance

protection trip

Current unbalance pickup

Current unbalance time delay

Off, 5% – 25%

0 – 240 seconds

1%

1 second

Phase loss protection -

current based trip

Phase loss setting

Phase loss time delay

On, Off

1 – 30

seconds 1 second

j Digitrip 1150 ANSI/UL versions are limited to 1200A to comply with UL and NEC® standards.

k Only available on Digitrip 1150i versions

l Only available on Digitrip 1150 versions

Section 2: Specication Tables

Effective September 2013

Instructional Leaet IL01301064E Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Table 3. Protective Relay Functions

Protection Digitrip 1150/1150i Step Size

Voltage Protection

Voltage trip protection (Line to Line) Enable, Disable

Undervoltage trip Off, 90 - 670 V 1 volt

Undervoltage time 1 - 250 seconds 1 second

Overvoltage trip Off, 180 - 720 V 1 volt

Overvoltage time 1 - 250 seconds 1 second

Voltage unbalance trip Off, 5% - 50% 1%

Voltage unbalance time 1 - 250 seconds 1 second

Frequency Protection

Frequency trip protection Enable, Disable

Underfrequency trip Off, 45 - 65 Hz 0.1 Hertz

Underfrequency time 0.20 - 5.0 seconds 0.02 seconds

Overfrequency trip Off, 45 - 65 Hz 0.1 Hertz

Overfrequency time 0.20 - 5.0 seconds 0.02 seconds

Power Quality Protection

Reverse Power Pickup Off, 1 - 65500 kW 1 kW

Reverse Power Time Delay 1 - 60 seconds 1 second

7

EATON www.eaton.com

Effective September 2013

Instructional Leaet IL01301064EOperating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

8

EATON www.eaton.com

Effective September 2013

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Table 4. Alarms

Alarm Type Digitrip 1150/1150i Step Size

Alarms - Current

High load alarm setting

Off, 50% - 100% x

(I

r

)

5%

High load alarm time delay 1 - 60 seconds 1 second

Amp unbalance alarm setting

Off, 5% - 25% x

(I

r

)

1%

Amp unbalance alarm time delay 0 - 240 seconds 1 second

Neutral ampere alarm setting Off, 10% - 100% 5%

Neutral ampere alarm time delay 1 - 60 seconds 1 second

Ground alarm Off, 10% - 100% Style LSIG or LSIA only 1%

Ground alarm time delay 100 ms

–

Alarms - Voltage

Voltage Alarms Enable, Disable

Undervoltage alarm Off, 90 - 670V 1 volt

Undervoltage alarm time 1 - 250 seconds 1 second

Overvoltage alarm Off, 180 - 720V 1 volt

Overvoltage alarm time 1 - 250 seconds 1 second

Voltage unbalance alarm Off, 5% - 50% 1 %

Voltage unbalance alarm time 1 - 250 seconds 1 second

Phase rotation alarm Off, ABC, CBA

–

Alarms - Frequency

Frequency Alarms (based on Van) Enable, Disable

Underfrequency alarm Off, 45 - 65 Hz 0.1 Hz

Underfrequency alarm time 0.20 - 5.0 seconds 20 ms

Overfrequency alarm Off, 45 - 65 Hz 0.1 Hz

Overfrequency alarm time 0.20 - 5.0 seconds 20 ms

Alarms - Power Quality

Power Alarms Enable, Disable

kW Demand Setting off, 1- 65500 kW 1 kW

kW Demand Time Delay 1 - 60 seconds 1 second

kVA Demand Setting off, 1 - 65500 kVA 1 kVA

kVA Demand Time Delay 1 - 60 seconds 1 second

Reverse Power Setting off, 1 - 65500 kW 1 kW

Reverse Power Time Delay 1 - 60 seconds 1 second

Power Factor Setting off, 50% - 95% 5 %

Power Factor Time Delay 1 - 60 seconds 1 second

THD Setting off, 10% - 30% 1 %

THD Time Delay 1 - 60 seconds 1 second

Alarms - System Diagnostics

Status/long pickup LED

•

Cause of trip LEDs j

•

Alarm LED

•

Operation count alarm

Off, 1 - 12500 counts

1 count

j Four cause of trip LEDs indicate LONG, SHORT, INST, or GROUND trip. Making Current Release protection trip is indicated by the Instantaneous LED

Table 5. Current Voltage Frequency Metering Data

Current Metering Units Accuracy Notes

IA, IB, IC, IN, IG Amperes ±1% of

Reading j

IA, IB, IC, IN, IG

(min.)

Amperes ±1% of

Reading jl

Group values held until reset

IA, IB, IC, IN, IG

(max.)

Amperes ±1% of

Reading jl

Group values held until reset

IA, IB, IC, IN, IG

(demand)

Amperes ±1% of

Reading jl

Window 5 - 60 minutes

Sliding or Fixed

IA, IB, IC, IN, IG

(demand max)

Amperes ±1% of

Reading jl

Group values held until reset

Current Metering Range Notes

Current Unbalance --- 0 - 100%

Voltage Metering

Units Accuracy Notes

VAB, VBC, VCA Volts ±1% of

Reading k

Line to Line Voltage

VAB, VBC, VCA

(min)

Volts ±1% of

Reading k

VAB, VBC, VCA

(max)

Volts ±1% of

Reading k

VAN, VBN, VCN Volts ±1% of

Reading k

Line to Neutral Voltage

VAN, VBN, VCN

(min)

Volts ±1% of

Reading k

VAN, VBN, VCN

(max)

Volts ±1% of

Reading k

Frequency

Metering Units Accuracy Notes

Frequency Hz ±0.2 Hz of

Reading k

Range is 20 to 255 Hz

Frequency (min)) Hz ±0.2 Hz of

Reading k

Value held until reset

Frequency (min)) Hz ±0.2 Hz of

Reading k

Value held until reset

j Accuracy applicable for 5 to 100% of I

n

and current will start metering at 2% of rating plug

k Applicable to the voltage range of 34 to 690 Vac.

l All currents share a common configured demand window. All powers share a common configured demand window.

9

EATON www.eaton.com

Effective September 2013

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Table 6. Power and Energy Metering Data

Power Metering Units Accuracy Notes

Power kW ±2% of Reading

jk

Approximately 1- second

update

kVA kVA ±2% of Reading

jk

Approximately 1- second

update

kvar kvar ±2% of Reading

jk

Approximately 1- second

update

Demand kW kW ±2% of Reading

jkl

Window 5 - 60 minutes

Sliding or Fixed

Demand (max). kW kW ±2% of Reading

jkl

Value held until reset

Demand kVA kVA ±2% of Reading

jkl

Window 5 - 60 minutes

Sliding or Fixed

Demand (max). kVA kVA ±2% of Reading

jkl

Value held until reset

Demand kvar kvar ±2% of Reading

jkl

Window 5 - 60 minutes

Sliding or Fixed

Demand (max) kvar kvar ±2% of Reading

jkl

Value held until reset

Power Metering Range Notes

PF (power factor) --- 0 - ±1.00

PF (min. absolute) --- 0 - 1.00 Value held until reset

PF (max. absolute) --- 0 - 1.00 Value held until reset

Energy Metering Units Accuracy Notes

Energy kWh kWh ±2% of Reading

jk

Total

Energy fwd kWh kWh ±2% of Reading

jk

Forward

Energy rev kWh kWh ±2% of Reading

jk

Reverse

kVAh kVh ±2% of Reading

jk

Net Reactive

Metering

Configuration

Settings Notes

Reverse Feed

Configuration

Normal or Reverse Line to load is normal and

the default setting

Energy Log Interval Off, 5, 10, 15, 20, 30, 60

minutes

Table 7. Metered Power Quality System Data

Harmonics Range Notes

Crest Factor IA 1.0 - 64 Peak divided by the RMS

Crest Factor IB 1.0 - 64

Crest Factor IC 1.0 - 64

Crest Factor IN 1.0 - 64

THD IA 0 - 6300% Total Harmonic Distortion

THD IB 0 - 6300%

THD IC 0 - 6300%

THD IN 0 - 6300%

Individual Harmonic

Current Data

IA Harmonics from 1 to 31 0 - 100% Phase A current

IB Harmonics from 1 to 31 0 - 100% Phase B current

IC Harmonics from 1 to 31 0 - 100% Phase C current

IN Harmonics from 1 to 31 0 - 100% Neutral current

Individual Harmonic Line to

Line Voltage Data

VAB Harmonics from 1 to 31 0 - 100%

VBC Harmonics from 1 to 31 0 - 100%

VCA Harmonics from 1 to 31 0 - 100%

Individual Harmonic Line to

Neutral Voltage Data

VAN Harmonics from 1 to 31 0 - 100%

VBN Harmonics from 1 to 31 0 - 100%

VCN Harmonics from 1 to 31 0 - 100%

Effective September 2013

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

10

EATON www.eaton.com

Table 8. Event Recording

Data

Number of

Events Saved

in Digitrip

Trip Unit j

Number of

Events Saved

in CAM

Modules jl Data Captured

Voltage and

Current Waveforms

Captured in

Digitrip Trip Unit j

Voltage and

Current Waveforms

Captured in CAM

Modules jl

Summary 60 200 _ _

Power Up Event Type

Time Stamp

Setpoint Download

TIme Adjustment

Trip

Alarm

Enter Test Mode

Exit Test Mode

Test Complete

Plug Changed

Enter Maintenance Mode

Exit Maintenance Mode

Closed by Communications

Opened by Communications

Trip (Prime)

20 k 100 max n

3 5

Long Delay Time Stamp

Status: Primary, Secondary and Cause

Currents: IA, IB, IC, IN, IG

Voltage: VAB, VBC, VCA, VAN, VBN, VCN

Power: Watts, VAR, VA

THD: IA, IB, IC

Demand: IA, IB, IC, IN, Watts, VAR, VA

Frequency

Operations Count

Temperature

Power Factor

IA, IB, IC, IN, IG,

VAB, VBC, VCA

10 cycles - 6 pre-event

and 4 post event

IA, IB, IC, IN, IG,

VAB, VBC, VCA

10 cycles - 6 pre-event

and 4 post event

Short Delay

Instantaneous

Ground

Phase Loss

Current Unbalance

Over Voltage

Under Voltage

Voltage Unbalance

Reverse Power

Over Frequency

Under Frequency

Maintenance Mode

Neutral

Trip (Basic) Time Stamp

Status: Primary, Secondary and Cause

Currents: IA, IB, IC, IN, IG

Voltage: VAB, VBC, VCA, VAN, VBN, VCN

Power (Watts, VAR, VA)

THD: IA, IB, IC

Demand: IA, IB, IC, IN, Watts, VAR, VA

Frequency

Operations Count

Temperature

Power Factor

_ _

Missing Plug

Communication Initiated

Test Initiated

Over-Temperature

Making Current Release

On-demand Harmonic

Waveform Capture

1 1 Currents: IA, IB, IC, IN, IG

Voltage: VAB, VBC, VCA, VAN, VBN, VCN)

IA, IB, IC, IN, IG,

VAB, VBC, VCA, VAN,

VBN, VCN

1 cycle

IA, IB, IC, IN, IG,

VAB, VBC, VCA, VAN,

VBN, VCN

1 cycle

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Effective September 2013

Instructional Leaet IL01301064E

11

EATON www.eaton.com

j All event buffers and waveforms are stored in a serial sequence retaining the most recent data.

k Data buffers from the event are retained independent of whether waveform data was or could be captured at the time of the event.

l Data is approximate for most styles of CAM module. Consult the specific CAM module literature for more information.

m Discrete logging data is not stored and not viewable in the display module.

n Prime and Basic events share the same memory space. The maximum number stored will dependent upon the maximum number received of each event.

Table 9. Event Recording (continued)

Data

Number of

Events Saved

in Digitrip

Trip Unit j

Number of

Events Saved

in CAM

Modules jl Data Captured

Voltage and

Current Waveforms

Captured in

Digitrip Trip Unit j

Voltage and

Current Waveforms

Captured in CAM

Modules jl

Alarm (Prime)

20 k 100 max n

3 8

Long Delay Pick-up Time Stamp

Status: Primary, Secondary and Cause

Currents: IA, IB, IC, IN, IB

Voltage: VAB, VBC, VCA, VAN, VBN, VCN

Power: Watts, VAR, VA

THD: IA, IB, IC

Demand: IA, IB, IC, IN, Watts, VAR, VA

Frequency

Operations Count

Temperature

Power Factor

IA, IB, IC, IN, IB,

VAB, VBC, VCA

6 cycles

IA, IB, IC, IN, IG,

VAB, VBC, VCA

6 cycles

Current Unbalance

Ground Fault

Incomplete Contact Close

High Load

Neutral Current

Phase Rotation

Over Voltage (Line to Line)

Under Voltage (Line to Line)

Voltage Unbalance (Line to Line)

Over Frequency

Under Frequency

Low Power Factor

Reverse Power

Apparent Power Demand

Power Demand

THD

Alarm (Basic) Time Stamp

Status: Primary, Secondary and Cause

_ _

Calibration Alarm

Setpoint Fault

RAM Fault

ROM Fault

RTC Error

NV Memory Error

Watchdog Timer Operation

ADC Calibration Error

Long Delay Pick-up (test mode)

Ground Fault (test mode)

Trip Actuator Fault

Operations Count

Low Control Voltage

Trend Logging

0 m

50 Forward Active Energy

Reverse Active Energy

Apparent Energy

_ _

Energy Log

Time Adjustment 20 200 Previous Time

New Time

_ _

Real Time Clock Change

Effective September 2013

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

12

EATON www.eaton.com

Section 3: General description

Series NRX Circuit Breakers

Series NRX circuit breakers are tripped automatically on

overload and fault current conditions by the combined action of

three components:

1. The current sensors, which provide lower-level signals to the

Digitrip trip unit.

2. The Digitrip trip unit, which measures the signals from the

sensors, and when the levels and time delay settings are

exceeded will provide a tripping signal to the trip actuator.

3. The low-energy trip actuator, which converts electrical

energy to mechanical energy to trip the circuit breaker.

The automatic overload and short circuit tripping characteristics

for a specific circuit breaker are determined by the rating plug

and the selected functional protection settings.

When the functional protection settings are exceeded, the

Digitrip unit supplies a trip signal to the trip actuator. As

a result, all tripping operations initiated by the protection

functions are performed by its internal circuitry. There is no

mechanical or direct magnetic action between the primary

current and the mechanical tripping parts of the circuit breaker,

and external control voltage is not required

for basic current protection functionality.

• WARNING

IMPROPER POLARITY CONNECTIONS ON THE TRIP ACTUATOR COIL

TO THE DIGITRIP TRIP UNIT WILL DEFEAT THE OVERLOAD AND

SHORT CIRCUIT PROTECTION, WHICH COULD RESULT IN PERSONAL

INJURY. OBSERVE POLARITY MARKINGS ON THE TRIP ACTUATOR

LEADS IF LEADS OR CONTACTS ARE EVER REMOVED.

Low-energy trip actuator

The mechanical force required to initiate the tripping action of

Series NRX circuit breakers is provided by a special low-energy

trip actuator. The circuit breaker mechanism assembly contains

a mechanism-actuated reset lever and a trip lever to actuate the

tripping action of the circuit breaker.

Digitrip trip units

The Digitrip 1150/1150i trip units are circuit breaker subsystems

that provide the protective functions of a circuit breaker. The

trip units are in removable housings, installed in the breaker,

and can be replaced or upgraded in the field by the customer.

All trip unit models are microprocessor-based AC protection

devices that provide true RMS current sensing for the proper

coordination with the thermal characteristics of conductors

and equipment. The primary function of the trip unit is circuit

protection. The Digitrip unit analyzes the secondary current

signals from the circuit breaker current sensors. When current

level and time delay settings are exceeded, the Digitrip trip unit

will send an initiating trip signal to the trip actuator of the circuit

breaker.

The Digitrip trip unit system consists of 3 modules, the

frame, the trip unit and the display. The frame module is

fixed to the circuit breaker. This module is matched to the

frame interruption rating of the circuit breaker and should

not be changed. The trip unit module contains the Digital

Signal Processor (DSP) that performs the measurements and

calculations for protection and metering. The display module

is the user interface and requires external control power to

operate. The trip unit does not require the display module to be

operational to perform any of the protective functions.

The current sensors consist of two coils; one coil on an iron

core and one coil on an air core (Rogowski) (Figure 3). As

current begins to flow through the circuit breaker, the iron core

coil generates a secondary current which powers the trip unit.

At the same time, the air core coil provides signal values which

are processed by the electronic circuitry.

Figure 3. Series NRX NF Frame Phase Current Sensor

Protection

Each trip unit is completely self-contained and requires no

external control power to operate its current protection system

functions. It operates from power and current signal levels

derived through sensors mounted in the circuit breaker. To

satisfy the protection needs of any specific installation, the

exact selection of the available protection function adjustments

should be set by the user.

Ground fault sensing schemes

When the trip unit includes ground fault protection features, the

distribution system characteristics (such as system grounding,

number of sources, and number and location of ground points)

must be considered along with the manner and location in

which the circuit breaker is applied to the system.

The Digitrip trip unit can use one of three modes of sensing

to detect ground fault currents: residual, source ground, and

zero sequence. 3-pole and 4-pole Series NRX circuit breakers

can accom modate all three types of sensing. A jumper

connection on the circuit breaker secondary contact inputs is

used to select either internal residual ground fault sensing or an

external sensor for source ground or zero sequence schemes.

If a Communications Adapter Module (CAM) is used the jumper

is located on the CAM module not on the circuit breaker

terminal contacts.

If there is no jumper from contacts 19 to 20 of the circuit

breaker the trip unit will be programmed for a residual ground

fault scheme. The jumper from 19 to 20 programs the trip unit

for either a source ground or zero sequence configuration. In

all three schemes, the proper current sensor is required ( Table

10).

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Effective September 2013

Instructional Leaet IL01301064E

13

EATON www.eaton.com

Mode of trip and status information

All trip units have a tricolored light-emitting diode (LED), labeled

STATUS that could light green, red or orange. The LED will blink

green approximately once each second to indicate the trip unit

is operating normally. This Status LED will blink at a faster rate

if the Digitrip is in a pick-up or overload condition.

The Digitrip has the ability to detect a problem with nonvolatile

memory or if the trip actuator coil is an open circuit, or if there

is a circuit breaker mechanism problem. Depending upon the

state and the status of power to the trip unit when a problem is

detected, the Status LED will light red or flash red or orange.

There are LEDs on the face of the trip units (for INST, LONG,

SHORT, and GROUND) that flash red to indicate the cause or

trip mode for an automatic trip operation. A battery located in

the Frame Module maintains the trip indication until the Reset/

Battery Test button is pushed. The battery is good if the LED

lights green when the Battery Check button is pushed (see

Section 9: Trip unit battery).

ote:N The trip unit provides all protection functions regardless of the

status of the battery. The battery is only needed to maintain the cause

of trip indication during a power loss condition.

Trip Unit Installation

The Digitrip trip units are designed as a field replaceable

unit. To mount the Digitrip trip unit align it with the two guide

grooves of the Series NRX circuit breaker. Keep it parallel with

the receiving, molded deck plate. Press the unit into the circuit

breaker until the trip unit seats firmly into the receiving housing

and the two latching tabs click into place.

Figure 4. Trip Unit Installation on a Frame Module

Rating Plug Installation

Insert the rating plug into the cavity on the right side of the trip

unit. Wiggle the plug slightly to help align the pins on the plug

with the sockets in the cavity. The plug should engage with a

slight insertion force when it is approximately 3/16-inch (4 mm)

above the Digitrip. When this occurs, tighten the mounting

screw to its stop positions. 4 turns should be sufficient.

• CAUTION

IF A RATING PLUG IS NOT INSTALLED IN THE TRIP UNIT, THE UNIT

WILL INITIATE A TRIP WHEN IT IS ENERGIZED.

Figure 5. Installation of the Rating Plug into the Trip Unit

ote:N Rating plugs are keyed to circuit breaker frame groups. If the

wrong rating plug is used it will not engage and properly tighten down

to the circuit breaker frame, see Section 10: Frame ratings and rating

plugs for the tables of available rating plugs.

• CAUTION

DO NOT FORCE THE RATING PLUG INTO THE CAVITY.

Use a 1/8-inch (3 mm) wide screwdriver to tighten the

mounting screw and secure the plug and the trip unit to the

circuit breaker.

• CAUTION

THE RATING PLUG SCREW SHOULD BE TIGHTENED ONLY UNTIL IT

STOPS. DO NOT USE A LARGE SCREWDRIVER. A 1/8-INCH (3 MM)

WIDE SCREWDRIVER BLADE IS ADEQUATE.

Trip unit/rating plug removal

To remove the rating plug from the trip unit, use a 1/8-inch (3

mm) wide screwdriver to loosen the screw. It will take about

four turns to release it. Pry up the top or bottom side lips of the

rating plug to pull it away from the trip unit.

To remove the trip unit from the circuit breaker’s Frame Rating

Module, break the factory seal, deflect the two locking tabs,

and pull to release the unit from the frame module mounting

plate. Pull the unit to disengage the molded, 24-pin connector

from the frame module printed circuit board. (See Figure 6 and

Figure 7.)

Effective September 2013

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

14

EATON www.eaton.com

Figure 6. Trip Unit Locking Tabs

Figure 7. Frame Module With Trip Unit Removed

Wiring

The internal components of the circuit breaker and how

they are wired internally and externally to the circuit breaker

secondary contacts are shown in the master connection

diagrams. See “Section 12: References” for the number of

the Technical Document that contains the Series NRX circuit

breaker master connection diagrams.

Plexiglass cover

A clear, tamper-proof, plexiglass cover fits on the Digitrip.

This cover allows the settings to be viewed but not changed

(except by authorized personnel). The plexiglass cover meets

applicable tamper-proof requirements. Security is ensured by

the insertion of a standard meter seal wire through the thumb

screw holes. The plexiglass cover denies access to the SAVE

pushbutton to prevent unauthorized access to change settings.

Auxiliary voltage requirements

When the circuit breaker is wired for external 24 Vdc input,

it will provide an auxiliary voltage supply so that the Digitrip

graphic Liquid Crystal Display (LCD) will be functional. A

Digitrip 1150 trip unit without auxiliary voltage will not display

any data on the display. The burden of the trip unit is 6 watts.

If a CAM module is used the 24 Vdc input is connected to the

CAM terminal block. The CAM will then provide an isolated

supply for the trip unit which allows the external power supply

to be used for both trip unit power and communications power.

ote:N All current protection features will be active when the current

breaker load current reaches approximately the following levels.

Single Phase Three Phase

NF Frame 200A 50A

RF Frame 400A 100A

Display

The Digitrip 1150 trip unit is equipped with a color graphic Thin

Film Transistor Liquid Crystal Display (TFT-LCD). The display

has 1/4 VGA resolution capability for a sharp color and graphical

interface to the user. The display has LED back lighting

capability which incorporates 3 redundant LEDS in parallel.

The display has a power saver feature that after 10 minutes of

inactivity will blank the screen. The power saver mode will then

flash a display showing the present screen menu for 2 seconds,

and then turn blank for 10 seconds. If any pushbutton is

pressed the display will go back to the screen that was diplayed

last before the 10 minute inactivity period occurred.

Standards

The Digitrip 1150/1150i trip units are listed by Underwriters

Laboratories Inc. for use in Series NRX-NF and Series NRX-

RF circuit breakers. These same units are also listed by the

Canadian Standards Association (CSA).

All Digitrip units have also passed the IEC 60947-2 test program

that includes EMC testing according to Appendix F. As a result,

all units meet the low voltage and EMC directives and carry the

CE mark.

Effective September 2013

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Pry Locking

Tabs Open

15

EATON www.eaton.com

16

EATON www.eaton.com

Section 4: Principles of operation

General

All models of trip units are designed for industrial circuit

breaker environments where the ambient temperatures can

range from –20°C to +85°C but rarely exceed 70°C to 75°C. If,

however, temperatures near the trip unit exceed this range,

the trip unit performance may be degraded. In order to ensure

that the tripping function is not compromised due to an over-

temperature condition, the microcomputer chip has a built-in

over-temperature protection feature, factory set to trip the

circuit breaker if the trip unit temperature is excessive. If over-

temperature is the reason for the trip, the LONG LED will flash

on and off with an orange color.

The Digitrip uses an integrated circuit that includes a Digital

Signal Processor (DSP) to perform its numeric and logic

functions. A block diagram of the major components of

operation of the trip unit are shown in Figure 8.

All sensing and tripping power required to operate the current

protection functions is derived from the current sensors in

the circuit breaker. The signals from these sensors provide the

correct input information for the protection functions, as well as

tripping power, whenever the circuit breaker is carrying current.

The DSP microcomputer continually digitizes the signals from

the sensors even when the circuit breaker is open. This data is

used to calculate the true RMS current values, which are then

continually compared with the protection function settings and

other operating data stored in the memory. The trip unit then

determines whether to initiate protection functions, including

tripping the circuit breaker using the trip actuator.

Trip and operation indicators

The LEDs on the face of the trip unit, shown in Figure 12,

flash red or orange to indicate the reason for any automatic trip

operation. Following an automatic trip operation, the backup

battery continues to supply power to the LEDs. An LED pulse

circuit is provided to reduce battery burden and will flash a trip

LED approximately once every four seconds. It is therefore

important to view the unit for at least five seconds to observe a

flashing cause of trip indicator.

Following a trip operation, push the Reset/Battery Test button to

turn off the cause of trip LED.

A Status LED, shown in Figure 12, indicates the operational

status of the trip unit. Once the load current through the circuit

breaker exceeds approximately 50A (NF Frame) or 100A (RF

Frame) three phase power, the green LED will flash on and off

once each second to indicate that the trip unit is energized and

operating properly.

Note: A steady green STATUS LED typically indicates a low level

of circuit breaker load current indicating that the trip unit is not fully

powered up.

Alarm LED

An orange Alarm LED is provided to indicate real-time alarm

conditions are existing on the power system. See Appendix

D: Display, Indicators and Menus for the programing of these

alarms. If an unusual condition is detected within the Digitrip’s

hardware or firmware, this LED will light with a message on the

display indicating the type of alarm.

Effective September 2013

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

PT

Module

Com

Com

+

24 V dc

–

+

24 V dc

–

Analog

Circuits

Voltage Signals

Figure 8. Block Diagram With Breaker Interface

Trip LED

The Trip LED is illuminated upon any trip condition. It is also

a real-time display and incorporates the circuit breaker’s 52b

auxiliary switch (also called MCR switch) input for its logic.

Pushing the Reset pushbutton or closing the circuit breaker will

clear this LED.

Making current release (MCR)

All trip units styles have a making current release function.

This safety feature prevents the circuit breaker from being

closed and latched-in on a faulted circuit. The NRX NF Frame is

equipped with a nonadjustable release that is preset to pick up

at a peak current of 45,000A. The release level of the RF Frame

is preset to 36,000A for 1600A frame ratings, 56,000A for

2000A and 2500A frame ratings, and 90,000A for 4000A frame

ratings. The level is set by the sensors, frame module, and the

trip unit of the circuit breaker.

The MCR is enabled only for the first two cycles following the

initial circuit breaker closing operation. The MCR circuit will trip

the circuit breaker instantaneously with no intentional delay and

flash the instantaneous (INST) red LED.

High instantaneous

All Series NRX NF frame modules have a high instantaneous

withstand trip feature. Some Series NRX RF frame modules

will have the high instantaneous feature if specified.

This element is always active even when the customer

instantaneous adjustment is set to the OFF position. The high

instantaneous is a separate analog peak detecting circuit that

is set in the frame rating module of the circuit breaker. It will

initiate a trip at a current peak set to match the withstand rating

of the circuit breaker frame. A trip from this feature will be

indicated by flashing the red instantaneous (INST) LED. For

additional information regarding high instantaneous trip levels,

consult the time current curves for the R-Frame breaker located

in publication AD0130100SE.

Ground current sensing schemes

Depending upon the installation requirements, alternative

ground fault sensing schemes may be dictated. The Digitrip

1150 trip units can accommodate one of three different

schemes of sensing.

Ground fault alarm

A ground fault alarm is one of many possible programmable

alarms and can provide an early warning of a ground fault

condition through an alarm LED. In addition, this trip unit can

be programmed to energize an alarm relay upon this condition.

The alarm relay will reset automatically if the ground current is

less than the Ground Alarm Pickup setting.

The Digitrip 1150 provides a greater flexibility in the use of

ground current alarms. If the Ground Alarm option has been

enabled on the LSIA, RLSIA, LSIG, or RLSIG style trip units,

a red Alarm LED will indicate the presence of ground current

when it is in excess of the Ground Alarm setting. See Table

4 for the specifications on all settings for all of the alarms. A

programmed alarm relay (Relay 1 or 2) will be energized when

the ground current continuously exceeds the ground alarm

setting for a time in excess of 0.1 second. The alarm relay will

reset automatically if the ground current reduces to a value less

than the ground fault pickup setting.

Ground fault trip alarm

On LSIG and RLSIG style trip units, Relay 1 and Relay 2 can be

programmed as a trip relay to indicate when the circuit breaker

trips on a ground fault. You must then push the Reset button in

order to reset the relay contact.

Residual ground current sensing

Residual sensing is the standard mode of ground fault sensing

in Series NRX circuit breakers. This mode uses one current

sensor on each phase conductor and one on the neutral for a

four-wire system. If the system neutral is grounded, but no

phase to neutral loads are used, the Digitrip trip unit includes

all of the components necessary for ground fault protection.

This mode of sensing vectorially sums the outputs of the three

or four individual current sensors. If the vectorial sum is zero,

then no ground fault exists. Residual ground fault sensing

features are adaptable to main and feeder circuit breaker

applications. If an external neutral sensor is used with reverse

feed breaker applications, the proper polarity of the neutral

needs to be considered.

• CAUTION

ALWAYS OBSERVE THE POLARITY MARKINGS ON THE INSTALLATION

DRAWINGS. IF THE NEUTRAL SENSOR CONNECTIONS ARE

INCORRECT, A NUISANCE TRIP MAY OCCUR.

To ensure correct ground fault equipment performance and

compliance, conduct field testing as required to comply with

country or regional requirements.

Source ground sensing

The ground return method is usually applied when ground fault

protection is desired only on the main circuit breaker in a simple

radial system. This method is also applicable to double-ended

systems where a mid-point grounding electrode is employed.

For this mode of sensing, a single current sensor mounted on

the equipment-bonding jumper will directly measure the total

ground current flowing in the grounding electrode conductor.

Applying the source ground jumper will enable this protection.

ote:N When using a Communication Module (see Section 14:

Communications), the enabling of source ground mode is done via the

position of the jumper located on this module.

Zero sequence sensing

Zero sequence sensing, also referred to as vectorial

summation, is applicable to mains, feeders, and special

schemes involving zone protection.

17

EATON www.eaton.com

Effective September 2013

Instructional Leaet IL01301064E

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Figure 9. Series NRX RF Frame Neutral Sensor

Figure 10. Series NRX NF Frame Neutral Sensor

Zone selective interlocking (optional)

The zone selective interlocking function is an option when

ordering the Series NRX circuit breaker. The circuit breakers

that are built with the zone interlocking function ordered will

have three wires (Zout, Zcom, Zin) connected to secondary

contacts (27, 28, 29). These contacts can then be wired for

zone interlocking to other circuit breakers above and below in

the other zones.

Table 10. Series NRX/Digitrip Ground Fault Sensing Modes

Ground (Earth)

Sensing Method Sensor Style IZMX Type Code

Breaker Secondary

Contacts - if no

CAM module

Optional

CAM Module

Jumper Position

Neutral Input

Contacts

Ground Sensor

Input Contacts

Residual NF Frame 5721B76G12 IZMX-CT16-N No jumper Disable position 15 ,16 -

Residual RF Frame 70C1718G11 IZMX-CT40-N No jumper Disable position 15 ,16 -

Source ground 70C1527G14 IZMX-CT-NGS Jumper 19 to 20 Enable position - 17 ,18

Zero sequence 70C1527G14 IZMX-CT-NGS Jumper 19 to 20 Enable position - 17 ,18

ote:N This information applies to only trip units with ground fault or ground protection.

Zone selective interlocking is available on the SHORT delay and

GROUND fault protection functions. The zone interlocking, if

supplied, is wired via a single set of three wires labeled Zone

In (Zin) and Zone Out (Zout) along with a zone common wire.

The zone selective interlocking function has combined the logic

interlocking of SHORT delay and GROUND fault in one signal.

A zone out signal is sent whenever the ground fault pickup is

exceeded or when the short delay value of 2 x (Ir) is exceeded.

This provides maximum selectivity for coordination with larger

upstream circuit breakers. Zone selective interlocking provides

the fastest possible tripping for faults within the zone of

protection of the circuit breaker and yet also provides positive

coordination among all circuit breakers in the system (mains,

ties, feeders, and downstream circuit breakers). When zone

interlocking is employed, a fault within the zone of protection of

the breaker will:

• Trip the affected circuit breaker immediately.

• Send a signal to upstream Digitrip units to restrain from

tripping immediately. The restraining signal causes the

upstream circuit breakers to follow their set coordination

time delays, so that the service is interrupted to the

isolated fault area only while the fault is cleared in the

shortest time possible.

For an example of how zone selective interlocking may be used,

see Appendix A: Zone Selective Interlocking Examples of

this manual.

Diagnostics indicator—circuit breaker/trip unit

The Digitrip trip unit has LEDs for diagnostic reasons. The

Status LED is bicolored. A normally powered trip unit will flash

the green status at a 1 second repetition rate. The Status LED

will flash red and orange if a problem is encountered in any of

the following scenarios:

• Internal self test problem

• MCR auxiliary switch or circuit breaker mechanism is in an

improper state

• Trip actuator (TA) coil circuit is open

This LED status is indication of an issue that needs attention

as soon as possible (see Appendix B: Troubleshooting). In

addition, the Digitrip units provide a relay contact that can

provide a diagnostic alarm signal externally.

18

EATON www.eaton.com

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Effective September 2013

Instructional Leaet IL01301064E

Potential Transformer module

The PT (potential or voltage transformer) module is external to

the circuit breaker on the NRX NF frame. It may be externally

mounted or internally mounted and wired in the NRX RF frame

circuit breaker to the line side circuit breaker terminals. It

provides the signals to measure the system voltage. These

input signals are used to measure voltage and calculate; power,

energy, and if selected, perform protection functions on voltage

and frequency. The PT module is a three-phase, three-wire

input and a four-wire output step-down transformer with a wye

to wye configuration.

The power and energy metering and protection functions are

calculated with the convention that power flow is from line to

load through the circuit breaker. This assumes the top side

conductor to be the line side. If the distribution system is

configured such that the bottom side is the incoming side, the

power values will indicate reverse power. This can be changed

via setpoint programming.

Trip Events

1. Observe any Trip LED flashing on trip unit.

2. Observe message on the display.

3. Step to the event submenu to observe the timestamp

of event and trip current data. This data, along with the

timestamp, will also be stored in the event log. The maximum

trip current value that can be displayed is 65535A.

4. After any trip condition, the trip unit should be reset by

pressing the Reset pushbutton

A reset pushbutton operation does the following after a trip:

• Clears the cause of trip flashing LED after a trip event

• Clears the Trip LED

• Clears display data

5. Reclose circuit breaker as desired.

See Appendix D: Display, Indicators and Menus for more

information on viewing trip events and screen information that

can be viewed after the event

Waveform capture - Trip

The following causes for a trip will perform a 10 cycle waveform

capture. The waveform information will contain 6 pre-event

cycles and 4 post-event cycles of data.

• Long Delay

• Short Delay

• Instantaneous

• Ground

• Phase Loss

• Current Unbalance

• Over Voltage

• Under Voltage

• Voltage Unbalance

• Reverse Power

• Over Frequency

• Under Frequency

• Maintenance Mode

• Neutral

19

EATON www.eaton.com

Alarm Events

1. Alarm LED flashing on trip unit.

2. Observe message on the display.

3. Step to the event submenu to observe the timestamp of

event and data. This data, along with the timestamp, will also

be stored in the event log.

4. After any alarm condition, the trip unit should be reset by

pressing the Reset pushbutton

See Appendix D: Display, Indicators and Menus for more

information on viewing alarm events and screen information

that can be viewed after the event.

Alarms are tracked in real-time and a Reset pushbutton may

momentarily clear the alarm but the Alarm LED and alarm

message will reappear if the condition is still present.

The ESCape pushbutton activation will remove the alarm

message from the display and return to normal menu viewing

mode, but the Alarm LED will remain lit.

ote:N A way to clear an alarm if desired, after reviewing the alarm

and its associated data, is to enter the Program settings submenu and

change or turn off the associated alarm setpoint value.

Waveform capture - Alarms

The following alarms will perform a 6 cycle waveform capture:

• Long Delay Pickup

• Current Unbalance

• Ground Fault

• High Current Fault

• High Load

• Neutral Current

• Phase Rotation

• Over Voltage

• Under Voltage

• Voltage Unbalance

• Over Frequency

• Under Frequency

• Low Power Factor

• Reverse Power

• kVA Demand

• kW Demand

• THD

Effective September 2013

Instructional Leaet IL01301064EOperating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Trip Unit Indicators

Status Indicator – A red and green colored LED can be

switched on to produce colors of green, red or orange for this

indicator. When the trip unit is healthy and operational with

auxiliary power or current through the circuit breaker that is

greater than 50A (NF Frame) or 100A (RF Frame) three phase,

the indicator will ash green at a 1 second (1 Hz) rate. If the

trip unit is picked up in long delay overload protection, the

green LED will ash at twice the speed of the normal status

indication. When an abnormal condition is detected in the

circuit breaker the trip unit will turn on the red status LED

creating a red then orange ashing color from the indicator.

This Status LED indication can occur if an abnormal condition

is detected in the circuit breaker, trip actuator, or an internal

electronic validation check has failed.

Maintenance Mode Indicator (optional) – A blue colored LED

will be illuminated whenever the ARC FLASH MAINTENANCE

MODE protection circuit is active.

Long Indicator – A red colored LED that ashes when a long

delay protection overload trip has occurred. An orange colored

LED will be illuminated and ashing to indicate if an over-

temperature trip has occurred.

Metering

Current

Voltage

Power

Energy

Frequency

SEL

SAVE

ESC

Status

Maint. Mode

Long

Short

Inst.

Ground

Trip

Type NF Frame

Group A

Rating Plug

In=400A

Cat NA250T

Test

Port

Aux.

Power

Alarm

+

Battery

-

CR 1/3N

DL 1/3N

Battery Check

Reset/

Bettery Test

Metering

Current

Voltage

Power

Energy

Frequency

SEL

SAVE

ESC

Status

Maint. Mode

Long

Short

Inst.

Ground

Trip

Type NF Frame

Group A

Rating Plug

In=400A

Cat NA250T

Test

Port

Aux.

Power

Alarm

+

Battery

-

CR 1/3N

DL 1/3N

Battery Check

Reset/

Bettery Test

Figure 12. Trip Unit Indicators (LSIG style with Maintenance

Mode)

20

EATON www.eaton.com

Section 5: Display Module Interface

Display

The Digitrip 1150 trip unit has a graphic color LCD display on

the front of the trip unit. The self contained display module

holds the LCD display and the push buttons that interface to

the trip unit as shown in Figure 11.

The Digitrip 1150 trip unit will be operational in the event

that something on the display module is not functional or

is removed. All protective setpoints are stored in the main

trip unit body. If any one of the Communication Accessory

Modules (CAM) is used with the Digitrip 1150, a duplicate

copy of the setpoints may be stored in that module as well

as the trip unit body.

Figure 11. Trip Unit and Display Module

Operating Manual for Series NRX

Digitrip Trip Units 1150 / 1150i

Effective September 2013

Instructional Leaet IL01301064E

/