Instructions-Parts

InvisiPac® InvisiPac®

InvisiPac®

GS35 GS35

GS35

Plug-Free™ Plug-Free™

Plug-Free™

Hot Hot

Hot

Melt Melt

Melt

Applicator Applicator

Applicator

3A2805M

EN

For For

For

dispensing dispensing

dispensing

hot hot

hot

melt melt

melt

adhesive. adhesive.

adhesive.

For For

For

professional professional

professional

use use

use

only. only.

only.

Not Not

Not

for for

for

use use

use

in in

in

waterwash waterwash

waterwash

environments. environments.

environments.

Not Not

Not

approved approved

approved

for for

for

use use

use

in in

in

explosive explosive

explosive

atmospheres atmospheres

atmospheres

or or

or

hazardous hazardous

hazardous

locations. locations.

locations.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanual.Savethese

instructions.

1500 psi (10.3 MPa, 103 bar) Maximum

Working Fluid Pressure

80 psi (0.5 MPa, 5.5 bar) Maximum Air

Pressure

See page 6 for models and approval

information.

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents Contents

Contents

Warnings...........................................................3

Approvals...........................................................5

Models...............................................................6

ComponentIdentication.....................................7

Overview............................................................8

Grounding..........................................................8

Installation..........................................................9

Mounting.....................................................9

ConnectHeatedHose..................................9

ConnectSolenoidValve...............................9

ConnectTriggeringDevice...........................10

PrimeBeforeUsingEquipment.....................10

Flush...........................................................11

InstallNozzle...............................................11

SelectRTD..................................................11

Operation...........................................................12

PressureReliefProcedure............................12

Maintenance......................................................13

ReplaceInletFilter.......................................13

FilterMaintenanceGuidelines.......................13

Troubleshooting..................................................14

CheckModule..............................................16

CheckNozzleandModule............................16

CheckHeater..............................................17

CheckRTD..................................................17

CheckThermalCutoff..................................18

Repair................................................................19

BeforeBeginningRepair...............................19

ReplaceHeaterCartridge.............................20

ReplaceRTD...............................................20

ReplaceThermalCutoff................................20

ReplaceCordset..........................................22

ReplaceSolenoidValve...............................24

ReplaceModule...........................................24

ReplaceApplicator.......................................24

Notes................................................................25

Parts..................................................................26

KitsandAccessories...........................................44

Dimensions........................................................46

TechnicalData...................................................50

Notes................................................................51

GracoExtendedWarranty...................................52

2

3A2805M

Warnings

Warnings Warnings

Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING WARNING

WARNING

BURN BURN

BURN

HAZARD HAZARD

HAZARD

Equipmentsurfacesanduidthat’sheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

ELECTRIC ELECTRIC

ELECTRIC

SHOCK SHOCK

SHOCK

HAZARD HAZARD

HAZARD

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

SKIN SKIN

SKIN

INJECTION INJECTION

INJECTION

HAZARD HAZARD

HAZARD

High-pressureuidfromdispensingdevice,hoseleaks,orrupturedcomponentswillpierce

skin.Thismaylooklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

Get

immediate immediate

immediate

surgical surgical

surgical

treatment. treatment.

treatment.

•Donotpointdispensingdeviceatanyoneoratanypartofthebody.

•Donotputyourhandovertheuidoutlet.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenyoustopdispensingandbeforecleaning,

checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

3A2805M 3

Warnings

WARNING WARNING

WARNING

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Flammablefumes,suchassolventandpaintfumes,inwork work

work

area area

area

canigniteorexplode.Tohelp

preventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

Grounding

instructions.

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.Donotusepaillinersunless

theyareantistaticorconductive.

•Stop Stop

Stop

operation operation

operation

immediately immediately

immediately

ifstaticsparkingoccursoryoufeelashock. .

.

Donotuse

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

EQUIPMENT EQUIPMENT

EQUIPMENT

MISUSE MISUSE

MISUSE

HAZARD HAZARD

HAZARD

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnicalData

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenequipmentisnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

4

3A2805M

Approvals

WARNING WARNING

WARNING

TOXIC TOXIC

TOXIC

FLUID FLUID

FLUID

OR OR

OR

FUMES FUMES

FUMES

HAZARD HAZARD

HAZARD

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadMSDSstoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL PERSONAL

PERSONAL

PROTECTIVE PROTECTIVE

PROTECTIVE

EQUIPMENT EQUIPMENT

EQUIPMENT

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisprotective

equipmentincludesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

Approvals Approvals

Approvals

4002346 4002346

4002346

ConformstoANSI/ULStd.

499CertiedtoCAN/CSA

Std.C22.2No.88

3A2805M 5

Models

Models Models

Models

Allmodelsusea240Vheater.Additional

congurationsareavailable.ContactGracocustomer

servicefordetails.

Note

ApplicatorswithNi120RTDtypescomewith

a6–pinrectangularcordset(24W088).See

Parts,page26.

Single Single

Single

Part Part

Part

Series Series

Series

RTD RTD

RTD

Type Type

Type

Solenoid Solenoid

Solenoid

Valve Valve

Valve

24P073B

Pt100(385)24VDC

24P074B

Pt100(385)110VAC

24P246B

Pt100(385)

None

24P299BNi120

24VDC

24P300BNi120

110VAC

24P307BNi120None

Slim Slim

Slim

(Single) (Single)

(Single)

Part Part

Part

Series Series

Series

RTD RTD

RTD

Type Type

Type

Solenoid Solenoid

Solenoid

Valve Valve

Valve

24U021B

Pt100(385)24VDC

24U022B

Pt100(385)110VAC

24U023B

Pt100(385)

None

24U024BNi120

24VDC

24U025BNi120

110VAC

24U026BNi120None

Dual Dual

Dual

Part Part

Part

Series Series

Series

RTD RTD

RTD

Type Type

Type

Solenoid Solenoid

Solenoid

Valve Valve

Valve

24P075B

Pt100(385)24VDC

24P076B

Pt100(385)110VAC

24P247B

Pt100(385)

None

24P301BNi120

24VDC

24P302BNi120

110VAC

24P308BNi120None

Low Low

Low

Prole Prole

Prole

- -

-

Dual Dual

Dual

Part Part

Part

Series Series

Series

RTD RTD

RTD

Type Type

Type

Solenoid Solenoid

Solenoid

Valve Valve

Valve

24U027B

Pt100(385)24VDC

24U028B

Pt100(385)110VAC

24U029B

Pt100(385)

None

24U030BNi120

24VDC

24U031BNi120

110VAC

24U032BNi120None

Quad Quad

Quad

Part Part

Part

Series Series

Series

Module Module

Module

Spacing Spacing

Spacing

Type* Type*

Type*

RTD RTD

RTD

Type Type

Type

Solenoid Solenoid

Solenoid

Valve Valve

Valve

24P077BI

Pt100(385)24VDC

24P078BI

Pt100(385)110VAC

24P079BII

Pt100(385)24VDC

24P080BII

Pt100(385)110VAC

24P250BI

Pt100(385)

None

24P254BII

Pt100(385)

None

24P303BINi120

24VDC

24P304BINi120

110VAC

24P305BIINi120

24VDC

24P306BIINi120

110VAC

24P309BINi120None

24P310BIINi120None

*

See Dimensions, page 46 .

Low Low

Low

Prole Prole

Prole

- -

-

Quad Quad

Quad

Part Part

Part

Series Series

Series

RTD RTD

RTD

Type Type

Type

Solenoid Solenoid

Solenoid

Valve Valve

Valve

24U033B

Pt100(385)24VDC

24U034B

Pt100(385)110VAC

24U035B

Pt100(385)

None

24U036BNi120

24VDC

24U037BNi120

110VAC

24U038BNi120None

6 3A2805M

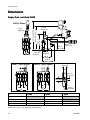

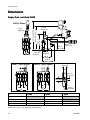

ComponentIdentication

Component Component

Component

Identication Identication

Identication

A

C

B

AD

E

F

G

H

J

M

K

K

L

N

P

Figure124P075Shown

ADispensemodule

B

Fluidoutlet/nozzle(3/8–24)

CFluidlter(notvisible)

D

Manifold

E

Fluidinlet(9/16–18,—6JIC,37°are)

F

Cordset(24W087shown)

G

Airtube

H

Mountingclamp(1/2in.diameterbar)

J

Solenoidvalve(24VDC,110VAC);not

includedwithallmodels

K

Mufer

L

Airinlet(3/8in.diametertubing)

MManualoverrideswitch

N

Solenoidvalveelectricalconnector

PInsulator

3A2805M

7

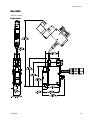

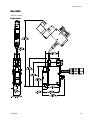

Overview

Overview Overview

Overview

Thevalveusestheair-opened,springclosedmode

ofoperation.Itusesathree-wayexhaustingsolenoid

tocontrolthepistoninsidethedispensemodule.

Fluidislteredthroughthemanifoldlter(C)before

enteringthedispensemoduleuidinletport.Then

theuidislteredonenaltimethroughthemodule

lter(P),whichislocatedineachmodule,directly

beforetheballandseat.

Whenairmovesthepistonrodandballfromitsseat,

itopenstheuidoutlet.Whentheairshutsoff,the

springpushesthepistonrodandballintoitsseatand

closestheuidoutlet.

Thegunshouldberigidlymountedandremotely

operatedbyameltersystemandtriggeringdevice.

Themeltersystemprovidespressurizeduidtothe

valve.Thetriggeringdevicecontrolstheuidowby

openingandclosingthesolenoidvalve.

C

P

Figure2AirandFluidFlow

Air Air

Air

Fluid Fluid

Fluid

Grounding Grounding

Grounding

Theequipmentmustbegroundedtoreducethe

riskofstaticsparking.Staticsparkingcancause

fumestoigniteorexplode.Groundingprovidesan

escapewirefortheelectriccurrent.

•Pump: Pump:

Pump:

followmanufacturer’srecommendations.

•Dispense Dispense

Dispense

applicator: applicator:

applicator:

groundedthroughelectrical

connection.

•Air Air

Air

compressor: compressor:

compressor:

followmanufacturer’s

recommendations.

•Fluid Fluid

Fluid

supply supply

supply

container: container:

container:

followlocalcode.

•Solvent Solvent

Solvent

pails pails

pails

used used

used

when when

when

ushing: ushing:

ushing:

followlocal

code.Useonlyconductivemetalpails,placed

onagroundedsurface.Donotplacethepail

onanonconductivesurface,suchaspaperor

cardboard,whichinterruptsgroundingcontinuity.

•To To

To

maintain maintain

maintain

grounding grounding

grounding

continuity continuity

continuity

when when

when

ushing ushing

ushing

or or

or

relieving relieving

relieving

pressure: pressure:

pressure:

ensuremountingmanifoldand

electricalpowerconnectoraregroundedproperly.

8 3A2805M

Installation

Installation Installation

Installation

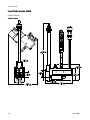

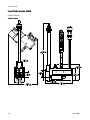

Mounting Mounting

Mounting

NOTICE NOTICE

NOTICE

Topreventheattransferringintoothercomponents

ofthepackagingline,ensurethattheinsulator(P)

isinstalled.

Low Low

Low

Prole Prole

Prole

Models: Models:

Models:

Usea3/4in.(19mm)wrenchto

adjustnutsthatcontrolpositionofgunassemblyon

threadedrod.

All All

All

Other Other

Other

Models: Models:

Models:

Seethefollowinginstructions.

Mountmanifoldona1/2in.(12mm)diameterbar

usingmountingclamp(H)toholdthegunassembly

inplaceandensureadhesiveisappliedproperly.

1.Usea5mmAllenwrenchtoloosenthemounting

clampandslidethegunassemblyonthe

mountingbar.

2.Tightenthemountingclamp.

Note

Provideenoughroomtoaccesssidesof

applicatorformaintenanceandrepair.

H

P

Figure3MountingClamp

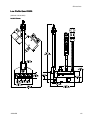

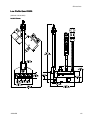

Connect Connect

Connect

Heated Heated

Heated

Hose Hose

Hose

1.Connectthehoseuidoutlettothemanifolduid

inlet(E).Usetwo11/16in.wrenchestotighten

thehosetting.

M

E

Figure4ConnecttheHeatedHose

2.Connectthecordset(M)tothehose.

3.Connectthehoseinlettothemeltersystem

outlet.Seetheheatedhosemanualfor

installationguidelines.

4.Connectthehosecordsettomelter.Seethe

heatedhosemanualforinstallationguidelines.

Connect Connect

Connect

Solenoid Solenoid

Solenoid

Valve Valve

Valve

1.Connect3/8in.diameterairsupplytubingtoa

clean,dry,andnon-lubricatedairsupplyandto

thepush-to-connectairinlettting(L).

L

Figure5AirInletFitting

2.Connectsolenoidvalveto24VDCor110VAC

signal.SeeConnectTriggeringDevice,page10.

For For

For

applicators applicators

applicators

without without

without

a a

a

supplied supplied

supplied

solenoid solenoid

solenoid

valve: valve:

valve:

•Usesolenoidvalveswithanoverrideswitch.

•Ensurethatyoursolenoidvalveisconnectedtothe

manifoldwithtubingratedfor400°F(204°C).

•Ensurethesolenoidvalveisratedfor

high-temperatureapplications.

3A2805M 9

Installation

Connect Connect

Connect

Triggering Triggering

Triggering

Device Device

Device

Identifyifyourmodelusesa24VDCor110VAC

solenoidvalve.Connectsolenoidvalveto24VDC

or110VACsignal.

Improperelectricalconnectioncanresultinelectric

shock.Allelectricalwiringmustbedonebya

qualiedelectricianandcomplywithalllocalcodes

andregulations.

1.Loosenthemountingscrewanddisconnectthe

electricalconnector(N)fromthesolenoidvalve

(J).Setthegasketandscrewaside.

J

N

P

Figure6SolenoidValveElectricalConnector

2.Insertasmallscrewdriverwherethemounting

screwwasremovedandgentlypressthe

electricalconnector(P)outoftheelectrical

connectorhousing(N).

3.Threadathree-conductorcablethroughthestrain

relief.Connectthepositiveandnegativewiresto

terminals1and2ontheelectricalconnector(P).

Connectthegroundwiretothegroundterminal.

Note

Itdoesnotmatterwhichterminal

thepositiveandnegativewiresare

connectedto.

21

GND

SolenoidValveConnector

Figure7

4.Reassembletheelectricalconnector(P)and

housing(N).Retightenstrainrelief.

5.Placethegasketonthehousingandconnectthe

electricalconnectorintothesolenoidvalve(J)

withthemountingscrew.SeeFig.6.

Prime Prime

Prime

Before Before

Before

Using Using

Using

Equipment Equipment

Equipment

Theequipmentwastestedwithoil,whichisleftinthe

uidpassagestoprotectparts.Primetheequipment

withhotmeltuntilalloftheoilispushedoutbefore

usingtheequipment.SeeFlush,page11.

10 3A2805M

Installation

Flush Flush

Flush

1.Disconnectorturnoffthedevicewhichtriggers

thesolenoidvalve.

2.Heatthesystemtoworkingtemperature.

3.Placewastecontainerundertheguntocatchthe

adhesive.

4.Ensurethenozzleisremoved.

5.Pressthemanualoverrideswitch(S)tomanually

triggerthesolenoidvalve.

6.Dispensehotmelt(adhesive)untilitisclean.

Figure8

Install Install

Install

Nozzle Nozzle

Nozzle

Use1/2in.wrenchtoinstallnozzle.See

KitsandAccessories,page44.

Select Select

Select

RTD RTD

RTD

Note

ForInvisiPacsystemsonly.

IdentifyRTDtypeusedinapplicatoronthesystem

AdvancedDisplayModule(ADM).TheRTDtypeis

listedonthemanifoldcoverplate.SeetheInvisiPac

systemmanualforinstructionstocongurethis

setting.

NOTICE NOTICE

NOTICE

AnincorrectRTDsettingwillcausethesystem

tobeincapableofmaintainingthetemperature

setting.Theapplicatormayoverheatandtripthe

thermalcutoff,iftheapplicatorusesaPT100(385)

andNI120isselectedontheADMSetupscreen.

Theapplicatormayunder-heatiftheapplicator

usesaNI120andPT100(385)isselectedonthe

ADMSetupscreen.

•IfPT100(385)islisted,selectPT100(385)inthe

ADMSetupscreens.

•IfNI120islisted,selectNI120intheADMSetup

screens.

3A2805M

11

Operation

Operation Operation

Operation

Pressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

FollowthePressureReliefProcedure

wheneveryouseethissymbol.

Thisequipmentstayspressurizeduntilpressure

ismanuallyrelieved.Tohelppreventserious

injuryfrompressurizeduid,suchasskininjection,

andsplashinguid,followthePressureRelief

Procedurewhenyoustopsprayingandbefore

cleaning,checking,orservicingtheequipment.

1.Depressurizesystem.

2.Closethebleed-typemasterairvalve.

3.Actuatetheapplicatorrepeatedlyuntilnouid

ows.

Materialinsidethemoduleandhosemaystill

benearsetpointtemperature.Wearprotective

clothingtoavoidsevereburns.

4.Ifyoususpectthemodulenozzleisclogged,

removenozzleandthenactuatethemoduleto

relievepressure.

5.Ifyoususpectthemoduleoruidhoseis

cloggedorthatpressurehasnotbeenfully

relievedafterfollowingthestepsabove,VERY

SLOWLYlooseninlettting,inletlter,orhose

endcouplingtorelievepressuregradually,

thenloosencompletely.Clearhoseormodule

obstruction.

6.Turnoffairpressuretothesolenoidvalve.

12

3A2805M

Maintenance

Maintenance Maintenance

Maintenance

Materialinsidetheapplicatorcanbenearsetpoint

temperature.Wearprotectiveclothingtoavoid

severeburns.

Daily: Daily:

Daily:

Cleanhotmeltfromexteriorofgun.

Weekly: Weekly:

Weekly:

Inspecttheapplicator,uidlines,cordset,

andsolenoidcableforwearordamage.See

Repair,page19forinstructions.

Replace Replace

Replace

Inlet Inlet

Inlet

Filter Filter

Filter

NOTICE NOTICE

NOTICE

Removethelterwhenthegunishot.Ifthegunis

cold,theadhesivewillbehardandtheltermay

bedifculttoremoveordamaged.

1.Disablegunassembly.See

BeforeBeginningRepair,page19.

Materialinsidetheapplicatorcanbenear

setpointtemperature.Wearprotectiveclothing

toavoidsevereburns.

2.Removedirtylter(16)frommanifold(1).

16

1

Figure9InletFilter

3.Applyathincoatingofhigh-temperaturelubricant

tosealsonthenewlter(16)andinstallinthe

manifold(1).Torqueto30in.-lbs(3.4N∙m),

usinga5/32in.(4mm)Allenwrench.

Filter Filter

Filter

Maintenance Maintenance

Maintenance

Guidelines Guidelines

Guidelines

These recommendations are service level guidelines

- actual service levels required in your factory

will vary based on environmental and operating

conditions. High or low volume adhesive usage, as

well as adhesives that contain a powered release

agent or are otherwise dusty, will have an impact

on the frequency of lter maintenance. To establish

a preventative maintenance cycle tailored to your

environment, Graco recommends inspecting lters

every 4 weeks after installation and replacing when

necessary. Document replacement intervals and

use this as your preventative maintenance schedule

moving forward.

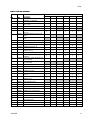

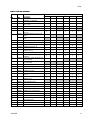

Environment Environment

Environment

Classication Classication

Classication

Clean Clean

Clean

Moderate Moderate

Moderate

Dusty Dusty

Dusty

Gun

manifold

lter

Solenoid

exhaust

lters

Replace

lterevery

six six

six

months

Replace

lter

everyfour four

four

months

Replace

lter

everytwo two

two

months

3A2805M 13

Troubleshooting

Troubleshooting Troubleshooting

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

DebrisinmanifoldlterReplacemanifoldlter.See

ReplaceInletFilter,page13.

CloggedhoseCleanorreplacehose.

Failedsolenoidvalve

Checkforcorrectoperation.Clean

orreplace.

Nosignaltosolenoidvalve

Checksolenoidvalveforcorrect

operation.

Incorrectsolenoidvalvewiring

Checksolenoidvalvewiring.

Incorrectsignaltosolenoidvalve

Checkif24VDCor120VAC.

SolenoidmuferpluggedCheckandreplacemufers.

NouidpressureCheckadhesivedeliverysystem.

Heaterfailure(coldgun)Checkandreplace

heatercartridges.See

ReplaceHeaterCartridge,page20.

Noairtosolenoidvalve

Checkairsupply.

DirtyorfaultytriggeringdeviceCheck,clean,orreplacetriggering

device.

Solenoidvalveconnected

incorrectly

Checksolenoidvalveairconnections.

Noadhesiveorincorrect

amountofadhesiveoutofall

moduleswhentriggered

CloggedmanifoldpassageCleanorreplacemanifold.

Debrisinnozzle

Cleanorreplacenozzle.

Failedmoduleinclosedposition

Checkforcorrectoperation.

Cleanorreplace.See

CheckModule,page16.

DebrisinmodulelterReplacemodule.See

ReplaceModule,page24.

Noadhesiveorincorrect

amountofadhesiveoutof

one/somemoduleswhen

triggered

CloggedmanifoldpassageCleanorreplacemanifold.

Failedmoduleinopenposition

Cleanorreplacemodule.See

ReplaceModule,page24.

Adhesiveoutofone/some

moduleswhennottriggered

Adhesivepressuretoohigh

Checkandreduceuidpressure.

14

3A2805M

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

HeaterfailureCheckandreplace

heatercartridge.See

ReplaceHeaterCartridge,page20.

Loosecordsetconnection

Checkconnection.

RTDfailureCheckandreplaceRTD.See

CheckRTD,page17.

IncorrectRTDforadhesivedelivery

system

CheckdeliverysystemRTD

requirement

ThermalcutofffailureCheckandreplace

thermalcutoff.See

ReplaceThermalCutoff,page20.

Gunwillnotheat

WrongRTDtypeselected

CheckRTDtypesettingsonthe

system.Changeifnecessary.See

SelectRTD,page11.

HeaterfailureCheckandreplace

heatercartridge.See

ReplaceHeaterCartridge,page20.

RTDfailureCheckandreplaceRTD.See

CheckRTD,page17.

IncorrectRTDforadhesivedelivery

system

CheckdeliverysystemRTD

requirement.

Incorrectpowertoheater

Checkandcorrectpower.

Gunoverheats

WrongRTDtypeselected

CheckRTDtypesettingsonthe

system.Changeifnecessary.See

SelectRTD,page11.

HeaterfailureCheckandreplace

heatercartridge.See

ReplaceHeaterCartridge,page20

RTDfailureCheckandreplaceRTD.

IncorrectRTDforadhesivedelivery

system

CheckdeliverysystemRTD

requirement.

Incorrectpowertoheater

Checkandcorrectpower.

Gununder-heats

WrongRTDtypeselected

CheckRTDtypesettingsonthe

system.Changeifnecessary.See

SelectRTD,page11.

Moduleo-ringfailureCheckandreplaceo-ring.See

ReplaceModule,page24.

InletttinglooseTightentting.

Manifoldltero-ringfailureCheckandreplaceo-ring.

NozzlelooseTightennozzle.

Adhesiveleakingfromgun

ModulesealfailureCheckandreplacemodule.See

CheckModule,page16.

3A2805M 15

Troubleshooting

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

SolenoidvalvefailureCheckandreplacesolenoidvalve.

Adhesivepressuretoohigh

Checkandreduceuidpressure.

Solenoidvalveconnected

incorrectly

Checksolenoidvalveairconnections.

Adhesiveoutofallmodules

whennottriggered

ModulefailureCheckandreplaceallmodules.See

CheckModule,page16.

Check Check

Check

Module Module

Module

Checkthemoduleoperationtoverifyifthemodule

hasfailedandneedstobereplaced.

1.InsertasmallAllenwrenchintothetopofthe

module.

2.Pressthesolenoidvalveoverrideswitch(S)to

manuallytriggerthegun.

2

Figure10CheckModule

Ifthewrenchmovesupanddown,thenthemodule

isoperatingproperly

Ifthewrenchdoesnotmove,thenthemoduleneeds

tobereplaced.SeeReplaceModule,page24.

Check Check

Check

Nozzle Nozzle

Nozzle

and and

and

Module Module

Module

Triggerthegunwithoutthenozzletodetermineifthe

nozzleormoduleisclogged.

1.Disablegunassembly.See

BeforeBeginningRepair,page19.

2.Usea1/2in.wrenchtoremovethenozzle.

Figure11

3.Connectthepowerandsolenoidcable.

4.Returnthegunbackintooperation.

5.Triggerthegun.

a.Ifadhesiveows,cleanthenozzleand

reinstallonthemodule.

b.Ifadhesivedoesnotow,themoduleis

cloggedandneedstobereplaced.See

ReplaceModule,page24.

16 3A2805M

Troubleshooting

Check Check

Check

Heater Heater

Heater

Checkthecontinuityoftheheatertoverifyproper

resistance.Ifthereisnocontinuity,theheater

mayhavefailedandneedtobereplaced.See

WiringDiagram,page21,andpartsillustrations.

1.Disablegunassembly.See

BeforeBeginningRepair,page19.

2.Checkresistanceoftheheaterusingamultimeter

betweenthepinsofthecordsetconnector.See

connectorsillustrationsincordsetpintables.

•Ifthereisnocontinuitymeasureresistanceof

theheateratthebuttspliceterminals(52b).

•Iftheresistanceisoutsidetherangelisted

belowreplacetheheatercartridge.See

ReplaceHeaterCartridge,page20.

Cordset Cordset

Cordset

Check Check

Check

Pins Pins

Pins

Gun Gun

Gun

Model Model

Model

Resis- Resis-

Resis-

tance tance

tance

Values Values

Values

24U021–24U0

26

24U027–24U-

032

260–280

ohms

24W087,

Pt100

(385)RTD

Cordset

AandC

Allother

models

130–140

ohms

24U021–24U0

26

24U027–24U-

032

260–280

ohms

24W088,

Ni120

RTD

Cordset

1and2

Allother

models

130–140

ohms

Table Table

Table

1 1

1

24W087, 24W087,

24W087,

Pt Pt

Pt

100 100

100

(385) (385)

(385)

RTD RTD

RTD

Cordset Cordset

Cordset

Pin Pin

Pin

Description Description

Description

A

ThermalCutoff

B

Ground

C

Heat-

D

RTD(White)

E

RTD(Red)

Table Table

Table

2 2

2

24W088, 24W088,

24W088,

Ni Ni

Ni

120 120

120

RTD RTD

RTD

Cordset Cordset

Cordset

Pin Pin

Pin

Description Description

Description

1

ThermalCutoff

2Heat-

3

RTD(White)

5

RTD(Red)

GGround

Check Check

Check

RTD RTD

RTD

CheckthecontinuityoftheRTDtoverifyproper

resistance.Ifthereisnocontinuity,theRTDhas

failedandneedstobereplaced.

1.Disablegunassembly.See

BeforeBeginningRepair,page19.

2.CheckresistanceoftheRTDusingamultimeter

betweenthepinsofthecordsetconnector.See

connectorsillustrationsincordsetpintables.

Cordset Cordset

Cordset

Check Check

Check

Pins Pins

Pins

Resistance Resistance

Resistance

Values Values

Values

At At

At

Room Room

Room

Temperature Temperature

Temperature

70–72 70–72

70–72

° °

°

F F

F

(21–22 (21–22

(21–22

° °

°

C) C)

C)

24W087,Pt

100(385)

RTDCordset

DandE107-115

ohms

24W088,Ni

120RTD

Cordset

3and5130-140

ohms

3.ReplacetheRTDiftheresistancereadingis

outsidetherange,orifthereisnocontinuity.See

ReplaceRTD,page20.

3A2805M

17

Troubleshooting

Check Check

Check

Thermal Thermal

Thermal

Cutoff Cutoff

Cutoff

Ifworkingproperly,thecutoffwilltripat450°F

(232°C)andresetsat370°F(187°C).Iffailureis

suspected,allowguntocoolandthencheckthe

continuityofthethermalcutofftoverifyithasnot

failed.Ifthereisnocontinuity,thecutoffhasfailed

andneedstobereplaced.

1.Disablegunassembly.See

BeforeBeginningRepair,page19.

2.Removecoverplate.

3.Checkforcontinuityusingamultimeterbetween

pinofcordsetconnectorandthewiresfromthe

thermalcutoffthatconnectstotheheaterlead.

Cordset Cordset

Cordset

Check Check

Check

Pins Pins

Pins

24W087,Pt100(385)

RTDCordset

A

24W088,Ni120RTD

Cordset

1

Thermal Thermal

Thermal

Cutoff Cutoff

Cutoff

W

WLL DD

18 3A2805M

Repair

Repair Repair

Repair

Required Required

Required

Tools Tools

Tools

•Phillipsscrewdriver

•Flatbladescrewdriver

•5/64in(2mm)and5/32in.(4mm)Allenwrenches

•1/2in.and7/16in.wrenches

•Torquewrench

•Wastecontainer

•High-temperatureanaerobicthreadsealant(110110)

•High-temperaturelubricant(24T156)

•Anti-sieze(24T179)

•Crimptool(24W086)

Before Before

Before

Beginning Beginning

Beginning

Repair Repair

Repair

1.Turnoffthemeltersystem.Seemeltermanual

forshutdowninstructions.

2.Relievepressure.See

PressureReliefProcedure,page12.

3.Disconnectthecordsetfromtheheatedhose.

Figure12DisconnectCordset

4.Loosenthemountingscrewanddisconnectthe

solenoidvalvepowerconnector(N)fromthe

solenoidvalve(J).

J

N

Figure13DisconnectSolenoidValvePower

Connector

3A2805M 19

Repair

Replace Replace

Replace

Heater Heater

Heater

Cartridge Cartridge

Cartridge

1.Disablegunassembly.

2.UseaPhillipsscrewdrivertoremovescrews(15)

andmanifoldcoverplate(52).

3.Removetheheatercartridges(3)fromthe

manifold(1).

Note

Notetheplacementoftheheatersand

leadlengths.

Note

On guns that are not low prole,

ifthe

heatercartridgedoesnoteasilypullout,

removetheothercoverplate(18)and

pressoutwithasmallscrewdriver.

4.Removebuttsplices(52b)fromheaterwires(3),

thermalcutoff(52a),andcordsetwireleads(17).

5.Recrimpnewheaterwiresintonewsplices(52b).

Seewiringdiagram.

NOTICE NOTICE

NOTICE

Topreventashorttogroundandblowinga

MZLPfuse,ensurebarewiresarecovered

withberglasstapeandsleeves(52c)are

centeredoversplices(52b).

6.Insertthenewheatercartridges(3)intothe

manifold(1),placingtheheaterwiththeshorter

leadsclosertothewiringport.

Note

Donotapplythermalgreasetothe

heatercartridge.

7.Reinstallthemanifoldcoverplate(52).

8.Reconnectthecordset(17)totheheatedhose.

9.Reconnectthesolenoidvalvepowerconnector

tothesolenoidvalve(9).

Replace Replace

Replace

RTD RTD

RTD

TheRTDisreplacedbyreplacingtheentirecordset.

SeeReplaceCordset,page22,forinstructions.

Replace Replace

Replace

Thermal Thermal

Thermal

Cutoff Cutoff

Cutoff

1.Disablegunassembly.

2.UseaPhillipsscrewsdrivertoremovethefour

screws(15)andmanifoldcoverplate(52).

3.Removesplicesfromheaterwires(3)and

cordsetwireleads(17).

4.Crimpwires.SeeWiringDiagram,page21.

NOTICE NOTICE

NOTICE

Topreventashorttogroundandblowinga

MZLPfuse,ensurebarewiresarecovered

withberglasstapeandsleeves(52c)are

centeredoversplices(52b).

a.Slidesleeves(52c)overeachpairofwires

beforecrimping.

b.Crimpbuttsplice(52b)oncordsetheater

wires(17)andheaterwires(3).Lightpullon

splicetoensureitiscrimped.

c.Crimpwhitewiretoonethermalcutofflead

(52a).

d.Crimpotherthermalcutofflead(52a)toone

heaterwire(s)(3).

e.Crimpotherheaterwire(s)toblacklead(17).

f.Wrapashortpieceofberglasstapearound

eachsplice(52b).

g.Centersleeves(52c)overeachtapedsplice

(52b).

5.Gentlypresswiresintothemanifold.Installplate

(52)andscrews(15).

W

WLL EE

00 00

DD

EE

FF

20 3A2805M

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

-

17

17

-

18

18

-

19

19

-

20

20

-

21

21

-

22

22

-

23

23

-

24

24

-

25

25

-

26

26

-

27

27

-

28

28

-

29

29

-

30

30

-

31

31

-

32

32

-

33

33

-

34

34

-

35

35

-

36

36

-

37

37

-

38

38

-

39

39

-

40

40

-

41

41

-

42

42

-

43

43

-

44

44

-

45

45

-

46

46

-

47

47

-

48

48

-

49

49

-

50

50

-

51

51

-

52

52

Graco InvisiPac GS35 Plug-Free User manual

- Type

- User manual

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Graco 3A2805K User manual

-

Graco 334627R, InvisiPac GM100 Plug-Free Hot Melt Applicator Operating instructions

-

Graco 334627EN-S Operating instructions

-

Graco Glue Gun GM100 User manual

-

Graco 333347F User manual

-

Graco 3A4938EN-M Operating instructions

-

Graco 3A7259C, InvisiPac HM10 Hot Melt Delivery System Operating instructions

-

Graco 3A2824B User manual

-

Graco 309968D - 950 Series Sealant Gun User manual

-

Graco Therm-O-Flow 200 Bulk Hot Melt System 334130T User manual

Other documents

-

T'nB NEEC010 Datasheet

T'nB NEEC010 Datasheet

-

Nordson AltaBlue Customer Product Manual

-

3M Hot Melt Applicator Accessories Operating instructions

-

T'nB NEEC005 Datasheet

T'nB NEEC005 Datasheet

-

ESAB Powder Attachment Troubleshooting instruction

-

Idealtech TR 70 LCD Operating Instructions Manual

Idealtech TR 70 LCD Operating Instructions Manual

-

VALCO MELTON EC14 User manual

VALCO MELTON EC14 User manual

-

Frymaster 8196345 User manual

Frymaster 8196345 User manual

-

Aim MXm User guide

-

3M Hot Melt Applicator Accessories Operating instructions