Page is loading ...

©1997-2016 Aerovent

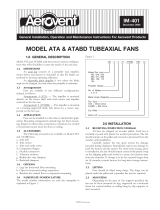

Typical Panel Fan Installations

MOUNTING BLOCKS

OR PLATES

STD. MOUNT

WWII

GUARD

STD. FLG.

SHUTTER

AIRFLOW

ANGLE IRON

FRAME

ALLOW SPACE FOR

DAMPER MOTOR

BIRD

SCREEN

WEATHER HOOD

FAN & SHUTTER

FLUSH-MOUNTED

MOUNTED IN WALL

SHUTTER FLUSH ON OUTSIDE

ANGLE

IRON

FRAME

AIRFLOW

AIRFLOW

FLAT

GUARD

PMS

GUARD

REV. FLG.

SHUTTER

WEATHER HOOD

BIRD

SCREEN

OR

OR

OR

REVERSE FLOW

PANEL

STANDARD FLOW

PANELS

REVERSE MOUNT

PANEL

WWII

GUARD

INSIDE MOUNT OUTSIDE MOUNT

SHUTTER

MTR. OPERATED

CTR. PIVOT ONLY

BIRD

SCREEN

WEATHER HOOD

PMS GUARD

REVERSIBLE PANELS

EXHAUST INSTALLATIONS

INSTALLATION REQUIRES SHUTTER SIZE TO BE SAME AS PANEL SQUARE.

General Installation, Operation and Maintenance Instructions For Aerovent Products

IM-110

June 1997

Panel and Ring Fans

Throughout this manual, there are a number of HAZARD WARNINGS that must be read and adhered to in

order to prevent possible personal injury and/or damage to equipment. The signal word "CAUTION" is used to

indicate the severity of a hazard and is preceded by the safety alert symbol.

CAUTION

Used when minor or moderate injury or product / equipment damage MAY result from misuse or failure to

follow specific instructions.

It is the responsibility of all personnel involved in installation, operation and maintenance to fully understand

the Caution procedures by which hazards are to be avoided.

2 Aerovent Installation and Maintenance Manual IM-110

INSTALLATIONS USING MOUNTING ADAPTORS

AIRFLOW AIRFLOW

AUTOMATIC

SHUTTER

AUTOMATIC

SHUTTER

STANDARD MOUNT

ALTERNATE MOUNT

(REVERSIBLE)

AIRFLOW

(REVERSE FLOW)

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

AIRFLOW

CENTER-PIVOT

MOTOR-OPERATED

SHUTTERS

RECOMMENDED MOUNT RECOMMENDED MOUNT

(REVERSE CONSTRUCTION)

NOTE: ALL INSTALLATIONS SHOWN

USE SAME SIZE SHUTTERS &

HOODS AS FAN SIZE.

CENTER-PIVOTED

MOTOR-OPERATED

SHUTTER

CENTER-PIVOTED

MOTOR-OPERATED

SHUTTER

FLAT

GUARD

AUTOMATIC

SHUTTER

OUTSIDEOUTSIDE

SUPPLY

ARRANGEMENT

EXHAUST

ARRANGEMENT

AUTOMATIC

SHUTTER

EXHAUST W/MTG. ADAPTOR

SUPPLY W/WALL HOUSING

STANDARD CONSTRUCTION

ALTERNATE SOLUTIONS

Aerovent Installation and Maintenance Manual IM-110 3

Typical Ring Fan Installations

STANDARD FLOW

AIR-

FLOW

ALTERNATE

WMF GUARD

REPLACES

SPLIT WIRE

GUARD

MOUNTS

TO WALL

STD. FLOW RING FAN

W/MTG. PLATE, ROUND

PROP SIDE GUARD &

SPLIT WIRE GUARD

WALL

STD.

SHUTTER

AIR-

FLOW

WALL

ALTERNATE

WMF GUARD

REPLACES

SPLIT WIRE

GUARD

MOUNTS

TO WALL

STD. FLOW RING FAN

W/MTG. PLATE, ROUND

PROP SIDE GUARD &

SPLIT WIRE GUARD

STD.

SHUTTER

WEATHERHOOD

W/BIRD SCREEN

REVERSE CONSTRUCTION

REVERSE FLOW OR REVERSIBLE

AIR-

FLOW

ALTERNATE

WMF GUARD

REPLACES

SPLIT WIRE

GUARD

MOUNTS

TO WALL

REV. CONSTRUCTION

RING FAN W/MTG.

PLATE, ROUND

GUARD & SPLIT

WIRE GUARD

REVERSE

FLANGE

MOUNTING

ADAPTORWALL

REV. FLANGE

CENTER-PIVOTED

MOTOR-OPERATED

SHUTTER

AIR-

FLOW

ALTERNATE

WMF GUARD

REPLACES

SPLIT WIRE

GUARD

MOUNTS

TO WALL

REVERSE FLOW

OR REVERSIBLE

RING FAN W/MTG.

PLATE, ROUND

GUARD & SPLIT

WIRE GUARD

WALL

CENTER-

PIVOT

MOTOR-

OPERATED

SHUTTER

WEATHERHOOD

W/ BIRD SCREEN

AIRFLOW

FAN MOUNTED

FLUSH TO WALL

FAN MOUNTED

TO DUCTWORK

Rear Wire Guard (WWII)(Motorside)

For Panel Fans

PARTS

(1) Rear Panel

(4) Side Panels

(16) or (24) Hex Head Locknuts

(16) or (24)

5

∕16" x 1" Hex Head Capscrews

(32) or (48)

3

∕8" I.D. Flat Washers

ASSEMBLY

1. Bolt three sides of guard to rear panel using

5

∕16" capscrews, nuts and flat washers.

2. Bolt partially assembled guard to panel fan

using capscrews, nuts and flat washers.

3. Arrange for electrical hook-up to fan motor. Two

methods may be used:

a. Drill out hole in fan panel and route wire or

conduit through opening.

Round Motorside Basket Guard

– OR –

b. Bend or cut side panel wire guard and route

wire or conduit through opening.

4. Assemble fourth side to guard and panel, sliding

along conduit or wiring if routing through guard.

5. Securely tighten all locknuts.

Cleaning Propellers

The propeller in an axial flow fan must be kept

reasonably clean if it is to perform properly. Fans

handling fresh air for ventilating purposes will

seldom need cleaning. Fans exhausting process air

should be cleaned as required. Dirt or chemical

deposits will usually build up on a propeller evenly

and they present no problem to performance or

operation until they become thick enough to break

away in crust-like pieces. When this happens, the

propeller may be thrown out of balance and the

resulting vibration could be serious. Accumulations

of deposits should be removed by solvent cleaning

or scraping. If the propeller has been coated, be

careful not to cut through the protective covering.

Care and Maintenance

Regular and systematic inspection of all fan

parts is a necessity for good fan maintenance.

A general installation and maintenance

brochure (IM-100) has been supplied with this

shipment. It includes fan and motor bearing

lubrication, care and replacement of V-belt

drives and taperlock bushing instructions.

2MWG04/16

Attach

Guard

To Wall

4 Mounting

Holes

Ring Fan

Basket Guard

WWW.AEROVENT.COM

5959 Trenton Lane N | Minneapolis, MN 55442 | Phone: 763-551-7500 | Fax: 763-551-7501

®

Recommended distance between fan blade and shutter is approximately equal to

1

⁄3

of the fan’s diameter.

CAUTION

/